SETRONIC VERONA ILIA ERHSO712 User manual

EN 54-12 Costruito in conformità con la Norma Europea

Built in compliance with European standard

Erfüllt die Europäische Norm

Certificazione CE

CE Certification

CE Zertifizierung

0786-CPR-20925

Riferimenti normativi - Reference regulations - Vorschriften normen

SETRONIC Verona

Prodotto secondo la norma di rispetto ambientale

Manufactured in accordance with the regulations and

respect for the environment as in

Produktion im Einklang mit allen gültigen Umweltschutzbestimmungen

2002/96/CE

01111 Certificazione russa

Russian certificate

Russisches Zertifikat

II

Certificazione VdS

VdS certification

VdS Zertifizierung

n° G209195

EN 54-17 Costruito in conformità con la Norma Europea

Built in compliance with European standard

Erfüllt die Europäische Norm

ENGLISH MANUAL

CONTENTS

mod. ERHSO712 (Transmitter-Receiver version)

Basic characteristics.....................................................51

Product characteristics...................................................51

System description......................................................52

Working Principle.......................................................53

Calibration and assembly procedure........................................54

Main calibration procedures...............................................55

Procedure for further adjustment...........................................56

Technical features ......................................................57

Setting of diaphragm ....................................................58

mod. ERRHSO712 (Reflection version)

Basic characteristics.....................................................60

Product characteristics...................................................60

System description......................................................61

Working Principle.......................................................62

Calibration and assembly procedure........................................63

Main calibration procedures...............................................64

Procedure for further adjustment...........................................65

Technical features ......................................................66

Setting of diaphragm ....................................................67

CONTROLLER mod. CSRLS / mod. CSRLS - Dust

Display message and programming step. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

1. Menu access protect by password.....................................69

2. Sensibility Setting..................................................69

3. Modify of Transmitter level and check of the signal level received . . . . . . . . . . . . . . . . 70

4. Auto calibration of Transmitter level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

5. Alarm Auto test....................................................73

6. Alarm Reset.......................................................74

7. System Configuration...............................................74

8. Modify of the password for menu access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

9. Display messages for events .........................................76

Choose the right cable...................................................78

Caution for installation...................................................78

Parameter of simple «autonomous» isolator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Socket circuit with protection..............................................79

Dip-switch for the address of the smoke beam detectors . . . . . . . . . . . . . . . . . . . . . . . . 79

Typical connection to a conventional control panel with end line resistor . . . . . . . . . . . . 80

Typical connection to an addresable control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Connection to MRS reset module ..........................................82

Typical of possible connections............................................83

BEAM DETECTOR ILIA MAINTENANCE AND CONTROL 86

ADDITIONAL CONTROLS 86

TROUBLE SHOOTING 87

ENGLISHENGLISH

Mod. MII rev. 01 SETRONIC Verona 49

HIGH SENSITIVITY

LINEAR BEAM DETECTOR

MODEL ERHS0712

ENGLISH

50 Mod. MII rev. 01

SETRONIC Verona

TRANSMITTER - RECEIVER VERSION

Basic characteristics

Ÿ Detector: Project, Technology, Design and Production fully made in Italy

Ÿ Suitable for use in all civil and industrial premises

Ÿ Very easy to install and program

Ÿ Low cost for mounting, cabling and maintenance

Ÿ The Detector can be installed horizontally or vertically and can work at any angle

Ÿ Micrometric adjustment for alignment

Ÿ Integrated diaphragm with a wide range of adjustment

Ÿ Control Unit for programming, calibration and performing of remote test on line

beam detectors.

Ø Basic configuration for two Detectors even of different types

Transmitter/Receiver or Reflection

Ø Expansion board for connection up to 3 to 8 detectors and line loop closure

(optional)

Ø Ground level installation for the Control Unit

Ø Alarm and Fault outputs can be programmed for each individual detector

Ø Operational access to keyboard protected by password

Ø Control Unit or Control Panel reset facility or by the MRS module

Ÿ Base

Ø Plug-in base to detector connection

Ø Base complete with back up board short circuit isolator to ensure continued

work even after a short circuit

Ÿ Special Allen Key suitable for mechanical alignment, diaphragm regulation, unhook of

detector base and open/close of control unit

Product characteristics

Ÿ Standard EN 54-12

Ÿ Protection rating IP65 (Transmitter Unit, Receiver Unit and Controller Unit)

