SF AllVac Commercial Owner's manual

RRGA-SVX01A-EN

Model Numbers: RRGA123E0A0, RRGA123B0A0, RRGA123C0A0,

RRGA123F0A0, RRGA123G0A0, RRGA323E0A0, RRGA323B0A0,

RRGA323C0A0, RRGA323F0A0, RRGA323G0A0

Installation

Operation

Maintenance

AllVac Commercial

High and Low Pressure Commercial Refrigerant

Recovery System

2RRGA-SVX01A-EN

General Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Model Number Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Literature History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

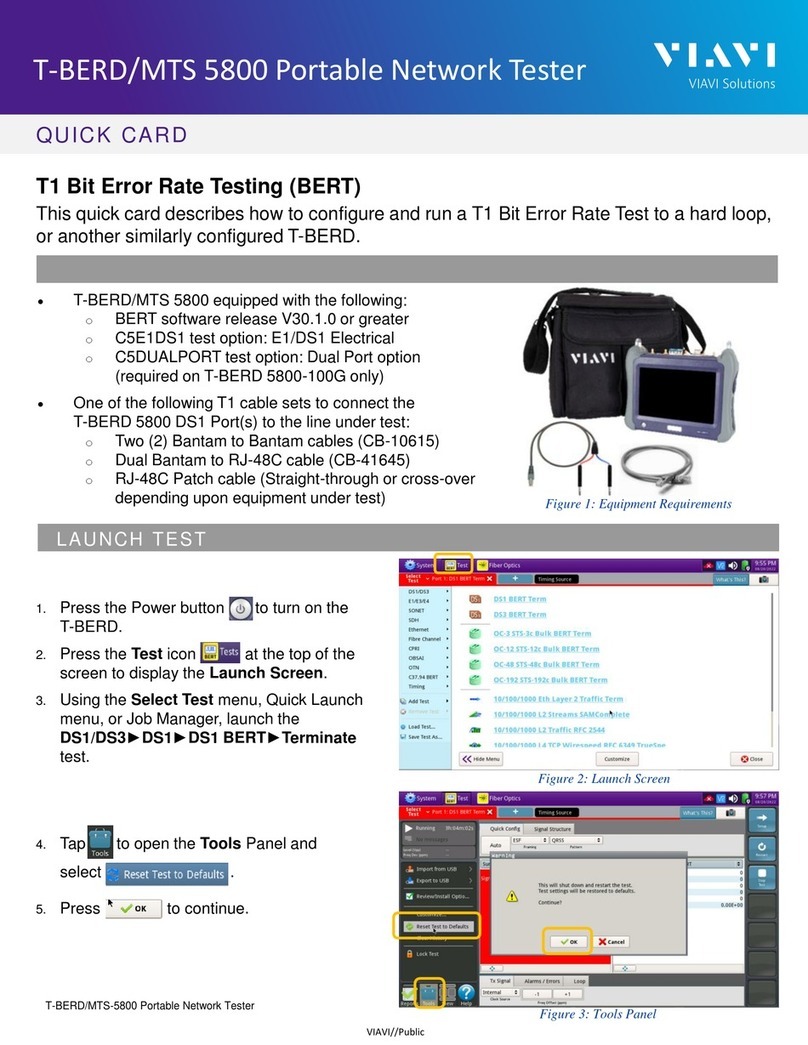

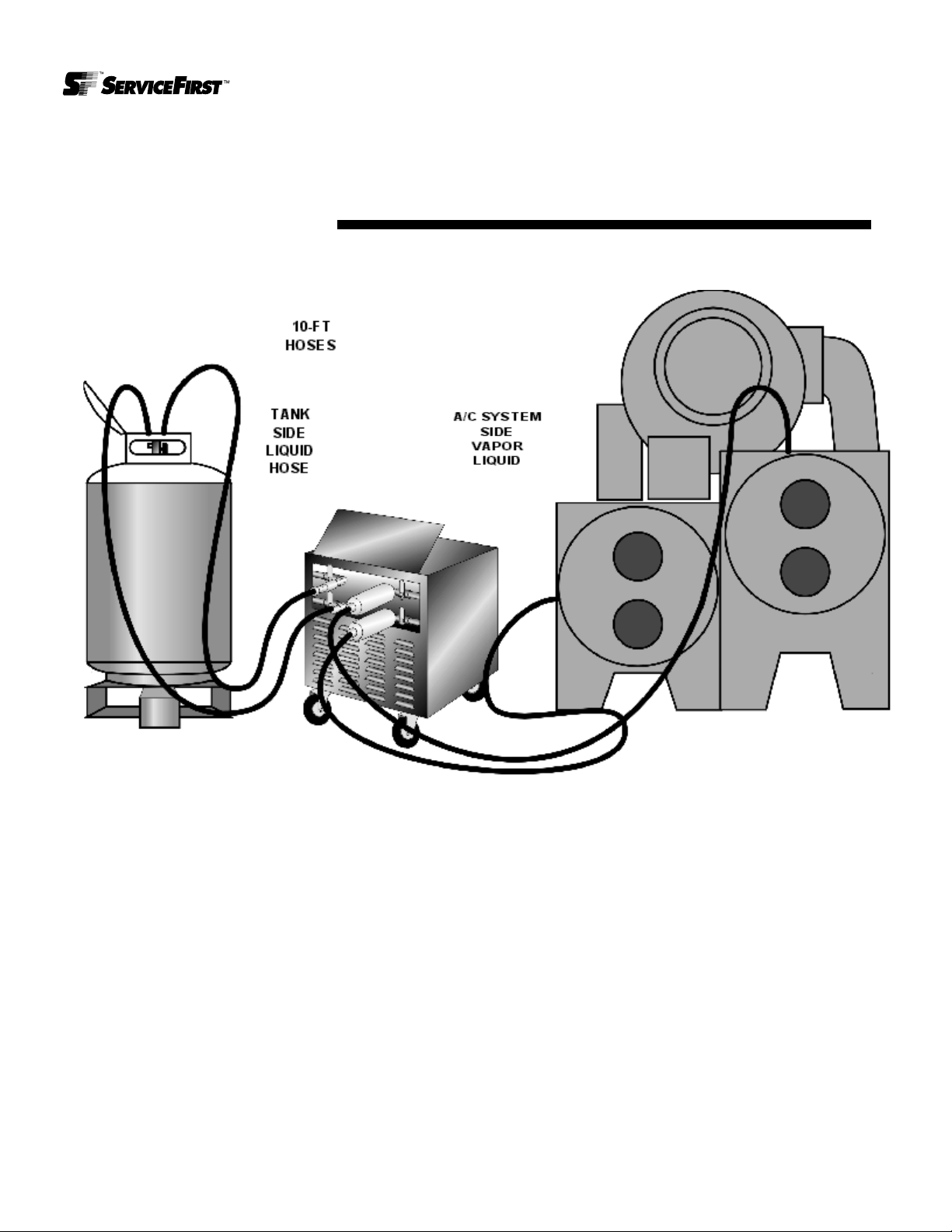

Figure 1 — AllVac Connections . . . . . . . . . . . . . . . . . . . . . . . . . 6

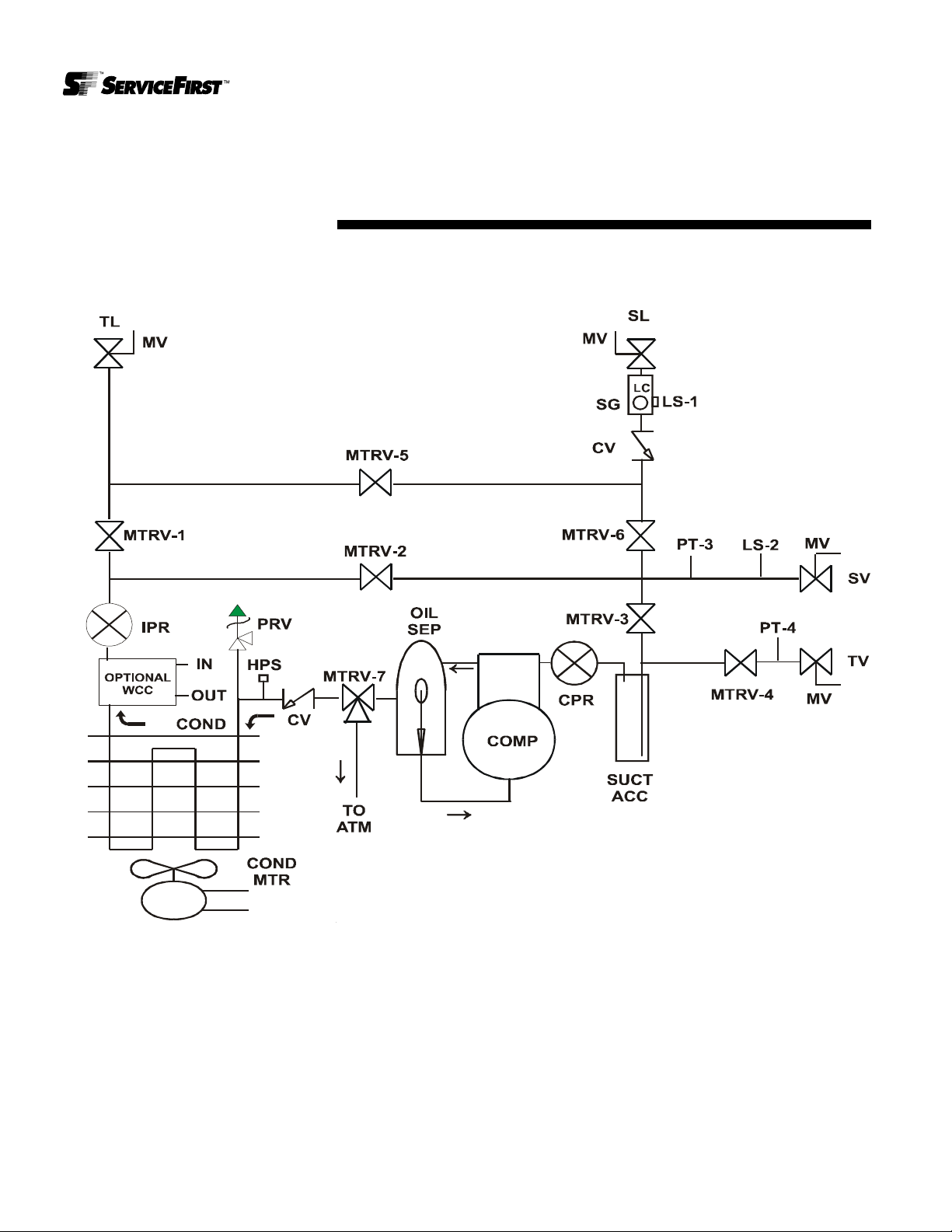

Figure 2 — AllVac Schematic. . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operating Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Removing Residual Refrigerant . . . . . . . . . . . . . . . . . . . . . . . . 14

