SETRONIC VERONA ILIA-OZ User manual

SETRONIC Verona 1

2SETRONIC Verona

MONOZONE REFLECTIVE BEAM DETECTOR

INDEX ....................................................................................................................................................................... 2

1. GENERAL PRODUCT INFORMATION ........................................................................................................................ 3

1.1. Contents of packaging and accessories available on request ............................................................... 3

1.2. General characteriscs .......................................................................................................................... 4

1.3. Product characteriscs .......................................................................................................................... 5

1.4. Descripon of system ............................................................................................................................ 5

1.5. Working principle .................................................................................................................................. 7

2. INSTALLATION OF THE DETECTOR ............................................................................................................................. 8

2.1. Posioning .......................................................................................................................................... 8

2.2. Opening the detector ............................................................................................................................ 9

2.3. Installaon procedure ........................................................................................................................... 10

2.4. Detector cabling ..................................................................................................................................... 11

2.5. Closing the detector .............................................................................................................................. 12

3. DIAPHRAGM .............................................................................................................................................................. 13

4. INSTALLATION OF REFLECTIVE UNIT ......................................................................................................................... 15

5. INSTALLATION OF CONTROL UNIT ............................................................................................................................. 16

5.1. Opening of the control unit ................................................................................................................... 16

5.2. Securing the control unit ....................................................................................................................... 17

5.3. Control unit cabling ............................................................................................................................... 18

5.4. Closing the control unit ......................................................................................................................... 19

6. CABLING ..................................................................................................................................................................... 20

6.1. Choice of cable ....................................................................................................................................... 20

6.2. Connecons to control unit ................................................................................................................... 21

7. CALIBRATION ............................................................................................................................................................. 22

7.1. Switching on the system ........................................................................................................................ 22

7.2. First set-up ............................................................................................................................................. 23

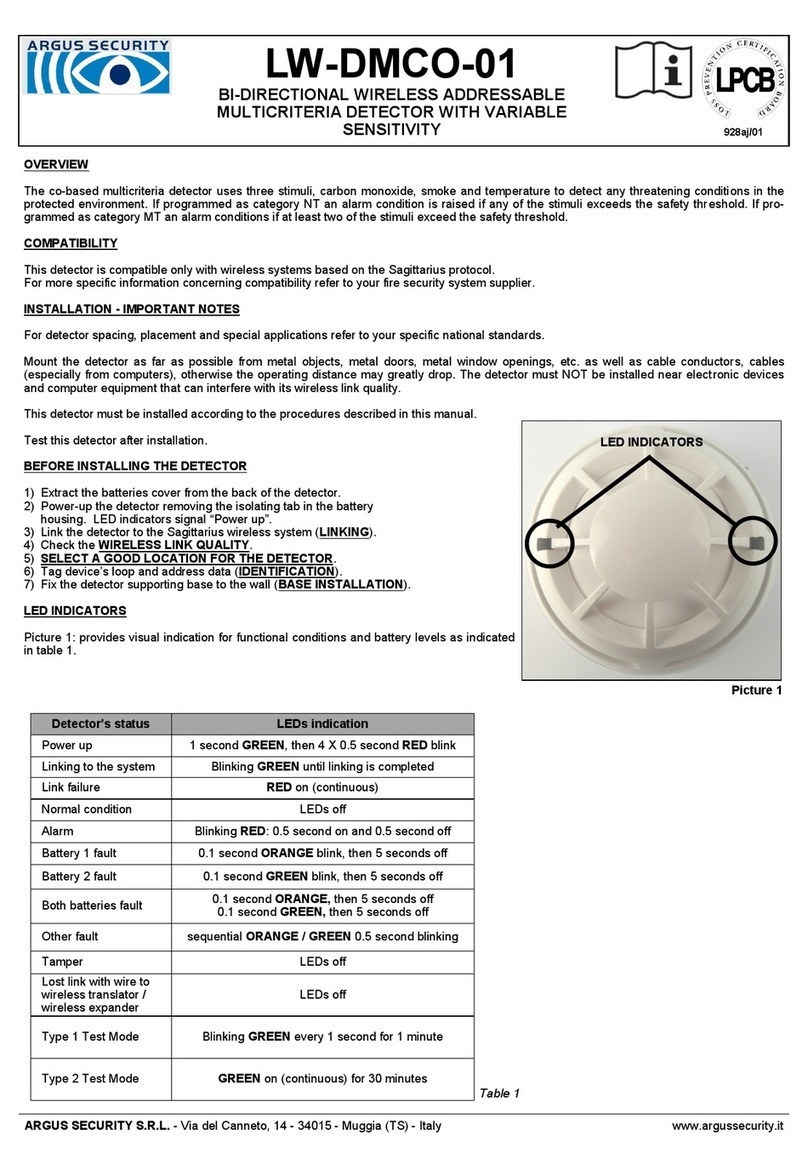

7.3. Indicaons on working status ................................................................................................................ 23

