Serai MT/B6 User manual

E R A IS

GATE AUTOMATION DIVISION

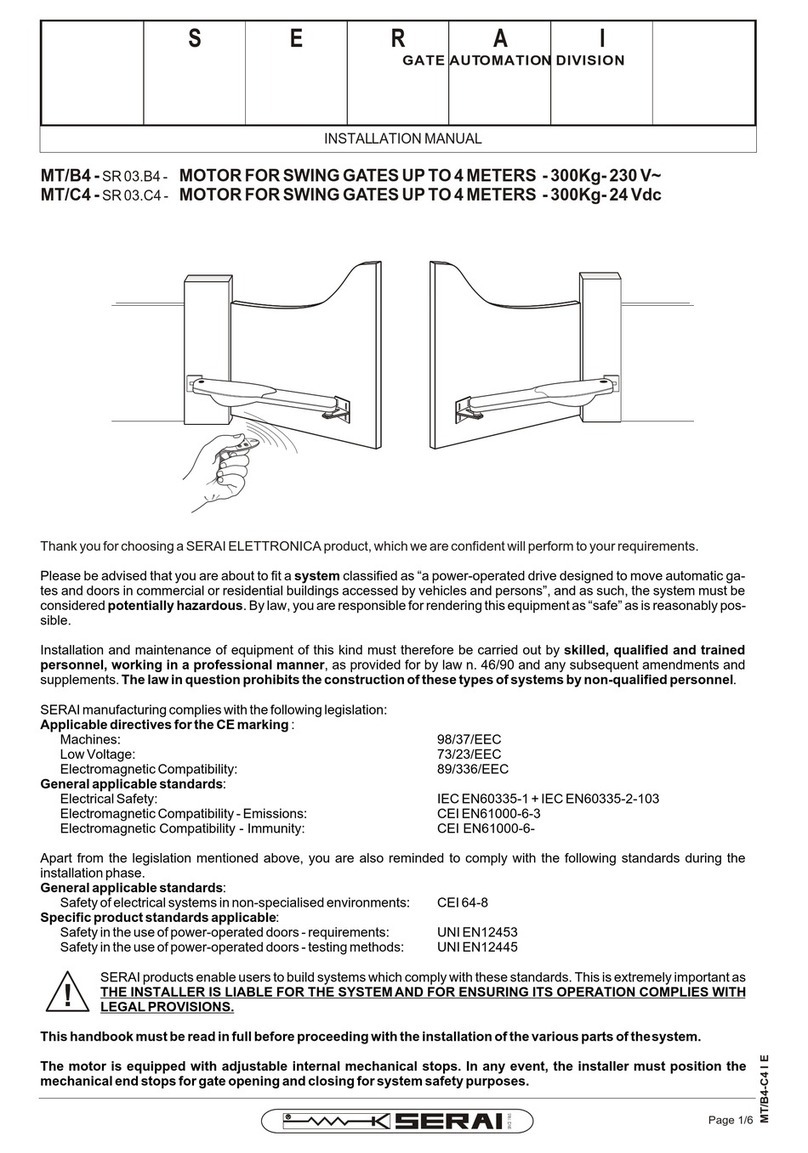

MT/B6 - SR 03.B6 - MOTOR FOR SWING GATES UP TO 6 METERS - 400Kg- 230 Vac

MT/C6 - SR 03.C6 - MOTOR FOR SWING GATES UP TO 6 METERS - 400Kg- 24 Vdc

Page 1/6

INSTALLATION MANUAL

MT/B6-C6 I E

!

Thank you for choosing a SERAI ELETTRONICA product, which we are confident will perform to your requirements.

Please be advised that you are about to fit a system classified as “a power-operated drive designed to move automatic ga-

tes and doors in commercial or residential buildings accessed by vehicles and persons”, and as such, the system must be

considered potentially hazardous. By law, you are responsible for rendering this equipment as “safe” as is reasonably pos-

sible.