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Calibration Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Changing Compressor Fluid. . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 3 — 230/460, 1 Phase Model . . . . . . . . . . . . . . . . . . . . 21

Figure 4 — 230, 1 Phase Model. . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 5 — 230/460, 3 Phase Model . . . . . . . . . . . . . . . . . . . . 23

Display Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Electrical Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 6 — Electrical Parts Breakdown . . . . . . . . . . . . . . . . . . 27

Replacement Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 7 — Replacement Parts Diagram . . . . . . . . . . . . . . . . . 29

Figure 8 — 230/460, 1 Phase Model, Electrical Controls. . . . . 30

Figure 9 — 230/460, 3 Phase Model, Electrical Controls. . . . . 31

Figure 10 — 230, 1 Phase Model, Electrical Controls . . . . . . . 32

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table of Contents

RRGA-SVX01A-EN 3

General

Information

Warnings and Cautions

Warnings and Cautions appear at appropriate locations throughout this

manual. Read these carefully.

Indicates a potentially hazardous

situation which, if not avoided,

could result in death or serious

injury.

Indicates a potentially hazardous

situation which, if not avoided,

may result in minor or moderate

injury. It may be used to alert

against unsafe practices and

where property-damage-only

accidents could occur.

WARNING

!CAUTION

!

Model number description

Refrigerant Recovery

Digits 1, 2 - Product Description

RR = Refrigerant Recovery

Digit 3 - Model Identifier

A = MicroVac

B = HandiVac

C = MityVac

D = EVAC Commercial

E = EVAC Industrial

F = LoVac

G = AllVac

Digit 4 - Development Sequence

A = First Development

Digit 5 - Condenser Type

1 = Air Cooled

2 = Water Cooled

3 = Air/Water Cooled

Digit 6 - Control Type

1 = Electromechanical

2 = Microprocessor

Digit 7 - Connection Type

1 = 1/4” flare

2 = 1/2” flare

3 = 3/4” flare

4 = 1.25” pipe thread fitting w/ball valve

5 = Quick Connects on unit and hoses

Digit 8 - Unit Voltage (voltage/hz/phase)

A = 115/60/1, 110/50/1

B = 230/60/1, 220/50/1

C = 460/60/3, 415/50/3

D = 575/60/3, 220/50/3

E = 230/60/3, 220/50/3

F = 575/60/3

G = 230-460/60/1, 220-415/50/1

H = 460-575/60/3, 415-550/50/3

Digit 9 - Safety Features

0 = Open

1 = Float Cable Connection

2 = Low Pressure Shut-Off

3 = Float cable connection, LP shut-off

Digits 10, 11 - Design Sequence

A0 = First Design Sequence

Literature History

RRGA-SVX-01A (April 2001)

Original issue of manual. Describes the Installa-

tion, Operation and Maintenance procedures for

this unit.

RRGA111A0A0

1234567891011

4RRGA-SVX01A-EN

General

Information

Electrical Power Requirements

Recovery Main Components & Controls:

• 115VAC, 50/60 Hz, 1-Phase, 20-Amperes Min. CKT 15.0 Amp, Max

Fuse 20 Amps

Models RRGA123G0A0 & RRGA323G0A0:

•Compressor 230/460 VAC, 50/60Hz, 1 Phase Min. CKT 20.0 Amp,

Max Fuse 30 Amps.

Models RRGA123B0A0 & RRGA323B0A0:

•Compressor 220/240VAC, 50/60Hz, 1 Phase MIN CKT 20.0 AMP,

Max Fuse 30 Amps.

Models RRGA123E0A0 & RRGA323E0A0:

• Compressor 230 VAC, 50/60Hz, 3 Phase Min. CKT 10.0 Amp, Max-

Fuse 20 Amps.

Models RRGA123C0A0 & RRGA323C0A0:

• Compressor 460 VAC, 50/60Hz, 1 Phase Min. CKT 10.0 Amp, Max

Fuse 15 Amps.

Models RRGA123F0A0 & RRGA323F0A0:

• Compressor 575 VAC, 50/60Hz, 1 Phase Min. CKT 10.0 Amp, Max

Fuse 15 Amps.

Dimensions (approximate)

• 41” high x 24” wide x 27” deep

Weight

• 240-lbs. (340-lbs. shipping)

Notice

The Trane Company urges that all HVAC servicers working on Trane equipment, or any

manufacturer’s products, make every effort to eliminate, if possible, or vigorously reduce the

emission of CFC, HCFC and HFC refrigerants to the atmosphere resulting from installation,

operation, routine maintenance, or major service on this equipment. Always act in a

responsible manner to conserve refrigerants for continued use even when acceptable

alternatives are available. Conservation and emission-reduction can be accomplished by

following recom- mended Trane service and safety procedures published in Trane General

Service Bulletin CTV-SB-81. The information and procedures provided in CTV-SB-81

supersedes those published in this manual. Copies of this bulletin may be obtained by

contacting your local Trane commercial representative.

WARNING!

To avoid injury or death due to inhalation of, or skin exposure to refrigerant, closely follow all

safety procedures described in the Material Safety Data Sheet for the refrigerant and to all

labels on refrigerant containers. Certain procedures common to refrigeration system service

may expose personnel to liquid or vaporous refrigerant.

RRGA-SVX01A-EN 5

General

Information

Product Description

RefTec’s AllVac recovery system provides automated recovery of most low &

high pressure refrigerants and blends.