7.4. Opcal alignment .................................................................................................................................. 24

7.5. Alignment procedure ............................................................................................................................. 27

8. CONFIGURATION OF THE SYSTEM ............................................................................................................................. 30

8.1. Self-calibraon of transmier level ....................................................................................................... 30

8.2. Regulaon of sensivity thresholds ...................................................................................................... 32

8.3. Conguraon of the system .................................................................................................................. 33

8.4. Other menu funcons ........................................................................................................................... 34

8.5. Events messaging ................................................................................................................................... 39

9. DETECTOR MAINTENANCE AND CHECKS ................................................................................................................... 40

9.1. Check aer installaon .......................................................................................................................... 40

9.2. Maintenance .......................................................................................................................................... 40

9.3. Addional checks .................................................................................................................................. 41

9.4. Resoluon of main problems ................................................................................................................ 42

10. TECHNICAL DETAILS ................................................................................................................................................. 43

10.1. Maximum current draw ....................................................................................................................... 43

10.2. Operang characteriscs ..................................................................................................................... 43

10.3. Mechanical characteriscs .................................................................................................................. 43

E N G L I S H

SETRONIC Verona 3

E N G L I S H

1. GE NE R AL PR O DU C T I NF ORM AT I O N

1. 1 C O N T E N TS O F P A C K A G I N G

AC C E S S O R I E S A V A I L AB L E O N R E Q U ES T

REFLECTIVE UNIT

4K40

FOR DISTANCES FROM 81m TO 100m

STAINLESS STEEL BRACKET

SACA-G

FOR TRx UNIT

TRx UNIT

TRx-OZ

CONTROLLER UNIT

CSRLS-OZ

REFLECTIVE UNIT

SMK

FOR DISTANCE FROM 5m TO 80m

INSTRUCTION MA-

NUAL

ALLEN KEY

PACKAGE

4SETRONIC Verona

1. 2 G E N E RA L C H A R A C T E R I S TI C S

D e t ec t or wi th p lan n i n g, t e ch n olo gy , d e si gn and ma nuf a ct ur e al l

wh o lly m a d e in Ita ly

Fo r use in a ny in du st r ia l or c ivi l en viro n m ent

Ex treme ea se o f ins t alla on a n d p ro gra mm in g

Cab lin g req u ired onl y fo r th e TRx un it

Ve ry lo w, a s semb ly , c ab lin g, an d m ain t en an c e c ost s

Th e d et e ct o r ma y b e i n s tal l ed h oriz on tal ly o r v er c ally a nd can

wo rk at a ny an g le

In t egr a t ed dia p hra g m th at can b e v ario u sly a dj uste d (on th e

TR x u n i t )

Co n t ro l Uni t fo r pr o gr a m m in g , ca li b r a o n a n d th e p e r f o r m a n ce of

re mo te b ea m d et e c tor t e sng w ith t h e po ssib il i t y o f:

S et -up fo r spec i c b e a m de t e ct o r for I L IA -OZ

On si t e in s tall a on at h um an h e i ght

Alarm an d fa ult o u tpu t s

Pa s swo rd ac c e ss to p r o g ra mm in g k eyb o a rd

Re s e a b l e by key b o ard an d /or con t r ol a nd in d i ca n g

eq u ip men t ( C I E)

Se c u rin g Base sep a r at el y in stal l ab l e f r o m t h e d et ec t or t o ma k e pr e -

ca b l in g po s si b l e

P lu g -in co n n e co n b et w e en d et ec t or a n d b ase

Sp ec ial Key for ha n d align m en t, di aph r a g m regul a o n , op e ning an d

clo s in g o f b a se an d c o n t rol u nit

E N G L I S H

SETRONIC Verona 5

1. 3 P R O D U C T C H A R A C T E R I S T I CS

Sy stem con t e nt:

T ra n s mi er -Rec ei v e r Un i t ( T Rx)

SM K r e e c v e unit wit h s w i ve l c onn ec on, for dist a nces

up to 8 0 m

C SR L S -OZ c ont r o l un it

Ad ju st er wr e nch

4K 40 re ecve u n it fo r d i sta n c es up t o 10 0 m, a v a il a b l e on

r eq u es t

EN 54 -1 2 st a nd ard

Prot ec on r ang IP 65

Ro H S co mpa b ili t y

Me ch a n ical pa rt s ma de of PPE +P S hi gh res i sta n c e s hoc k -p ro o f

th e rmo p l a s c s

Co mp le t e d i r eco na l s tabi lity o ver me

Op era n g d i stan c e 5÷8 0 wit h SM K , 8 1 ÷100 m with 4K4 0

Conn ec on t o 4 c on duc t or c a b l es o n R S 4 8 5 se ri a l bus

Ad ju st a ble sen sivi ty t h resh o ld selectab l e fr o m a wid e ran ge

us ing t h e C S RL S -O Z c o n t rol u ni t

A ut o -adj u st m ent t hres h old

Alarm t e st fun c on

Ma in te n an ce req u e st sign al

Au toma c d et ecto r rese t o n i n t err u p on o f in fr are d b ea m

Ou tpu t f aul t rela y d e la y u p t o 90 s eco nd s

A ut o -tes ng o f cor r e ct RS48 5 co mm uni c a on

Po wer sup p l y 2 4 V DC

1. 4 D ES C R I P T I O N O F S Y S T E M

Th e TR x uni t ha s a lt e r, m echan i cally a d j u stab l e ex t er n a ll y , th a t

ca n b e u s ed to r e so l ve e n vi r on m en t a l p ro b lems , in p a r cul a r

re gar d in g the arc h itectural sp ace, in th e pr e s en c e of fa l se

re econ s or if th e D e t ec t o r ha s t o w ork in o p c ally l i m it ed sp a c e s.

Th e D et ec tor' s c onnec on s a r e car ried o ut at t h e wa ll fa st e n ed

ba s e, whic h ha s a p lu g -in con n e cto r . Th i s me an s a ny n e c ess ary

ca blin g can be ca rr i e d out at the me of wir i n g wit hou t ha vin g to

E N G L I S H

6SETRONIC Verona

le ave th e d et e ct o r i n sta l l ed on si t e a nd w or k in g, th u s a vo id in g the

ri sk o f da mage, lo ss of a lig n m en t o r i t gen g di r ty.

Th e CSRLS -O Z con tr o l u n i t i s us ed rem o t ely at grou n d le ve l with

th e d et ec t o r managed vi a a sin g l e s er i a l con n e c on . It ca n

th e ref o r e be in st a lled dir ectl y on sit e wit h a l l oper a o n s c arri ed

ou t th er e si mp ly and e ec v el y wi tho ut ha v in g to do so at he igh t

ex c ep t for th e a ctu al secu r in g and r st a li g n m e nt o f t h e d et e ct o r .

It i s mad e up o f a pl a s c c on tain e r wi th a 5 -func o n k ey k ey b oa rd

an d ba c klit disp l ay o f 16 char a ct er s on 2 lin e s.

En t eri n g y ou r p a s s wo r d , the sy ste m set -up me n u c an be us ed to

pr ogr a m t h e d ev ices fr o m th e sa fety of th e groun d, to s et th e

si gn a l lev e ls and thresh o ld s o f i n t er v en o n , chec k e n vi r o n m en t a l

in t er fer en c e s and ala r m thr esh olds , te st p ro p e r w o rk in g t erms of

fau lt c ond i on s and a larm and t o ca r ry o u t a r e s et .

Th e p a s swo r d c an b e s et by f ollo win g t h e pro g ramming menu

in str u c on s ( se e pag e 3 8) .

Th ere i s a n alar m an d fau l t / ma i n t en a n c e r e qu est r el a y in th e

co ntro l unit . Th e m essa g e s o n sy st e m work i n g st atu s a r e c lear l y

in dica t ed on t h e d i sp l a y a n d a r e r e p ea t ed by t h e c orres p on d ing

front LE Ds .

Th e fa u lt r e lay can be set a s N C o r NO an d med wit h t h e con t ro l

un it menu.