Ÿ RoHS Compatibility

Ÿ Operating distance 10 ÷ 200 m for Tx/Rx model

Ÿ Width of cover up to 15 m

Ÿ Connections to 4 serial line conductor RS485

Ÿ Local and remote maintenance request

Ÿ Automatic threshold compensation

Ÿ Angle misalignment ± 1degree max

Ÿ Complete directional stability over time

Ÿ Sensitivity adjustable and selectable over a wide range, using the control unit model CSRLS

Ÿ Automatic reset of detector after break in infrared beam

Ÿ Self tester for RS485 communication

Ÿ Fault relay output delayed up to 90 seconds

Ÿ Power supply 24 V DC

Ÿ It is available, on request, the Control unit model CSRLS in the DUST version, with special

thresholds applicable in critical environments characterised by high levels of dust, steam or

other vapours

ENGLISH

Mod. MII rev. 01 SETRONIC Verona 51

SYSTEM DESCRIPTION

The ILIA MODEL ERHS0712 detector consists of a Transmitter Unit, a Receiver

Unit and a Beam Controller Unit for programming, setting and testing. The Beam

Controller Unit is used to remotely manage the detector or detectors in the field

using a single line. The Beam Controller Unit is put at a place on ground level from

where the detector can be controlled without having to climb up to the detector, as

regards all normal operations. The Beam Controller Unit is made of plastic, has a

keyboard for programming and a backlight 16x2 display.

By entering a password of 4 digits you can program the system from ground level to

determine the detector's signal level, to check environmental disturbances, to set

the required thresholds based on these and to check the alarm threshold; the

default password FFFF can be changed by the programmer by following the

instructions in the remote programming menu.

The system configuration menu becomes available when you just touch any of

the 5 buttons on the keyboard and by then entering the default password FFFF on

the first programming session, customising the password from then on (the

password can be reset if lost or forgotten by use of the beam controller Unit reset

hardware).

The Beam Controller Unit electronic base permits direct connection of two detector

units; by means of an expansion circuit (SMLS), it is able to pilot up to 8 detectors

connected together and a connection with two stub lines or by a closed loop. With

this second typology the system continue proper working even if the cables are cut

or in the case of a short circuit by the protection circuit inserted in each single

detector. There are also programmable relay contacts in the Unit for each

individual detector connected. These relays can have their polarity reversed with

the use of the software and permit the transmission to a single central unit of the

individual alarm, fault and maintenance request signals. Any breakdown in

communication between Beam Controller Unit and the detectors connected to it

will be immediately signalled by the simultaneous flashing of the yellow Led and

the green Led on the Transmitter and the Receiver, as well as being indicated on

the display of the Beam Controller Unit itself.

The controller is also available in the Dust version (CSRLS-2-DUST), suited to

very difficult environments, using special VdS certified software that enables the

detection threshold to be calculated up to the maximum limit permitted by standard

EN54-12 without losing the principal characteristics of this model: producing early

detection in any environment.

ILIA with the Dust version controller has already come successfully through lab and

environmental real scale fire testing; these tests have shown that the model's

detection ability assures early alarm in any environment, overcoming unfavourable

conditions that could give rise to false or to fault alarms.

ILIA with the Dust version controller is thus a highly reliable response to the needs

of problematic environments with dust, steam, fumes or particular working

processes where other technologies are unable to assure the required security

and accurate and precise detection.

ENGLISH

52 Mod. MII rev. 01

SETRONIC Verona

The working voltage of the equipment is between 12 and 24 Volts without switching

(± 20%). The Transmitter Unit emits a beam of modulated infrared light at 1 KHz in

the form of a cone which crosses the space under surveillance to reach the

Receiver Unit. As the modulated infrared crosses the environment under

surveillance, it collects along its path all information that could suggest the start of a

fire. The events that intervene between Transmitter and Receiver affect the

infrared carrier, alternatively optically modulating it in frequency and in amplitude.

WORKING PRINCIPLE

The Receiver Unit demodulating from the infrared received the information that is

optically gathered, transforms each symptom of a possible fire into corresponding

electrical signals referable to “smoke”.

Such signals are electronically assessed by means of a special algorithm local to

the Receiver Unit, and are transmitted to the Beam Controller Unit. All the units

have a microcontroller that carries out a full scan of the working mode, i.e. not only

of the alarm, but also of faults, blinding and maintenance requests. The messages

are clearly given on the display and repeated by the four leds on the Unit, as well as

with the local led's on every individual piece of equipment. A message on the

display will indicate the type of event and the detector number.

NOTE: The Dip-Switch must always be used during installation to

determine the detector address number, also if is there only

one detector. In the loop configuration the Dip-Switch 4 must

stay in the «OFF» position.

