Serai MC/5C User manual

DAL 1965

Pag. 1/6

MC/5C I E

MC/5C UNDERGROUND MOTOR 230 Vac FOR WING GATES UP TO 3,00m AND 300 Kg EACH

WING + FOUNDATION BOX IN HOT-GALVANISED STEEL

- 03.5C

!

Thank you for choosing a SERAI ELETTRONICA product, which we are confident will perform to your requirements.

Please be advised that you are about to fit a system classified as “a power-operated drive designed to move automatic ga-

tes and doors in commercial or residential buildings accessed by vehicles and persons”, and as such, the system must be

considered potentially hazardous. By law, you are responsible for rendering this equipment as “safe” as is reasonably pos-

sible.

Installation and maintenance of equipment of this kind must therefore be carried out by skilled, qualified and trained

personnel, working in a professional manner, as provided for by law n. 37/08 and any subsequent amendments and

supplements. The law in question prohibits the construction of these types of systems by non-qualified personnel.

SERAI manufacturing complies with the following legislation:

Applicable directives for the CE marking :

Machines: 2006/42/EEC

Low Voltage: 2006/95/EEC

Electromagnetic Compatibility: 2004/108/EEC

General applicable standards:

Electrical Safety: IEC EN60335-1 + IEC EN60335-2-103

Electromagnetic Compatibility - Emissions: CEI EN61000-6-3

Electromagnetic Compatibility - Immunity: CEI EN61000-6-

Apart from the legislation mentioned above, you are also reminded to comply with the following standards during the

installation phase.

General applicable standards:

Safety of electrical systems in non-specialised environments: CEI 64-8 V2

Specific product standards applicable:

Safety in the use of power-operated doors - requirements: UNI EN12453

Safety in the use of power-operated doors - testing methods: UNI EN12445

SERAI products enable users to build systems which comply with these standards. This is extremely important as THE

INSTALLER IS LIABLE FOR THE SYSTEM AND FOR ENSURING ITS OPERATION COMPLIES WITH LEGAL

PROVISIONS.

This handbook must be read in full before proceeding with the installation of the various parts of thesystem.

The installation of the mechanical end stops for gate opening and closure is necessary for system safety purposes

and therefore this operation must be performed before proceeding with the installation of the control unit.

ATTENTION: The IP66 protection degree -protection against powerful water jets- is guaranteed with rainfall

and perfectly functioning drain. On installations at the side of asphalt roads, where the waters are acid due

to the washing away, the external parts of the motor can be corroded and, in time, generate water

infiltrations. For this reason perfectly functioning drains are very important so that the water -especially if

acid- remains the least possible time in contact with the motor.

E R A IS

GATE AUTOMATION DIVISION

INSTALLATION MANUAL

DAL 1965

Pag. 2/6

MOTOR AND FOUNDATION BOX PARTS

230V~

3x1,5 mm²

4 x 0,5 mm²

2 x 0,5 mm²

4 x 0,5 mm²

4 x 1,5 mm²

2 x 0,5 mm²

3 x 0,5 mm²

RG58 + 2 X 0,75 mm²

2

4

55

6

31

4 x 1,5 mm²

1

SEALING RING

THREADY PINS TO HOUSE THE MOTOR

GUIDE SHOE

GEARED MOTOR

CAPACITOR

FOUNDATION BOX !

STIRRUP WITH UNCLAMPING

COVER

MC/5C I E

IMPORTANT:

GREASE THE PIVOT

BEFORE FITTING THE

LEVER GROUP

4 M/10 electric key

5 Pair of P/10 photocells

6 RZ/20 F Flashing light with antenna

1 Geared motor + f MC/5C

2 CR/41 electronic control unit with built-in receiver

3 OG/62 2-channel minitransmitter

oundation box

STANDARD INSTALLATION

Advice for wiring up in non-specialised environments.

1. Fit an omnipolar switch upstream of the system, choosing one with a gap of at least 3mm between the contacts. Or,

alternatively, use a 10Athermal magnetic circuit breaker.

2. Always make connections, of any type, with the system disconnected from the power supply, i.e. with the main switch

set to OFF (symbol “0”). The control unit, in particular, must never be connected to the power supply either during the

wiring up, or when fitting any expansion boards.

