barfield 2548H Operator's manual

USER INSTRUCTION MANUAL

M/N: 2548H, P/N: 101-00420

Doc. P/N: 56-101-00420

Revision C

November 7, 2014

____________________________________

BARFIELD, INC.

Corporate Headquarters

4101 Northwest 29thStreet

Miami, Florida 33142

www.barfieldinc.com

Email: [email protected]

Copyright © 2014 Barfield Inc. All Rights Reserved.

2548H FUEL QUANTITY TEST SET

2548H INSTRUCTION MANUAL

56-101-00420 Rev. C Contact

Nov /07 /14 Page ii

CONTACT INFORMATION

Users are requested to notify the manufacturer of any discrepancy, omission, or error found in

this manual. Inquiries should include specific questions and reference the publication title,

number, chapter, page, figure, paragraph, and effective date.

Please send comments to:

TECHNICAL CUSTOMER SUPPORT - GSTE

BARFIELD, INC.

P.O. BOX 025367

MIAMI, FL 33102-5367

USA

Telephone (305) 894-5400

(800) 321-1039

Fax (305) 894-5401

2548H INSTRUCTION MANUAL

56-101-00420 Rev. C Attention

Nov /07 /14 Page iii

ATTENTION

Although every effort has been made to provide the end user of this equipment with the most

current and accurate information, it may be necessary to revise this manual in the future. Please

be sure to complete and return the enclosed OWNER WARRANTY REGISTRATION CARD to

Barfield in order to validate the warranty and to ensure that you will receive updated information

when published. You MUST have your name and address on file at Barfield as a registered

user of this equipment, to be able to obtain the service covered by the warranty.

Visit the company website, http://barfieldinc.com/, for publication updates.

Please send the Registration Card to:

Barfield, Inc.

P.O. Box 025367

Miami, FL 33102-5367

USA

2548H INSTRUCTION MANUAL

56-101-00420 Rev. C REV

Nov /07 /14 Page iv

REVISION RECORD

REV.

ECO #

REV. DATE

DESCRIPTION OF CHANGE

A

B

C

N/A

260-00729

260-01053

March 1, 2003

February 3, 2009

November 7, 2014

Initial Release. This manual supercedes

2548H-8005 Instruction manual and/or previously

released Instruction manuals for model 2548H.

Updated Company Information and logo. Page

numbering and format were reformatted.

Updated Barfield logo

2548H INSTRUCTION MANUAL

56-101-00420 Rev. C Maint.

Nov /07 /14 Page v

MAINTENANCE AND REPAIR INFORMATION

The manufacturer of this equipment does not recommend the user to attempt any maintenance

or repair. In case of malfunction, contact the manufacturer, to obtain the list of approved repair

facilities worldwide, ensuring that this equipment will be serviced using proper procedures and

certified instruments. A Return Maintenance Authorization (RMA) number will be assigned

during this call, to keep track of the shipment and the service.

BARFIELD PRODUCT SUPPORT

DIVISION

Shipping Address:

Telephone (305) 894-5400

(800) 321-1039

Fax (305) 894-5401

Barfield, Inc.

4101 NW 29th Street

Miami, Florida 33142

USA

Mailing Address:

Barfield, Inc.

4101 NW 29th Street

Miami, Florida 33142

USA

THIS PAGE INTENTIONALLY LEFT BLANK

2548H INSTRUCTION MANUAL

56-101-00420 Rev. C TOC

Nov /07 /14 Page vii

TABLE OF CONTENTS

Contact Information

Attention Page

Revision Record Page

Maintenance and Repair Information

Table of Contents

List of Figures

Page

INTRODUCTION

1. PUBLICATION BREAKDOWN ..............................................................................1

2. INFORMATION PROVIDED WITH THE UNIT......................................................1

3. RECERTIFICATION ...............................................................................................2

CHAPTER 1: GENERAL INFORMATION

1. PURPOSE ..............................................................................................................5