The unit consists of a 3 or 5-hp compressor with oil separator, disposable

liquid & vapor prefilter driers, high capacity air cooled condenser,

microprocessor control system, and actuated valving system. Unit

connections are 3/4” male flare with isolation valves.

After hoses are connected and purged or evacuated, AllVac starts

automated recovery by letting refrigerant migrate from the A/C system to the

recovery tank. It then draws vapor off the recovery tank, heats it via

compression, and injects it back into the A/C system high side, thus creating

a pressure differential before commencing liquid transfer.

A sensor determines when liquid transfer is complete, and AllVac’s

compressor begins moving vapor, which is first cleansed by a filter drier.

Discharged hot compressed gas passes through an oil separator and the oil

is returned to the compressor. Refrigerant is then condensed by the air-

cooled condenser and sent to the recovery tank.

The AllVac can be programmed to stop transfer at either 0 PSI or at 15” Hg

vacuum for high pressure refrigerant and either 0 PSI or at 29” Hg vacuum

for low pressure refrigerants. Transfer stops when a pressure transducer

indicates the A/C system reaches the programmed pressure. The unit then

confirms the vacuum level by monitoring pressure for two minutes. Should

pressure in the A/C system rise, AllVac energizes again to achieve A/C

system selected level of vacuum.

6RRGA-SVX01A-EN

General

Information

DRIERS

3/4” RECOVERY

CYLINDER PORTS

VAPOR

20-FT

3/4” PORT: 3/4” PORT:

CONDENSER

Figure 1. AllVac Connections

RRGA-SVX01A-EN 7

General

Information

Furnished with the AllVac are:

• Two -10-ft. and 20-ft. 3/4” hoses equipped with four 3/4” female flare

fittings with isolation valves

• Two - 3/4”-5/8” flare reducing fittings

• Two - 5/8” -1/2” flare reducing fittings

• Two - 3/4” female flare unions

• 50-ft., 230/460-VAC power cord

• 100-ft., 120-VAC power cord

• Two - 3/4” female flare 0.73-liter disposable in-line filter driers

Please follow the recommended procedures outlined in this manual for

regular changing of compressor fluid. Before every recovery job install

new liquid and vapor drier cores.

Peak Performance:

To get the highest performance from your AllVac unit, we recommend that

you:

1. Connect to 3/4” evaporator and condenser ports on the chiller or A/C sys-

tem and to recovery cylinders with 3/4” full ports whenever possible and

with a minimum 3/4” liquid dip tube.

2. Whenever there is an additional liquid access port on the A/C system,

connect an additional refrigerant line (3/4” if possible) directly from the

A/C system, through a drier, to the recovery cylinder. AllVac’s pressure

differential will motivate the refrigerant to the recovery cylinder, increasing

recovery speed. See Notes 1, 2, & 3 or 4 & 5 in Operating Procedures.

8RRGA-SVX01A-EN

General

Information

Figure 2. AllVac Schematic

RRGA-SVX01A-EN 9

Operation

Operating Procedures

To ensure your safety as well as others, before attempting to recover an A/C,

refrigeration or chiller system, proper and thorough preparation must take

place:

• Make sure you have a recovery cylinder with a minimum 3/4” male

flare vapor port and a minimum 3/4” male flare liquid port and 3/4” dip

tube. This tank or series of tanks must be able to hold the entire

refrigerant charge at 80% full. Both the tank and the refrigerant hoses

also must be pressure rated for the specific refrigerant being recov-

ered.

Reminder: Refrigerant full weight is 80% of water capacity weight

determined as follows: Maximum allowable gross weight = 80% of water

capacity weight + cylinder tare weight.

• In addition, a suitable scale should be used to weigh the tanks in case

AllVac needs to be shut down to prevent overfilling tanks. If a scale is

not available, the tanks can be equipped at time of purchase with a

float switch that will deactivate AllVac’s microprocessor control circuit

when the tank reaches 80% capacity.

• Finally, the recovery cylinder or cylinders must be pulled into a 29”

vacuum before recovery commences. Failure to follow these above

stated procedures will decrease the likelihood of AllVac performing at

its highest possible effectiveness.

1. Turn the A/C system off; make sure that the chiller cannot restart.

2. When using dual voltage model ARLH-A-D24-1-M connect has follows:

For 230-VAC, 1-phase power, connect the 50-ft., 230/460-VAC, 1-phase

power cord to a minimum 20 amp, maximum 30 amp circuit breaker or

fused disconnect and plug the quick connect Hubbell into AllVac’s control

box. When using 460-VAC, 1-phase power, connect the 50-ft., 230/460-

VAC, 1-phase power cord to a minimum 10 amp, maximum 20 amp cir-

cuit breaker or fused disconnect and plug the quick connect Hubbell into

AllVac’s control box. Connect the 100-ft., 120-VAC, 1-phase power cord

for controls. At this time, follow procedures 5 & 6 in selecting 1-phase

voltage, 230 or 460, failure to select proper voltage will result in major

damage to compressor motor. All other models connect to proper voltage

and required amperage as rated on equipment label.

3. At this point, the display lights up indicating the unit has power and

prompting you to press “Start”.

RRGA-SVX01A-EN 10

Operation

An additional feature can be accessed at this time, by pressing the “M” key.

This display will show you total compressor run time as well as give you a

historical maintenance schedule. In addition, at every 10 hours of cumulative

operating run time for the compressor, an automatic message will appear

each time you start the AllVac until maintenance is performed. After

changing oil, press the “Enter” key which records that maintenance has been

performed. Message will then not appear until the next 10 hours of

compressor run time is accumulated. The system will retain a log of each

maintenance event recorded.