3. The following cables must be used for installation of the system:

22

- for the control unit, motor and electric lock power supplies: 1.5mm section for lengths of up to 19m, 2.5mm section

for lengths of up to 31m,

22

- for the flashing light: 0.75mm section for lengths of up to 3m, 1.5mm section for lengths of up to 19m,

- for the low voltage and current lines, (e.g. for the photocells, control buttons, electromechanical key, sensitive

22

edges and other safety devices: 0.5mm section for lengths of up to 50m, 0.75mm section for lengths of up to 100m.

4. Wire up the earth connection in compliance with legal provisions.

DAL 1965

Pag. 3/6

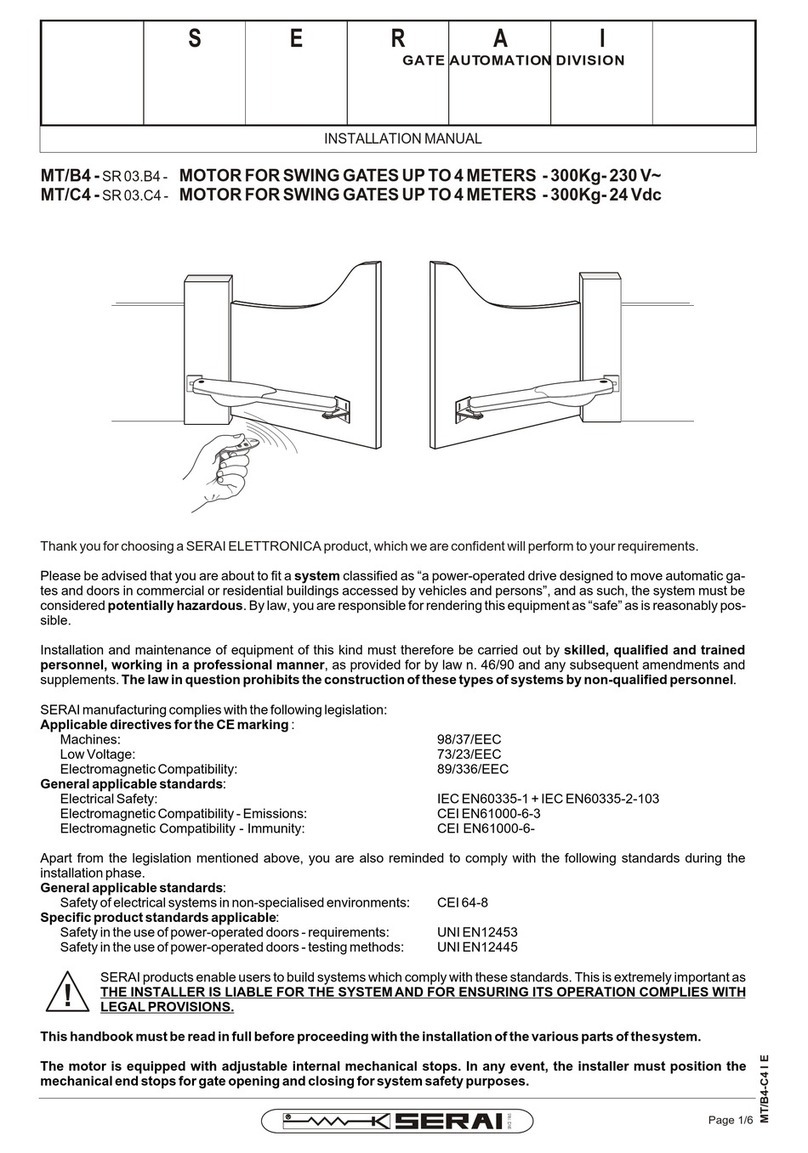

1- Check that the height between the gate and the ground is greater by 65 mm.

2- Choose the position and opening angle of the motor.

3- Get stop blocks and place them right where you want mouvement is to be stopped.

INSTALLING THE MOTORS

PILLAR

INSTALLATION AREA WITHOUT SHEARING HAZARD: up to 90° opening angle

INSTALLATION AREA WITH SHEARING HAZARD up to: 90° opening angle

MAX 90° MAX 90°

60mm

60mm

If the position of the gate towards

the pillar allows it, it is possible to

have also an opening up to 180°,

but in this case it is to consider

that:

- in the points O-A-C there is no

shearing hazard

- in the point B there is shearing

hazard

PILLAR

180mm

60mm

220mm

160mm

E

G F

D

In the indicated area Fig. 2 it is possible the correct functioning with shearing hazard up to 90° opening angle

In this case, being the shearing hazard, all needed caution/protection (covers, rubber profiles,

warning signals, etc) must be taken

.

