SEWOO LK-P12B User manual

All specifications are subject to change without notice

USER’S MANUAL

MODEL : LK-P12B

SEWOO TECH CO.,LTD.

374-2, Gajang-dong, Osan-si, Gyeonggi-do, 447-210, Korea

TEL : +82-31-459-8200 FAX : +82-31-459-8880

www.miniprinter.com

P12B Rev. B 12/13

1

RISK OF EXPLOSION IF BATTERY IS REPLACED BY AN INCORRECT TYPE.

DISPOSE OF USED BATTERIES ACCORDING TO THE INSTRUCTION

23

Table of Contents

1. Safety Caution

4

2.

Unpacking

6

3. Product overview 7

4. Installation & Usage 8

4-1. Display 8

4-2. Installing the Battery 9

4-3. Removing the Battery 10

4-4. Charging the Battery 11

4-5. Using the Vehicle Charger 12

4-6. Installing Belt Clip 13

4-7. Roll Paper installation 14

4-8. Peel Mode 15

4-9. Shoulder Strap Installation 17

4-10. Diagnostic Test 18

5. Peripherals Connection 20

5-1. Bluetooth Connection 20

5-2. Interface Cable Connection 21

6. Printer Cleaning 22

6-1. PrintHead Cleaning 22

6-2. Platen Roller Cleaning 23

7. Pritner Specication 24

7-1. Specication 24

8. CPCL Command Compatibilit

y

26

9. ESC/POS Command Compatibilit

y

29

10. ZPL Command Compatibilit

y

31

45

WARNING

Failure to follow these instructions could result in re, electric shock,

or other injuries, or property damage

Failure to follow these instructions could result in re, electric shock,

or other injuries, or property damage

(Turn off the power at installation,

transportation, wiring and inspection.)

(You may get hurt and it can be broken

when it falls)

(Potential risk of re or unit malfunction)

(Potential risk of re or unit malfunction)

(Potential risk of discoloration or

electric shock)

(Potential risk unit malfunction, electric

shock or re. When the product needs

to be repaired, please contact in place

where you ordered.inspection.)

Dealer

Do not pull out the power plug to turn off

the product.

Do not install the product in uneven or

inclined surface.

If the product that needs to be repaired,

please contact in place where you ordered.

Please do not give excessive shock.

Keep product away from the water and

other material.

Do not disassemble, repair or modify the

product.

CAUTION

For higher reliability and safety, consider the following precautionary measures.

Read and follow the instructions carefully before running of the product.

1. Safety Caution

WARNING

Failure to follow these instructions could result in re, electric shock,

or other injuries, or property damage

Indication

Prohibition

(Potential risk of electric shock or re)

(Potential risk of electric shock or re) (Potential risk of electric shock or re)

(Potential risk of electric shock or re)

Must follow

Do not disassemble Unplug the power from the

outlet

Grounding to prevent electric

shock

Do not handle the product

with wet hands

Do not pull or touch the power plug with

wet hands.

Do not bend the wire and do not allow the

wire to be pressed by heavy object.

If a power plug is broken or a plug is cut or

worn, do not use it.

Do not overload the power plug into one

outlet.

67

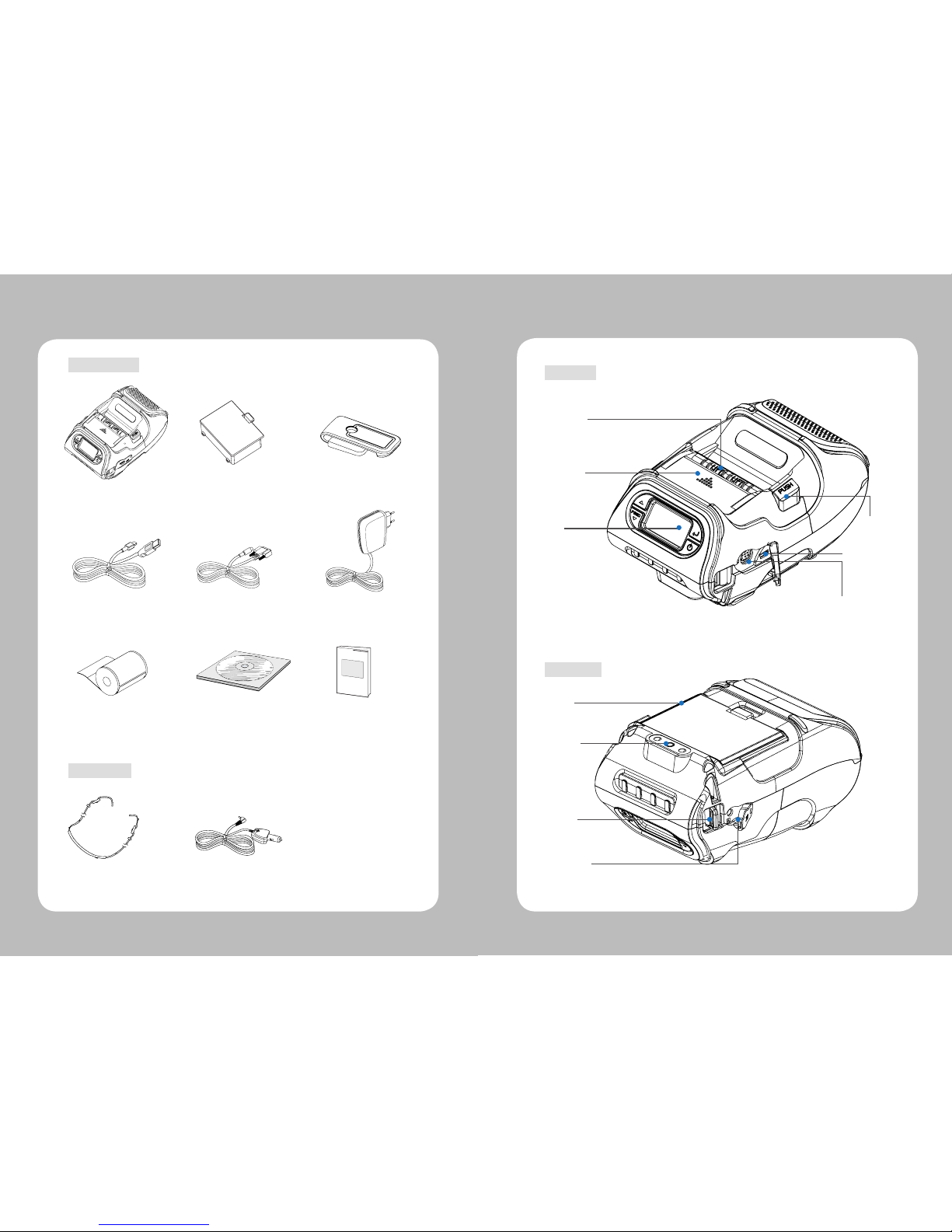

2. Unpacking

Optional

Standard

SHOULDER

STRAP RING

3. Product overview

CHARGER

CONNECTOR

COVER OPEN

BUTTON

Front

Bottom

PEELER BODY

PEELER WING

BATTERY

BELT CLIP

CONNECTOR

SERIAL

USB

DISPLAY

Printer Battery Belt Clip

Recharger

CD

USB Cable

Quick Reference

Paper

Shoulder Strap

Serial cable

Cigar jack

89

4-1. Display

4. Setting Up the Product

Button Name function

Paper Feed/

Down button

Advances the supply. Clears error message.

