SERVO D-1000X User manual

PLEASE READ THE OPERATION MANUAL BEFORE USE.

KEEP THE MANUAL AND INSTALLATION DIRECTIONS FOR REFERENCE.

INDEX

WARNINGS BEFORE INSTALLATION

INSTALLATION

OPERATION

MAINTENANCE

TROUBLE SHOOTING

OUTSIDE DIMENSIONS

ACCESSORIES & PARTS LIST

PARTSLIST

INSTALLATION & OPERATION MANUAL

MODEL:D-1000X

D-1000XLD

D-1000Y

D-1000Z

D-1000YLD

WARNINGS BEFORE INSTALLATION

Pleasebesurethe powerisoffbeforeinstallation. Donot connect thepowertable feedto

thepower toavoidan accident duringinstallation.

Thispowertable feedrequiresAC120V 50/ 60Hzelectricalservice. Please besuretheinput

poweris incompliancewiththis requirement. Ifthe input powerisnotAC120V50/60Hz, please

usean appropriatetransformer. Failuretouse thecorrectpower will damagethepower feed

andcan createadangerous condition resultingininjury ordeath.

Exceptthe forconsumableparts or maintenanceparts,do notdisassemblethepower tablefeed.

Openingthe powerfeedmay cause injurytooperator ordamagetomachine andwillinvalidate

thewarranty.

1

INSTALLATION

Step1:Gathertogetherthefollowingitemsthatyouwillneedto complete this installation.

a)Softhammer

b)3/4"socketwrench

c)Setofinchhexwrenches

d)Grease

e)Cleanshoprag

Step 2:Movethetabletotheextremeleft.

Step 3:Removethenut,handle,anddialassemblyfromthe right-hand end of thetable.

Step 4:Removethefourcapscrewsholdingthebearinghousingin place.

Step 5:Usingasofthammer,tapthebearinghousingoff.Cleantheendsurfaceof the

table.

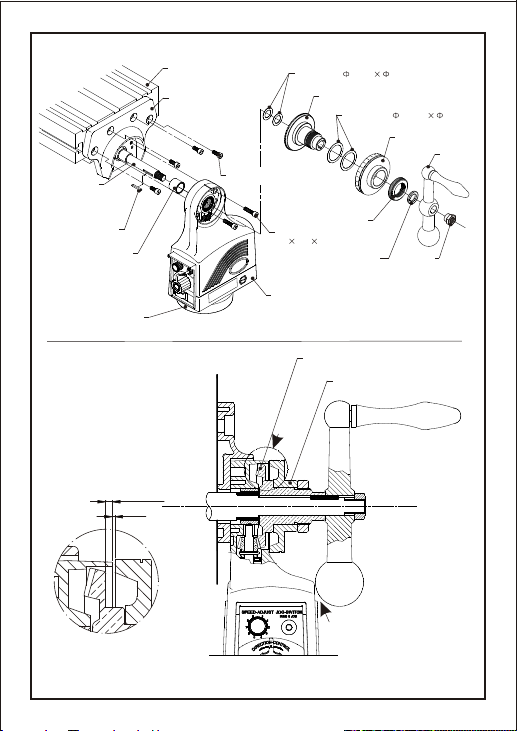

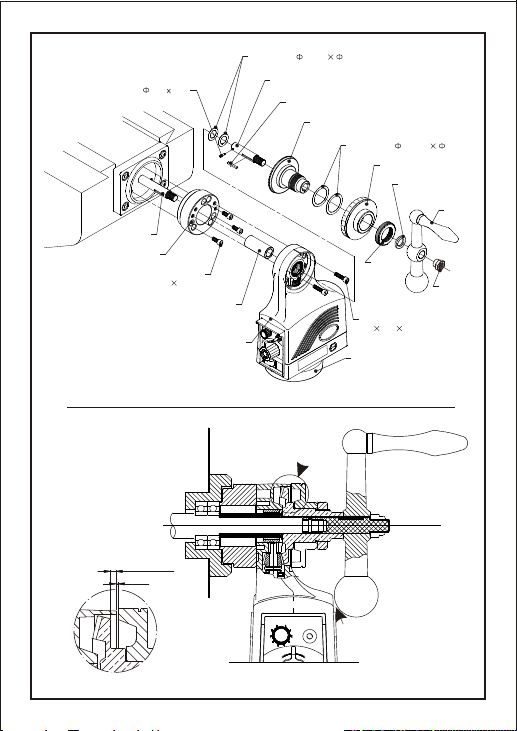

D-1000X & D-1000XLD REPUBLIC LAGUN

PREPARATION

Step 1:Withthetableintheextremeleft-handposition,installthe adaptor with the four

capscrews.

NOTE:Onsomemachinesthedrivepinholesdonotline up with the adaptor.

Removeanddiscardthepinsinsuchcases.Thefourcapscrewsareall that is necessary.

Step 2:Slidethebearingraceontotheleadscrew.

Step 3:Slidethepowerfeedontothebearingraceandpush flush to the endofthe

adaptor.

SecurewithtwoM6XP1.0X25mmlongsocketheadcapscrews.

POWER FEED INSTALLATION

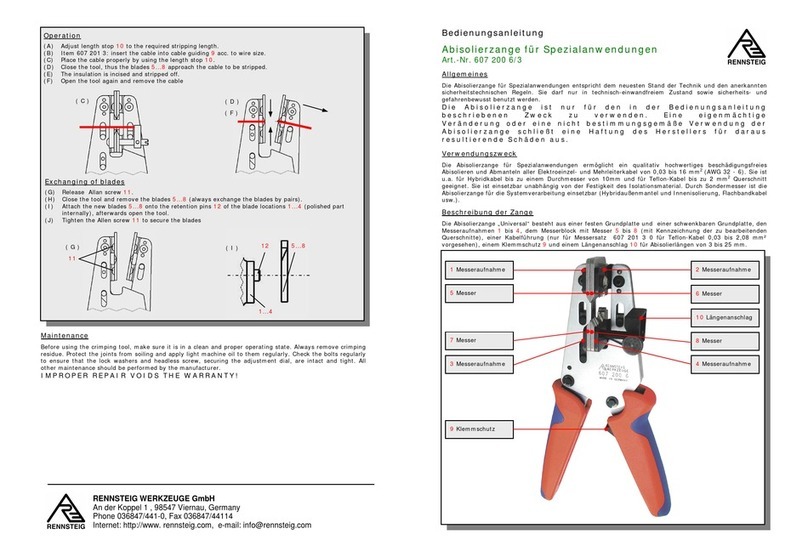

BEVEL GEAR INSTALLATION

Step 1:Installshimwashers,approx..080thick.SeeFig.A

Step 2:Installkey,bevelgear,andcrank handle.