The connection of one or more detectors is with leads of a minimum cross-section,

2

in accordance with current regulations, of 0.5 mm . For the type of cable to use

please refer to current regulations; it is not necessary to use shielded cable.

The detection of the start of a fire will mean information is sent from the field

(detector) to the Beam Controller Unit which will in turn send an alarm signal to a

central control unit. System resetting is possible both from the Beam Controller

with a dedicated command or from the central control unit or closing, by a normally

open contact, the two terminal blocks of the MRS module.

The Beam Controller Unit can be used to set the blinding fault relay switching delay

for every individual detector, for times from 0 to 90 seconds.

The Receiving Unit (RX) has an internal diaphragm that means it is possible,

following the instruction to mechanically set for the use of a diaphragm filter, to

solve environmental problems in particular architectural situation where there are

awkward reflections or the optical beam must work in limited spaces or get dirty

before the starting up.

ENGLISH

Mod. MII rev. 01 SETRONIC Verona 53

ASSEMBLY PROCEDURE

NOTE 1: Use the SETRONIC "Allen Key" for the opening and the closing of the detector and the

mechanical alignment of the equipment.

NOTE 2: to grant that the socket maintain the IP65 protection degree, be sure that i twill be fixed in flat

surface. If this it is not possible use a bracket or a swivel.

1. Fix the socket connection of the detector and carry out the wiring of the line (power supply and serial line).

2. Set the address of the detector between 1 and 8 consequently using the Dip-Switch according to the table on page

79. This operation must be done on both unit, so to have the same address on Transmitter and Receiver.

It's suggested to make these operation before the fixing of the socket.

NOTE: The Dip-Switch 4 must be set to ON only in the last socket connected to the line open. It must

also be set with a single detector.

3. Insert the connector plug on the bottom of the detector into the socket until you hear a "click", then lock the unit to

the socket by rotating the hooks with the appropriate Allen key and guide it to the paired device from the opposite.

4. Repeat above operations for all the detectors installed. Verify that the Transmitter and Receiver pair have the

same address.

CONNECTIONS CHECK BEFORE START-UP

(to be made only with the loop configuration)

1. Disconnect the two terminals "power output" and "serial line" of the main module and the two terminals "power

output" and "serial line B" of the expansion module.

2. With a multimeter measure the resistance on the wires, between the positive output of the first power supply and

the positive of the second supply line. Also measure the resistance, always on the wires, between the negative

output of the first power supply and the negative of the second supply line.

3. Both resistance values read, must be less than 100 Ω

4. Reconnect the cables and make sure that the clamps are inserted securely.

CALIBRATION PROCEDURE

1. Power the system via the controller and set the number of detectors connected and the configuration of connection

to serial line. The controller also allows the use of the two serials in an independent manner, as if they were two

separate lines open. In this case, the addresses remain the same from set 1 to 8, but you set the end of the line

(Dip-Switch 4 to ON) of both the last detector.

2. At this point the green led of the two detector units should switch on and you must switch controller, a short flash

confirms the continuous scanning of the line. If on the units is present the condition of led flashing green and yellow

with flashes of about 2 sec., means that there is no serial communication (check the wiring for possible errors or

inversions) or incorrect configuration of the switch address. In such a case please verify: the cabling for possible

mistakes or inversions, the wrong configuration of the address switches (double same number) or the wrong

number of connected detectors (menu system set-up).

3. Point the Transmitter through the Allen key adjustment in order to obtain the led blinking yellow.

4. Starting i.e. from the left to move the unit slowly until the yellow led stops flashing. Then rotate the unit to the right

(the yellow led starts to flash again). Count how many turns of the key are made to obtain the yellow led off to the

opposite side. Reposition the center of movement found by dividing in half the number of revolutions counted. The

yellow led continues to blink.

5. Do the same for the vertical axis.

6. Point the Receiver following the same steps 3, 4, 5.

7. Perform the calibration by the ground controller to follow the menu <Auto Adjust>.

8. Now cover the Transmitter Unit or Receiver Unit with a card or opaque object. When you cover the Unit check that

the yellow led remains continuously on.

ENGLISH

54 Mod. MII rev. 01

SETRONIC Verona

MAIN CALIBRATION PROCEDURES

1. E nter menu

ž from the main screen, press OK;

ž enter the password, using the direction buttons „‚ƒ; press OK;

2. Set up detection lines

ž press „ or ƒ until you get to < System Setup >; press OK;

ž press or ‚ to edit the number of the detection lines; press OK;

ž press or ‚ change the delay time for fault outputs; press OK;

ž press or ‚ change the configuration of fault outputs; press OK;

ž press or ‚ to set the <Com Line> configuration; press OK;

ž press OK to skip debug function.