Moves down through menu options.

1. Refer to “3-10” for Diagnostic Test information.

2. Refer to the service manual regarding Hexadecimal

Dumping.

Enter button Selects the highlighted menu option.

Up button Moves up through menu options.

Power

button

Turns the printer on and off. Press to turn

power on. Press for three seconds to turn power off.

Wakes the printer from sleep mode.

NOTE

1. The battery status LEDs indicate amount of power remaining. Actual run-time

remaining depends on factors such as the contents of output,

distance to computer, etc.

2. When the battery level is very low, high density printing can result in the printer

switching o during printing resulting in possible loss of data.

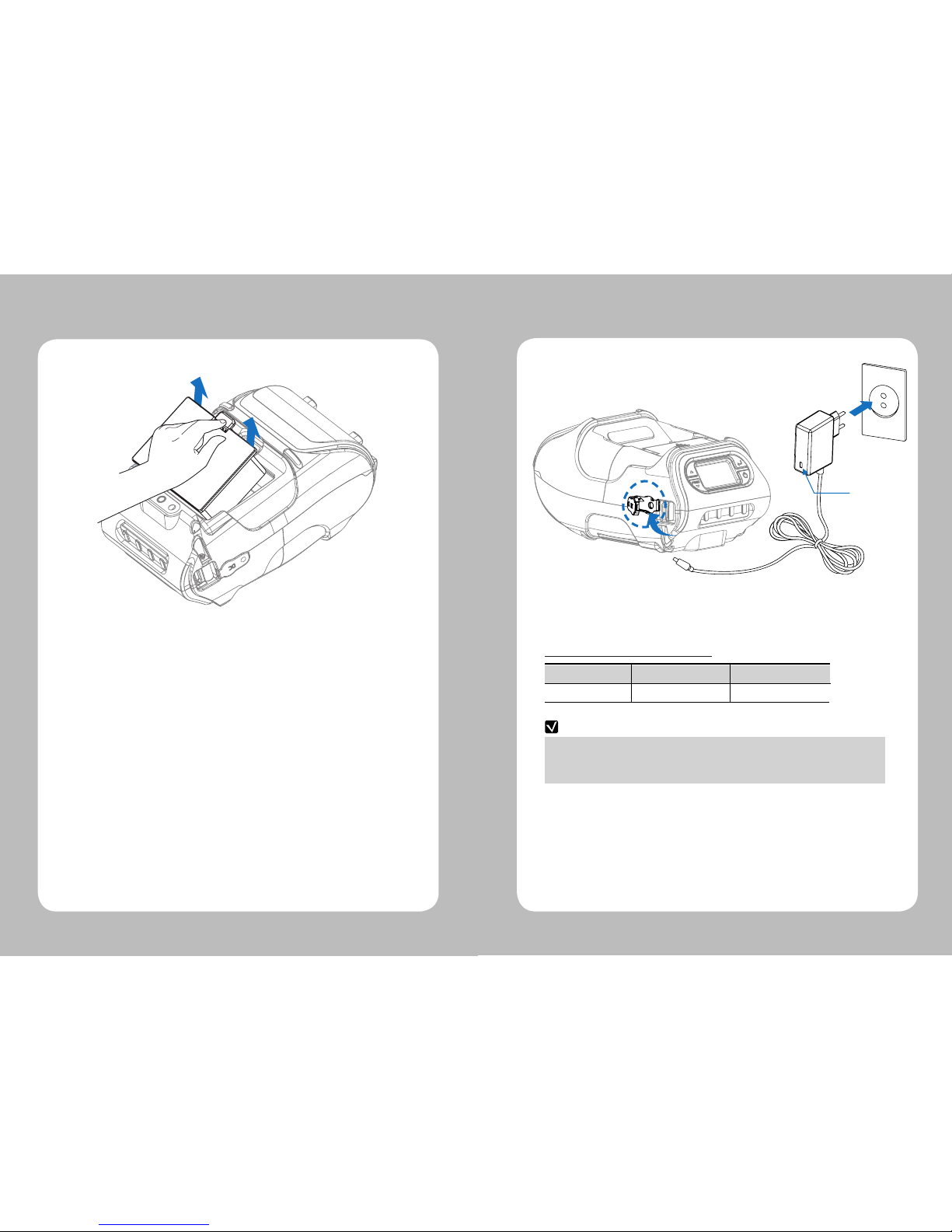

