Setra Systems 370 User manual

Operator's Manual

Model 370

Digital Pressure Gauge

INTRODUCTION

About t is Manual....................................................................................... iii

SECTION ONE

Installing t e Model 370 ..............................................................................1

SECTION TWO: SUMMARY OF FUNCTIONS

2.1 Keyboard Functions ............................................................................3

2.2 Display Symbol....................................................................................4

2.3 Display Messages ...............................................................................5

SECTION THREE: DIGITAL PRESSUREGAUGE FUNCTIONS

3.1 Entering a Number or Function ...........................................................7

3.2 Clearing a Number or Function ...........................................................7

3.3 If You Make a Mistake.........................................................................7

3.4 Converting Engineering Units..............................................................8

3.5 Tracking Min and Max Values .............................................................8

3.6 Setting and C ecking Alarm Setpoints................................................9

3.7 Tares and Offsets..............................................................................10

3.8 Printing Out Information ....................................................................11

3.9 Repetitive Printing .............................................................................12

3.10 Printing Setup Status.........................................................................13

3.11 Interfacing wit a Computer ..............................................................13

SECTION FOUR: ADVANCED PRESSUREGAUGE FUNCTIONS.

4.1 User Defined Engineering Units ........................................................15

4.2 Digital Altimeter Setting Indicator (DASI) ..........................................17

SECTION FIVE: DISPLAYING ALTITUDE

5.1 Standard Altitude Conversions..........................................................19

5.2 True Corrected Altitude .....................................................................20

5.3 Relative Altitude ................................................................................22

Table of Contents

i

Appendix I: SETUP FUNCTIONS

I.1 Formatting Baud Rate .......................................................................23

I.2 Disabling Beeper...............................................................................24

I.3 Programmable Stability Indicator ......................................................24

I.4 Omitting Engineering Units................................................................25

I.5 Software Revision Number................................................................25

I.6 Self Diagnostics.................................................................................26

Appendix II: CALIBRATION

II.1 Zero Calibration.................................................................................27

II.2 Span Calibration................................................................................28

Appendix III: RS-232 SERIAL DATA COMMUNICATIONS

III.1 Interfacing Setra 370 to a Computer .................................................29

III.2 Sending Commands to t e 370.........................................................30

III.3 Receiving Data from t e 370.............................................................31

III.4 Immediate and Repetitive Print Modes .............................................32

III.5 Verify Function ..................................................................................32

III.6 Status After Power is Applied............................................................32

III.7 RS-232 Interface Hardware...............................................................33

Appendix IV: ACCESSORIES AND OPTIONS

IV.1 Battery Powered Operation ...............................................................35

IV.2 In Case of Difficulty ...........................................................................36

IV.3 Options ..............................................................................................36

IV.4 Specifications ....................................................................................37

Appendix V: WARRANTY INFORMATION

V.1 Limited Warranty - Pressure Products ..............................................39

Appendices

ii

Introduction

Congratulations, and t ank you for purc asing a SETRA Model 370 ig accu-

racy Digital PressureGauge. Its ease of operation and durable construction will

provide years of reliable service. W ile t egauge is easy to operate, it is advis-

able to read t is guide carefully before use. It is designed to elp you take full

advantage of t e functions and performance of t e gauge.

T is guide is divided into five major sections:

Section One explains installation and power requirements for t e Model 370.

Section Two provides a summary of t e various keys, functions, displays and

messages you will encounter w en using t is pressure gauge.

Section T ree explains in detail t e basic functions and uses of t is gauge in

pressure measurement.

Section Four describes some advanced pressure measurement features avail-

able in t e Model 370.

Section Five provides detailed instructions for t e correct measurement of

altitude for Model 370's wit absolute or barometric pressure sensors.