3. First calibration of the detection lines (after mechanical adjustment of the

detectors)

ž press „ or ƒ until you get to < AUTO Adjust. >; press OK;

ž press or ‚ to change the number of the detection line to be worked on; press OK;

ž wait until the TX value stabilises and press OK;

ž the value of the RX must be about 100% (see note at pag. 72)

ž press OK to confirm the setting.

4. Calibration of detection lines (with the barriers already previously installed)

ž press „ or ƒ until you get to < AUTO Adjust. >; press OK;

ž press or ‚ to change the number of the detection line to be worked on; press OK;

ž wait until the TX value stabilises and press OK;

ž the value of the RX must be about 100% (see note at pag. 72)

ž press OK to confirm the setting.

5. Adjustment of detection line sensitivity

ž press „ or ƒ until you get to < sensitivity >; press OK;

ž press or ‚ to change the number of the detection line to be worked on; press OK;

ž read the Detec value to quantify environmental disturbances;

ž press or ‚ to change the smoke threshold value (the value of the highest

disturbance value seen by Detec shall be less than the threshold setted) ; wait for

2 sec and press OK;

ž read the Detec value to quantify environmental disturbances;

ž press to ‚ change the fire threshold value (the value of the highest

disturbance value seen by Detec shall be less than the threshold setted);

ž wait for 2 sec and press OK to confirm the setting.

ENGLISH

Mod. MII rev. 01 SETRONIC Verona 55

PROCEDURE FOR FURTHER ADJUSTMENT

ž1. Enter menu

ž from the main screen, press OK;

ž enter the password, using the direction buttons „‚ƒ; press OK;

2. Checking the signal and manual adjustment of detection lines

ž press „ orƒ until you get to < adjustment >; press OK;

ž press or ‚ to edit the number of the detection lines; press OK;

ž read the RX signal; it must normally be about 100% (see note at pag. 72);

ž press or ‚ to change the TX value;

ž press OK to confirm the setting.

ž

3. Alarm simulation for detection lines

ž press „ or ƒ until you get to < Alarm Test >; press OK;

ž press or ‚ to edit the number of the detection lines; press OK;

ž press OK to start the alarm testing;

ž wait for the barrier alarm;

ž press OK to reset the barriers (for details about menu see pag. 73);

4. Reset the detection lines alarm

ž press „ or ƒ until you get to < Reset Alarm >; press OK;

ž press OK to reset the alarm;

žIt is possible to reset the alarm also by the MRS module, if connected

(see pag. 82)

5. Change the password for access to the menu

ž press „ or ƒ until you get to <Change password; press OK;

ž enter the new password, using the direction buttons „‚ƒ;

ž press OK to confirm the setting.

ENGLISH

56 Mod. MII rev. 01

SETRONIC Verona

TECHNICAL FEATURES

ILIA High Sensitivity Transmitter / Receiver Linear Beam Detector model ERHS0712

Working temperature -20°/+65° C

Storage temperature -20°/+70° C

Electromagnetic disturbance EMC test up to 30 Volt/m (VdS protocol)

Power supply 2 4V DC ± 20%

Cable type minimum section of 0,5 mm² with 4 wires

type CEI 20-22 (see details on page 78)

Maximum cable length max 1200 m from Control Unit to line detectors

Maximum permitted cover 1600 m² per detector

Width cover max 15 meters

Operating distance from 10 to 200 meters

Angle misalignment ± 1 degree max

Detector protection rating IP65

RAL Colour 5004 black blue

1013 oyster white (on request)

With material PPE+PS HI

RAL Colour 9005 jet black

With material PPE+PS «Noryl» Flame Class V0 selfextinghuishing

Size 162x145x193 mm

Weight Tx Unit 735g, Rx Unit 775g

Beam Controller Unit mod. CSRLS / mod. CSRLS - Dust

Working temperature -20°/+65° C

Storage temperature -20°/+70° C

Power supply 2 4V DC ± 20%

Cable section per output max 0,5 mm²

Maximum cable length Max 1000 m with 1 mm² cable

for power supply to Control Panel

Contact capacity Alarm/Fault optorelay max 150 mA

Connectable detectors 1 to 8

Control Unit protection rating IP65

RAL Colour 5004 black blue

With material PPE+PS HI

RAL Colour 9005 jet black

With material PPE+PS «Noryl» Flame Class V0 selfextinghuishing

Size 177x145x69 mm

Weight 375g

Current absorption

ENGLISH

Mod. MII rev. 01 SETRONIC Verona 57

POWER SUPPLY 24V ± 20%

max 48 mA0

max 50 mA0

max 261 mA

max 270 mA

Stand By

1 DETECTOR CONNECTED

8 DETECTORS CONNECTED

Typical (alarm or fault relay active)