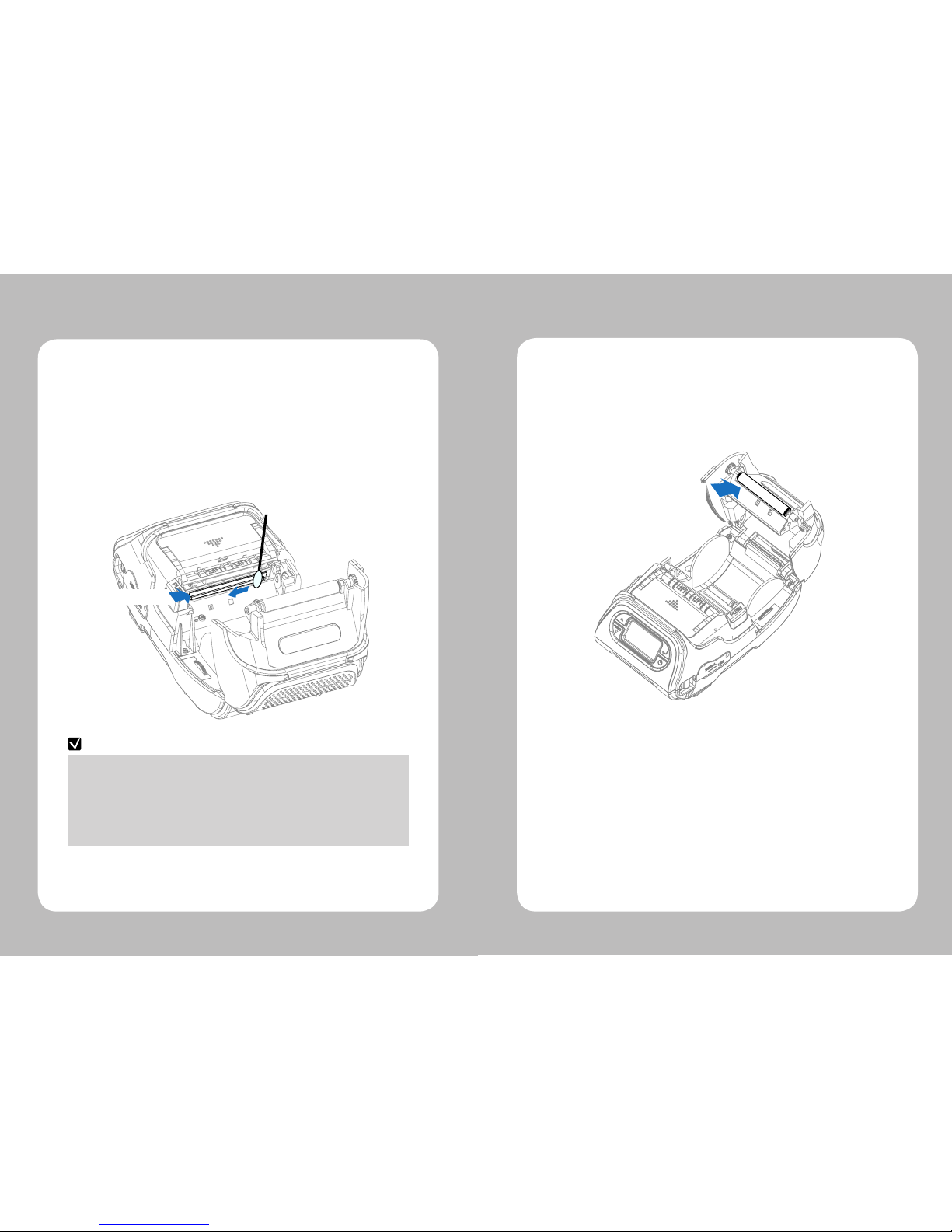

4-2. Installing the Battery

NOTE

Remove the battery. Insert the battery as shown.

1

2

Replace the battery.

You must fully charge the battery when you receive the printer.

Batteries can be charged in the printer or in an optional external cradle

10 11

4-3. Removing the Battery

Remove the battery. Lift out the battery.

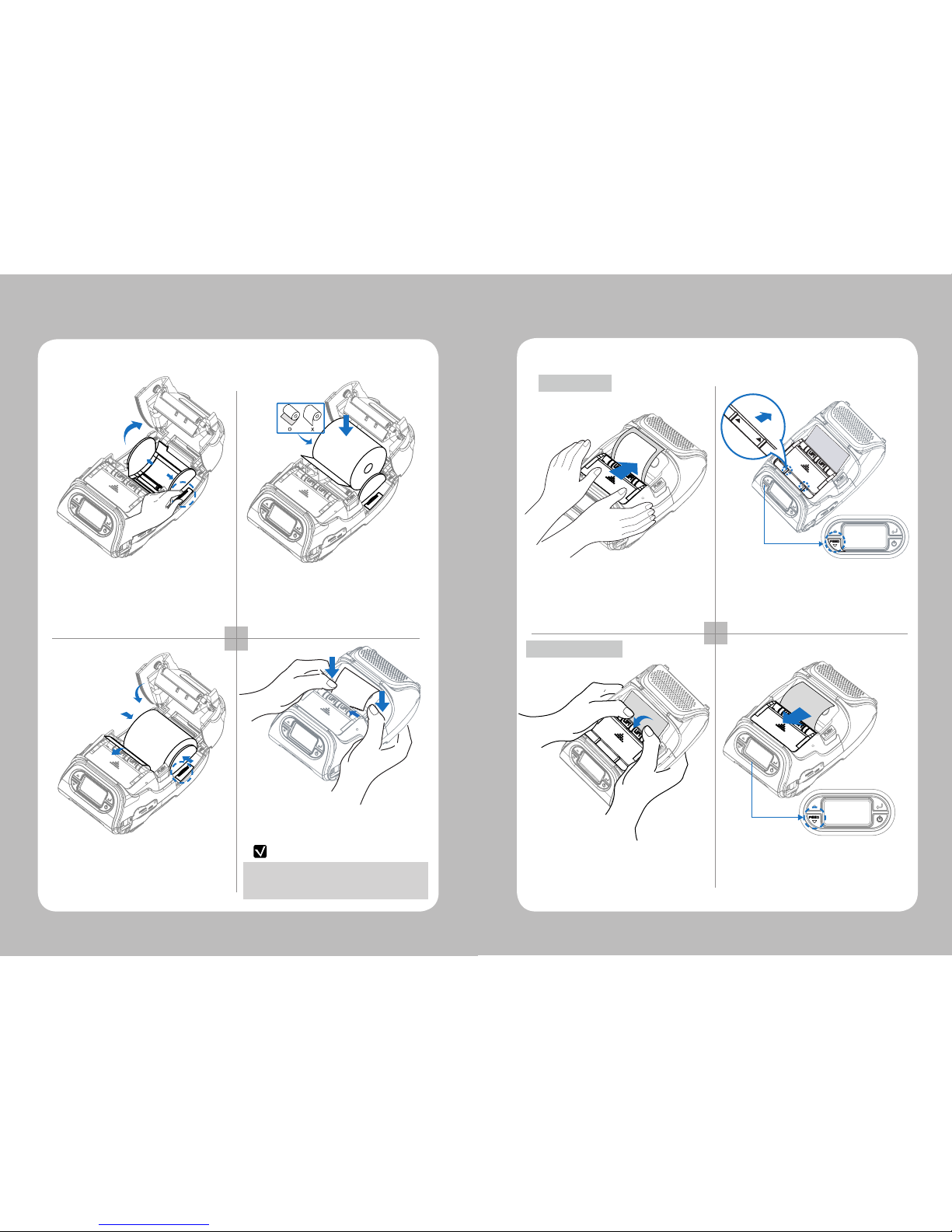

4-4. Charging the Battery

1. Be sure that the printer is turned o

2. After open the DC JACK cover, insert DC JACK into the printer.

3. Plug the power code to electrical outlet.

4-4-1 The status of lamp in charging

Status charging charging complete

Charging Lamp Red

Green

②

①

LED

If there is trouble while charging the battery, the charge indicator LED blinks green.

