Serai MT/C4 User manual

This manual suits for next models

2

Other Serai Garage Door Opener manuals

Popular Garage Door Opener manuals by other brands

Wayne-Dalton

Wayne-Dalton 9800 Installation instructions and owner's manual

Genie

Genie GCL-GH installation manual

Chamberlain

Chamberlain B500 owner's manual

Alutech

Alutech Levigato LG Series Assembly and operation manual

Overhead door

Overhead door PowewrMax XL 4060 Operation and maintenance manual

V2

V2 Calypso400 Operating and installation instructions

Craftsman

Craftsman 139.53403 owner's manual

Aprimatic

Aprimatic XT2500/XL INSTRUCTIONS AND RECOMMENDATIONS FOR THE INSTALLER

Chamberlain

Chamberlain Smart Garage MYQ-G0401 quick start guide

CAB

CAB DUMPER Installation and user manual

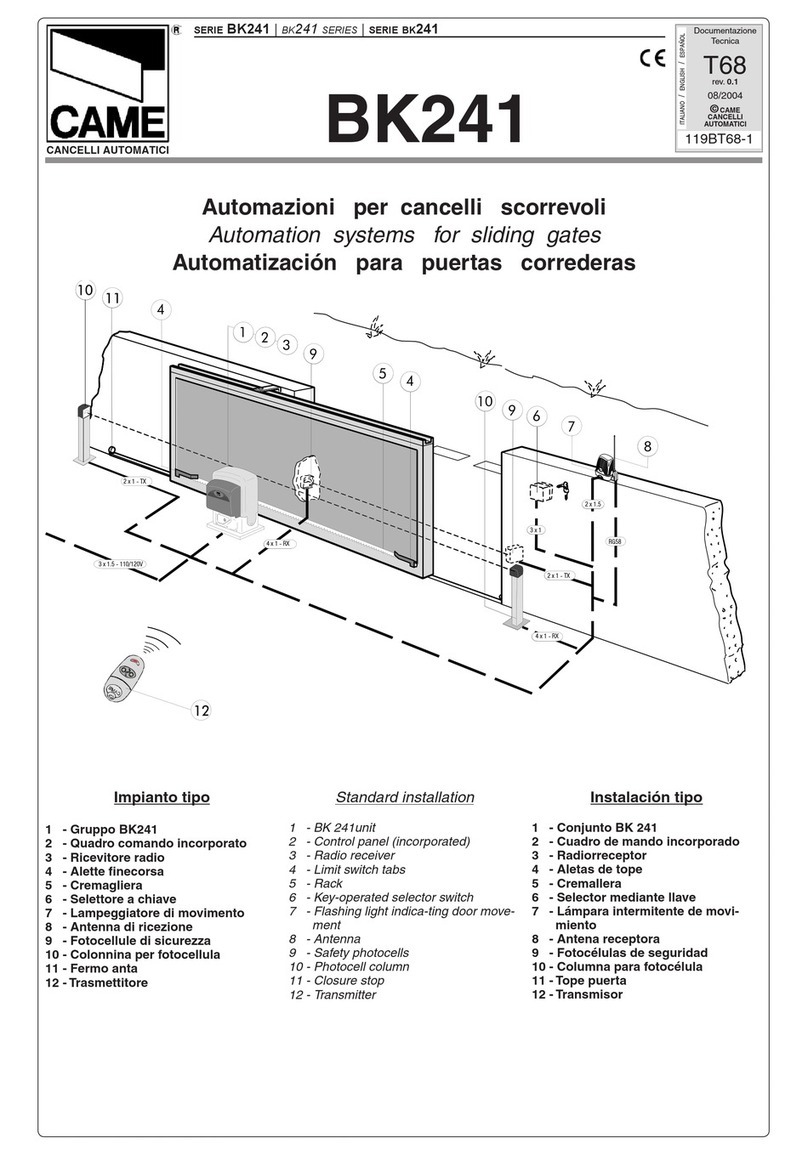

CAME

CAME BK241 installation instructions

Erreka

Erreka CAT Quick installation and programming guide

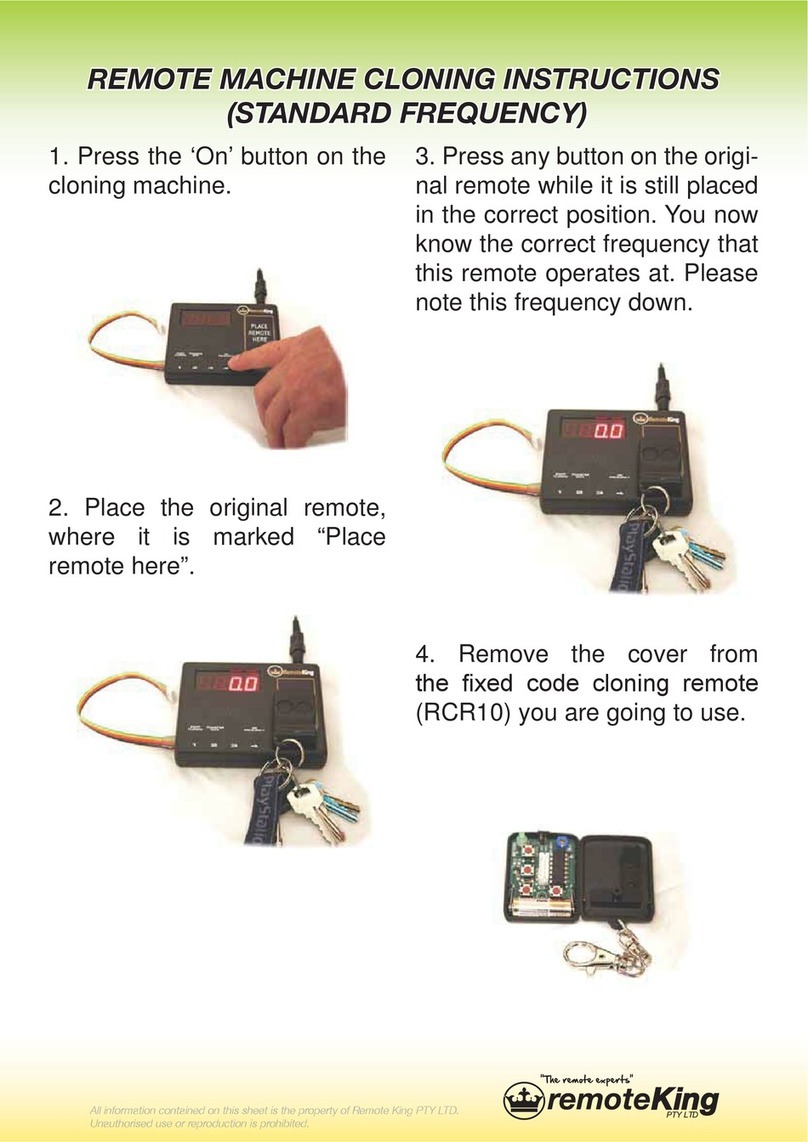

Remote King

Remote King RCR10 instructions

SkyLink

SkyLink G6K user manual

Chamberlain

Chamberlain Security+ 3240 owner's manual

Chamberlain

Chamberlain Power Drive Security+ 182649D owner's manual

Chamberlain

Chamberlain Power Drive Security+ PD210C owner's manual

4Ddoors

4Ddoors 4DS2 v1 Installation instructions and user guide