Installation and maintenance of equipment of this kind must therefore be carried out by skilled, qualified and trained

personnel, working in a professional manner, as provided for by law n. 46/90 and any subsequent amendments and

supplements. The law in question prohibits the construction of these types of systems by non-qualified personnel.

SERAI manufacturing complies with the following legislation:

Applicable directives for the CE marking :

Machines: 98/37/EEC

Low Voltage: 73/23/EEC

Electromagnetic Compatibility: 89/336/EEC

General applicable standards:

Electrical Safety: IEC EN60335-1 + IEC EN60335-2-103

Electromagnetic Compatibility - Emissions: CEI EN61000-6-3

Electromagnetic Compatibility - Immunity: CEI EN61000-6-

Apart from the legislation mentioned above, you are also reminded to comply with the following standards during the

installation phase.

General applicable standards:

Safety of electrical systems in non-specialised environments: CEI 64-8

Specific product standards applicable:

Safety in the use of power-operated doors - requirements: UNI EN12453

Safety in the use of power-operated doors - testing methods: UNI EN12445

SERAI products enable users to build systems which comply with these standards. This is extremely important as

THE INSTALLER IS LIABLE FOR THE SYSTEM AND FOR ENSURING ITS OPERATION COMPLIES WITH

LEGAL PROVISIONS.

This handbook must be read in full before proceeding with the installation of the various parts of thesystem.

The motor is equipped with adjustable internal mechanical stops. In any event, the installer must position the

mechanical end stops for gate opening and closing for system safety purposes.

