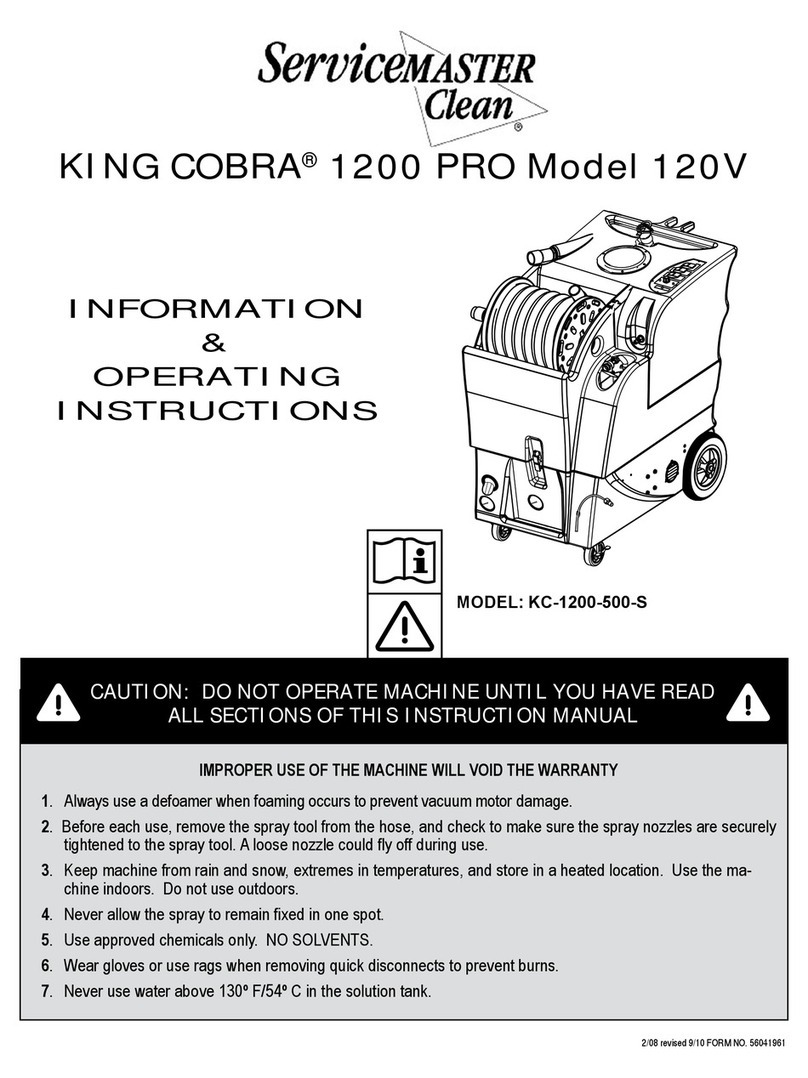

ServiceMASTER Clean 19300 User manual

Owner’s Manual: 19300

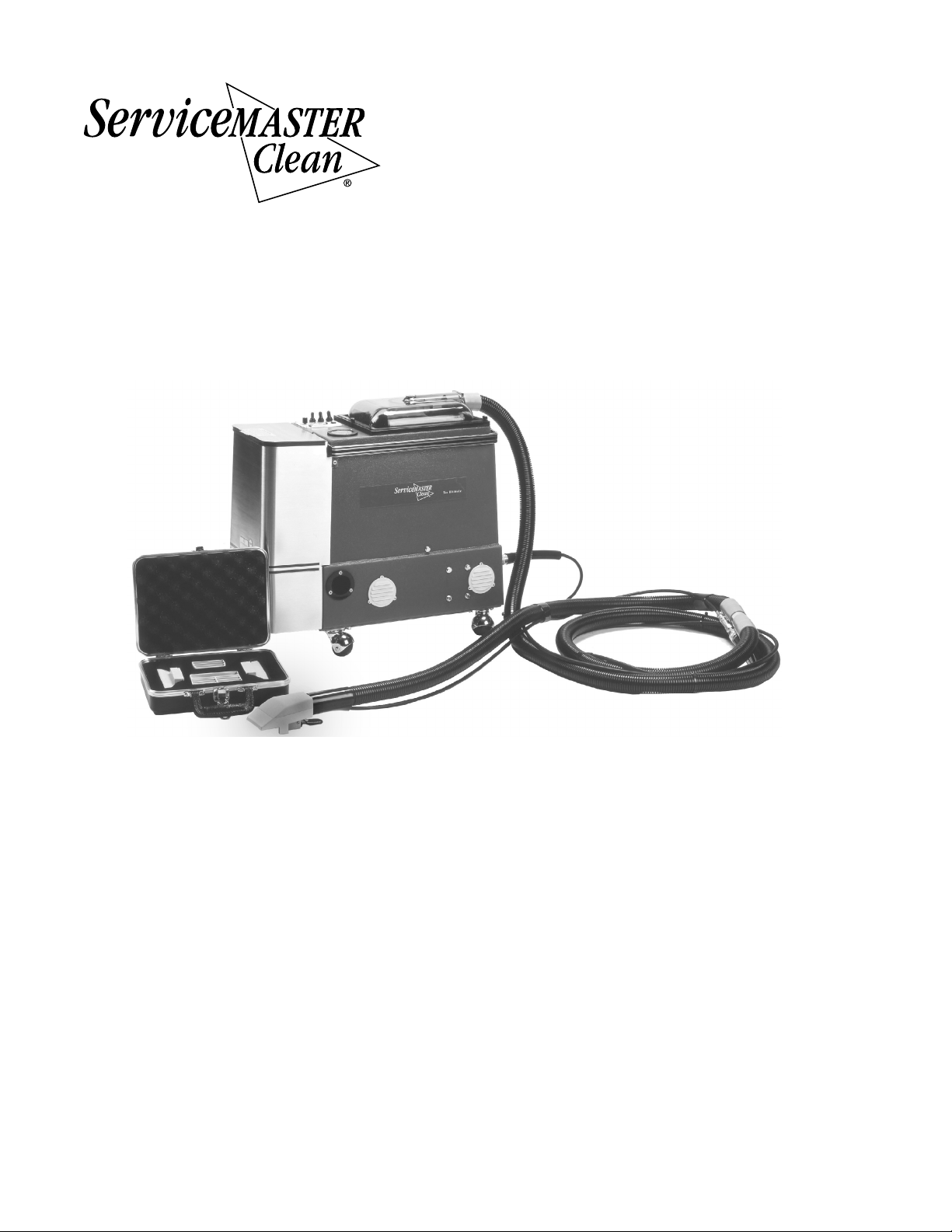

Title: ULTIMATE WET DRY EXTRACTOR

Serial number:__________________

The ServiceMaster Company

860 Ridge Lake Blvd.

Memphis, TN 38120

800-756-5656 (Tech Support)

Date: 12/15/2010

Revision: D

ServiceMaster® Manual

Copyright 2004 by

ServiceMaster Clean

All rights reserved

56041877

FORM NO. 56041877 - Page 2

INSPECTION:

Carefully unpack and inspect your Wet Dry Extractor for shipping damage. Each machine is tested and

inspected before shipping. Any damage incurred during shipping is the responsibility of the carrier. You

should notify the carrier immediately if you notice damage to the box or to the machine or parts.

CLEANING SOLUTIONS:

The Wet Dry Extractor is capable of either wet or dry cleaning. Only liquid cleaners are recommended

(no powders). Solvents with a flash point above 140 ºF are required. Solvents are normally used full

strength. Water-based cleaners are normally diluted. Follow label directions.

MAINTENANCE:

Clean the float rod each time the recovery bucket is emptied to make sure it is clean and the float can

freely travel up. Inspect and clean the filters after each job. The quick disconnects and castors can be

lubricated with a silicone based lubricant. Use a cleaner like Armor-All®on the plastic body.

For optimum performance, flush the machine with clear water at the end of working day. Once a

month, minimum, run a flushing compound through the machine to cut any mineral or chemical build-

up.

SAFETY PRECAUTIONS:

• We recommend the use of a respirator and rubber gloves when using dry cleaning solvents. In