Note: With feed in neutral turn hand crank. If it turns freely in one direction

but catches in the other direction backlash is too large.

If rough engagement of gear is heard or felt in both directions you

probably require additional shims.

2

A

MUSTHAVECLEARANCE

MORETHAN0.080"

USE07177HANDLEWASHER IFREQUIRED

<FIG.A>

0.080-0.085"

0.005"

D-1000XLD 59331BEVELGEAR (LAGUN)

1169DIAL(LAGUN)

HANDLE

DIALNUT

LARGESHIM( 1-23/32" 1-5/16")

SMALLSHIM( 1-1/32" 5/8")

NUT

SCREW

(M6P 1.02 5(mm))-2pcs

X-AXISADAPTOR

LEADSCREW

X-AXISBEARINGRACE

POWERTABLEFEED

WORKTABLE

KEY

EXISTINGSCREW-4pcs

BOTTOMCOVER

BEVELGEAR

DIAL

HANDLEWASHER

3

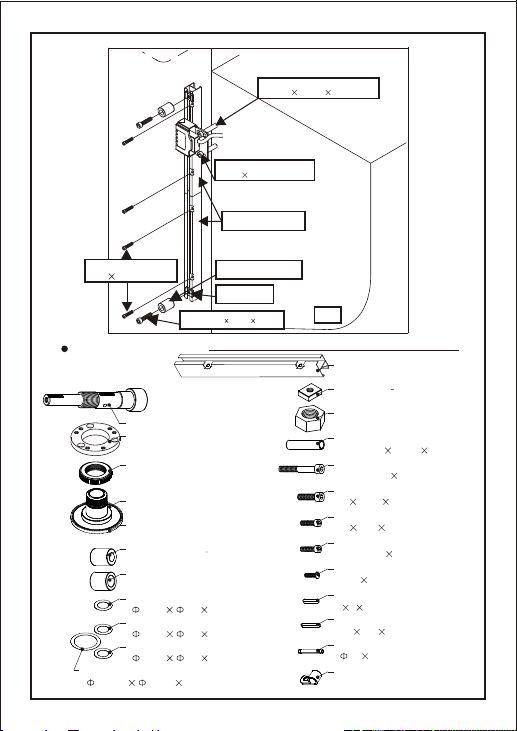

LIMIT SWITCH INSTALLATION

Step 1:Remove thestandardtable stop piecesandinstall thetablestoppieces furnished.

Putthestandardstops backinaposition topreventfeed stops frombeingset

beyondextremetabletravel.

Step 2:Remove theT shapedtablestop andinstalllimitswitch usingexistingscrews.

Aspacermayberequiredto spacelimitswitchfrom table.

NOTE

Step 1:For properoperation,the electrical limitswitchshould beengaged0.4inch

before the mechanicalstopto allowforcoastingof thetable.

Step 2:Put thecableclamp on thecableand securetotheright-hand chipscraperscrew.

Step 1:Aftergettingthepropergear backlash,thedial should beadjustedto obtain.005"spacing

from the faceofthe powerfeed.

This isimportantin ordertokeepchips fromenteringthegear train.

Washersareprovided forthis.Shimas required.

Step 2:In thefollowingsequence, replace thekey(if removed),dial,anddial-locking nut.

Slide the handleinplace andtightenwithsupplied nut.

DIAL AND HANDWHEEL INSTALLATION

EXISTINGSCREW-2pcs

CABLETIETOBRACKET

07237T-NUTS-2pcs

07164LIMITSTOP-2 pcs

59332(LAGUN)

SCREW

(M8P 1.253 0(mm))-2pcs

07253L/SCOVER(1)

07254L/SSPRINGS(2)

07252L/SBRACKET(1)

1000 L/SBRACKET(LAGUN)

ACCESSORIES & PARTS LIST

ACCESSORIES SPECIAL FOR D-1000X & D-1000XLD

4

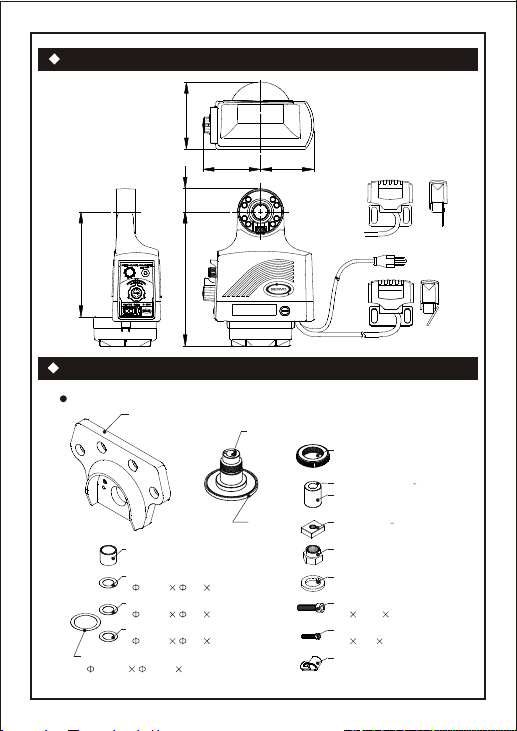

OUTSIDE DIMENSIONS

07256

X-AXISADAPTOR

07255

BEARINGRACE

07436CABLECLAMP

(1/4S)-1pcs

07237T-NUT2 pcs

07177HANDLEWASHER- 2pcs

07194SMALLSHIM

(1-1/32" 5/8" 0.008")-6pcs

07195SMALLSHIM-2pcs

(1-1/32" 5/8" 0.004")-2pcs

07196SMALLSHIM-3pcs

(1-1/32" 5/8" 0.040")-3pcs

07197LARGESHIM

(1-23/32" 1-5/16" 0.008")-4pcs

07176SOCKETSCREW

M6 -2pcsP1.0 25(mm)