Try unplugging and reconnecting charger, charging should resume.

Charging is complete when the LED changes to solid green.

NOTE

12 13

Connect the vehicle charger to the printer.

4-5 Usage of Cigar Jack Charger

Printer

Optional

Input 12 ~ 24V

8.4V 0.8 ~ 1.2A

Output

Connect the vehicle charger to the printer.

NOTE

The belt clip is included with the printer but is not required to be used or installed!

4-6. Belt clip Usage

Insert screw into belt clip.

Tighten the screw with driver as shown.

1

2

NOTE

14 15

Close the paper with both hands and run

the paper line up by pressing feed button.

NOTE

If the users close the cover with one hand,

it would not be closed completely.

Please use both hands to close.

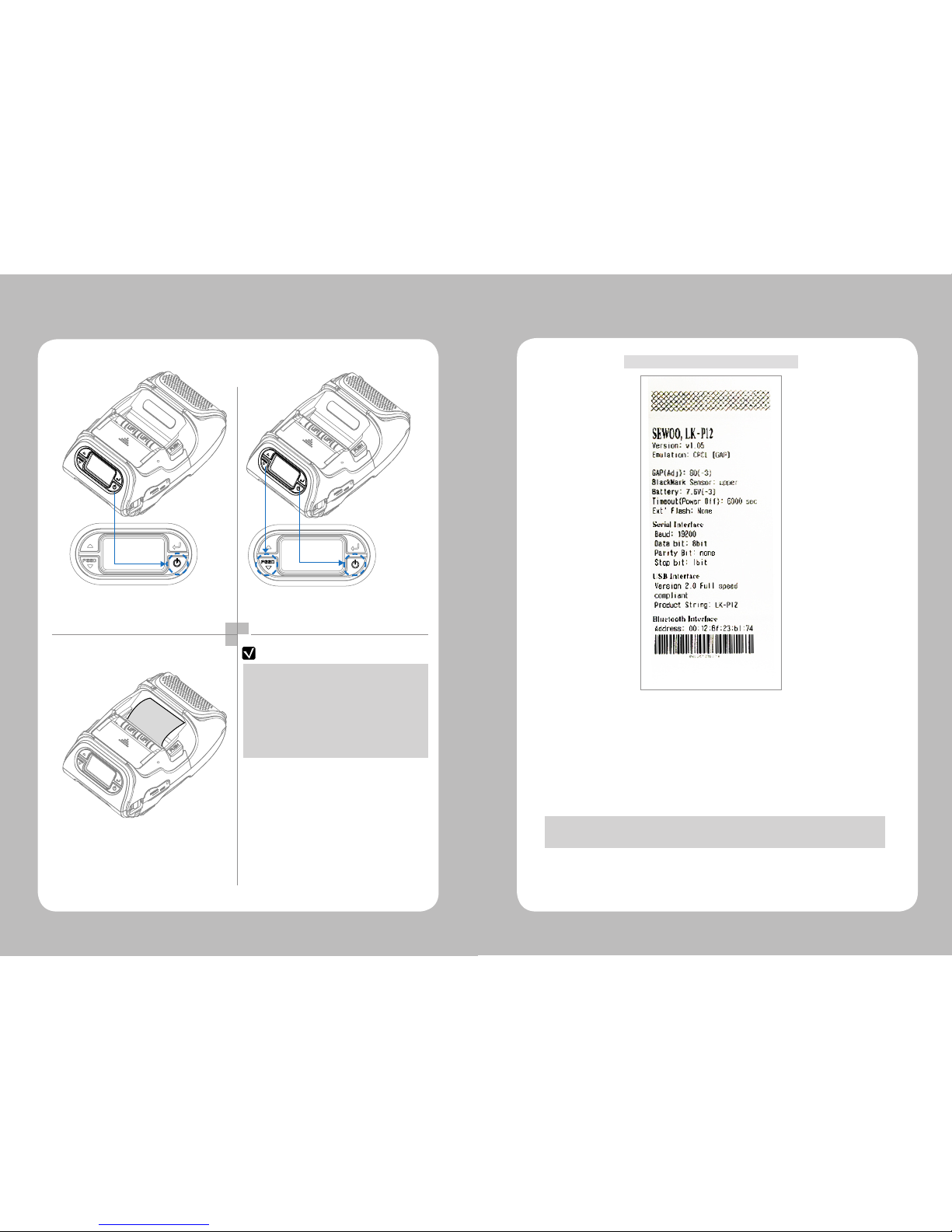

4-7. Roll Paper installation

1 2

34

Put the stock in so it unrolls from the

bottom. Remove the stock core when

it is empty. Pull a short length of stock

out of the printer.

Open the Paper cover by pressing the

Open button and set the width of paper

guide by turning the knob with nger.

Close the cover.

4-8. Peel Mode

1 2

1 2

With a roll of stock installed, slide the

peeler body towards the back of the

printer.

Lift the peeler wing and slide the peeler

body towards the front of the printer.

Press the feed button.

Peel Mode

Non-Peel Mode

Push the peeler body until you see two

complete triangles. Press the feed button.

16 17

Paper (1)

Label Paper

Engraved Line

Paper (2)

Label Paper

When users operates the peeler like the image below that has

slits on the label(1) and the perforated label(2) , there might

be an error in the peeler function

Insert the strap into the hook of the printer.

Place the end of the strap into

the hook of shoulder strap.

After pulling out the end of the

strap tightly, put it into the clip

to be fastened.