If the position of the gate towards

the pillar allows it, it is possible to

have also an opening over 90°,

but with following limits:

- in the points D-E-F max 100°

with shearing hazard

- in the point G max 150° with

shearing hazard

MC/5C I E

O

B

A

C

!

!

Starting from the centre of the hinge, it is possible the correct functioning without shearing hazard -90° opening

angle- in a area measuring 60 x 60 mm, see Fig 1

In this case, being the

shearing hazard, all

needed caution/protection

(covers, rubber profiles,

warning signals, etc) must

be taken

Fig. 1

Fig. 2

WORKING AREA WITHOUT SHEARING

HAZARD UP TO 90° OPENING ANGLE FIG. 3

PILLAR PILLAR

PILLAR

WORKING AREA WITH

SHEARING HAZARD

PILLAR

PILLARPILLAR

DAL 1965

Pag. 4/6

195

!

4- Take the motor out of the metal botton box.

ATTENTION

The motor is fixed on the foundation box by means

of two normal nuts, due to problems of transport.

To install the motor in the system, these two nuts

have to be removed and trown away, replaced with

four self-locking nuts as standard.

!

MC/5C I E

5- Arrange the founding box at ground level and check the horizontal level.

6- Pre-arrang the piping for the electrical connections.

7- Pre-arrange piping for the draining of the rainfall.

8- Cement definitively with concrete.

The connection between the power supply cable of the motor and the cable of the control panel

has to be carried out outside the foundation box and inside a weather proof housing. On the

contrary a water infiltration may be occur through the power supply cable causing the motor

failure.

!

> 65mm

GATE HING

WATER DRAIN PIPE WITH

SUITABLE SLOPE

VERY IMPORTANT

WELL WITH ABUNDANT DRAINAGE FOR

THE WATER DRAIN

WATER-PROOF CONTAINER WHERE TO

CARRY OUT ELECTRIC CONNECTIONS

DRAIN PIPE

GUIDE SHOE

STIRRUP WITH UNCLAMPING

DAL 1965

Pag. 5/6

9- Put the motor in the metal box again and insert the connecting rod between the motor and the pivoting bracket.

ATTENTION:

Periodically check the fixing of the 4 self locking nuts.

!

!

10- The position of the slide depends on the position of the motor and the opening angle of the gate. Therefore

temporarily place the guide slide on the gate and make a complete manual manoeuvre of opening and closing,

verifying that the bearing of the arm glides inside the guide slide without ever hitting the ends

11- After this check, permanently fix the guide slide.

MC/5C I E

Before permanently fixing the guide

slide, verify with a manual

manoeuvre that the bearing does

not hit the ends

!

IMPORTANT:

GREASE THE PIVOT

BEFORE FITTING THE

LEVER GROUP

EMERGENCY MANOEUVRE IN CASE OF BLACK OUT

Capacitor:

MC/5C I E 02 06 110628 -A4Vf/r -IS MC5C-E

Power supply

Max absorption

Power

Max torque

Opening time for 90°

Max leaf length

Max leaf weight

Max opening angle

Motor force adjusted:

Motor thermal protection

Protection rating

Operating temperature

Foundation box

Weight -motor + foundation box-

230 V~ ±10% 50/60 Hz

1,9 A

150 W

540 Nm

23 s

3,0 m

300 Kg

180°

via power control supply

voltage

150 °C

IP66

-20° ÷ +60°C

hot-galvanised

27,5 Kg

TECHNICAL SPECIFICATIONS

14 µF 450V

MC/5C

57mm

140mm

30mm

59mm

263mm

404mm

98mm

300mm 30mm

Ø36mm

60mm

!

YELLOW GREEN = EARTH

SKY BLUE = COMMON

BLACK =

BROWN =

OPEN/CLOSE

OPEN/CLOSE

ELECTRIC CONNECTIONS OF MOTOR

MOTOR FORCE ADJUSTMENT

The SERAI CR/41 control unit allows:

A- adjustment of the motors strength by acting on the "Power" potentiometer in the control unit

B- programming of the slowing which prolongs the life of the motor avoiding the gate banging against the

mechanical stops

If slowing has been inserted, the motor has less strength and therefore the gate, if not well-done,

may stop before having completed the manoeuvre.