07251NUT1/2-20

07238SOCKETSCREW

M8 P1.25 30(mm)-2pcs

07164LIMITSTOP2 pcs

59332LIMITSTOP2

LAGUN

59254DIALNUT

59331

BEVELGEARLAGUN

07159BEVELGEAR(X/Y-AXIS)

4-23/32"

1-5/8"

4-1/16" 3-3/4"

7-3/8"

9-13/32"

INSTALLATION

5

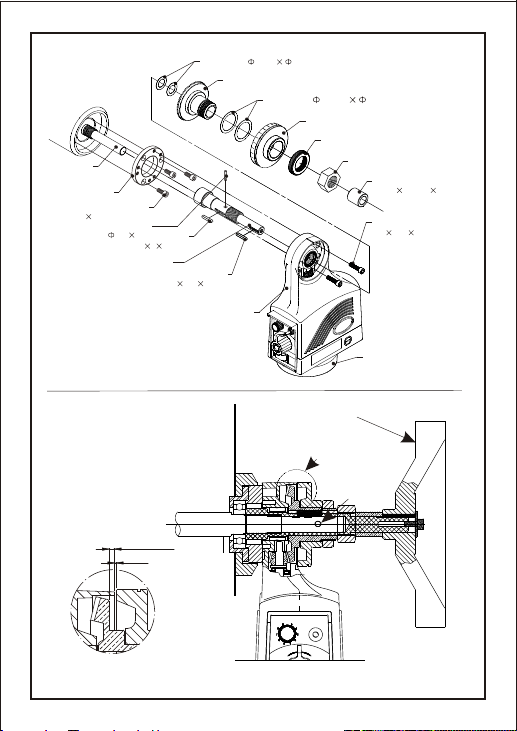

Step 1:Move thetableto the frontofthe knee.

Step 2:Remove thenut,crank, dial assembly,andkey fromthelead screw.

Step 3:Remove bearingretainerfrom bearing housing

Step 4:Install bearingretainersuppliedusing existingscrews.

NOTE:IF EXISTINGSCREWSARE SHORTREDRILLANDTAP1/4-20ANDINSTALL

USING 1/4-20 X1.00(3) SUPPLIED.

Step 5:Screw shaftextensiononto lead screw.Usingpilot hole drill5/32thru andinstallrollpin.

File smooth.

Step 6:Slide bearingraceon to leadscrew.Slidepower feedonto bearingrace.UsingM6

X P1.0 X25mm(2) securepowerfeedto adaptor.

TOO

D-1000Y

POWER FEED INSTALLATION

Step 1:Mount limitswitchon end ofsaddle,right handsideofmill.

Step 2:Afterdeterminingproperlocationof limitswitchusing limit switchbracketas

a template drillandtap 5/16-18(2)places.

Step 3:Install limitswitchbracket using (2)spacersand (2)5/16-18X1.50 longscrews.

Step 4:Using triprailas a template,drill andtap10-24(4) places.

Step 5:Install triprailwith(4) 10-24B.H.C.S.

LIMIT SWITCH INSTALLATION

NOTE

1. LIMIT SWITCH INSTALLATION DESIGNED FOR SERIES 1 TYPE MILLS MANUFACTURED

IN USA.

2. MOUNTING OF TRIP RAIL AND LIMIT SWITCH MAY HAVE TO BE REPOSITIONED OR

MODIFIED DEPENDING ON MANUFACTURER

Step 1:Install shimwashersapproximately.080 thickSeeFig.A

Step 2:Install key,bevelgear andcrankhandle.

BEVEL GEAR INSTALLATION

NOTE: With feed in neutral turn hand crank. If it turns freely in one direction

but catches in the other direction backlash is too large.

If rough engagement of gear is heard or fel s you require additional shims.t in both direction

Step 1:Aftergettingtheproperbacklash, thedialshouldbe adjustedtoobtain .005"

spacing from thefaceof thepowerfeed.Thisisimportantin ordertokeep chips

from entering thegeartrain. Metalwashersareprovided forthis.Shimas required.

Step 2:In thefollowingsequence, replace dialanddial lockingnut,slidethe crankonto

shaft extension andsecurewith suppliednut.

DIAL AND HANDCRANK INSTALLATION

6

C

E

C

R

D

I

O

T

I

0

N

-

SPEED-ADJUST

9 0

L

O

R

O

T

N

JOG-SWITCH

FEED 0 JOG

MUSTHAVECLEARANCE

MORETHAN0.080"

A

A

<FIG.A>

0.080~0.085"

0.005"

POWERTABLEFEED

SCREW

(M6P 1.02 5(mm))-2pcs

BEARINGRACE(Y-AXIS)

EXISTINGSCREW

1/4"-20UNC1 "-3pcs

FIXSTAND(Y-AXISADAPTOR)

AXISSHAFT

NUT

HANDLE

DIALNUT

DIAL

LARGESHIM( 1-23/32" 1-5/16")

BEVELGEAR

SMALLSHIM( 1-1/32" 5/8")

KEY

EXTENSIONSHAFT(Y-AXIS)

ROLLPIN( 5/32"9 /16")

BOTTOMCOVER

HANDLEWASHER

7

ACCESSORIES FOR D-1000Y

KNEE

00670 (2) 5/16-18 X 5/8

INSTALLED BACK SIDE

07164 (2) L/S STOP, T-NUT &

M8X1.25X30mm

SADDLE

59326 (2) L/S SPACER

59566 (1) L/S BRK'T

07160 (2) TRIP RAIL

05125 (2) 5/16-18X1.5

00622 (2) 8/32X1/2 P.H.

