Server 55034 User manual

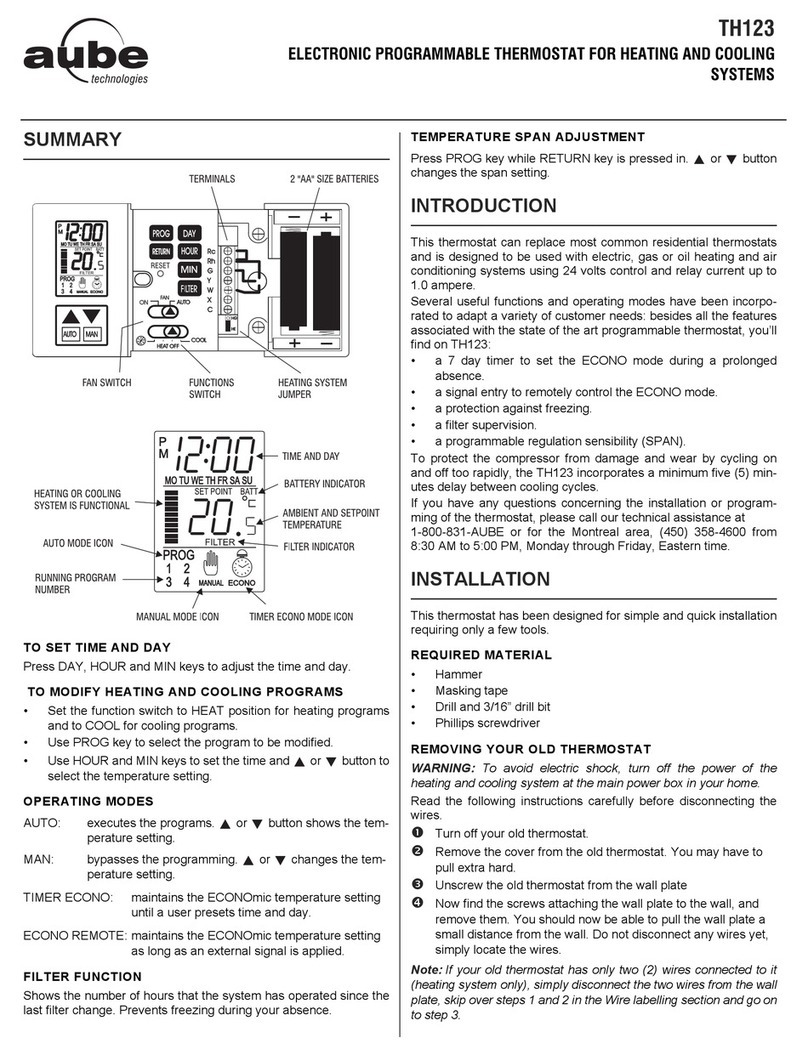

Thermal Cutout Lead

connects to

Angled Terminal

Heating Element Lead

connects to

Straight Terminal

01608-REVA-122711

1 TURN UNIT OFF AND UNPLUG CORD. Allow

unit to fully cool before proceeding to the next

step.

2 REMOVE THE PLASTIC DOME, PUMP, AND

STAINLESS STEEL BOWL FROM THE UNIT.

3 REMOVE THE TWO SCREWS at the top of the

operator's panel.

4 REMOVE THE PICTURE ASSEMBLY. Turn

the unit around so the picture side is facing

you. Turn the two black 1/4 turn fasteners

at the bottom of the picture, 1/4 turn

counterclockwise, then pull out and down on

the bottom of the picture assembly to remove

it.

5 REMOVE THE TWO SCREWS AT THE TOP of

the exposed light panel.

6 TIP THE ENTIRE UNIT ONTO THE RIGHT OR

LEFT SIDE. Grasp the mask and tilt it toward

the operator's side of the unit.

7 REMOVE THE RUBBER FEET AND ANY

SCREWS SECURING THE BASE TO THE UNIT.