Stand By

Typical (alarm or fault relay actives)

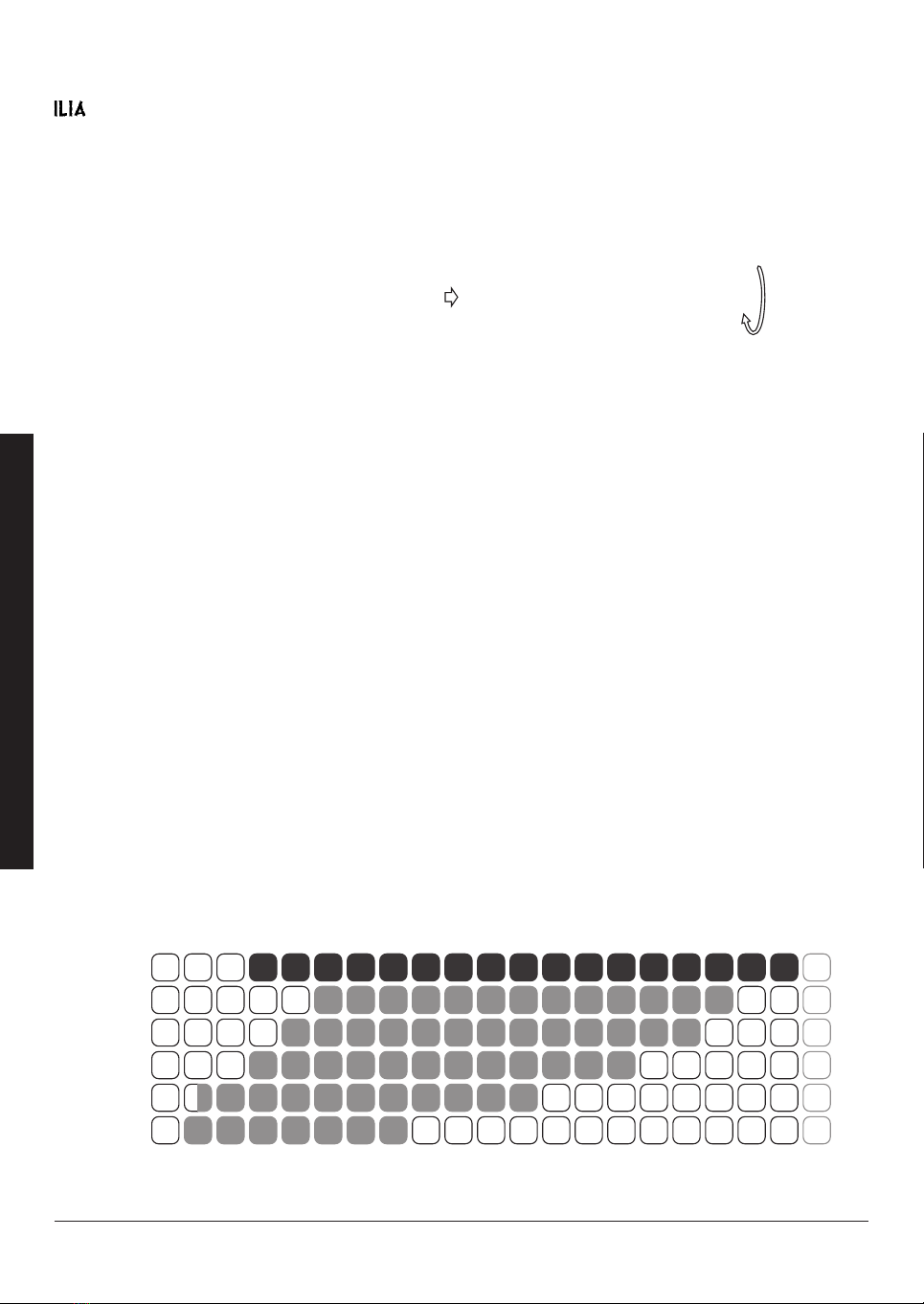

SETTING OF DIAPHRAGM FOR MODEL ERHS0712

has an internal 6 (0 Totally open ÷ 5 max closure) position diaphragm that can be used

where problems arise in the protected environment, for example the presence of direct

sunlight or awkward reflections or flare.

The diaphragm permits short distance adjustments and/or to have the beam pass through

narrow spaces or in any case to limit its size.