T e Appendices include calibration and setup information, and instructions for

interfacing t e gauge wit computers and ot er equipment. Also provided are

specifications, lists of accessories, and a warranty statement.

iii

iv

OUTLINE DRAWING

Rear View

oo

AC Power

Pressure Port

RS-232 I/O On/Off

(Battery Only)

ide View

8.55

217

5.5

140

6.0

152

7.2

183

7.5

191

8.55

217

ection One

IN TALLING THE MODEL 370

T e Setra Digital PressureGauge, Model 370, is a ig ly accurate pressure meas-

urement system utilizing t e patented SETRACERAM sensor, advanced micro-

computer based electronics, and sop isticated firmware, resulting in a 0.02% FS

system accuracy.

T e unusual ergonomic design of t e Model 370 allows it to be used as a benc top

instrument (wit keypad and display at t e proper angle for viewing), as a portable

device wit a built in carry andle, or as a rack mount instrument wit t e optional

19" rack mount kit.

ETUP

Connect t e pressure gauge to an AC outlet by inserting one end of t e provided

power cord into t e back of t e gauge, and t e ot er end of t e cord to t e AC outlet.

T e gauge will operate at any voltage from 100 to 240 VAC, 50 or 60 Hz. Once you

ave plugged your gauge into a live outlet, it is automatically on.

T e gauge uses very little power, and may be left connected permanently.

If you ave t e optional battery, refer to Appendix IV concerning battery power and

automatic rec arging.

DI PLAY TE T

W en your gauge is first powered on, it automatically performs a display test, s ow-

ing all possible display segments. T is test lasts approximately six seconds. T e

gauge next displays "HELLO" and performs self-diagnostics to ensure proper

operation. T e gauge t en counts down to zero, and is ready for use.

PRE URE CONNECTION

T e Model 370 provides a standard 1/8" NPT female pipe t read pressure port wit

filter, for connection to a variety of available fittings. T e pressure gauge is rated for

clean dry gas (nonconductive/noncorrosive).

T e Proof Pressure of t e Model 370 (t e maximum pressure w ic can be applied

wit out disturbing t e calibration of t e gauge) is 150% of t e full scale pressure. To

ensure t at t e pressure applied to t e gauge does not exceed t e proof pressure,

properly rated relief valves s ould be installed in any system t is gauge is connected

to.

T at's all t ere is to installation. It is important t at you read t is User's Guide

t oroug ly to ensure proper use of t e gauge. T e summary of Functions in t e next

Section serves as a andy reference.

1

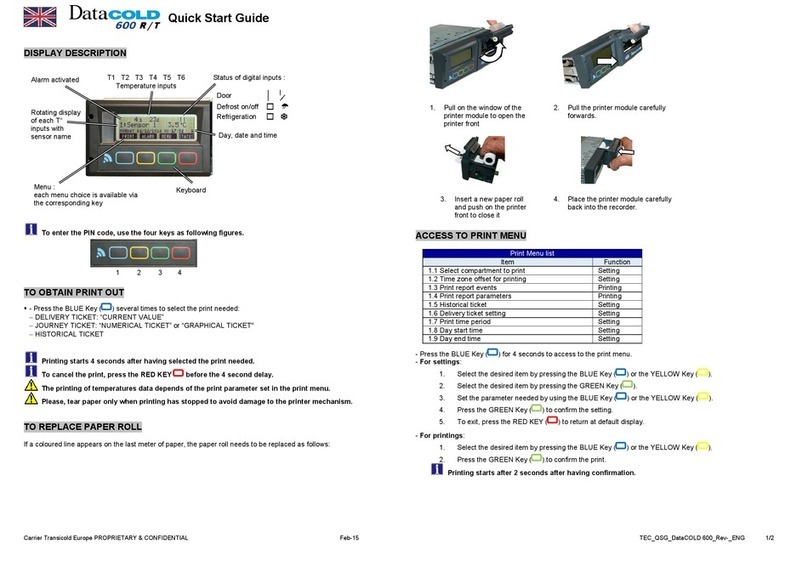

7 8 9

4 5 6

1 2 3

0-.

min

max

f(p)

set

points

set up zero

print span

conv clear

EA

LEVEL HI LO ALARM

O.K.

units ft

mmbar

in hg

H2O P I

-888888

Digital Pressure Gage

Display

6 digit LCD wit Annunciators for

Alarms, Min/Max values and

Engineering Units.

span

Use wit SetUp

Key for Full Scale

Calibration.

clear

Exits Programming Mode To

Normal Operation.