An y c o mm uni c a on br eak d o wn be t w een th e co ntr o l u n i t a n d the

de t e ct or is i m me d ia te l y sig n all ed by s i mu ltaneo u s a sh in g o f th e

yello w and green L E D s o n t h e o n -sit e u n i t w it h a c o m mu n i c ao n

er ror a l so sho wn a u t om a cally on t h e d is p la y , as i s an y

in t er ce pon o f th e be a m.

De tect o r re s et c an ta k e pla c e i n d i e r ent ways: by m ean s o f th e

p as swo r d -prot ect ed menu , b y s wit c hin g o power to th e s y st e m fo r

a c oup le o f seco nd s o r by c lo s i ng by m ea n s of a d ed i c ated N O in p u t

co nta c t in t he c o ntr o l u ni t.

Th e co n n ecn g ca b l e s mu st h a v e t h e th ick nes s e s i ndi c ated i n

cu rren t r egu lao n s , th a t i s t o say a m ini mu m se c o n o f 0.5 s q mm.

Fo r th e t y p e of cab l e to us e, r efer to c urre n t n a on a l st a n d ard .

1. 5 H O W I T W OR K S

E N G L I S H

SETRONIC Verona 7

In th e TR x u n i t th e T r an smi er emit s tw o mo du la t ed 1 KH z in f rar e d

light b ea ms a s two c o nes wh ich c ro ss h e en viro n m en t t o b e

mon ito r e d. Th e s e be a m s re a ch th e r e e c t or un l and are

tr an smi ed ba ck to th e R e c eive r. The cro ssing of th e en viro n m ent

by th e t wo in f r ared bea m s me an s all th a t ha p p en s b et w een ca n be

mon ito r e d a s t h e info r ma o n is c o n n uo u sly re cei v ed that co u ld

in dica t e t h e st a r t o f a r e .

Th is o ccu r s b y mean s of o p c al d em o d ula o n o f t h e i n fra r e d

fr eq u en cy ca rrie r, in bot h freq u en c y an d amp l it u d e , and

mi crop ro c essor man ag e r t hat rec e i ves t h e i n forma on n e c es s ary to

de t e ct t he st a rt o f a r e disn gu is hin g t his in f orma on f r o m th a t

of a n ob st a c le o r a w eak e ning o f s ignal due to d i r t o n th e op c s .

Th e stat u s o f th e d et ec on i s sen t b y th e TR x t o th e co n t rol u n i t by

me an s o f th e R S485 lin e and i t is t here mad e a v aila ble by t w o clean

co nta c t s (ala r m and fau lt) th a t c an be ma n aged b y a c e nt ra l

si gn a l l in g a n d con t r o l s ign a l u n it . The sy st em ’ s wo rkin g sta t u s is

in dica t ed on th e co n tr ol un i t by th e di sp la y an d re p ea t ed on t he

LE D s o n t h e d et e ct or.

E N G L I S H

8SETRONIC Verona

2. INS TAL LAT I O N O F TH E D ETE C TOR

2. 1 P OS I TI O N I N G

Select a suitable posion for the installaon of the TRx and the Reector such that

there are no visible obstacles between them. Remember that the system funcons

according to principle of a reducon in the infrared beam, so it is therefore

necessary that:

In the TRx-Reector distance there must be an obstacle-free area of at

least 1 sq m;

There are no reecng surfaces on the Reector side, such as glazing or

translucent surfaces.

If there were any obstacle breaking or crossing the infrared beam for long

periods, then the posioning is not suitable.

Please note that for both TRx and reector mounng, it is important to ensure that

the mounng surface is solid (such as a wall) so that the detector alignment

remains stable and does not have to be installed on a surface with connuous and /

or strong vibraons.

The ILIA-OZ detector should not be installed in the following places:

In open spaces where there is no roof covering or ceiling;

Places exposed to direct sunlight (intensity > 5000 lux);

In damp spaces where condensaon forms, or in acid atmospheres.

N.B. For proper installaon in relaon to heights, coverage types, ceiling

distances and xed obstacles refer to the naonal standard.

E N G L I S H

SETRONIC Verona 9

C L O S I N G B U T T O N

2. 2 O P E N I N G T H E D E T E C T OR

Use the Allen key provided by Setronic to open the detector.

The detector is mounted on the base with two fastening buons.

The detector can be opened by twisng the fastener buons and liing the

detector boy upwards to free it from the base.