addition, a fan or blower is beneficial to blow fumes away from the operator. Always work in a well

ventilated area.

• Always work with the exhaust hose attached to the machine when cleaning with solvent.

• Solution from the machine may be dangerous as a result of its temperature, pressure, or

chemical content.

• Do not leave the machine unattended when it is plugged in

.

• Read all instructions before operating the machine.

• Use only manufacturer’s approved attachments / tools.

ULTIMATE WET DRY EXTRACTOR

INFORMATION & OPERATING INSTRUCTIONS

DO NOT OPERATE MACHINE UNTIL YOU HAVE READ ALL SECTIONS

OF THESE INSTRUCTIONS

IMPROPER USE OF THE MACHINE WILL VOID THE WARRANTY

1. NEVER use the “Booster” heat when solvent is in the machine. (See special features).

2. ALWAYS use a non-flammable solvent with a flash point above 140 ºF.

3. Keep your machine from rain and snow, extremes in temperatures, and store it in a heated

location.

4. Do not let pump run dry.

5. Always use a drop cloth under the machine during operation.

6. Always use a defoamer when foaming occurs to prevent damage to vacuum

motor.

7. Never operate a machine that is leaking or in need of repair.

8. Extension cords must be at least 12 gauge, three wire, and no longer than 50 ft.

9. Always evacuate the solution tank and lines when switching from a solvent to a water-

based solution, and vice versa.

10. Use a rag when handling quick disconnects to prevent burns.

FORM NO. 56041877 - Page 3

OPERATING INSTRUCTIONS

1. Make sure the recovery bucket under the dome is in place and in the

correct orientation. Place the dome on and secure it.