1004 L/S MTG PLATE

07193

10-24X3/4 B.H.C.S-4 pcs

07197LARGESHIM

(1-23/32" 1-5/16" 0.008")-4pcs

07164LIMITSTOP2 pcs

07251NUT1/2-20

07177HANDLEWASHER- 2pcs

07238SOCKETSCREW

M8 P1.25 30(mm)-2pcs

07176SOCKETSCREW

M6 -2pcsP1.0 25(mm)

07436CABLECLAMP

(1/4S)-1pcs

07257ROLLPIN

( 5/32"9 /16 -1pcs")

07258

SOCKETPARALLELKEY

00586SOCKETSCREW

1/4"-20UNC 1.0"-3pcs

05125SOCKETSCREW

5/16"-18UNC 5/8"-2pcs

07160TRIPRAIL-2pcs

07194SMALLSHIM

(1-1/32" 5/8" 0.008")-6pcs

07195SMALLSHIM-2pcs

(1-1/32" 5/8" 0.004")-2pcs

07196SMALLSHIM-3pcs

(1-1/32" 5/8" 0.040")-3pcs

07175EXTENSIONSHAFT(Y-AXIS)

07165BEARINGRACE

59254DIALNUT

07237T-NUT2 pcs

07159BEVELGEAR(X/Y-AXIS)

07162ADAPTOR(Y-AXIS)

07193SOCKETSCREW

10-24 3/4B.H.C.S-4pcs

INSTALLATION

8

Step 1:Move thetableto the frontofthe knee.

Step 2:Remove thenut,crank, dial assembly,andkey fromthelead screw.

Step 3:Remove bearingretainerfrom bearing housing

Step 4:Install bearingretainersuppliedusing existingscrews.

NOTE:IF EXISTINGSCREWSARETOSHORTREDRILLANDTAP1/4-20ANDINSTALL

USING 1/4-20 X1.00(3) SUPPLIED.

Step 5:Screw shaftextensiononto lead screw.Usingpilot hole drill5/32thru andinstallrollpin.

File smooth.

Step 6:Slide spacerontolead screw.

Step 7:saddletoward column thatthelead screw isfirmlyengaged withcross

shaft bearing.

Step 8:Slidebearing race leadscrew.Slidepower feed bearingrace.

UsingM6X P1.0X25mm (2) securepowerfeed toadaptor.

Crank ensuring

onto onto

D-1000YLD CROSS FEED

POWER FEED INSTALLATION

Step 1:Mount limitswitchon end ofsaddle,right handsideofmill.

Step 2:Afterdeterminingproperlocationof limitswitchusing limit switchbracketas

a template drillandtap 5/16-18(2)places.

Step 3:Install limitswitchbracket using (2)spacersand (2)5/16-18X1.50 longscrews.

Step 4:Using triprailas a templatedrilland tap10-24(4)places.

Step 5:Install triprailwith(4) 10-24X3/4longB.H.C.S.

LIMIT SWITCH INSTALLATION

NOTE

1. LIMIT SWITCH INSTALLATION DESIGNED FOR SERIES 1 TYPE MILLS MANUFACTURED

IN USA.

2. MOUNTING OF TRIP RAIL AND LIMIT SWITCH MAY HAVE TO BE REPOSITIONED OR

MODIFIED DEPENDING ON MANUFACTURER

Step 1:Install shimwashers,approximately .080thickSee Fig "A"

Step 2:Install key,bevelgear andcrankhandle.

BEVEL GEAR INSTALLATION

NOTE: With feed in neutral turn hand crank. If it turns freely in one direction

but catches in the other direction backlash is too large.

If rough engagement of gear is heard or felt in both directions you require

additional shims.

probably

Step 1:Aftergettingtheproperbacklash, thedialshouldbe adjustedtoobtain .005"

spacing from thefaceof thepowerfeed.Thisisimportantin ordertokeep chips

from entering thegeartrain. Metalwashersareprovided forthis.Shimas required.

Step 2:In thefollowingsequence, replace dialanddial lockingnut,slidethe crankonto

shaft extension andsecurewith suppliednut.

DIAL AND HANDCRANK INSTALLATION

KNEE

00670 (2) 5/16-18 X 5/8

INSTALLED BACK SIDE

07164 (2) L/S STOP, T-NUT &

M8X1.25X30mm

SADDLE

59326 (2) L/S SPACER

59566 (1) L/S BRK'T

07160 (2) TRIP RAIL

05125 (2) 5/16-18X1.5

00622 (2) 8/32X1/2P.H.

1004 L/S MTG PLATE

07193

10-24X3/4 B.H.C.S-4 pcs

9

#1262 SPACER (1)

#59329 ADAPTOR (1)

#59328 BEARING RACE (1)

#1169 DIAL (1)

#01318 WOODRUFF KEY (1)

5mmx6.5mm

#2418 SHAFT EXT. (1)

#00564 ROLL PIN 1/8x5/8 (1)

#59327 BEVEL GEAR (1)

FEED 0 JOGFEED 0 JOG

O

N

C

T

I

O

C

E

N

R

T

I

R

D

O

L

O

N

C

T

I

O

C

E

N

R

T

I

R

D

O

L

00

07160TRIPRAIL-2pcs

01318

WOODRUFFKEY5mmX6.5mm

07251NUT1/2-20

07177HANDLEWASHER- 2pcs

07238SOCKETSCREW

M8 P1.25 30(mm)-2pcs

07176SOCKETSCREW

M6 -2pcsP1.0 25(mm)

07436CABLECLAMP

(1/4S)-1pcs

00564ROLLPIN

( 1/8"5 /8 -1pcs")