Optional

1

32

4-9. Shoulder Strap Installation

18 19

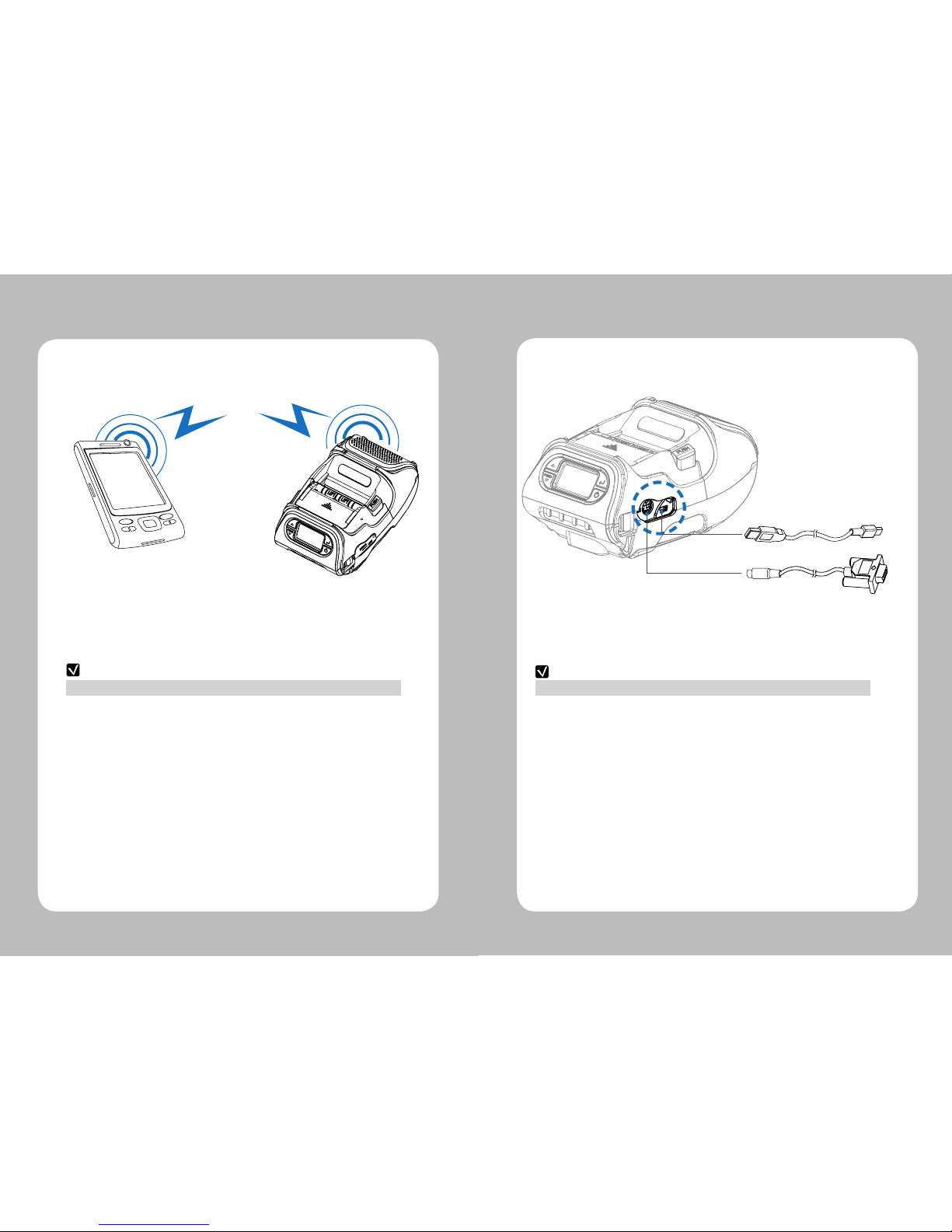

4-10. Diagnostic Test

1 2

3

NOTE

Turn o the printer.

The information label prints.

Press and hold the feed

button and power button.

1. For Hex Dump mode, do steps 1-2 then

press the feed button.

2. After printing ASCII pattern,

the diagnostic test is complete.

3. If the feed button is not pressed to go to

Hex Dump mode, the printer exits

diagnostics after three seconds.

The sample of self test printout

Upon initial installation or for troubleshooting, you can run the diagnostic test to get

information about:

Firmware version, emulation, codepage, sensor settings, interface settings, etc.

If no issues are found with diagnostic test, examine other devices and software.

The diagnostic test is working independent of devices and software.

●Do not overheat the motor

To prevent the motor from overheating, stop the printer for at least 30 seconds

after continuously printing 1.5 meters.

20 21

5. Peripherals Connection

1. Printer can be connected to the PDA and PC which can do wireless

communication.

2. By using Bluetooth function supported in PC, printer can be connected.

NOTE

Refer to the System Administrator Guide for more information.

This printer can communicate with Peripherals device via Bluetooth and cables.

5-1 Bluetooth Connection

5-2. Interface Cable Connection

1. Connect the USB or Serial cable to the cable connector on the printer.

2. Connect the interface cable into the USB or Serial port of the device

(PDA, PC, etc.)

NOTE

Use only the cables oered by the printer manufacturer.

Serial

USB

22 23

6-1. PrintHead Cleaning

6. Printer cleaning

If the interior of the printer is dusty, printing quality can be lowered.

In this case, follow the instructions below to clean the printer.

NOTE

1. Make sure to turn the printer power o prior to cleaning

2. The printhead can become very hot during printing; allow the printer

approximately 10 minutes to cool before cleaning.

3. Do not touch the printhead, it can be damaged by static electricity.

4. Take care not to allow the print head to become scratched and /or

damaged in any way.

1. Use an applicator swab moistened with an isopropyl alcohol to clean

the print head and remove any dust.

2. Once cleaning is complete, allow the printer to dry then install the

stock and close the cover.

PrintHead

6-2. Platen Roller Cleaning

1.Clean the platen roller with a clean soft cloth moistened with isopropyl

alcohol or a cleaning pen.