O.K.

User Program-

mable Indication

of Pressure Signal

Stability.

set up

Program Custom

Functions and

Perform

Recalibration.

print

Sends Display Data T roug a

Bidirectional RS-232 I/O Port. Program-

mable for Continous or Interval Printing,

300-9600 Baud Rate.

conv

Automatic Engineering Units

Conversion for Pressure and

Altitude. Predefined Units are

Pa, PSI, mbar, mmHg, inHg,

mmH2O, inH2O, ft, m, units.

set points

Hi/Lo Alarms-User Defined.

Alarm Indications are

Display Flas ing, Audible

Tone and Message Sent

Out I/O Port.

f(p)

Programmable Non-

Linear Function Key for

Barometric Ranges.

Converts True Baromet-

ric Pressure To Sea

Level Pressure.

min/max

Tracks Minimum and Maximum

Values Encountered.

zero

Dual Function Key

Operates as Tare or

wit SetUp key as

Zero Calibration.

Keypad

Numeric keypad for

Entry of Custom

Conversion Factors,

Setpoints and

Calibration Data.

2

Portability and Accuracy

Right Where You Need It

ection Two

UMMARY OF FUNCTION

2.1 KEYBOARD FUNCTION

Send information to a printer or ot er perip eral.

Convert engineering units being displayed.

Display HI and Lo Alarm setpoints.

Enter relative or absolute tare value.

Display minimum and maximum value encountered.

Clear t e number or key sequence being entered or displayed.

Convert true pressure to SEA-LEVEL pressure (absolute pressure).

Send status summary to a printer or ot er perip eral.

C ange Hi and Lo Alarm setpoints.

Enter MIN/MAX tracking mode.

Exit MIN/MAX tracking mode.

Perform ZERO calibration procedure.

Perform SPAN calibration procedure.

Clear t e display, turn off MIN/MAX, clear t e tare value, convert

to display t e units t e gauge was calibrated in.

clear

f(p)

set

points

clear

setup print

min

max

setup

setup

3

set

points

setup

zero

min

max

conv

print

min

max

setup zero

span

2.2 DI PLAY YMBOL

OK

T e readings are wit in t e user defined stability requirement.

hPa

T e reading s own is given in ectopascals.

P I

T e reading s own is given in pounds per square inc .

inHg

T e reading s own is given in inc es of mercury.

mbar

T e reading s own is given in millibars.

mmHg

T e reading s own is given in millimeters of mercury.

inH2O

T e reading s own is given in inc es of water.

mmH2O

T e reading s own is given in millimeters of water.

ft

T e reading s own is given in feet of altitude.

m

T e reading s own is given in meters of altitude.

EALEVEL

T e reading s own is corrected to sea level.

units

T e reading s own is given in user-defined pressure units.

HI ALARM

T e reading s own exceeds t e HI setpoint.

LO ALARM

T e reading s own exceeds t e LO setpoint.

HI

T e reading s own is t e maximum value encountered.

LO

T e reading s own is t e minimum value encountered.

4

2.3 DI PLAY ME AGE

UnAbLE

T e gauge is unable to execute t e requested function in its

current configuration. Clear t e display and continue.

OFLO

T e display is over-ranged because excess pressure is applied

or because t e user-defined conversion exceeds t e number of

digits available in t e display.

FLA HING

DI PLAY

T e pressure applied exceeds t e rated range of t e sensor.

BU Y

T e gauge is acquiring a stable reading.

Ot er messages w ic are displayed in t e course of using t e various functions of

t e Model 370 are explained in t e sections of t e manual concerning t ose functions.

5

6

ection Three

DIGITAL PRE URE GAUGE FUNCTION

3.1 ENTERING A NUMBER OR FUNCTION

To enter a number or function, simply press t e key or keys w ic

correspond to t e numbers or functions you wis to enter.