D E T E C T O R B O D Y

B A S E

E N G L I S H

10 SETRONIC Verona

2. 3 I N S TAL L AT I O N PR OC E D URE

I MP O R T AN T : To en su re th e IP 65 ra n g is r e t a i n e d a t t h e

se cu rin g b as e, mak e sur e you ca n in st a l l th e d e tecto r on a

a t su rfac e. I f th i s i s no t po s s ibl e us e a suppor t o r th e

SA C A -G bra c k et wh ic h is a vai l abl e on r equ es t .

Mo unt t h e ba se o n th e wa lls or su itab l e su r f ace, usi n g t h e 4 sc r e w s

in sert ed in th e fast en in g hole s .

Avoi d mak i ng h oles oth er th an i n t h o se p ro vid ed.

C A B L E G L A N D

F A S T E N I N G H O L E

CABLE PASS

B A S E

TERMINAL SOCKET

CABLE PASS

P R O T E C T I V E C A P

E N G L I S H

SETRONIC Verona 11

2. 4 DET ECT OR C A BL I N G

Us e a 4 -wire ca b l e o f a seco n o f 0.5 sq mm to 1 . 5 s q mm wit h a

ma ximu m ex te rna l di a me t er o f 8 m m .

Ei th er one o f t h e t w o term ina l so ck ets c an b e u sed.

Re m o ve t h e p r otec v e ca p f ro m on e o f t h e t w o g la n d s an d f e ed

in th e ca b l e .

Thread th e cab le so it c o mes ou t th e o th er s ide t o a b o u t 20 cm.

Remove a b o ut 5 cm o f the out er in sul a on an d conn ect to th e

termin a l b o x .

No te th e co lour a n d m a rki n g on th e in d i v id ua l wi r e s wit h resp ect

to th e sy mb o l s on th e b oar d (+, A, B , -).

Se cu re ly g h t en th e s crews at th e t er m in a l and dr a w back e x c e ss

ca ble t o wa r d s t h e o u t si de o f t h e e q u ip me nt .

Ti gh t en we l l t h e h e ad o f t he ca b l e gl and a n d c ut th e pla sc

sp lin e at th e c abl e outle t.

E N G L I S H

12 SETRONIC Verona

D E T E C T O R B O D Y

B A S E

R J 4 5 C O N N E C T O R

2. 5 C L OSIN G T H E DE T EC T O R

Mo v e t h e d e t e ct o r b o d y up to t h e se curin g ba s e .

In sert t h e R J 4 5 c o nn e ct or in to th e so ck et on ba se on th e

termin a l so c k et boar d .

Th e co nn e ct or sh all b e cor r ectly sea ted w h en yo u h ear a cl i ck.

Arr an g e th e ca b les so t h ey cannot be p i nche d on th e

clo su r e of th e d etect o r.

Fa st e n t h e bo dy of th e det e cto r to th e base an d cl o s e.

Turn t h e t w o fast eni n g bu o n s t o ens u r e i t i s p r oper ly c lo sed .

S O C K E T

E N G L I S H

SETRONIC Verona 13

3. DIAPHRA GM ADJUSTMENT

In s id e th e ILIA -O Z det e ct o r th er e i s 6 -pos i on di aph r a g m ( fu ll y

op en, fu l ly c lo sed ) t h a t c an b e us ed if th ere are op c al

pr obl e m s i n t h e p rot ec t ed en vi r on men t, s uch as th e pr e se n c e o f

di r ec t ligh t o r fal s e r e eco n s .

Th e d ia p h ragm p e r mi t s sho r t d i st an c e a d j u st me n ts fo r th e i n f rar ed

be a m to pa s s t hr ou gh nar row sp a c es or to limi t th e angle of view

of t he r ec e i vi n g l e n s .

To re gu la t e th e diap h r a gm u se th e Allen key pr o vid ed by Set r onic

to t u rn th e nu mb ered rin g at the rear o f the d et e ct o r ( s e e

fo llo w i ng p age).

It is an ad va n tage fo r th e in s t alla on to pro v i d e imme diat e ly fo r

an y p o s sib l e nee d f o r use of t h e di aph ra g m, ta ki n g i n t o a c cou n t

ab o ve all th e min imu m a n d m a ximu m o p er a n g d ista n ces, wher e

th e la e r is r edu ce d b y th e lt er, and p r e f er a b l y c h o o si n g a "h i g h"

po s i o n to re d uce to a m in im u m th e in ue n c e o f int er f eren c e s

fro m t h e l o cal e n vi r on m en t .