2. Turn the platen roller with your nger to clean the entire surface.

Platen Roller

24 25

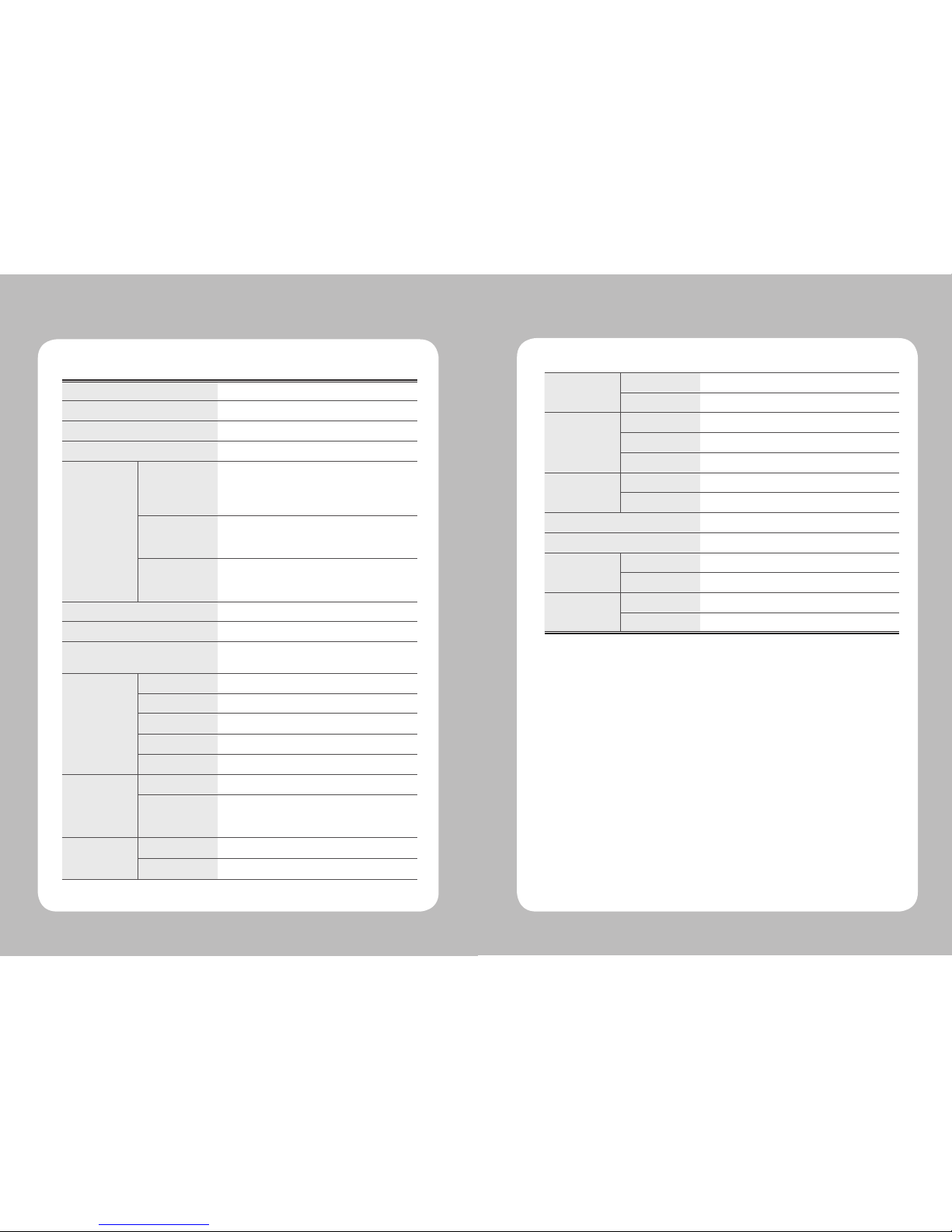

Printing Method Direct Thermal

Printing Speed 80mm/sec

Resolution 203 DPI X 203 DPI

Character ALPHA NUMERIC Character, Extension Character

Barcode One-Dimensional

Barcodes

UPCA +2/+5, UPCE +2/+5, EAN8 +2/+5, EAN13

+2/+5,

EAN 128, Interleaved 2 of 5, Extended Code 39,

Codabar (NW7), Code 128, Code 93, PostNet

Two-Dimensional

Barcodes

PDF417, MaxiCode, Aztec, QR Code (Quick

Response),

Datamatrix

Stacked One-

Dimensional

Barcodes

GS1 Databar (RSS or Composite Code)