Remove the base from the unit.

8 DISCONNECT THE TWO WIRES FROM THE

HEATING ELEMENT.

9 REMOVE THERMOSTAT KNOB. (Pointer type

knobs have a setscrew.)

J REMOVE THE INSULATION FROM AROUND

THE INNER VESSEL.

K SLIDE THE INNER VESSEL TOWARDS THE

PICTURE SIDE OF THE UNIT until the

thermostat shaft clears the front panel.

L CUT THE WIRE TIE, IF THERE IS ONE, to

further access wiring and thermostat.

• DISCONNECT THERMAL CUTOUT

LEAD from angled terminal on

thermostat.

• DISCONNECT HEATING ELEMENT

LEAD from straight terminal on

thermostat.

M REMOVE THE INNER VESSEL FROM THE

UNIT.

NREMOVE HARDWARE SECURING THERMOSTAT

TO THE BRACKET and remove the defective/

old thermostat.

OWITH THE INNER VESSEL IN AN UPSIDE-

DOWN POSITION, install the new thermostat

on the bracket so the angled terminal is

upward. Secure the thermostat with the

mounting hardware.

• Make sure there is a lockwasher

under the nut.

• Tighten the nut to 18 in.lbs (2.03

N.m) torque.

StockNo.55034

This kit replaces thermostat 81034

Thermostat Shaft

Old ThermOsTaT remOval and new ThermOsTaT InsTallaTIOn

ThermostatReplacementKits

PCONNECT LEAD FROM THE HEATING

ELEMENT TO THE STRAIGHT TERMINAL ON

THERMOSTAT. Connect thermal cutout lead

to angled terminal on thermostat.

QINSTALL THE INNER VESSEL IN THE SHROUD.

Reassemble the unit, reversing the disassembly

procedures in steps 2 through 11.

RINSTALL KNOB by aligning knob groove with

spline on new thermostat shaft, then push

knob onto shaft. (Tighten the knob setscrew

if used.)

SPLUG UNIT INTO POWER SOURCE.

TCALIBRATE UNIT per calibration

instructions on the following page.

This gives instructions for thermostat

replacement the

04400 DS DUAL SERVER

Series 81 to present.

1 TURN UNIT OFF AND UNPLUG CORD. Allow

unit to fully cool before proceeding to the next

step.

2 REMOVE THERMOSTAT KNOB. (Pointer type

knobs have a setscrew.)

3 REMOVE THE FOUR SCREWS securing the

bottom wrapper at the light body assembly

and the butter platform assembly.

Pull the bottom wrapper toward you and

remove it from the unit.

4 REMOVE THE INSULATION FROM THE

BOTTOM OF THE BUTTER PLATFORM.

5 REMOVE THE TWO HEX NUTS SECURING

THE THERMOSTAT BRACKET TO THE

PLATFORM.

Tilt the bracket as needed to clear the studs

so the thermostat shaft can be withdrawn

from the panel.

6 CUT THE WIRE TIE, IF THERE IS ONE,

TO FURTHER ACCESS WIRING AND

THERMOSTAT.

DISCONNECT THERMAL CUTOUT LEAD from

angled terminal on thermostat.

DISCONNECT HEATING ELEMENT LEAD from

straight terminal on thermostat.

Remove hardware securing thermostat to

the bracket and remove the defective/old

thermostat.

7 POSITION NEW THERMOSTAT ON

BRACKET AND SECURE WITH ATTACHING

HARDWARE.

Make sure lockwasher is under nut. Tighten nut

to 18 in. lbs. (2.03 Nm) torque.

8CONNECT LEAD FROM THE HEATING

ELEMENT TO THE STRAIGHT TERMINAL

ON THERMOSTAT.

Connect thermal cutout lead to angled

terminal on thermostat.

9 START THE THERMOSTAT SHAFT INTO

THE PANEL OPENING. Secure the wiring

with a wire tie.