SINCE 1965

MT/B6-C6 I E

Page 2/6

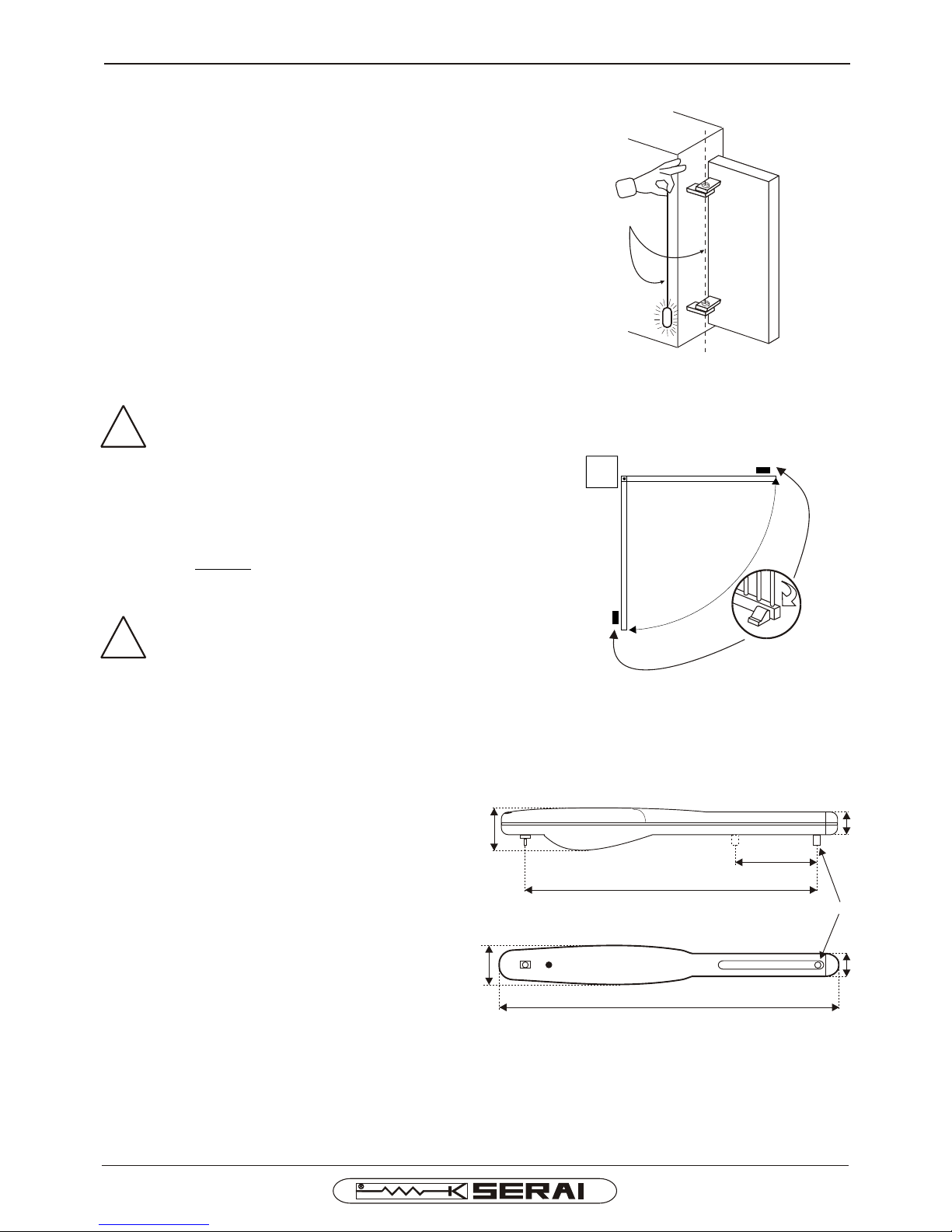

GATE

OPENING

AND CLOSING

END STOP

LATERAL VIEW

VIEW FROM BELOW

Fig. 3

Fig. 2

Fig. 1

430mm

885mm

70mm

130mm

90mm

1000mm

135mm

PM

!

!

SINCE 1965

BEFORE INSTALLING THE MOTORS

1- Ensure perfect right angles of the gate hinges to enable

totally smooth and balanced swing gate movement.

Otherwise the motor may be damaged when subject to

much higher levels of resistance with respect to the tho-

se specified for intended use.

2- The motor is equipped with internal mechanical

stops adjustable by means of a special screw (see

adjustment of internal mechanical stops) to enable

adjustment of the gate closing and opening stop po-

ints. In any event, the installer must position the me-

chanical end stops for gate opening and closing for

system safety purposes - see Fig. 2 -.

3- The installation of the mechanical end

stops for gate opening and closing is neces-

sary for system safety purposes.

4- The motor is supplied with the mobile pin (PM) - Fig. 3 -

in the correct position for installation. However, ensure

that the distance of the mobile pin from the rear connec-

tion point is: 885 mm.

Any distance greater than the above can cau-

se shutdown of the motor shortly before the

gate reaches the closing end stop; any di-

stance less than the above will cause a smal-

ler opening angle than required.

5) Choose the opening angle and calculate the

distances B, C (see Fig. 4 Fig. 5 and table) for

positioning of brackets. The values in the grey band

are recommended. The brackets can be resized

(shortened or lengthened) according to assembly

requirements, taking care to observe distances B

and C.

N.B. In the case of outward opening, the overall working

area of the gate is reduced due to the dimensions of the

motors. In this case installation of the motors on the upper

section of the gate is recommended.

IMPORTANT: failure to observe distances B and C

specified in the table will mean that the gate starts

movement suddenly with excessive oscillations,

which could lead to damage to the brackets and motor.

Page 3/6

MT/B6-C6 I E

BRACKET POSITIONING FOR INWARD OPENING BRACKET POSITIONING FOR OUTWARD OPENING

C

PM

INWARD OPENING

OUTWARD OPENING

PM

B

C

885 mm

B

Fig. 5

Fig. 4

OPENING ANGLE 90° OPENING ANGLE 100° OPENING ANGLE 110°

B C B C B C

260 190

250 200 230 170

240 210 220 180 200 160

240 220 210 190 190 170

230 230 220 220 180 180

220 240 190 210 170 190

220 250 180 220

210 260 170 230

200 270 160 240

190 280

Warning: to ensure correct gate movement, use values in the shaded band.

The gate opening (or closing) time varies according to the selected values B and C.

SINCE 1965

!

Fig. 7

Fig. 6

COVER "A"

NO

YES

Fig. 7A

PROVIDED SEAT FOR

CABLE GLAND PG11.