E N G L I S H

14 SETRONIC Verona

Distance min/max with SMK, Distance min/max with 4K4 0

I N S E R T I N G K E Y T U R N C L O C K W I S E

3. DIAPHRAGM ADJUSTMENT

E N G L I S H

SETRONIC Verona 15

For in stall a o n s gr ea t er than t h ese, th e re is a plat e ava ilab l e on

requ es t co n s i sn g o f 4 re e cto r s (4K 4 0)

To aa ch th e pl ate 4K 4 0 plat e to th e wa l ls ju s t se cu r e th e fou r

sc r e ws th r o u g h t h e h o l e s.

4. INSTALLATION OF REFLEC TIVE UNI T

Th e IL IA -O Z dete c t or c o m es w ith a re ecto r on a swi v el mo un t

(S MK) so as t o c o ver a d is ta n c e o f 5m t o 80 m .

To a x t h e SM K t o a wal l y ou n e e d on ly t wo sc r e w s th r ou gh th e

ho l e s r ea d y for it s s ecu r i ng.

If th e in st a l la on i s no t on a pe r fect ax is wit h the TR x un i t th e

re ect o r in c l in a on ca n be ad ju st ed wit h t h e two r egu l ato r

sc r e ws.

S H I F T S C R E W S

F A S T E N I N G H O L E

F A S T E N I N G H O L E

E N G L I S H

16 SETRONIC Verona

C L O S I N G B U T T O N

B A S E

C O V E R

5. IN ST ALLATI ON OF T HE CONTROL UNIT

5. 1. O P EN IN G THE CONT R O L U N I T

Us e th e A l len k ey pro vid ed by Se t ron i c t o op en t h e co ntro l un i t .

Th e contr o l un it c o n si s t s of a c o ver co nta i nin g th e el ectr on ic

pa rt s and a b a se f or s ecu r in g th e unit .

Th e uni t ca n b e o p ened b y twis n g th e fa sten er b uon s an d

li in g th e cove r up to f r e e i t fro m the s ecu r ing b a s e.

E N G L I S H

SETRONIC Verona 17

5. 2 SEC UR I NG T H E CON TR OL UN IT

Th e con t rol u n it ma y b e x ed to a w a ll o r o th e r su p p o rt su r fac e b y

me an s o f th e fo u r n g s o n the f a st e n ing b a s e.

Th ere ar e so m e b r ea k -in ho l e s for th e cab l in g req u ired fo r t h e

co nn ec o n t o th e d etec t or and t h e co nt ro l and sign a l u n i t.

Th e c ontro l u nit co n t a in e r h a s, a s su p p lied , a pr otec on

ra ng of IP6 5. If it is nec e s sa ry to ma int a in t h i s pr ot eco n

ra ng, i t i s th e t a sk of th e in st a ller t o e n su r e t he se a l s a re

in pl a c e, bot h fo r the s cr e w holes an d th e c a ble passag e

po int s.

P R E D I S P O S I T I O N F O R C A B L E S

P A S S I N G

P R E D I S P O S I T I O N F O R F A S T E N I N G

B A S E

E N G L I S H

18 SETRONIC Verona

T O R E S E T C O N T A C T

T O C I E / M O D U L E

T O D E T E C T O R

T O P O W E R S U P P L Y

5. 3 C O N TR O L UN I T C AB L IN G

On t h e c on tro l u n it co ver t h e r e is a n el ectr o n ic bo a rd with t h e

termin a l b ox e s to be wi r ed u p t o co n n e ct th e ext e rn al po w er

supp ly un it ( PS U ) to th e con tr o l a n d in d i ca n g eq u i p me n t ( CI E) , or

an ad d r e ssin g mo d ule, a n d t o t h e det e ctor ( TRx) .

Th ere i s a l so a r e s et m o d ule (MRS ) t h a t can b e co n n ected to an N O

co nta c t for r ese n g t h e d et ec tor i n a l arm mod e. To r e set th e

de t e ct or sw it ch o c on t a ct for at lea st 3 sec o nd s.

E N G L I S H

SETRONIC Verona 19

5. 4 C L OSIN G T H E CON TR OL UN I T

Tak e th e co v er o th e co nt ro l un i t and tak e it to th e fa st en in g

ba s e.