JPLACE THE ALUMINUM STANDOFF TUBE

OVER THE STUD not used to mount

the heating element and position the

thermostat bracket on the studs.

• Install the lockwashers and start

the nuts onto the studs.

• Do not tighten the nuts yet.

KROTATE THE HEATING ELEMENT as

needed to center the element terminals in

the rectangular opening in the thermostat

bracket.

Make sure that the dimple in the

thermostat bracket seats in the hole in

the heating element, then tighten the

bracket mounting nuts.

LPOSITION THE INSULATION BLOCK ON

THE THERMOSTAT BRACKET.

MINSTALL THE BOTTOM WRAPPER and

secure it with four screws.

NINSTALL KNOB by aligning knob groove

with spline on new thermostat shaft, then

push knob onto shaft (Tighten the knob

setscrew if used.)

OPLUG UNIT INTO POWER SOURCE.

PCALIBRATE UNIT per calibration

instructions on the following page.

This gives instructions for thermostat

replacement for the

BS and BSA

units BUTTER SERVER and BUTTER

SERVER AUTOMATIC units SERIES

81 TO PRESENT.

Thermostat Knob

Factory-installed thermostats are sealed after

calibration. Do not attempt to calibrate a

factory-installed thermostat.

ToolsNeededForCalibrationProcedure

• Hexagonal Wrench or Allen

Wrench (1.5 mm)-included in

Kit#55034

• Stem Type Dial Thermometer

tomeasuretemperaturesfrom

90°to170°F(32.2°-76.7°C)-not

includedinthermostatkit

• Coverwithholeinittocontain

heatwithinunitandtoholdthe

DialThermometer-notincluded

inthermostatkit

CalibrationProcedure

(Must Follow Thermostat Installation)

1Turn knob to setting of: 135°F (57.2°C)

2CAREFULLY REMOVE KNOB with straight pull

to avoid turning thermostat shaft.

3Place cover (with hole in it) over bowl and

insert thermometer through cover opening.

4Turn unit on and allow unit to heat up

to a MINIMUM OF: 145°F (62.8°C) This

"HEAT UP TO" temperature is considered

a minimum temperature because exceeding

this temperature will not affect the final

calibration.

• Ifthetemperature does not reach

the minimum "HEAT UP TO"

temperature, hold the thermostat

shaft with one hand and rotate

the calibration screw 1/2 turn

counterclockwise, using the

suppliedwrench.

• Continue to repeat the 1/2 turn

of the calibration screw, until

the temperature reaches the

minimum.

5When the temperature reaches the minimum

"HEAT UP TO" temperature, turn calibration

screw two full turns clockwise.

6Allow appliance to cool to: 135°F (57.2°C)

If unit does not cool to the above "COOL

TO" temperature, turn calibration screw two

additional full turns clockwise.

7WHEN THE TEMPERATURE REACHES THE

"COOL TO" TEMPERATURE, turn calibration

screw counterclockwise until a soft audible

click is heard.

8Repeat steps 4 THROUGH 7 until the following

steady temperatures are reached in the

water: 142°F (61.1°C) to 152°F (66.7°C)

9SECURE THE CALIBRATION SCREW by placing

suitable thread-locking material, such as

loctite, in the shaft center.

JALIGN KNOB ONTO THERMOSTAT SHAFT and

press knob onto shaft.

KRe-check setting and return unit to service.

Clockwise rotation of the calibration screw

LOWERS operating temperature.

Counterclockwise rotation of the screw

RAISES the operating temperature.

Rotation of the knob or the thermostat shaft

does just the OPPOSITE.

01608-REVA-122711

StockNo.55034

This kit replaces thermostat 81034

ThermostatReplacementKits

CalIbraTIOn Of new ThermOsTaT

Thermostat Shaft

• Turn calibration screw, using wrench,

counterclockwise for steps 4 and 7.

• Turn calibration screw, using wrench,

clockwise for steps 5 and 6.

Wrench

Other Server Thermostat manuals