Receiver Unit Fix the key Turn clockwise

Diaphragm position 0

Distance from 30 m up to 200 m

Diaphragm position 1

Distance from 50 m up to 180 m

Diaphragm position 2

Distance from 40 m up to 170 m

Diaphragm position 3

Distance from 30 m up to 150 m

Diaphragm position 4

Distance from 15 m up to 120 m

Diaphragm position 5

Distance from 10 m up to 80 m

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 190 200 metri

POS 0

POS 1

POS 2

POS 3

POS 4

POS 5

ENGLISH

58 Mod. MII rev. 01

SETRONIC Verona

HIGH SENSITIVITY REFLECTION

SYSTEM DETECTOR

MODEL ERRHS0712

ENGLISH

Mod. MII rev. 01 SETRONIC Verona 59

REFLECTION VERSION

Basic characteristics

Ÿ Detector: Project, Technology, Design and Production fully made in Italy

Ÿ Suitable for use in all civil and industrial premises

Ÿ Very easy to install and program

Ÿ Low cost for mounting, cabling and maintenance

Ÿ The Detector can be installed horizontally or vertically and can work at any angle

Ÿ Micrometric adjustment for alignment

Ÿ Integrated diaphragm with a wide range of adjustment

Ÿ Control Unit for programming, calibration and performing of remote test on line beam

detectors:

Ø Basic configuration for two Detectors even of different types Transmitter /

Receiver or Reflection

Ø Expansion board for connection up to 3 to 8 detectors and line loop closure

(optional)

Ø Ground level installation for the Control Unit

Ø Alarm and Fault outputs can be programmed for each individual detector

Ø Operational access to keyboard protected by password

Ø Control Unit or Control Panel reset facility or by the MRS module

Ÿ Base

Ø Plug-in base to detector connection

Ø Base complete with back up board short circuit isolator to ensure continued

work even after a short circuit

Ÿ Special Allen Key suitable for mechanical alignment, diaphragm regulation, unhook of

detector base and open/close of control unit

Product characteristics

Ÿ Standard EN 54-12

Ÿ Protection rating IP65 (Transmitter- Receiver Unit, Reflection Unit and Controller Unit)

Ÿ RoHS Compatibility

Ÿ Operating distance 10 ÷ 150 m for Reflection model

Ÿ Width of cover up to 15 m

Ÿ Connections to 4 serial line conductor RS485

Ÿ Local and remote maintenance request

Ÿ Automatic threshold compensation

ŸAngle misalignment: ±1 degree max TRx Unit

±5 degree max Ref Unit

Ÿ Complete directional stability over time

Ÿ Sensitivity adjustable and selectable over a wide range, using the control unit model CSRLS

Ÿ Automatic reset of detector after break in infrared beam

Ÿ Self tester for RS485 communication

Ÿ Fault relay output delayed up to 90 seconds

Ÿ Power supply 24 V DC

Ÿ It is available, on request, the Control unit model CSRLS in the DUST version, with special

thresholds applicable in critical environments characterised by high levels of dust, steam or

other vapours

ENGLISH

60 Mod. MII rev. 01

SETRONIC Verona

SYSTEM DESCRIPTION

The ILIA mod. MODEL ERRHS0712 detector consists of a Transmitter/Receiver

Unit, with a Reflection Unit and a Beam Controller Unit for programming, setting

and testing. The Beam Controller Unit is used to remotely manage the detector or

detectors in the field using a single line. The Beam Controller Unit is put at a place

on ground level from where the detector can be controlled without having to climb

up to the detector, as regards all normal operations. The Beam Controller Unit is

made of plastic, has a keyboard for programming and a backlight 16x2 display.

By entering a password of 4 digits you can program the system from ground level to

determine the detector's signal level, to check environmental disturbances, to set

the required thresholds based on these and to check the alarm threshold; the

default password FFFF can be changed by the programmer by following the

instructions in the remote programming menu.

The system configuration menu becomes available when you just touch any of

the 5 buttons on the keyboard and by then entering the default password FFFF on

the first programming session, customising the password from then on (the

password can be reset if lost or forgotten by use of the Beam Controller Unit's reset

hardware).