07193SOCKETSCREW

10-24 3/4B.H.C.S-4pcs

00586SOCKETSCREW

1/4"-20UNC 1.0"-3pcs

05125SOCKETSCREW

5/16"-18UNC 5/8"-2pcs

07237T-NUT2 pcs

07197LARGESHIM

(1-23/32" 1-5/16" 0.008")-4pcs

07194SMALLSHIM

(1-1/32" 5/8" 0.008")-6pcs

07195SMALLSHIM-2pcs

(1-1/32" 5/8" 0.004")-2pcs

07196SMALLSHIM-3pcs

(1-1/32" 5/8" 0.040")-3pcs

10

ACCESSORIES FOR D-1000YLD

59329ADAPTORLAGUN

2418EXTENSIONSHAFTLAGUN

59328BEARINGRACE LAGUN

Step 1:Slide thepowerfeed onto shaftextensionand securewithM6x 25mmS.H.C.S.(2)

POWER FEED INSTALLATION

Step 1:Remove allhardwarefrom jackshaft (Handcrank,nut, dial,bearingretaineretc.)

Step 2:Mount bearingretainerwith existing screws.Ifhole patternwillnotline upusebearing

retainer as atemplate.Transferholes tomill,drill and tap1/4-20ensuring thatmounting

holes for powerfeedare inthecorrectposition.

Step 3:Secure with1/4-20x 1.00 longS.H.C.S

Step 4:Screw shaftextensiononto jackshaft andtighten.

Step 5:Slide powerfeed,bevel gear,7/8nut,spacer and handwheelto ensure youhavethe

correct stack up.

Step 6:Afterdeterminingthatyouhave thecorrectstack up removeallitems exceptshaft

extension.

Step 7: Usingpilot holeinshaft extension drill

ASALLKNEESARENOTQUITE THESAME,MODIFICATIONSMAYBEREQUIRED.

#5(.205 dia.)thruand pin withrollpin. Filesmooth.

REFERENCE DRAWINGS ENCLOSED

INSTALLATION D-1000Z

07164LIMITSTOP2 pcs

59254DIALNUT

59331BEVELGEARLAGUN

11

NOTE: With feed in neutral turn hand wheel. If it turns freely in one direction but catches

in the other direction backlash is too large.

If rough engagement of gear is heard or felt in directions you require additional shims.both

BEVEL GEAR INSTALLATION

Step 1: Installshim washersapproximately.080thick. SeeFIG.A

Step 2: Installbevel gear,nut,spacerand handwheel.

Step 1: Aftergetting thepropergear backlash, thedialshould be adjustedtoobtain .005"

spacingfromthefaceofthe powerfeed.

Thisis importantinorderto keepchipsfromentering thegeartrain. Shim asrequired.

DIAL AND HANDWHEEL INSTALLATION

Step 1: After determining correctpositionof limit switchdrilland tap 1/4"-20fortrip rail(4)places.

Step 2: Drilland tap5/16-18 inkneefor limit switchbox.

Step 3: Using5-16 x2-1/2S.H.C.S. standoffinstalllimitswitch.

(Standoffmayhaveto bemodified)

and

LIMIT SWITCH INSTALLATION

NOTE: LIMITSWITCHINSTALLATIONDESIGNEDFOR SERIESONETYPEMILLS.MOUNTING

OF TRIPRAILANDLIMITSWITCHMAYHAVETOBEREPOSITIONEDDEPENDING ON

MANUFACTURER

Check hand crank clearances before operation.

Clearancesbetween thesurfacesofthe handcrankandthe non-moving

partsof theequipmentonwhich thehandcrankis installedmustbe at

leastone-fourth inch(1/4")toprevent injury.Modificationof existing

handcrank orreplacementmaybe required.

Do not operate withoutproper clearance!

Preventcontact duringfasttraverses.

WARNINGS

O

E

O

C

I

T

-

N

0

C

L

O

R

N

T

0JOG-SWITCH

FEED 0 JOG

9

R

D

I

SPEED-ADJUST

12

<FIG.A>

0.080~0.085"

0.005"

A

B

(ROLLPIN)

1685-1 HANDWHEEL(1)

7/8-14NUTTHREAD

DIALNUT

DIAL

LARGESHIM( 1-23/32 1-5/16")

BEVELGEAR(Z-AXIS)

SMALLSHIM( 1-7/32 7/8")

P/N00586

(1/4"-201 "S.H.C.S)-3pcs

P/N59333

ADAPTOR(Z-AXIS)

SCREW

(M6P 1.02 5(mm))-2pcs

AXISSHAFT

KEY

4 4 25(mm)

POWERTABLEFEED

BOTTOMCOVER

EXTENSIONSHAFT(Z-AXIS) KEY

(1/8" 1/8" 1-1/4")

SPACER

1"O.D. 5/8"I.D. 1-1/16LONG

ROLLPIN

( 0.2" 3/4")

13

07176SOCKETSCREW

M6 -2pcsP1.0 25(mm)

07436CABLECLAMP

(1/4S)-1pcs

07274ROLLPIN

( 0.2 3/4 -1pcs)

59496SOCKETPARALLELKEY

4425(mm)-1pcs

07193SOCKETSCREW

10-24 3/4B.H.C.S-4pcs

00586SOCKETSCREW

1/4"-20UNC 1.0"-3pcs

07237T-NUT2 pcs

57162SOCKETPARALLELKEY

1/8" 1/8" 1-1/4"-1pcs

07238SOCKETSCREW

M8 P1.25 30(mm)-2pcs

05292SOCKETSCREW

5/16"-18UNC 2-1/2"-2pcs

07261STANDOFF

L/S1/2O.D. 3/8I.D. 2.2LG.