WE ADVICE TO MAKE THE

HOLE IN THE SEAT ON THE

SIDE OF THE GATE

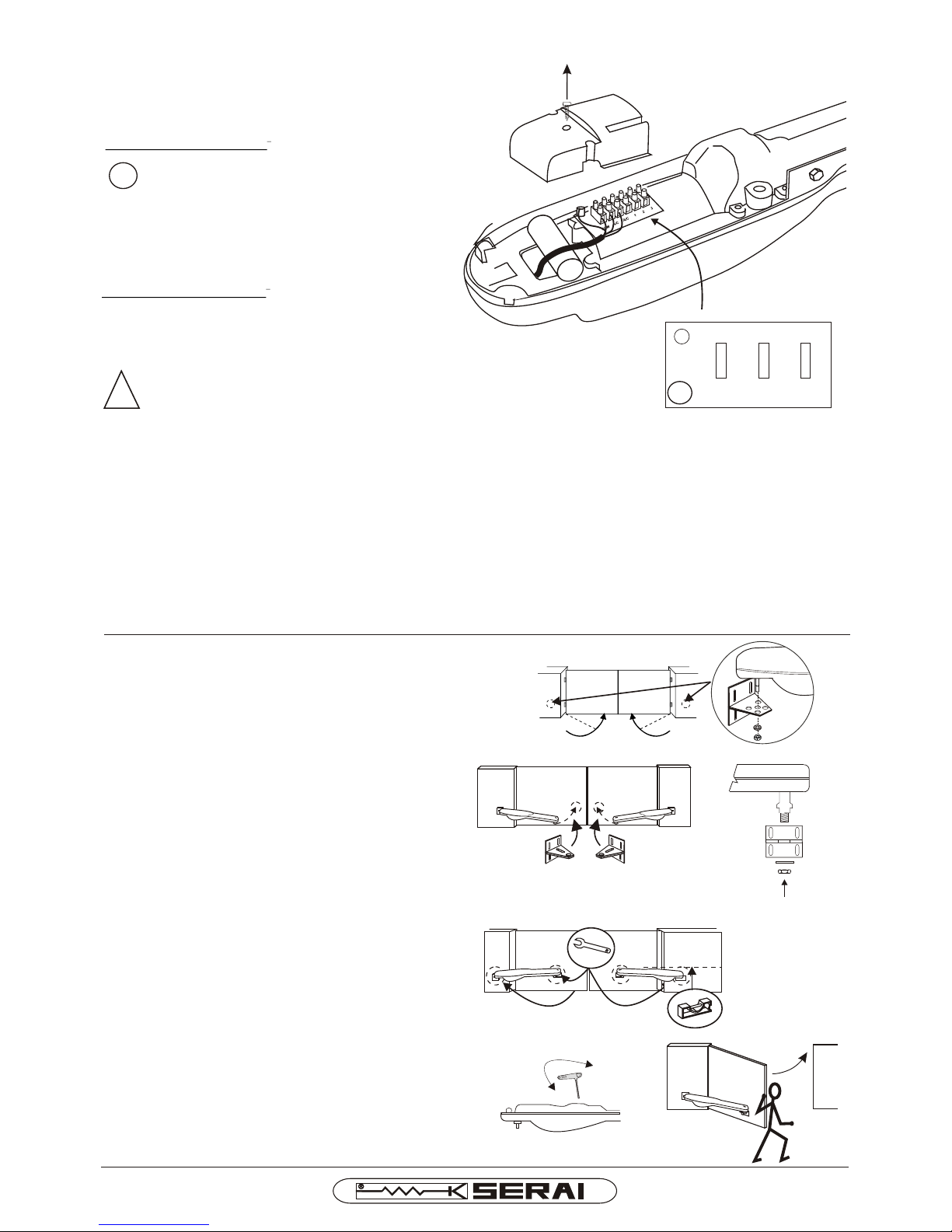

ELECTRICAL CONNECTION SET-UP

6- make a hole in the rear side of the covering part “A” le-

vel with the provided seat for the cable inlet FIG. 6. the

motor is supplied with unassembled covering. We advi-

ce to make the hole in the one on the side of the gate

We suggest to use a cable for external use that

keeps flexible with low temperatures and to fix it

using a cable gland PG11 - Fig. 6 - .