Ch ec k th a t th e ex t ra ct a b le t ermin al b o x es a r e p r op er ly in pl a c e.

Arr an g e th e cab lin g so n o wi res a r e p in ch ed b y t h e ed g e s o f

th e con tai n e r.

Put th e co v er on th e fa sten i ng ba s e an d clos e it. Turn th e

two f a st en in g bu o n s t o en sure i t i s p r op er ly cl o se d .

C L O S I N G B U T T O N

B A S E

C O V E R

E N G L I S H

20 SETRONIC Verona

D E T E C T O R

0 , 5 ÷ 1 , 5 m m 2

0 , 5 ÷ 1 , 5 m m 2

0 , 5 ÷ 1 , 5 m m 2

0 , 5 ÷ 1 , 5 m m 2

0 , 5 ÷ 2 , 5 m m 2

0 , 5 ÷ 2 , 5 m m 2

0 , 5 ÷ 2 , 5 m m 2

0 , 5 ÷ 2 , 5 m m 2

0 , 5 m m 2

0 , 5 m m 2

0 , 5 m m 2

0 , 5 m m 2

C O N T R O L L E R

6. CABLING

6. 1 C H O I C E O F C AB L E

Fo r the ca b ling b et w een t h e Con tro l u ni t an d th e D et ec t or an d

be t w een t he Con t r ol uni t an d the CIE, us e a cab l e cer ed

ac cor d i ng t o n a o nal s t and a rd.

Th e g ure sh ows t h e min i mu m and max i mu m seco n s u s eab l e f o r

th e in d ivi dual st re t ches o f c ab li n g.

Fo r t h e c on necon b et w een t h e Co nt ro l un i t a n d t h e De t ec t or a l so

us e a cab le wi t h th e fo ll o win g ch a ra ct e r i s c s:

Ma x i mu m cap a cit y : 10 0 nF/ k m

Ma x i mu m resi sta n c e: 5 0 Oh m /k m

Ma x i mu m ext e rnal dia m eter : 8 m m

E N G L I S H

Table of contents

Other SETRONIC VERONA Security Sensor manuals

Popular Security Sensor manuals by other brands

B.E.G.