By excluding the slowing the gate bangs against the mechanical stops causing a, more or less,

loud noise, according to installation. Also, the internal gears are subject to greater stresses.

POTENTIOMETER "POWER"

F1F1

F2F2

ON

SW1 SW2

345 6 78

SOG/4

POWER

+

-

ON

PED START STOP FOTO FOTO AP FINE CH FINE AP

DL9

DL8

DL10

1 2 910 11 121314 1516171819 20 21 22

272526

2324

SET BREAK WORK

A B C

Com

+24

spia

RX

2829

The considerable differences in

temperature between summer

and winter can cause differing

rates of expansion in all

materials, including those used

in the building of our motors.

That is why we recommend you

check the impact force setting at

the start of winter and summer.

ELETTRONICA PADOVA

I

SINCE 1965

MADE IN ITALY

VIA ENRICO FERMI, 22

35020 LEGNARO - PADOVA

I T A L I A

PHONE +39 049 79 08 58

FAX +39 049 88 30 529

E-MAIL [email protected]

WEB www.serai.com

TERMS OF GUARANTEE

The company reserves the right to make modifications to the equipment without prior notice thereof. SERAI products are covered by a standard guarantee with a term of 24 months.

Coverage starts on the date on which the tax document constituting proof of purchase is issued and guarantee services shall be provided on the company's premises at Legnaro - PD -

or at the Authorised Service Centres. Carriage costs shall be borne by the Customer.

CE CONFORMITY DECLARATION

SERAI spa declares that the product MC/5C has been desifned and manufactured according to the above mentioned directives and standards

WEEE DIRECTIVE 2002/96/EC

This appliance was manufactured after 13/08/2005. To protect the environment: when the equipment is no longer needed, take it to a special WEEE (Waste Electric and

Electronic Equipment) collection centre. Do not dispose of it with normal household waste.

Table of contents

Other Serai Garage Door Opener manuals

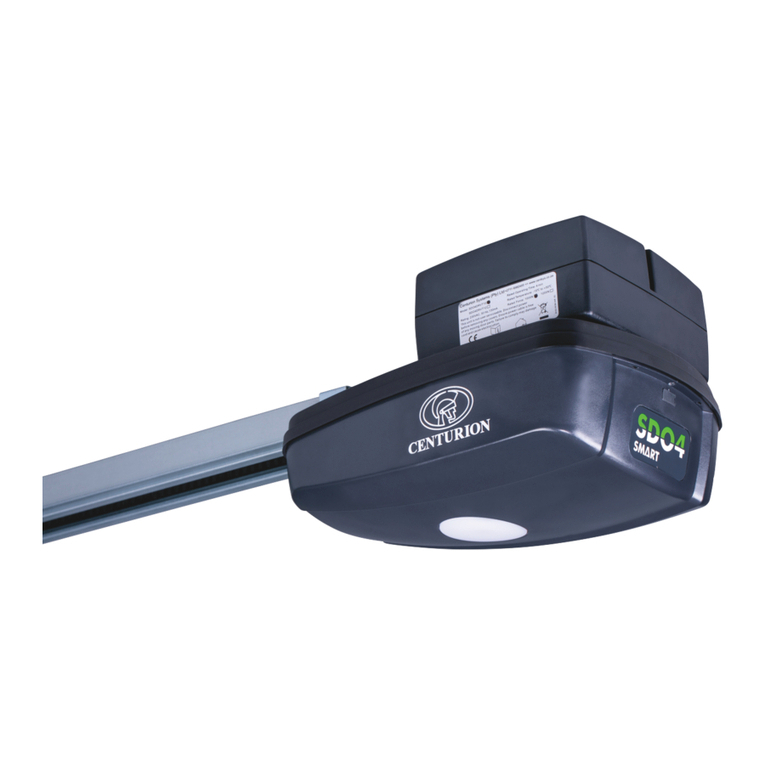

Popular Garage Door Opener manuals by other brands

BYOU

BYOU JUMP Instructions and Recommendations for installation and use

Chamberlain

Chamberlain Series 5000 1/2HP owner's manual

Merlin

Merlin Commander Extreme MS125MYQ Installation and operating instructions

Craftsman

Craftsman 139.3043 owner's manual

Chamberlain

Chamberlain 1265 owner's manual

CSI CLASSIC

CSI CLASSIC PRO Series manual