07260HEXNUT7/8-14

(Z-AXIS)

59333ADAPTOR(Z-AXIS)

ACCESSORIES FOR D-1000Z

07197LARGESHIM

(1-23/32" 1-5/16" 0.008")-4pcs

07164LIMITSTOP2 pcs

07160TRIPRAIL-2pcs

59254DIALNUT

59331BEVELGEARLAGUN

07233SMALLSHIM

( 1-7/32 7/8" 0.008")-4pcs

07234SMALLSHIM-2pcs

(1-7/32 7/8" 0.004")-2pcs

07235SMALLSHIM-3pcs

(1-7/32 7/8" 0.040")-2pcs

07167BEVELGEAR(Z-AXIS)

07259

HANDWHEELSPACER

07166EXTENSIONSHAFT(Z-AXIS)

KNEE

07164 (2) L/S STOP

07160 (2) TRIP RAIL

STANDOFF.

1/2"O.D. 3/8"I.D. 2.2LG.-2pcs

P/N05292

5/16-18 2-1/2S.H.C.S.-2pcs

07193

10-24 3/4B.H.C.S-4pcs

07237T-NUT

M8P 1.253 0mm

07238

14

1.Set"jog switch"at"FEED" position. Setspeed-adjustbetween 2and3.Set directioncontrol

knobto0position.

2.Turnonpower switch,turndirectionalcontrol toleftorright tocheckpower feed ismoving

intherightdirection.

3.Depresslimit switchindirection of travel,repeatin oppositedirectiontoensure limit

switchisstopping powerfeed.

CHECKING & CONFIRMING

POWER SWITCH AND RESET SWITCH

1.Theright sideofpower switch is ON. Theleft sideisOFF. Theredlightwill showwhen

poweris ON.

2.Thered oblong buttononright side isresetswitch

AVAILABLE FOR LONGITUDINAL / CROSS / KNEE TRAVEL

POWER CONNECTION

1.Powerfeed requires120VAC50/60Hz electrical service. Pleasebesure inputpower

isin compliancewiththis requirement. Iftheinput powerisnot120VAC50/60Hzpleaseuse an

appropriatetransformer.Failuretousethe correctpowerwill damage thepowerfeed andcan

createa dangerousconditionresultingin injuryordeath.

2.Pleaseavoid cableexposureto high temperature,highhumidity oranysharpobjects.

3.Tumoffpowerswitchbypressing leftsideofswitch. Connectplugto 120VAC50/60Hz.

Useathreeprong groundedoutletonly.

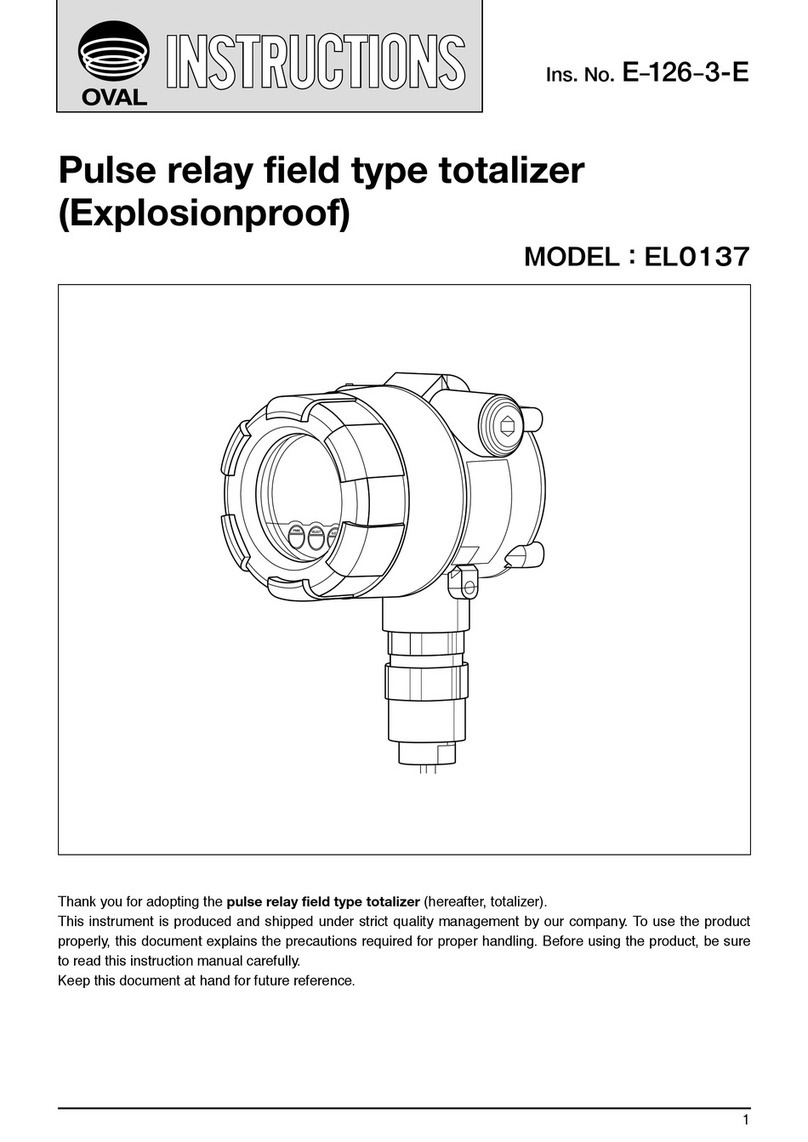

OPERATION (FIG.10)

JOGSWITCH

DIRECTIONCONTROL

RAPIDBUTTON

SPEEDADJUST KNOB

POWERSWITCH

RESETSWITCH

<FIG.10>

15

MAINTENANCE

Note: After operating jog switch, turn "DIRECTION CONTROL" to "0"

position. Then move "JOG SWITCH" to "0" "FEED"

position.

2.Besure tofollowthe above procedurerequiredfor jogoperationtoavoid anydamageorinjury

roperoperation.causedby imp

JOG SWITCH

1.Forjog movement,movejog switch to0position

2.Setspeed-adjustto0

3.Setdirection-controltodirection youwantpower feed tomove.

4.Theamountpowerfeed willmovedepends on speedsetting.Thesmallerthesetting theless

thepowerfeedwill move.The higher thespeedsetting thefurtherthepower feedwillmove.