7- fix the covering part “A” to the motor with the 3 screws

and washers supplied. FIG 7

WARNING: never make sharp bends in

the cable on exit from the motors - Fig.

7A - as this may cause damage and con-

stitute a hazard over time.

!

Page 4 /6

MT/B6-C6 I E

SINCE 1965

Advice for wiring up in non-specialised environments.

1. Fit an omnipolar switch upstream of the system, choosing one with a gap of at least 3mm between the contacts. Or, alternatively,

use a 10A thermal magnetic circuit breaker switch.

2. Make all types of connection with the system disconnected from the power, i.e. with the main switch set to OFF (symbol “0”). The

control unit, in particular, must never be connected to the power supply either during the wiring up, or when fitting any expansion

cards.

3. The following cables must be used for installation of the system:

22

- for the motor power supplies: 4x1.5mm version 230V,2x2,5mm version 24V,

2

- for the battery and electric lock power supplies: minimum 2.5 mm

22

- for the control unit power supplies: 1.5mm section for lengths of up to 19m, 2.5mm section for lengths of up to 31m,

22

- for the flashing light: 0.75mm section for lengths of up to 3m, 1.5mm section for lengths of up to 19m,

- for the low voltage and current lines, (e.g. for the photocells, control buttons, electromechanical key, sensitive edges and other

22

safety devices: 0.5mm section for lengths of up to 50m, 0.75mm section for lengths of up to 100m.

8- Remove the terminal board cover and proceed with elec-

trical connections. - Fig. 8 - Refit the terminal board cover.

|

__

_

_

Terminal board cover

WARNING: On versions MT/B6 - at 230V~ -

the capacitor is pre-wired internally.

FOR MOTOR 230V~

2

Use a cable of 4x1,5mm with the sequence:

Earth connection (MT/B6 only)

COM MT/B6 motor common

A/C MT/B6 open/close

A/C MT/B6 open/close

FOR MOTOR MT/C6 24Vdc

2

Use a cable of 2x2,5mm with the sequence:

2 MT/C6 open/close

3 MT/C6 open/close

!|

__

_

_COM A/C A/C 1 2 3

Fig. 8

PROVISIONAL MOTOR INSTALLATION

9-Close the gate completely. Provisionally fix the rear

bracket - Fig. 9 – onto the gate post by welding or by

means of screws + plugs, observing distances B and

C. Provisionally fix the motor to the rear bracket using

the central hole, As shown in Fig. 9

10-Move the motor up against the closed leaf to determi-

ne the front bracket welding point . Move the motor

away from the leaf.

Provisionally fix the front bracket to the gate, obser-

ving the distance and travel limits of the mobile pin.

Insert the mobile pin on the bushing and the latter on

the front bracket - Fig. 10A - then provisionally secure

by means of the nut and washer.

11-Ensure that the motor is levelled. - Fig. 11 -

12-Release the motor - Fig. 12 - using the special key fi-

xed to the terminal board cover. Check that movement

is smooth - Fig. 13 -. Return the gate to the closed po-

sition and block the motor using the special key fixed

to the terminal board cover - Fig. 12 - .

FRONT BRACKET

REAR

BRACKET

Bracket

Washer

Nut

Fig. 9

Fig. 10

Fig. 11

!!