The Beam Controller Unit electronic base permits direct connection of two detector

units; by means of an expansion circuit (SMLS), it is able to pilot up to 8 detectors

connected together and a connection with two stub lines or by a closed loop. With

this second typology the system continue proper working even if the cables are cut

or in the case of a short circuit by the protection circuit inserted in each single

detector. There are also programmable relay contacts in the unit for each individual

detector connected. These relays can have their polarity reversed with the use of

the software and permit the transmission to a single central unit of the individual

alarm, fault and maintenance request signals. Any breakdown in communication

between Beam Controller Unit and the detectors connected to it will be

immediately signalled by the simultaneous flashing of the yellow Led and the green

Led on the Transmitter and the Receiver, as well as being indicated on the display

of the Beam Controller Unit itself.

The controller is also available in the Dust version, suited to very difficult

environments, using special VdS certified software that enables the detection

threshold to be calculated up to the maximum limit permitted by standard EN54-12

without losing the principal characteristics of this model: producing early detection

in any environment.

ILIA with the Dust version controller has already come successfully through lab and

environmental real scale fire testing; these tests have shown that the model's

detection ability assures early alarm in any environment, overcoming unfavourable

conditions that could give rise to false or to fault alarms.

ILIA with the Dust version controller is thus a highly reliable response to the needs

of problematic environments with dust, steam, fumes or particular working

processes where other technologies are unable to assure the required security

and accurate and precise detection.

ENGLISH

Mod. MII rev. 01 SETRONIC Verona 61

The working voltage of the equipment is between 12 and 24 Volts without switching

(± 20%). The Transmitter/Receiver Unit emits a beam of modulated infrared light at

1 KHz in the form of a cone which crosses the space under surveillance to reach

the Reflection Unit. As the modulated infrared crosses the environment under

surveillance, it collects along its path all information that could suggest the start of a

fire. The events that intervene between Transmitter/Receiver Unit and Reflection

Unit affect the infrared carrier, alternatively optically modulating it in frequency and

in amplitude.

WORKING PRINCIPLE

The Transmitter/Receiver Unit demodulating from the infrared received the

information that is optically gathered, transforms each symptom of a possible fire

into corresponding electrical signals referable to “smoke”.

Such signals are electronically assessed by means of a special algorithm local to

the Transmitter/Receiver Unit, and are transmitted to the Beam Controller Unit. All

the units have a microcontroller that carries out a full scan of the working mode, i.e.

not only of the alarm, but also of faults, blinding and maintenance requests. The

messages are clearly given on the display and repeated by the four leds on the

Unit, as well as with the local led's on every individual piece of equipment. A

message on the display will indicate the type of event and the detector number.

Note: The Dip-Switch must always be used during installation to

determine the detector address number, also if is there only

one detector. In the loop configuration the Dip-Switch 4 must

stay in the «OFF» position.

The connection of one or more detectors is with leads of a minimum cross-section,

2

in accordance with current regulations, of 0.5 mm . For the type of cable to use

please refer to current regulations. It is not necessary to use shielded cable.

The detection of the start of a fire will mean information is sent from the field

(detector) to the Beam Controller Unit which will in turn send an alarm signal to a

central control unit. System resetting is possible both from the Beam Controller

Unit with a dedicated command or from the central control unit or closing, by a

normally open contact, the two terminal blocks of the MRS module.

The Beam Controller Unit can be used to set the blinding fault relay switching delay

for every individual detector, for times from 0 to 90 seconds.

The Transmitter/Receiver Unit (TRX) has an internal diaphragm that means it is

possible, following the instruction to mechanically set for the use of a diaphragm

filter to solve environmental problems in particular architectural situation where

there are awkward reflections or the optical beam must work in limited spaces or

get dirty before the starting up.

ENGLISH

62 Mod. MII rev. 01

SETRONIC Verona

ENGLISH

Mod. MII rev. 01 SETRONIC Verona 63

ASSEMBLY PROCEDURE

NOTE 1: Use the SETRONIC "Allen Key" for the opening and the closing of the detector and the

mechanical alignment of the equipment.

NOTE 2: to grant that the socket maintain the IP65 protection degree, be sure that i twill be fixed in flat

surface. If this it is not possible use a bracket or a swivel.

1. Fix the socket connection of the detector and carry out the wiring of the line (power supply and serial line).

2. Set the address of the detector between 1 and 8 consequently using the Dip-Switch according to the table on page 79.

It's suggested to make these operation before the fixing of the socket.

NOTE: The Dip-Switch 4 must be set to ON only in the last detector connected to the line open. It must

also be set with a single detector.

3. Insert the connector plug on the bottom of the detector into the socket until you hear a "click", then lock the unit to the

socket by rotating the hooks with the appropriate Allen key and guide it to the paired device from the opposite.

4. Repeat above operations for all the detectors are installed and the units of Reflection (Ref) omitting the part relating

to the connection line.