2. Fill the Stainless Steel tank with cleaning solution to the desired level.

Solution must be at least 3” above the filter in the bottom of the tank.

Attach the exhaust hose in the exhaust outlet hole in the side of the

machine when dry cleaning.

3. Connect the Hoses and cleaning tool. Position the tool over the

solution tank. Turn the pump on, and spray into the stainless steel

tank until solution flows smoothly.

4. HEATING. When using solvent, turn the heat switch on.

Make sure the Booster heat knob is turned all the way off. The

warning light “Water only. No Solvent” should not be lit.

NOTE: the heater will shut off completely if the Booster Heat

switch is turned on when solvent is in the tank.

When heating a water-based solution turn the heater switch

on, and rotate the Booster Heat knob to the desired temperature.

NOTE: With just the ON/OFF switch turned on, the water will

heat to about 140

º

F.

Wait two minutes after turning the heater on to allow the heater to

reach its operating temperature. Preheat the solution line and tool

before beginning to clean: spray into the solution tank for 15

seconds, wait 30 seconds then spray again for 15 seconds.

5. Turn the vacuum switch on. You are now ready to begin cleaning.

NOTE: all switches should be on.

6. As you clean, the recovered solution will flow into the recovery bucket

under the dome. When the bucket is nearly full, the float will have

risen high enough to turn the vacuum off. Turn off the vacuum toggle

switch, then remove the dome and carefully lift the bucket out.

Empty the bucket, and wipe it off. Reinstall the bucket in the

machine and reinstall the dome. Check the solution tank; add

solution if needed. Do not let the pump run dry. Turn the vacuum

switch on and continue cleaning.

7. When switching from solvent to water-based solution, or vice versa,

follow this procedure: turn off the pump and heat switches. Remove

the cleaning tool from the hoses. Place the open end of the vacuum

hose into the stainless steel solution tank to remove all of the

remaining solution. Place the vacuum hose directly over the filter in

the tank for 10 to 15 seconds. Finally, attach the solution hose to the

black suction plug, remove the vacuum hose from the hole in the

dome, and insert the black plug into the dome. This will enable the

vacuum to pull any remaining solution from the hose. Wait about 30

seconds before removing the plug. Turn the vacuum off, and prepare

the machine to begin cleaning.

NOTES:

FORM NO. 56041877 - Page 4

55°C

100°C

50°C

+

ACD

BE

NO SOLVENT

WATER ONLY

WHEN LIT

A = VACUUM

B = WARNING INDICATOR

C = PUMP

D = HEAT

E = BOOSTER HEAT

140 °F

200 °F

SOLVENT HEATING:

WATER HEATING:

WATER ONLY

NO SOLVENT (E):

CAUTION:

Turn on the Heater Switch (D). The Booster Heat switch

(E) must be all the way off (turned counterclockwise until it

‘clicks’ off) or the machine will not heat at all.

Turn on the Heater Switch (D). Turn on the Booster Heat

Switch (E) to the desired temperature, 130 - 200

°

F.

NOTE: Booster Heat will not work unless the Heat switch is

on.

This indicator light (B) illuminates when the Booster Heat

switch (E) is turned on. It is a reminder that the Booster

Heat will only work with water-based solutions.

USE A RAG TO DISCONNECT BRASS FITTINGS AFTER

USING THE BOOSTER HEAT. THE FITTINGS CAN GET

VERY HOT AND MAY CAUSE MINOR BURNS.

SPECIAL FEATURES

AUTO VAC SHUT-OFF:

SOLVENT

SENSING SYSTEM:

When the recovery bucket is full, the vacuum motor will

automatically shut off. The float in the bucket may not be

raised by foam. Defoamer must always be used to avoid

water damage to the vacuum motor.

This unique, patented system determines whether there

is solvent or water-based solution in the tank. If solvent is

used, the sensor will automatically prevent heating above

140

°

F. To prevent accidental over-heating of solvent, the

use of the Booster heat switch - with solvent in the tank -

will cause the entire heat system to shut off.

FORM NO. 56041877 - Page 5

6

1

2

3

4

5

20

21

22

21

21

23 47 46

21A

30

48

16

15

18 19

3233

36

35

37

33B 32A

31

34A 34B

34

39

38

42

44 40

41

32

33A

25

60

59

51

50

54

55

24

57

26 27B

27

28

27A

45

52

53

49

43

29

56

57

58

WET/DRY EXTRACTOR

Model 19300

2/22/2010

53A

8

917A

17

14

7

61

62

Table of contents

Other ServiceMASTER Clean Scrubber manuals

Popular Scrubber manuals by other brands

Windsor

Windsor Saber Cutter SC326 10052220 operating instructions

Powr-Flite

Powr-Flite PFX1380 SERIES Operators manual and parts lists

Olympus

Olympus M200H operating manual

Clarke

Clarke BEXT 100H Operation?and safety

JOHNY VAC

JOHNY VAC JVC70BCT user guide

RCm

RCm Elan Series Instruction and maintenance handbook