Emulation ESC/POS, ZPL, CPCL Command compatible

Driver Window CE 4.2&5.0, Window Mobile 5.0

Sensor Black-Mark Upper/Lower, Gap, Cover open, Peeler

Detect, Peeler S/W, Media-Width Detect

Paper paper type Thermal Paper

width 56mm

thickness 0.06 ~ 0.18 mm

External Diameter Max. Φ 56mm

Internal Diameter 12.5mm±0.5mm

Reliability TPH 50km

Battery Continuous Printing 54min

Standby for 11hours

Printing length: 249.8M

Communications standard Serial(RS-232C), USB

Optional Bluetooth Class2

7-1. Specication

7. Printer Specication

Battery Charger input AC100~240V, 50/60Hz

output 8.4V , 800~1200mA

Battery Battery type Li-ion

output 7.4V, 18.9wh

Charging time 3.7 Hrs Charging

Size WXDXH(mm) 104 X 85 X 158

WXDXH” 3.9 X 3.3 X 6.2

Weight 590g

Environmental sealing IP42

Temperature operation 5~50℃

storage -20~60℃

Humidity operation 35 ~ 80%

storage 10 ~ 90%

26 27

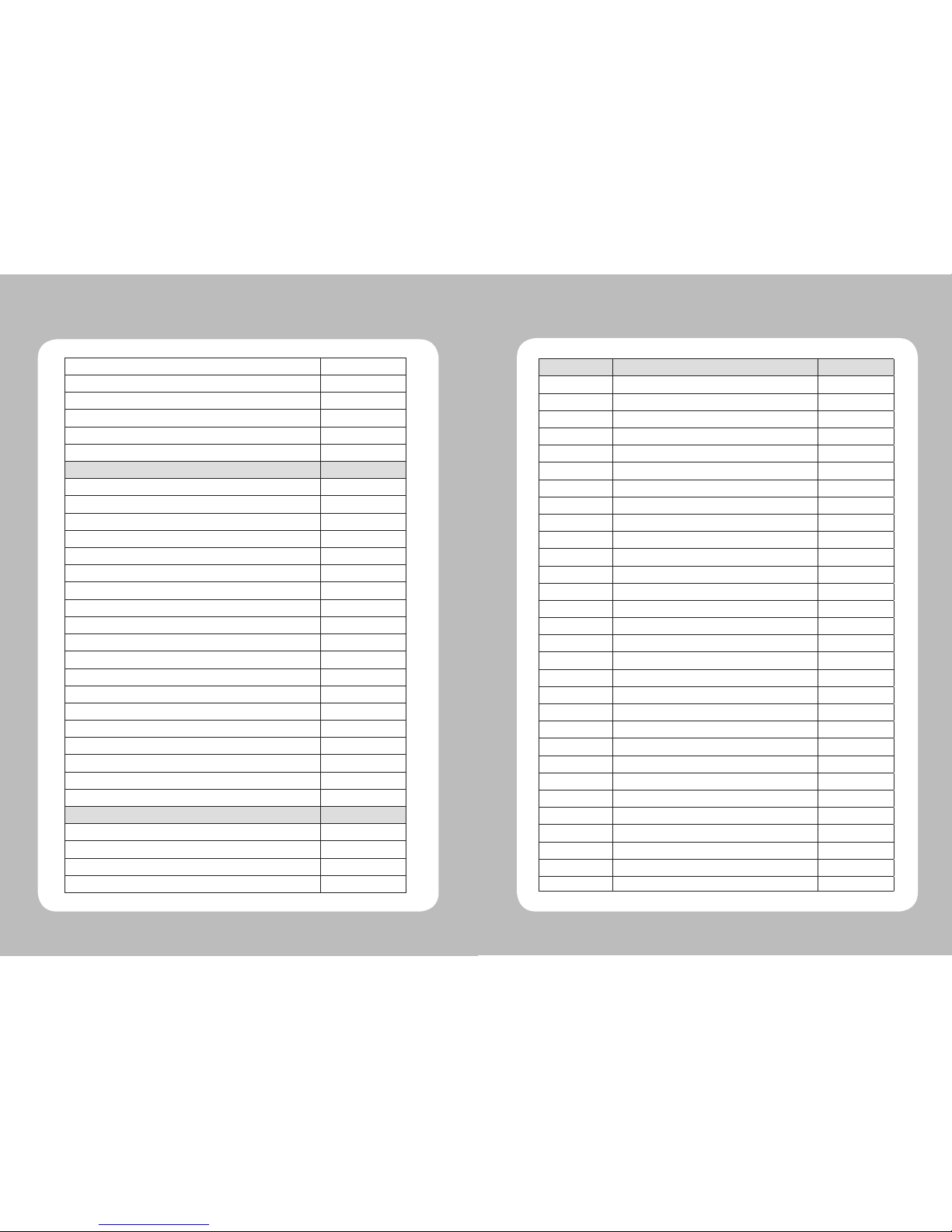

NOTE

Compatible Partially

Compatible

Not

Compatible

○●△x

Compatible with only

commanders provided by

the manufacturer.

8. CPCL Command Compatibility

Printer Commands Compatibility

PRINT

○

FORM

○

JOURNAL

○

UNITS

○

USING COMMENTS

○

TEXT Compatibility

TEXT

○

FONT-GROUP(FG)

○

TEXT CONCATENATION

○

MULTILINE(ML)

○

COUNT

○

SETMAG

○

SCALABLE TEXT Compatibility

SCALE-TEXT

○

SCALABLE CONCATENATION

○

LINEAR BARCODES Compatibility

BARCODE

○

BARCODE-TEXT

○

COUNT

○

Two-Dimensional Bar Codes Compatibility

PDF417 (PORTABLE DATA FILE)

○

MICROPDF-417

●

MAXICODE

○

QRCODE

○

DATAMATRIX

●

GS1(RSS-14)

○

AZTEC

○

GRAPHICS Compatibility

BOX

○

LINE

○

INVERSE-LINE

○

PATTERN

○

GRAPHICS

○

PCX

○

Advanced Commands Compatibility

CONTRAST

○

TONE

○

JUSTIFICATION

○

PAGE-WIDTH

○

PACE

○

NO-PACE

○

WAIT

○

SPEED

○

SETSP

○

ON-FEED

○

PREFEED

○

POSTFEED

○

COUNTRY/CODE PAGE

○

FORMAT FILES

○

BEEP

○

Line Print Mode Compatibility

SETLP

○

SETLF

○

Moving With X and Y Coordinates

○

LMARGIN

○

28 29

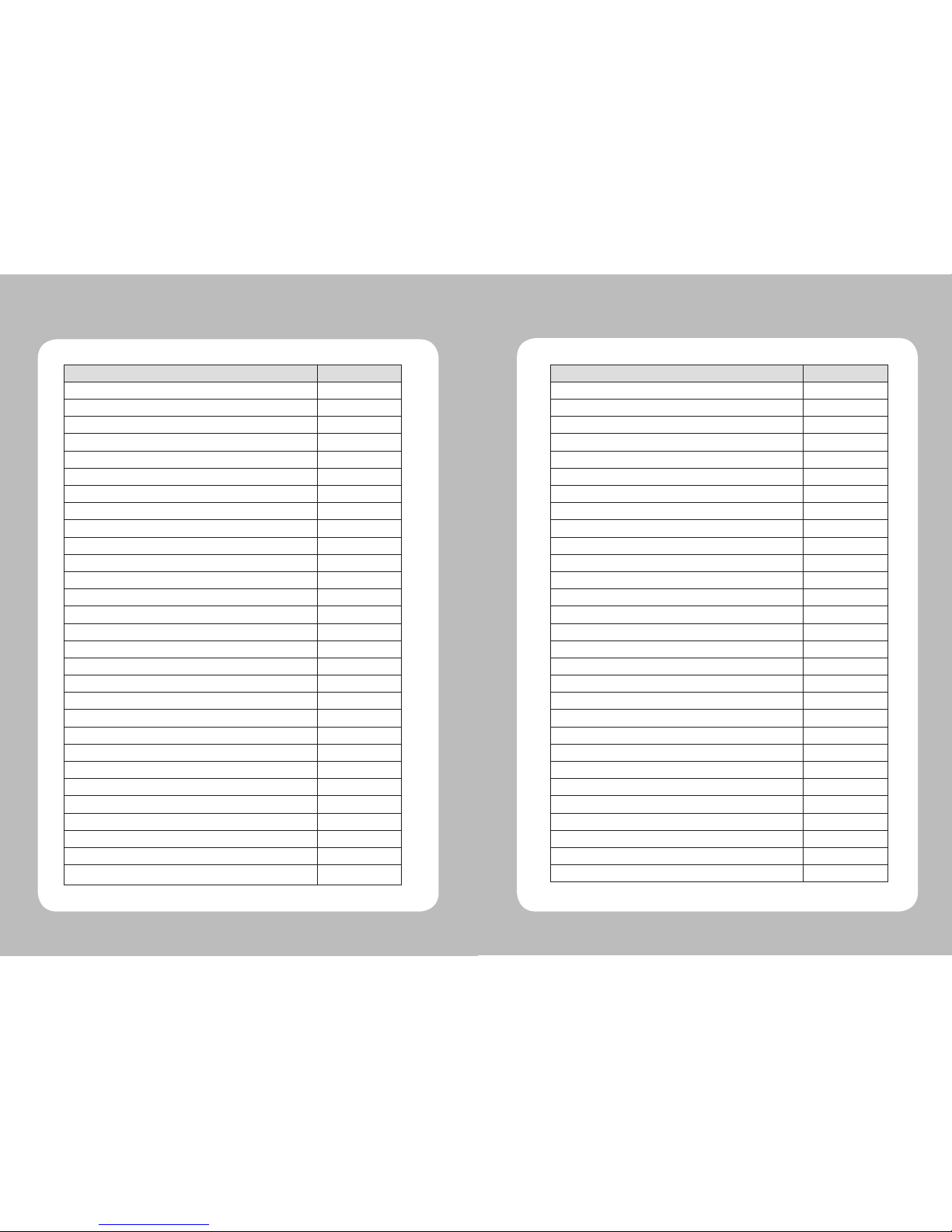

9.