CONNECTIONS CHECK BEFORE START-UP

(to be made only with the loop configuration)

1. Disconnect the two terminals "power output" and "serial line" of the main module and the two terminals "power

output" and "serial line B" of the expansion module.

2. With a multimeter measure the resistance on the wires, between the positive output of the first power supply and

the positive of the second supply line. Also measure the resistance, always on the wires, between the negative

output of the first power supply and the negative of the second supply line.

3. Both resistance values read, must be less than 100 Ω

4. Reconnect the cables and make sure that the clamps are inserted securely.

CALIBRATION PROCEDURE

1. Power the system via the controller and set the number of detectors connected and the configuration of connection

to serial line. The controller also allows the use of the two serials in an independent manner, as if they were two

separate lines open. In this case, the addresses remain the same from set 1 to 8, but you set the end of the line (Dip-

Switch 4 to ON) of both the last detector.

2. At this point the green led of the two detector units should switch on and you must switch controller, a short flash

confirms the continuous scanning of the line. If on the units is present the condition of led flashing green and yellow

with flashes of about 2 sec., means that there is no serial communication (check the wiring for possible errors or

inversions) or incorrect configuration of the switch address. In such a case please verify: the cabling for possible

mistakes or inversions, the wrong configuration of the address switches (double same number) or the wrong

number of connected detectors (menu system set-up).

3. Point the TRx Unit by Allen key adjustment in order to obtain the led blinking yellow.

4. Starting i.e. from the left to move the unit slowly until the yellow led stops blinking. Then rotate the unit to the right

(the yellow led starts to flash again). Count how many turns of the key are made to obtain the yellow led off to the

opposite side. Reposition the center of movement found by dividing in half the number of revolutions counted. The

yellow led continues to blink.

5. Do the same for the vertical axis.

6. Point the unit of reflection following the same steps 3, 4, 5 and looking LEDs on the TRx Unit.

7. Perform the calibration by the ground controller to follow the menu <Auto Adjust.>.

8. Now cover the Reflection Unit with a card or opaque object. When you cover the Reflection Unit check that the

yellow led on the TRx Unit remains continuously on.

MAIN CALIBRATION PROCEDURES

1. Enter menu:

ž from the main screen, press OK;

ž enter the password, using the direction buttons „‚ƒ; press OK;

2. Set up detection lines:

ž press „ or ƒ until you get to < System Setup >; press OK;

ž press or ‚ to edit the number of the detection lines; press OK;

ž press or ‚ to change the delay time for fault outputs; press OK;

ž press or ‚ to change the configuration of fault outputs; press OK;

ž press or ‚ to set the <Com Line> configuration; press OK;

ž press OK to skip debug function.

3. First calibration of the detection lines (with mechanical adjustment of detectors):

ž press „ or ƒ until you get to < AUTO Adjust. >; press OK;

ž press or ‚ to change the number of the detection line to be worked on; press OK;

ž wait until the TX value stabilises and press OK;

ž the value of the RX must be about 100% (see note at pag. 72)

ž press OK to confirm the setting.

4. Calibration of detection lines (with the detectors already previously installed):

ž press „ or ƒ until you get to < AUTO Adjust. >; press OK;

ž press or ‚ to change the number of the detection line to be worked on; press OK;

ž wait until the TX value stabilises and press OK;

ž the value of the RX must be about 100% (see note at pag. 72)

ž press OK to confirm the setting.

5. Adjustment of detection line sensitivity:

ž press „ or ƒ until you get to < sensitivity >; press OK;

ž press or ‚ to change the number of the detection line to be worked on; press OK;

ž read the Detec value to quantify environmental disturbances;

ž press or ‚ to change the smoke threshold value (the value of the highest

disturbance value seen by Detec shall be less than the threshold setted) ; wait

for 2 sec and press OK;

ž read the Detec value to quantify environmental disturbances;

ž press or ‚ to change the fire threshold value (the value of the highest

disturbance value seen by Detec shall be less than the threshold setted);

ž wait for 2 sec and press OK to confirm the setting.

ENGLISH

64 Mod. MII rev. 01

SETRONIC Verona

This manual suits for next models

1

Table of contents

Other SETRONIC VERONA Security Sensor manuals

Popular Security Sensor manuals by other brands

Major tech

Major tech MT222 instruction manual

Friendtrol Technologies

Friendtrol Technologies TMS PLUS Series manual

Nova

Nova RF Series installation instructions

NETTROTTER

NETTROTTER Ecco freeze quick start guide

EscortRadar

EscortRadar REDLINE 360c quick start guide

Halma

Halma SENSITRON SMART3G-GrI manual