4. AllVac then asks you to “Use M V To Select Scale or Float Switch”.

Scroll to either “Scale” or “Float Switch”, then press “Enter”.

Procedures 5 & 6 for ARLH-A-D24-1-M Model only

5. AllVac then asks you to “Use M V To Select Operating Voltage”. Scroll

to the desired voltage 230/460 using the “M V” keys, then press

“Enter”.

6. AllVac then tells you that “You Selected Single Phase ___V Operation

Is This Correct? Enter = Yes, Can = No”.

7. AllVac then asks you to “Select Refrigerant” being recovered. Scroll to

the desired refrigerant using the “M V” keys then press “Enter”.

8. AllVac then prompts you to check selection by displaying “Selected

Refrigerant R___ Is This Correct? Enter = Yes, Can = No”.

9. AllVac then prompts you to select the vapor transfer shutdown pressure

by “Use M V to select 0 PSI or 15 Hg Shutdown” for high pressure

refrigerants, or “Use M V to select 0 PSI or 29 Hg Shutdown” for low

pressure refrigerants. Scroll to the desired shutdown pressure, then press

“ENTER”.

10.AllVac then asks you to “Connect all Refrigerant Hoses” then press

“Enter”. Connect the two supplied 10-ft. hoses to AllVac’s recovery side

liquid and vapor ports and to liquid and vapor ports on the recovery cylin-

der. Connect the two supplied 20-ft. hoses to ports on the chiller evapora-

tor and condenser or A/C system and to the System Liquid and System

Vapor on AllVac unit as shown on Page 6.

• At this point, procedures for HIGH or LOW pressure refrigerant

recovery differ

For HIGH Pressure - follow steps 11 - 26

For LOW Pressure, go to page 7 follow steps 27 - 42

11. “Open System Vapor & Liquid Hand Valves on AllVac Recovery

Unit” then press “Enter”.

12.“Open Recovery Vapor & Liquid Hand Valves on AllVac Recovery

Unit” then press “Enter”.

Failure to select proper voltage

will result in major damage to

unit.

Caution

!

RRGA-SVX01A-EN 11

Operation

Note 1: If recovery tank side hoses have isolation valves, open them now.

13.“To Evacuate Hoses Press Enter, To Skip Hose Evacuation Press

Cancel” if “Enter” is pressed, unit displays “Hose Evacuation in Pro-

cess” followed by “Hose Evacuation Complete, Press Enter”.

14.Next “Open Vapor & Liquid Access Valves on A/C System Being

Recovered”then press “Enter”. If you pressed “Cancel” in step 13, All-

Vac will display “Purge Both Refrigerant Lines at the Recovery Tank”

then press “Enter”.

15.“Open Vapor and Liquid Hand Valves on Recovery Tank” then press

“Enter”.

16.AllVac then displays “Liquid Transfer!” and displays the A/C system and

recovery tank pressures.

• AllVac now begins automated recovery while continuously

displaying A/C system & recovery tank pressures.

Note 2: If additional liquid line is connected for faster liquid recovery, open A/

C system and recovery tank valves now. When AllVac goes into vapor

recovery, close recovery tank side of the hose.

17.Once pressure between the cooling system and recovery tank are within

15-psi of each other and a liquid sensor indicates that all liquid from liquid

transfer has been removed, the unit switches to vapor recovery, display-

ing “Vapor Recovery in Process” and continues to display the A/C sys-

tem & recovery tank pressures.

If AllVac does not switch to vapor recovery and you are absolutely sure that

all of the liquid has been removed, it may be because lines to the recovery

tank or to the cooling system are restricted. In this case, a bypass feature

can be accessed that forces the unit to begin vapor recovery. To perform this

task, press the enter key two times in a row during liquid recovery mode and

vapor recovery will commence. It is absolutely imperative that all liquid has

been transferred before using this override feature. Failure to do so may

result in liquid slugging to the compressor and causing major damage.

18.When the selected shutdown vacuum (either 0 PSI or 15” Hg) has been

achieved in the A/C system, the unit power shuts off and the display

reads “Vapor Recovery 2 Minute Wait State” and displays the time

remaining.

At this point, the microprocessor continues to monitor A/C system pressure.

Should pressure rise, AllVac restarts to again achieve the user selected

vacuum.

19.Then the display will read “Vapor Recovery Finished! press Enter”.

RRGA-SVX01A-EN 12

Operation

Upon pressing “Enter”, AllVac prompts you to perform the following

valve manipulations 20-26:

Note 3: Close additional liquid access valve at this time, if being used.

20.“Close Access Valves on A/C System Being Recovered” then

press”Enter”.

21.“Close Both Hand Valves on AllVac Unit A/C System Side” press

“Enter”.

22.AllVac compressor then restarts and begins to force remaining liquid in

AllVac as well as liquid in hose into the recovery tank. Displaying “Liquid

Refrigerant Clearing in Process”.

23.“Close Both Liquid & Vapor Hand Valves on Recovery Tank” press

Enter.

24.AllVac then begins evacuating the recovery tank vapor hose, displaying

“Hose Evacuation in Process”.

25.“Close Both Liquid & Vapor Tank Hand Valves on AllVac unit” then

press “Enter”.

26.Finally, the unit displays

“System Recovery Completed! Disconnect all Hoses and Power”.

At this time, close all four refrigerant hose isolation valves located on the

ends of the refrigerant hoses connected from AllVac to the recovery tank.