B.E.G. LUXOMAT PD4-M-DIM-Corridor Series Installation and operating instruction

PCB Piezotronics

PCB Piezotronics 301A10 Installation and operating manual

UEi

UEi CO95 instruction manual

SainSmart

SainSmart ToolPAC SMA19 user manual

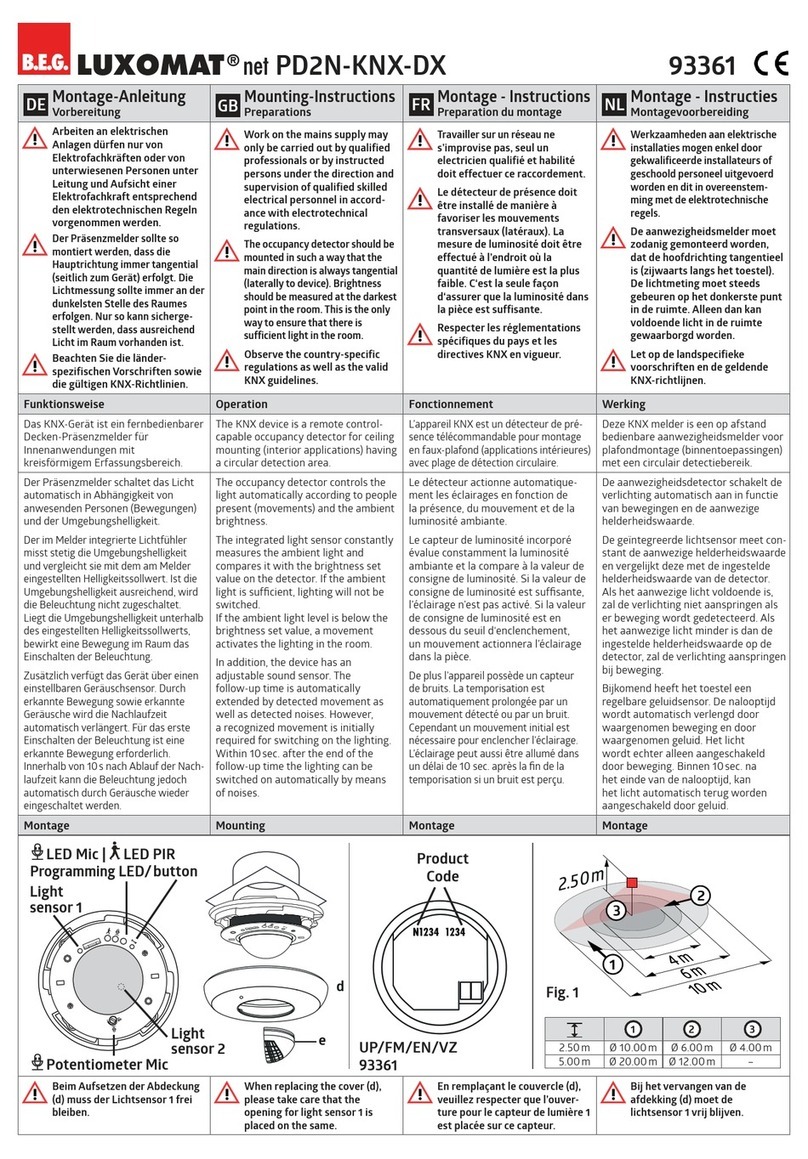

B.E.G. LUXOMAT

B.E.G. LUXOMAT PD2N-KNX-DX Mounting instructions

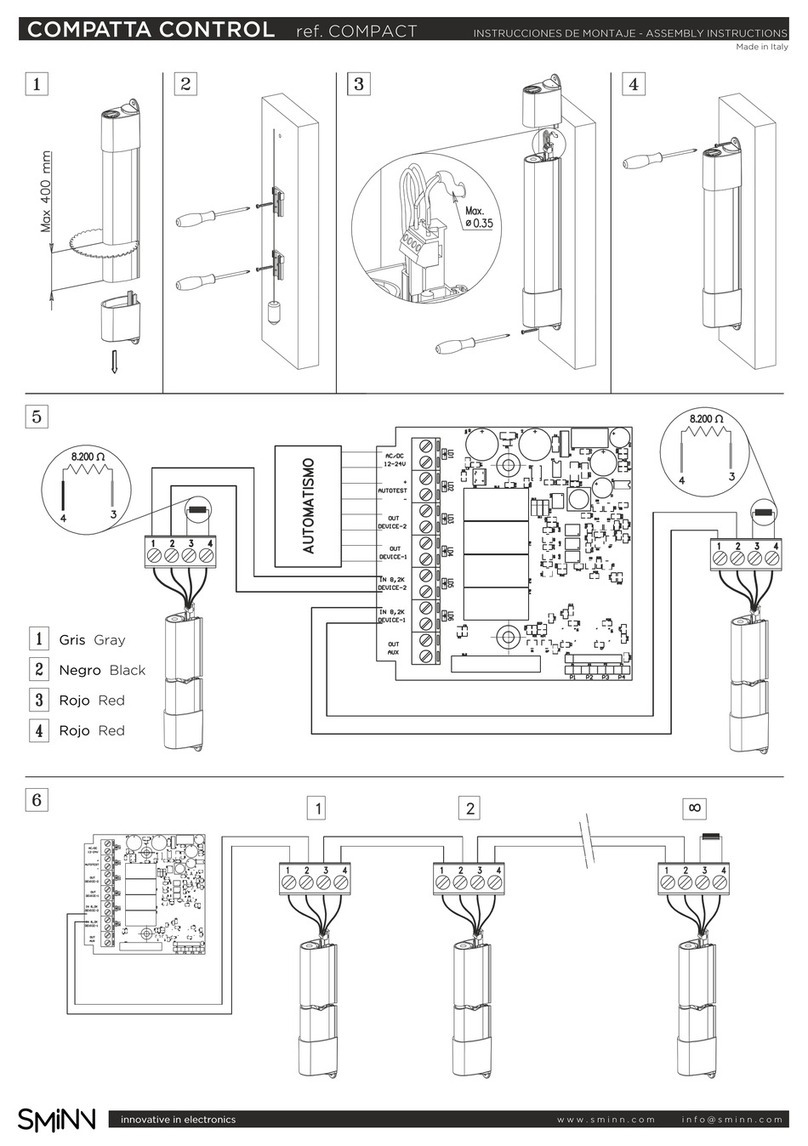

Sminn

Sminn COMPATTA CONTROL Assembly instructions