3.2 CLEARING A NUMBER OR FUNCTION

To clear a function or number you ave begun to enter, press t e CLEAR

key. T is automatically returns t e gauge to display mode, wit out affecting

any ot er functions w ic may be in use.

To reset t e Model 370 to its power up condition, press "-", t en CLEAR.

T is clears t e zero/tare value, s uts off MIN/MAX, and converts back to

t e original engineering units. All of t ese functions are described in later

sections of t is guide.

3.3 IF YOU MAKE A MI TAKE

If you mis-enter a number or enter a number or function t e gauge cannot

accept, t e display will read "UnAbLE". Press CLEAR to resume normal

display, and re-enter t e number or function.

7

3.4 CONVERTING ENGINEERING UNIT

T e Model 370 will measure pressure in any engineering units, including six

built-in pressure conversions, two built-in altitude conversions, and a

user definable conversion.

To convert from one unit to anot er, simply press t e CONV key repeatedly

until t e units you want are in t e display. T e order of units is as follows:

Pa - PSI - mbar - mmHg - inHg - mmH2O - inH2O - ft - m - units. To return

directly to t e units t e gauge was calibrated in, press "-" t en CONV.

See Section 4.1 for instructions on t e use of user-defined units ("units"),

or Section 5 for displaying altitude.

3.5 TRACKING MIN AND MAX VALUE

To use t e Model 370 to track t e minimum and maximum pressures applied to

t e sensor, enter t e tracking mode by pressing ETUP, t en MIN/MAX.

To examine t e values stored, press MIN/MAX. T e gauge will display "HI"

and t e maximum value encountered for about t ree seconds, t en will

display "LO" and t e minimum value encountered for about t ree seconds,

and t en will revert to normal display.

To s ut off t e min/max tracking mode, press "-", t en MIN/MAX.

If t e MIN/MAX key is pressed wit out aving first entered t e MIN/MAX

tracking mode as described above, t e display will read "UnAbLE". Press

CLEAR and t en follow t e above procedure.

8

3.6 ETTING AND U ING ALARM ETPOINT

T e Model 370 as an alarm capability w ic will indicate w en t e pressure

applied as exceeded a ig or a low setpoint. T e annunciators are an

audible tone, a display message of "HI ALARM", and a message sent

t roug t e communications port.

To examine t e current value of t e setpoints, press ETPOINT . T e

gauge will display "HI ALARM" and t e ig setpoint for about t ree

seconds, t en will display "LO ALARM" and t e low setpoint for about

t ree seconds, and t en will revert to normal display.

To enter new setpoints, convert to t e engineering units you wis to use,

and decide w at values you will enter in t e following procedure. Entering

a value w ic is too ig or too low will cause t e display to read "UnAbLE".

If t is appens, press CLEAR to resume normal display mode.

1. Press ETUP, t en ETPOINT . T e display will s ow "HI

ALARM" and t e current ig setpoint.

2. Now you can enter a new ig setpoint by entering a number. To

keep t e current setpoint wit out c anging it, proceed to t e next

step wit out entering a new number.

3. Press ETUP. T e Model 370 will accept t e number in t e display

as t e ig setpoint, and immediately s ow "LO ALARM" and t e

low setpoint.

4. Enter a new low setpoint, or to keep t e current low setpoint, proceed

to t e next step wit out entering a number.

5. Press ETUP. T e number in t e display will be accepted as t e

low setpoint, and t e gauge will revert to its normal display.

T e factory setting for t e ig setpoint is 105% of t e pressure range,

and t e low setpoint is 5% below t e pressure range. To effectively disable

t e alarm setpoints, reset t em to t ese values using t e above procedure for

entering setpoints.

9

3.7 U ING THE TARE AND ZERO FUNCTION

T e TARE function on t e Model 370 gives you a way of setting t e

displayed reading to zero or of subtracting a specified offset so t at you

can monitor c anges in pressure relative to a known starting point. T is is

done by creating a tare value w ic will be subtracted before eac up-

dated reading is displayed.