There will still be a small, residual amount of refrigerant in AllVac. This

amount must be removed if you want to change to a different type of

refrigerant. An explanation on how to remove this residual amount of

refrigerant is on page 14.

Low Pressure Section

27.Open Chiller Condenser & Evaporator Hand Valves on AllVac Unit” then

press “Enter”.

28.“Open Tank Vapor & Liquid Hand Valves on AllVac Recovery Unit”

then press “Enter”.

29.“To Evacuate Hoses Press Enter, To Skip Hose Evacuation Press

Cancel” if “Enter” is pressed, unit displays “Hose Evacuation in Pro-

cess” followed by “Hose Evacuation Complete, Press Enter”.

30.“Open Chiller Condenser & Evaporator Service Access Valves” then

press “Enter”.

31.Next “Open Vapor and Liquid Hand Valves on Recovery Tank” then

press “Enter”.

32.AllVac then displays “Liquid Transfer!” and displays the chiller pressure

and recovery tank pressures.

RRGA-SVX01A-EN 13

Operation

Note 4: If additional liquid line is connected for faster liquid recovery, open

chiller and recovery tank valves now. When AllVac goes into vapor recovery,

close recovery tank side of the hose.

33.AllVac will remain in liquid transfer state until manually switched to vapor

transfer as follows:

Once all liquid from chiller has been transferred and absolutely no liquid

refrigerant is remaining in clear recovery hoses and you are absolutely

sure that all of the liquid has been removed from the chiller, PRESS THE

ENTER KEY TWO TIMES IN A ROW. VAPOR RECOVERY WILL

COMMENCE. ALLVAC WILL DISPLAY “VAPOR RECOVERY IN

PROCESS” AND DISPLAY THE CHILLER AND RECOVERY TANK

PRESSURE. IT IS ABSOLUTELY IMPERATIVE THAT ALL LIQUID

HAS BEEN TRANSFERRED BEFORE SWITCHING TO VAPOR

RECOVERY MODE. FAILURE TO DO SO MAY RESULT IN LIQUID

SLUGGING THE COMPRESSOR AND CAUSING MAJOR DAMAGE.

34.When the user selected shutdown vacuum (either 0 PSI or 29” Hg) has

been achieved in the chiller system, the unit power shuts off and the dis-

play reads “Vapor Recovery 2 Minute Wait State”.

14 RRGA-SVX01A-EN

At this point, the microprocessor continues to monitor chiller pressure.

Should pressure rise, AllVac restarts to again achieve the user-selected

vacuum.

35.Then the display will read “Chiller Vapor Recovery Finished! press

Enter”.

Upon pressing “Enter”, AllVac prompts you to perform the following valve

manipulations 36 - 42:

Note 5: Close additional liquid access valve at this time, if being used.

“Close Both Service Access Valves on Chiller” then press”Enter”.

36.“Close Both Hand Valves on AllVac Unit Chiller Side” press “Enter”.

37.AllVac compressor then restarts and begins to force remaining liquid in

AllVac as well as liquid in hose into the recovery tank. Displaying “Liquid

Refrigerant Clearing in Process”.

38.“Close Both Liquid & Vapor Hand Valves on Recovery Tank” press

“Enter”.

39.AllVac then begins evacuating the recovery tank vapor hose, displaying

“Hose Evacuation in Process”.

40.“Close Both Liquid & Vapor Tank Hand Valves on AllVac unit” then

press “Enter”.

41.Finally, the unit displays “Chiller Recovery Completed! Disconnect all

Hoses and Power”.

At this time, close all four refrigerant hose isolation valves located on the

ends of the refrigerant hoses connected from AllVac to the recovery tank.

There will still be a small, residual amount of refrigerant in AllVac. This

amount must be removed if you want to change to a different type of

refrigerant. An explanation on how to remove this residual amount of

refrigerant is described in next paragraph.

Removing Remaining Residual Refrigerant

a) Connect the center tap of a manifold set to a suitable vacuum pump inlet

and discharge side of pump to an 50 lb. evacuated recovery cylinder. Con-

nect the low & high side of the manifold set to the 1/4” compressor suction

and discharge access ports located on the side of AllVac unit.

b) Open valve on 50 lb. recovery tank and turn on the vacuum pump. Open

the low & high side manifold valves and wait until a 29” vacuum has been

achieved on your manifold gauge.

c) Close both manifold valves, shut down vacuum pump and close recovery

tank valve. If you intend to use AllVac on a different type of refrigerant,

make sure to change compressor fluid and disposable driers.

Operation

RRGA-SVX01A-EN 15

Operation

Changing Replaceable Cores

Make sure you replace filter cores after each recovery job. Simply unscrew

used filter assembly and replace.

Procedures for Recharging System Using AllVac

These procedures provide for the transfer of refrigerant liquid and vapor from

a recovery tank to a centrifugal chiller system using the AllVac recovery unit.

These procedures are to be used when clean refrigerant is being returned to

a chiller without recycling.

When moving refrigerant between vessels, be certain that the pressure

never is greater than the vessel manufacturer’s recommendations.

Note: AllVac’s microprocessor displays instructions on the LCD screen as

recovery operations are implemented. During system recharging, the

references to the A/C System and the Recovery Tank are reversed.

Therefore, during recharging operations, the operator MUST assume that

the A/C System is now the Recovery Tank and the Recovery Tank is the A/C

System.

Select the desired vapor transfer stopping pressure, either zero (0) or 29”

Hg, for low pressure refrigerant.