5.Togglethe jogswitchtojog positionandrelease,the powerfeedwill stop.Ifyouhold jogswitch

powerfeedwillcontinue tomoveuntil released.

6.Afterobtainingpowerfeed position,setjog switch to0position anddirection-controlto0 position.

7.Setjogswitchto feedposition.Youcanbeginnormalmachining.

1.Thespeed canbeadjusted according tooperator'srequirement. The speedrangeis0 to9.

SPEED ADJUST KNOB

DIRECTION CONTROL AND RAPID BUTTON

1.Positiondirection-control todirectionyou want thepowerfeed tomove.

2.Therapid buttonisin the centerofdirection-control.

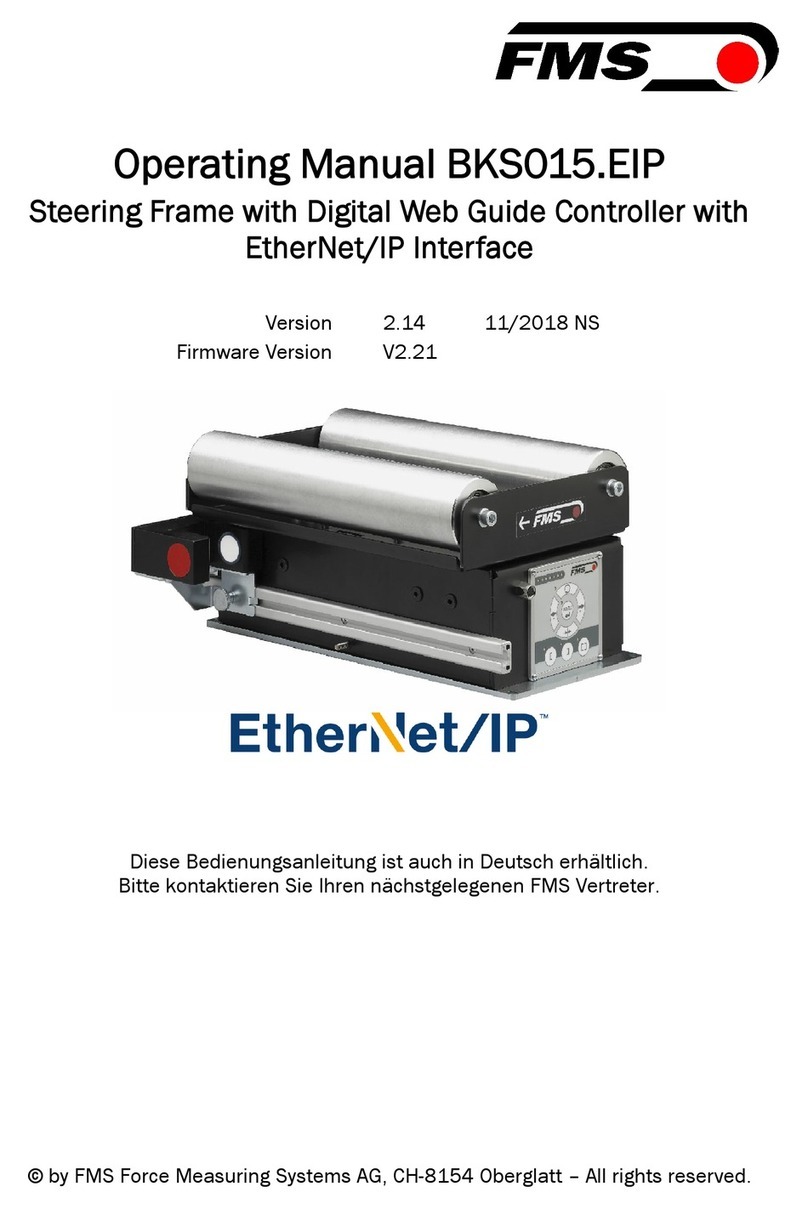

MAINTENANCE FOR GEAR LUBRICATION (FIG.11)

Every6 months,openthe bottom cover,andcheckif lubricationforbevel spiralgearis

sufficient. Itissuggestedto use graphitetypelubrication, donotusesilicone typelubrication.

CHECKING FOR GEAR WEAR (FIG. 11)

Tocheckthecondition ofspiralgear(made ofplastic107T)remove bottomgearcover. If

gearisworn out,pleasereplacewith anewgear. Theprocedure toreplacethe gear isasfollows:

1.Openthe bottomcover(pressthe edgeofhooks on bothsides,and pulldown.)

2.Loosenlock nut,sequentiallytakeout washer,adaptorass'y,roll pin, spacerwasher,

Gearass'yandthrust bearing.

3.Disassemblegear ass'y,replacebevel spiralgear,andthen installitback sequentially.

4.Thepressure plateassemblyandsurface ofGearAssemblymust bekeptclean, and cannot

contain oil. Ifthereis any oil,pleaseclean itwithsolvent,do notcleanwithwater.

CHECKING FOR CARBON BRUSH WEAR (FIG. 12)

Inevery 6months,opencarbon brushcap,to check ifbrushis wornout.Ifthe lengthofthe

brushis lessthan0.2",the brushesmustbe replaced immediately.