Fig. 10A

Fig. 13

Fig. 12

Page 5/6

MT/B6-C6 I E

SINCE 1965

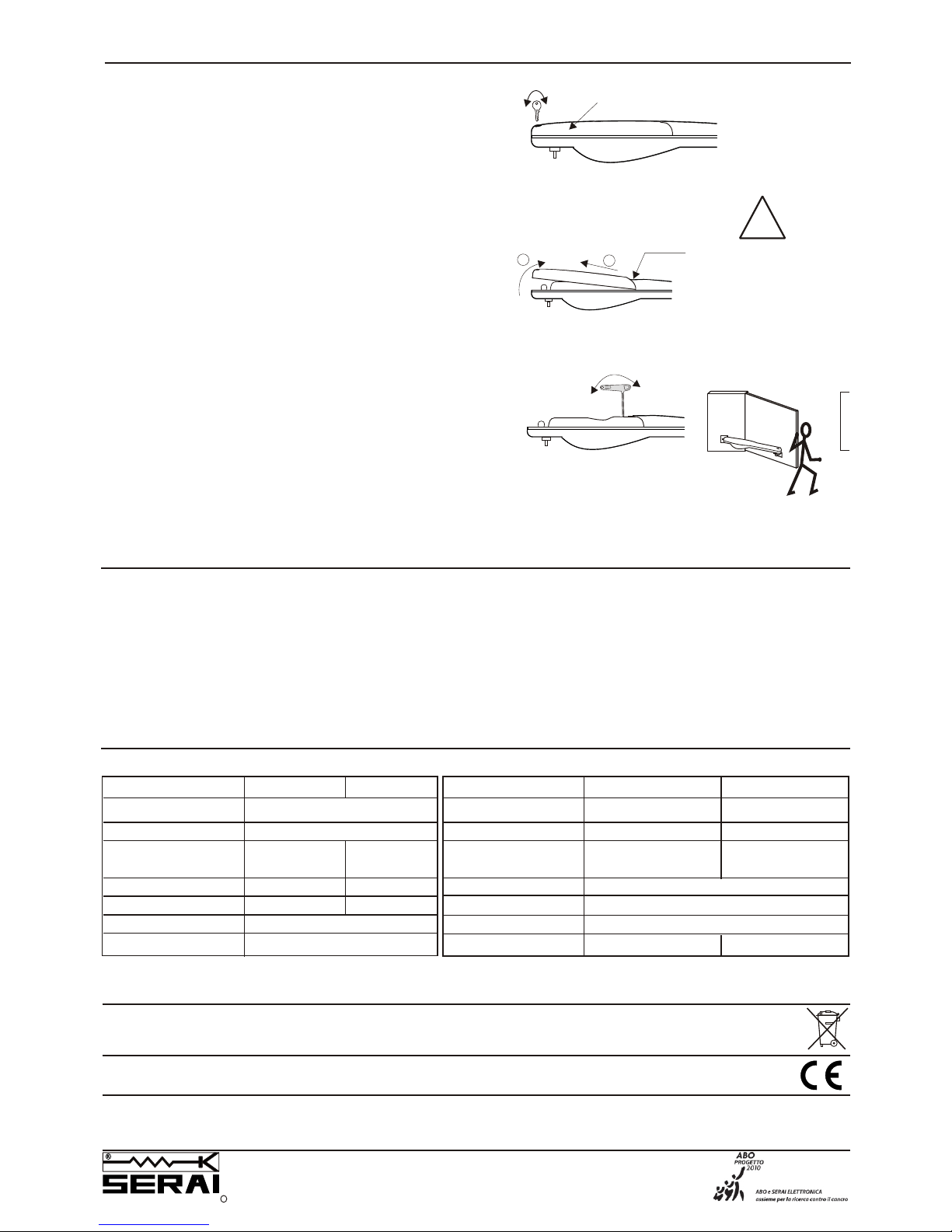

Fig. 14

Fig. 16

1

2

COVER "C"

3

FINAL INSTALLATION

13- Remove the motor from the brackets. Weld the front

bracket in its final position. Fix the rear bracket in its

final position. - Fig. 14 -

14- Refit the motor.Any differences in values B and C can

be compensated for using the 5 holes on the rear brac-

ket. - Fig. 9 -

15- If needed adjust the mechanical stops as per instruc-

tions in following page

17- Fix the covering part “C”: incline of few degrees, cou-

ple the pegs properly and close backside, locking it

with the “security key” FIG 16

16- Fix the covering part "B" in the front side with the

screw and washer and in the back side with the flat

screw FIG. 15

ADJUSTMENT OF INTERNAL MECHANICAL STOPS

-Open the covering part “C” with the “security key”

supplied with the motor. Picture 17

-Raise the covering part “C” backside of few degrees

and remove it without revolving it Picture 18

- Using a 13 mm wrench, set the two front (closing) me-

chanical stops and rear (opening) stops in the required

position. - Fig. 21 -

- Unscrew the back side and the front side screws fi-

xing the covering part "B" - FIG 19 -

- Raise the covering part "B" - FIG 20 -

Fig. 17

Fig. 18

2

1

!