1. Connect all liquid and vapor lines between chiller, AllVac recovery

unit and recovery tanks.

a) Refrigerant hoses should be connected in the following manner with all

valves in the closed position at this point:

Hose From To

Tank Vapor Tank AllVac System Vapor

Tank Liquid Tank AllVac System Liquid

Chiller Vapor Chiller AllVac Tank Vapor

Chiller Liquid Chiller AllVac Tank Liquid

Failure to adhere to the

procedures outlined herein can

cause severe damage to the

chiller. If liquid refrigerant is

introduced into the chiller while

the chiller is at deep vacuum, this

could result in tube freeze-up.

CAUTION

!

RRGA-SVX01A-EN 16

Operation

2. Evacuate Air from Chiller, AllVac and Hoses.

a) Once all lines are connected, open the AllVac valves in the following se-

quence: system liquid, system vapor, tank liquid, and tank vapor on AllVac

only.

b) Connect manifold gauge set and vacuum pump to ports on side of AllVac

unit at compressor suction and discharge ports.

c) Vacuum complete lines and AllVac to 29” Hg vacuum.

d) Close AllVac valves in the following sequence: system liquid, system va-

por, tank liquid, and tank vapor.

e) Disconnect manifold gauge and vacuum pump.

3. Increase Chiller Pressure Using Vapor From Recovery Tank.

(Refrigerant Vapor from the recovery tank is utilized to increase chiller

pressure at a controlled rate to prevent tube freeze-up when performing

procedure 4 below.)

a) Energize chiller condenser and evaporator water pumps. Water should be

flowing through both evaporator and condenser during this procedure to

reduce the potential for freezing chiller tubes.

b) Connect a vacuum gauge to the chiller.

c) Slowly open the specified valves in the following sequence:

(1) recovery tank vapor valve

(2) AllVac system vapor valve

(3) AllVac tank vapor valve

(4) chiller vapor valve

c) Continued. This step must be closely monitored manually at (4) chiller

vapor valve until the chiller pressure is sufficient to insure that it is above

freezing point for the refrigerant being transferred and until pressure has

equalized between the chiller and the recovery tank.

d) When pressure has equalized, close the specified valves in the following

sequence:

(1) chiller vapor valve

(2) recovery tank vapor valve

(3) AllVac system vapor valve

(4) AllVac tank vapor valve

4. Pump Liquid Refrigerant from Recovery Tank to Chiller

(Using AllVac to pump liquid refrigerant from recovery tank to chiller.)

a) Energize chiller condenser and evaporator water pumps. Water should be

flowing through both evaporator and condenser during this procedure to

reduce the potential for freezing chiller tubes.

During this procedure connect

the 120 VAC power for control

circuit to AllVac, but DO NOT

TURN THE ALLVAC UNIT ON until

this procedure 3 has been

completed and the pressure has

been equalized between the

chiller and the recovery tank AND

pressure is above the freezing

point.

Caution:

!

If liquid refrigerant is introduced

to the chiller when the pressures

are below the minimum levels as

noted in “b” below, severe

damage can occur due to freezing

of the chiller tubes.

Caution:

!

RRGA-SVX01A-EN 17

Operation

b) Before proceeding with this procedure, chiller pressure must be at a mini-

mum of 15” Hg. of vacuum or greater for R-11 or R-123. The minimum

pressure for R113 is 25” Hg. vacuum. If the chiller is not above the mini-

mum level, do not proceed with liquid transfer, but repeat procedure 3

above.

Do not continue this procedure until it is confirmed that chiller

pressure is above minimum required level.

c) Refrigerant hoses should be connected as follows:

Hose From To

Tank Vapor Tank AllVac System Vapor

Tank Liquid Tank AllVac System Liquid

Chiller Vapor Chiller AllVac Tank Vapor

Chiller Liquid Chiller AllVac Tank Liquid

d) Follow the procedures per the AllVac display, except you may ignore in-

structions to evacuate hoses at this time if hoses have already been evac-

uated per procedure 2 above.

Slowly open the specified valves in the following sequence:

(1) Recovery tank liquid valve

(2) AllVac system liquid valve

(3) AllVac tank liquid valve

(4) Chiller liquid valve

e) Monitor pressure in chiller condenser and evaporator. If pressure in chiller

becomes greater than 8 psig, shut down power to AllVac and remove non-

condensibles from chiller before resuming transfer.

f) Operate unit until all liquid refrigerant is removed from recovery tank. All-

Vac liquid sight glass, tank sight glass and liquid level gauge should all in-

dicate that all liquid refrigerant has been removed from the tank.

g) When all liquid refrigerant is removed from recovery tank, press “ENTER”

key two times on AllVac and vapor transfer from recovery tank will com-

mence. Continue to let AllVac run until vapor recovery is complete.

RRGA-SVX01A-EN 18

Operation

5. Evacuating Refrigerant Vapor From Recovery Tank and Hoses

(This step removes any liquid or refrigerant vapor in the recovery tank

and connecting hoses.)

a) Energize chiller condenser and evaporator water pumps. Water should be

flowing through both evaporator and condenser during this procedure to

reduce the potential for freezing chiller tubes.

b) AllVac provides for automated evacuation procedures of the recovery sys-

tem and hoses.

The operator reads the instructions provided by the microprocessor controls,

then performs the task described. This sequences each step for closing

valves and evacuating the AllVac and hoses

Important: AllVac’s microprocessor displays instructions on the LCD screen

as recovery operations are implemented. During system recharging, the

references to the A/C System and the Recovery Tank are reversed.