ESC/POS Command Compatibility

SETBOLD

○

SETSP

○

Special ASCII Characters

○

SETFF

○

SET-TOF

○

SETLP-TIMEOUT

○

ADVANCED UTILITIES Compatibility

VERSION

○

CHECKSUM

○

DEL

○

DIR

○

DEFINE-FILE

○

TYPE

○

BAUD

○

COUNTRY / CODE-PAGE

○

TIMEOUT

○

BEED

○

ON-LOW-BATTERY

○

LT

○

SET-TIME

○

GET-TIME

○

SET-DATE

○

GET-DATE

○

PRINTING A TIME STAMP

○

PRINTING A DATE STAMP

○

PAPER-JAM

○

PRINTER ESCAPE Compatibility

SET AND READ CODE

△

STATUS / INFROMATION

○

USER LABEL COUNT

○

POWER OFF

○

Command Function Compatibility

HT Horizontal tab

○

LF Print and line feed

○

CR Print and carriage return

○

FF Print end position label to start printing

○

CAN Cancel print data in page mode

○

DLE EOT Real-time status transmission

○

DLE ENQ Real-time request to printer

○

ESC FF Print data in page mode

○

ESC SP Set character right-side spacing

○

ESC ! Set print mode

○

ESC $ Set absolute print position

○

ESC % Select/cancel user-defined character set

○

ESC & Define user-defined characters

○

ESC * Set bit image mode

○

ESC - Turn underline mode on/off

○

ESC 2 Set 1/6 inch line spacing

○

ESC 3 Set line spacing using minimum units

○

ESC ? Cancel user-defined characters

○

ESC @ Initialize printer

○

ESC D Set horizontal tab positions

○

ESC E Select emphasized mode

○

ESC G Select double-strike mode

○

ESC J Print end feed paper using minimum units

○

ESC L Select page mode

○

ESC M Select character font

○

ESC R Select international character set

○

ESC S Select standard mode

○

ESC T Select print direction in page mode

○

ESC V Set/cancel 90˚cw rotated character

○

ESC W Set printing area in page mode

○

30 31

Command Function Compatibility

ESC\Set relative position

○

ESC a Align position

○

ESC d Print and feed paper n lines

○

ESC t Select character code table

○

ESC { Set/cancel upside-down character printing

○

FS p Print NV bit image

○

FS q Define NV bit image

○

GS ! Select character size

○

GS $ Set absolute vertical print position in page mode

○

GS * Define downloaded bit image

○

GS / Print down-loaded bit image

○

GS B Turn white/black reverse printing mode on/off

○

GS H Select printing position of HRI characters

○

GS I Transmit printer ID

○

GS L Set left margin

○

GS W Set printing area width

○

GS\Set relative vertical print position in page mode

○

GS a Enable/disable Automatic Status Back(ASB)

○

GS f Select font for HRI characters

○

GS h Set bar code height

○

GS k Print bar code

○

GS r Transmit status

○

GS v 0 Print raster bit image

○

GS w Set bar code width

○

GS S C Set Serial Baudrate

○

DLE EOT n Selects card read mode / Cancel card read mode

○

GS S P Power Save Mode

○

10. ZPL Command Compatibility

Command Compatibility

^A

○

^B0

○

^B1

○

^B2

○

^B3

○

^B4

○

^B5

○

^B6

○

^B7

○

^B8

○

^B9

○

^BA

○

^BB

○

^BC

○

^BD

○

^BE

○

^BF

○

^BI

○

^BJ

○

^BK

○

^BL

○

^BM

○

^BO

○

^BP

○

^BQ

○

^BR

○

^BS

○

^BT

○

^BU

○

32 33

Command Compatibility

^BX

○

^BY

○

^BZ

○

^CC ~CC

○

^CD

○

^CF

○

^CI

○

^CT ~CT

○

~DF

○

~DG

○

^FB

○

^FC

○

^FD

○

^FH

○

^FN

○

^FO

○

^FP

○

^FR

○

^FS

○

^FT

○

^FV

○

^FW

○

^FX

○

^GB

○

^GC

○

^GD

○

^GE

○

^GF

○

^GS

○

Command Compatibility

^ID

○

^IL

○

^IM

○

^IS

○

~JR

○

^JS

○

~JS

○

^KL

○

^LH

○

^LL

○

^LR

○

^LS

○

^LT

○

^MC

○

^MD

○

^MN

○

^PM

○

^PO

○

^PQ

○

^PR

○

~PR

○

^PW

○

^SC

○

^SD

○

^SF

○

^SL

○

^SN

○

^SO

○

^ST

○

34 35

Command Compatibility

~TA

○

^XA

○

^XF

○

^XG

○

^XZ

○

^ZZ

○

Table of contents

Other SEWOO Printer manuals

SEWOO

SEWOO LK-P43 User manual

SEWOO

SEWOO LK-P11B User manual

SEWOO

SEWOO SLK-TL122 User manual

SEWOO

SEWOO LK-P43B User manual

SEWOO

SEWOO LK-P41 Installation instructions

SEWOO

SEWOO LK-P41B User manual

SEWOO

SEWOO SLK-TS100 User manual

SEWOO

SEWOO SLK-TE12 Series User manual

SEWOO

SEWOO LK-P25 User manual

SEWOO

SEWOO SLK-T32EB Series User manual

SEWOO

SEWOO LK-P30 Installation instructions

SEWOO

SEWOO SLK-TL21 Series User manual

SEWOO

SEWOO LK-P11B User manual

SEWOO

SEWOO SLK-TE25 User manual

SEWOO

SEWOO LK-P20II User manual

SEWOO

SEWOO SLK-TL12X Series User manual

SEWOO

SEWOO SLK-TE25 User manual

SEWOO

SEWOO LK-B10 User manual

SEWOO

SEWOO LK-P400 User manual

SEWOO

SEWOO SLK-TS400 Instruction Manual