COVER "C"

COVER "C"

ATTENTION: the coupling

pegs could brake if the

covering part is inclined

more than 10-15°

Fig. 21 FRONT MECHANICAL STOPS

REAR MECHANICAL STOPS

COVER "B"

Fig. 20

Fig. 19

Fig. 15

COVER "B"

MOTOR FORCE ADJUSTMENT

Adjustment of motor force for the version MT/B6 at 230V~ is by variation of the power supply voltage, for example

using the control unit SERAI CR/41, and by variation of the current control on the version MT/C6 at 24Vdc, for

example using the control unit SERAI CR/41/24.

In any event, installation must be in full observance with current standards governing power-operated gates;

remember that the installer is responsible for the system and operation in compliance with

standards.

MOTOR TECHNICAL SPECIFICATIONS

MT/B6-C6 I E 04 06 110221 - A4Vf/r -IS MTB6-IS-E

MT/B6 MT/C6

Max. leaf length

Max. leaf weight

Power supply

Absorption

Power

Angular speed

Opening time

6,00

400 Kg

230 V~ ± 10% 24Vdc ±25%

50/60Hz

1,5A 1,5A

110W 110W

0,056 rad/s

30s

Max. thrust

Max. torque on leaf

Force adjustment

Protection rating

Temperature

Dimensions

Weight - without brackets -

1600N 1600N

300Nm 300Nm

variation of power current

supply voltage control

IP55

-20°C ÷ +60°C

1000 x 130 x 135 mm

10,5 Kg 9,5Kg

MT/B6 MT/C6

ELETTRONICA PADOVA

I

SINCE 1965

MADE IN ITALY

VIA ENRICO FERMI, 22

35020 LEGNARO - PADOVA

I T A L I A

PHONE +39 049 79 08 58

FAX +39 049 88 30 529

E-MAIL [email protected]

WEB www.serai.com

TERMS OF GUARANTEE

The company reserves the right to make modifications to the equipment without prior notice thereof. SERAI products are covered by a standard guarantee with a term of 24 months.

Coverage starts on the date on which the tax document constituting proof of purchase is issued and guarantee services shall be provided on the company's premises at Legnaro - PD -

or at the Authorised Service Centres. Carriage costs shall be borne by the Customer.

CE CONFORMITY DECLARATION

SERAI spa declares that the product MT/B6, MT/C6 has been desifned and manufactured according to the above mentioned directives and standards

WEEE DIRECTIVE 2002/96/EC

This appliance was manufactured after 13/08/2005. To protect the environment: when the equipment is no longer needed, take it to a special WEEE (Waste Electric and

Electronic Equipment) collection centre. Do not dispose of it with normal household waste.

MOVING THE GATE MANUALLY IN THE EVENT

OF A POWER FAILURE

Fig. 22

Fig. 23

2

1

!

Fig. 24 Fig. 25

COVER "C"

- Open the covering part “C” with the “security key” sup-

plied with the motor. Picture 22

- Raise the covering part “C” backside of few degrees and

remove it without revolving it Picture 23

-Unlock the motor with the internal key laying on the termi-

nal board cover:

180° anticlockwise : to unlock FIG. 24

-Now the gate can be manually operated FIG. 25

-To lock again (in any position) turn the internal key in oppo-

site direction:

180° clockwise: to lock FIG. 24

ATTENTION: the coupling

pegs could brake if the

covering part is inclined

more than 10-15°

This manual suits for next models

1

Other Serai Garage Door Opener manuals