16

CARBONBRUSHCAP

CARBONBRUSH

NOTLESSTHAN 0.2"

<FIG.12>

<FIG.11>

MOTORSHAFT

07247THRUSTBEARING

BOTTOMGEAR

GEARASSY'

07262NEEDLEPIN

( .12 .56")

07248

SPACERBOTTOMGEAR

ADAPTERASS'Y

07249

WASHERBOTTOM GEAR

07250

LOCKNUTBOTTOM GEAR

BOTTOMCOVER

DRIVESHAFT

CLUTCH'

SPIRALGEAR

ASS'YBOTTOMGEAR

07245

07264BUSHINGB.G.(3)

07265SCREWB.G.(3)

PRESSUREPLATEASS'Y

ADAPTER

07246ASS'YBOTTOM

GEARADAPTER

07269WASHERB.G. (3)

07268SCREWSB.G.(3)

17

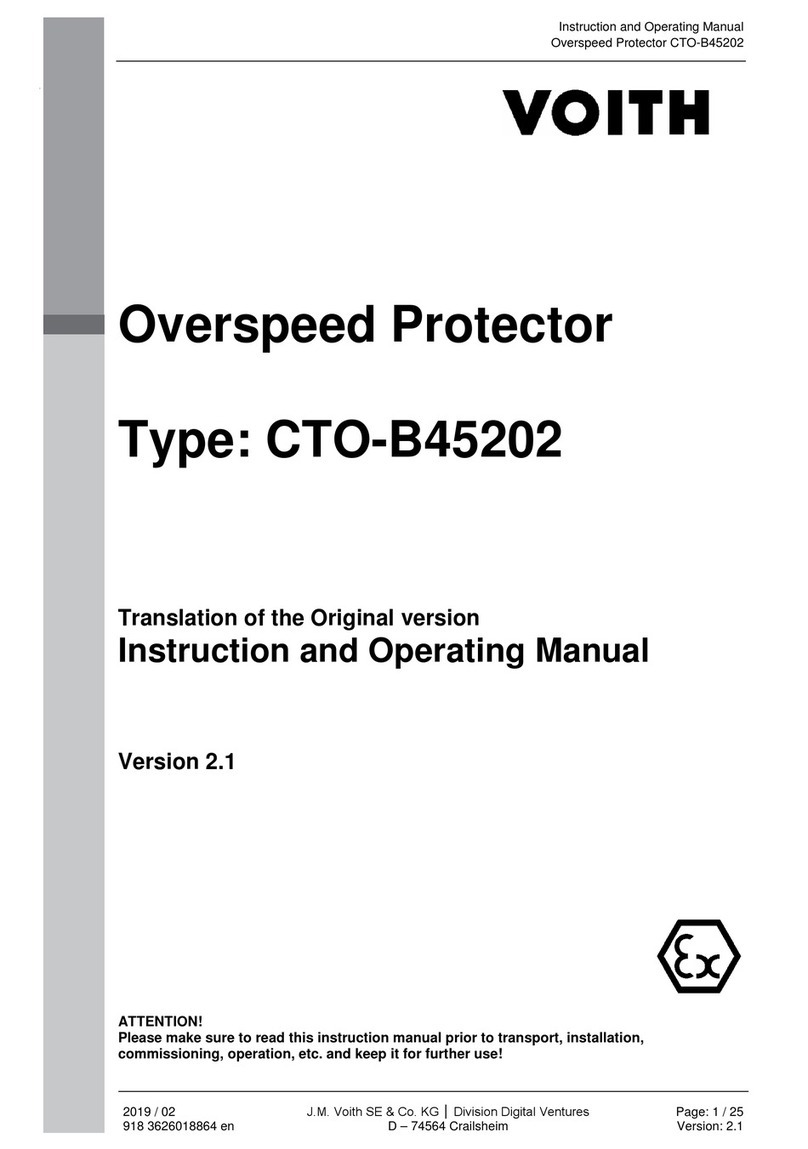

PARTS LIST

No

.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

TOPHOUSING

NEEDLEBEARING

BEVELGEARSET(18T)

THRUSTBEARING

TALLOYBRASS

MOTORBRACKET

ARMATURESET

STATORSET

CIRCUITBOARDSET

SWITCHBRACKETSET

SPEEDADJUSTKNOB

JOGSWITCHSET

MICROSWITCH

BOTTOMHOUSING

CARBONBRUSHHOLDER

CARBONBRUSH

CARBONBRUSHCOVER

TALLOYBRASS

MAGNETICYORKSET

POWERCABLE

LIMITSWITCHSET

YORKSET

SPIRALGEAR(107T)

OCCLUSIONSOFTSET

ADAPTER

GEARHOUSING

LIMITSWITCHCOVERSET

BOTTOMGEARASSY

JOGSWITCHBOOT

ON/OFFSWBOOT

ON/OFFSWITCH

PARTNAME

MECHANICALPARTS

PARTNO.

29 11 30 31 10 12

1

2

9

13

4

22

23

28

24

25

21

26

27

19

18

17

16

15

14 15 16 17

20

8

57

4

3

6

1.Check ifpowerisplugged in

1.Checkjog switchisin

"FEED"position?

1.Openbottom cover,checkthe

motorshaft&gear shaftnot

engaged.

Check poweroutlet& plug.

Turndirection-control to0off

position.Move jogswitchto feed

positionand restartpowerfeed

Checking Solution

Condition

ON/OFFlight isnot

ON,power tablefeed

isnot working.

ON/OFFlight isON,

Powerfeed isnot

working

Powerfeed slipping

Clutch woreout,to replaceyorkset

andocclusion softset(FIG. 11)?

Openthecarbon brushcapsand

replacetwo carbonbrushes.

Replacespiralgear.(FIG.11)?

2.Speedadjust knobat "0"

Position?

2.ON/OFFswitch atONposition.

3.Resetswitch ispoppedup.

Press theswitchto ON position.

(Redlight isON)

Reduce toolload,press reset

Switch,restart thepowerfeed

Turnthespeedadjustknob clockwise

directionuntil therequiredspeed

achieved.

2.Openbottom coverandcheck

ifspiralgearis wornout.

3.Carbonbrush woreout.

(Lessthan 0.2".)

TROUBLESHOOTING

18

SERVO PRODUCTS CO

FLORIDABRANCH

st

8950 131 Ave. N.

Largo, FL 33773

Ph. 727 585 8555

Fax 727 585 6555

HEADQUARTERS

34940 Lakeland Blvd.

Eastlake, OH 44095

Ph. 800 521 7359

Fax 400 942 9100

CALIFORNIABRANCH

14254 Valley Blvd

City of Industry, CA91746

Ph. 626 961 7800

Fax 626 961 2444

. UnitA

A HIGH QUALITY TOOLS Partner Company

2008.10

This manual suits for next models

4

Table of contents