Therefore, during recharging operations, the operator MUST assume that

the A/C System is now the Recovery Tank and the Recovery Tank is the A/C

System.

c) Operate AllVac until tank vapor pressure gauge indicates a vacuum great-

er than 29” Hg for low pressure refrigerants.

Note: If, at any time, chiller pressure gauge indicates a value greater than 10

psig:

1. Compare chiller gauge reading with the saturated pressure shown in a

standard pressure/temperature chart for the type of refrigerant being

transferred. If the chiller pressure exceeds the saturated pressure indi-

cated for the type of refrigerant being transferred for the present chiller

temperature, it is actually an indication of the presence of air in the chiller.

2. If there is air in the chiller, the operator should use the chiller’s purge sys-

tem to remove the air before continuing and/or use RefTec’s portable

Minipurge. The Minipurge is an oil-less compressor driven purge which is

designed to purge non-condensibles from any refrigerant.

Note: If chiller pressure repeatedly rises above 10 psig, this indicates an air

leak in either the recovery tank or connecting hoses. If leakage cannot be

stopped at this time, terminate the operation.

d) Upon completion of the evacuation procedures, follow the instructions

according to the AllVac display to shut down unit.

e) Disconnect all power cables and hoses.

RRGA-SVX01A-EN 19

Calibration

Pressure Transducer Calibration Procedure

AllVac unit is equipped with a sensitive pressure transducer which needs to

be calibrated prior to running the AllVac. This will take into account variations

in atmospheric pressure at various altitudes and locations.

RefTec recommends that this calibration procedure be performed if any of

the following events occur:

a) Any time a new pressure transducer is installed on the unit.

b) Any time that the unit is moved to a substantially different altitude or is ex-

posed to significantly different atmospheric pressure.

c) Any time that pressure readings appear to be questionable or there is any

reason to doubt the accuracy of the transducer readings.

Calibration Procedure Steps:

1. At power up, the AllVac Recovery Unit will display:

“AllVac COMMERCIAL RECOVERY UNIT”

“HAS POWER (PRESS START)“

2. At this screen you must press “CANCEL” twice within 5 seconds to enter

the CALIBRATION mode. The display will then show the following:

“OPEN PRESSURE TRANSDUCERS TO ATMOSPHERE “

“(THEN PRESS ENTER KEY)”

3. Now, with no hoses connected, open the liquid and vapor, system and

recovery tank, valves on the AllVac to the atmosphere and press

“ENTER”.

4. The screen will then display the following message:

“SYSTEM PRESSURE xx PSI”

“PRESS ENTER TO CALIBRATE THIS TRANSDUCER"

The system is displaying the raw, uncalibrated reading from the transducer. If

you press “ENTER”, it will calculate a calibration value and store it in the

computer’s nonvolatile memory. If you press “CANCEL”, a new calibration

factor will not be calculated.

5. It will then display the following message:

“RECOVERY TANK PRESSURE xx HG”

“PRESS ENTER TO CALIBRATE THIS TRANSDUCER”

20 RRGA-SVX01A-EN

Calibration

The system is once again displaying the raw, uncalibrated reading from the

transducer. Once you press ENTER, it will calculate a calibration value for

this transducer and store it in memory. If you press “CANCEL”, a new

calibration factor will not be calculated. It will then display the following

message and be ready for operation:

“ALLVAC COMMERCIAL RECOVERY UNIT”

“HAS POWER (PRESS START) “

Changing Compressor Fluid

The compressor’s charge of Poly Ester fluid should be regularly replaced

with an identical fluid or, at a minimum, after any of these events:

1. After a maximum of 10 hours of run time

2. When changing recovery jobs that involve different refrigerants

3. After a recovering a system with a burnt out compressor.

To remove and change the oil in the compressor and the oil separator:

WARNING

a) Make sure AllVac unit has no refrigerant in its internal parts.

b) Connect a manifold set to dry nitrogen and to the suction and discharge

service 1/4” access ports located on the side of the AllVac.

c) Connect another 1/4” hose to the access fitting on the bottom of the AllVac

oil separator fitting and the other end to a suitable disposable oil container.

d) Gradually allow dry nitrogen to go into the discharge port on the AllVac unit

until all oil has been forced out of the oil separator. Note: 10 to 15 PSI will

be more than adequate.

e) Connect another 1/4” hose to the access fitting on the bottom of the AllVac

compressor fitting and the other end to a suitable disposable oil container.

f) Gradually allow dry nitrogen to go into the suction port on the AllVac unit

until all oil has been forced out of the compressor.

g) To add new oil to the AllVac compressor, connect a vacuum pump to the

1/4” access port on the suction side of the compressor. Pull down into a

minimum 29” vacuum.

h) Connect other hose to the 1/4” access port on the bottom of the compres-

sor and into the new oil container. Note: fill compressor with exactly 18 oz.

of oil.

i) After compressor has been filled, connect other hose to the 1/4” access

port on the bottom of the oil separator and into the new oil container. Note:

fill oil separator with exactly 16 oz. of oil.

j) Once this procedure is finished, remove all hoses and pull entire AllVac

into a 29” vacuum. Dispose of old oil properly.

ARNING

Note: Failure to follow above procedures for recharging oil in compressor

with the exact amount of oil may result in major damage to the compressor.

When changing oil, it is highly

recommended that the same type

of oil being used with the

refrigerant being recovered, be

used in the AllVac compressor.

This will help ensure that cross

contamination does not occur.

Caution:

!

This manual suits for next models

10

Table of contents