To set t e display to zero, press ZERO. T e gauge will save t e reading in

t e display as t e tare value, and will subtract t at value from every sub-

sequent reading before displaying it.

To subtract an offset from t e display, enter t e amount of t e offset and

press ZERO.

To add an offset to t e display, press "-", t en enter t e amount of t e

offset and press ZERO.

To restore t e normal display, press "-", t en press ZERO. T e gauge will

set t e tare value to zero and resume displaying pressure in w atever

engineering units are selected.

If you enter a number w ic will result in a reading requiring more

digits t an are available in t e display, t e display will s ow "OFLO".

Press CLEAR to resume normal display.

10

3.8 PRINTING INFORMATION

Your Setra Digital Pressure Gauge is designed to print information w en

connected to a printer, using t e following procedure:

1. Set t e printer up as described in its' manual.

2. Connect t e RS-232 cable from t e printer to t e Model 370.

3. Make sure t e printers on-line lig t is on.

4. Press PRINT to send t e reading in t e Model 370 display to t e printer.

NOTE: W en using a printer set t e baud rate of t e gauge to matc t at of

t e printer (see Appendix I).

To interpret t e meaning of t e symbols printed, see Appendix III -

"RS-232 Serial Data Communications".

11

3.9 REPETITIVE PRINTING

It is sometimes desirable to record pressure measurements at fixed

intervals of time. To print at fixed intervals, follow t is procedure:

1. Connect a printer as outlined in Section 3.8.

2. Enter t e number of seconds between readings.

3. Press PRINT. T e gauge will print out a reading at t e specified interval.

4. To cancel repetitive printing, press "-" t en PRINT.

To interpret t e meaning of t e symbols printed, see Appendix III - "RS-232C

Serial Data Communications."

Most printers are equipped wit a buffer w ic allows t em to receive information

at ig speed from t e gauge, and print it at t e slower speed of t e printer.

Using repetitive print mode wit a printer w ic is not equipped wit a buffer

may cause a "Q-OFLO" message to be printed, indicating t at t e printer

cannot accept information at t e rate it is being sent. T ere are t ree solutions

to t is problem; eit er make t e repetitive print interval longer, use a printer

equipped wit a buffer, or set t e communications baud rate on bot t e gauge

and t e printer as slow as possible (300 baud, for instance).

12

3.10 PRINTING Y TEM TATU

To get a summary of t e condition of all active functions, press ETUP, t en

press PRINT. A sequence of information will be printed indicating t e range of

t e gauge and t e status of any functions w ic are currently in use, as s own

in t is example.

STATUS

ELEV: 256 FT

MAX: 14.4193 PSI

MIN: 14.5188 PSI

HI ALARM: 15.8000 PSI

LO ALARM: 11.0000 PSI

ZERO: 1.0000 PSI

UNIT: 689.47 PSI

T e actual messages will vary depending on w ic functions are in use.

3.11 INTERFACING WITH A COMPUTER

Your Setra Digital Pressure Gauge is designed to interface wit a wide

variety of computers. If your gauge is connected to a computer, you can

transmit information to t e computer using t e simple procedure given for

"Printing Information."

For more advanced and versatile print functions, see Appendix III - "RS-232

Serial Data Communications."

13

14

Table of contents

Other Setra Systems Measuring Instrument manuals

Setra Systems

Setra Systems SRIM1 User manual

Setra Systems

Setra Systems 760 User manual

Setra Systems

Setra Systems DATUM 2000 User manual

Setra Systems

Setra Systems SRCM Installation manual

Setra Systems

Setra Systems SRIMV Operating instructions

Setra Systems

Setra Systems MRMS User manual

Setra Systems

Setra Systems Power Patrol Manual

Setra Systems

Setra Systems Model 730 User manual

Setra Systems

Setra Systems 761 User manual

Setra Systems

Setra Systems SS-SPM User manual