2. 2548H FRONT PANEL COMPONENTS...............................................................6

CHAPTER 2: SPECIFICATIONS AND CAPABILITIES

1. CAPABILITIES ................................................................................................. 9

2. SPECIFICATIONS........................................................................................... 9

3. PHYSICAL DATA .......................................................................................... 10

CHAPTER 3: OPERATION

1. GENERAL INFORMATION ........................................................................... 11

2. PRELIMINARY .............................................................................................. 13

3. PRECAUTIONS............................................................................................. 14

4. SYSTEM INSULATION TEST ....................................................................... 14

5. INDIVIDUAL TANK UNIT INSULATION TEST.............................................. 18

6. SYSTEM CAPACITANCE TEST ................................................................... 19

7. INDIVIDUAL TANK UNIT CAPACITANCE TEST.......................................... 21

8. AMPLIFIER TEST/CALIBRATION ................................................................ 22

9. SYSTEM CALIBRATION............................................................................... 26

CHAPTER 3: RECEIVING, SHIPPING, STORAGE

1. RECEIVING................................................................................................... 33

2. SHIPPING ..................................................................................................... 33

3. STORAGE..................................................................................................... 33

2548H INSTRUCTION MANUAL

56-101-00420 Rev. C LOF

Nov /07 /14 Page viii

LIST OF FIGURES

Page

Figure 1 Identification Label ................................................................................... 1

Figure 2 Owner Warranty Registration Card .......................................................... 2

Figure 3 Limited Warranty Statement Card............................................................ 3

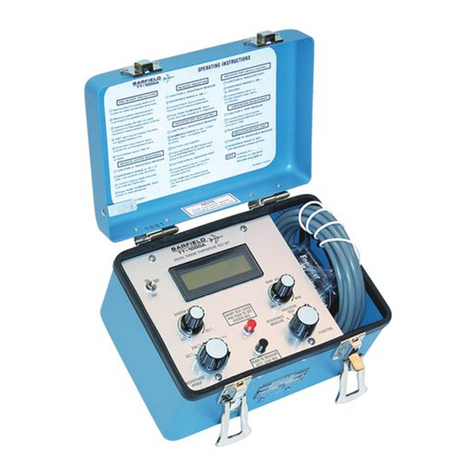

Figure 4 2548H AC Fuel Quantity Test Set............................................................ 5

Figure 5 2548H Front Panel Components.............................................................. 6

Figure 6 Insulation Test, Configuration #1 ........................................................... 16

Figure 7 Insulation Test, Configuration #2 ........................................................... 16

Figure 8 Insulation Test, Configuration #3 ........................................................... 18

Figure 9 Insulation Test, Configuration #4 ........................................................... 18

Figure 10 Configuration of Capacitance Test......................................................... 19

Figure 11 Individual Tank Unit Capacitance Test, Configuration #1 ...................... 21

Figure 12 Individual Tank Unit Capacitance Test, Configuration #2 ...................... 21

Figure 13 Capacitance Simulation, Configuration #1............................................. 23

Figure 14 Capacitance Simulation, Configuration #2............................................. 23

Figure 15 Capacitance Simulation, Configuration #3............................................. 24

Figure 16 System Calibration (Method 1), Configuration #1 .................................. 27

Figure 17 System Calibration (Method 1), Configuration #2 .................................. 27

Figure 18 System Calibration (Method 1), Configuration #3 .................................. 28

2548H INSTRUCTION MANUAL

56-101-00420 Rev. C Intro

Nov /07 /14 Page 1 of 33

INTRODUCTION

1. PUBLICATION BREAKDOWN

This instruction manual establishes the operation standards for the 2548H Fuel Quantity

Test Set

Its purpose is to provide sufficient information for the personnel unfamiliar with this unit to

understand this equipment, identify its parts, and operate it in accordance with proper

procedures, operating techniques, precautions and limitations.

2. INFORMATION PROVIDED WITH THE UNIT

Besides this User Instruction Manual, the 2548H Test Set is provided with the four items

described below.

A. An identification label similar to Figure 1 and located on the front bulkhead of the Test

Set, provides the following information:

Manufacturer Name

Designation of Equipment

Equipment Part Number

Equipment Model Number Equipment Serial Number

Equipment Modification (if applicable) Equipment Options (if applicable)

Figure 1 IDENTIFICATION LABEL

FUEL QUANTITY T/S

101-00420

2548H

2548H INSTRUCTION MANUAL

56-101-00420 Rev. C Intro

Nov /07 /14 Page 2 of 33

B. The Owner's Warranty Registration card, (Figure 2), which is to be completed by the

owner and returned to the Barfield within ten (10) days of purchase to insure validation

of the warranty.

Figure 2 OWNER WARRANTY REGISTRATION CARD

C. The Limited Warranty Statement, (Figure 3), which lists the manufacturer's obligation to

the original purchaser.

D. Each new or re-certified unit is delivered with a Certificate that shows the date when the

unit was tested by the manufacturer, its serial number, and when the next certification is

due. This certificate confirms that the unit performed according to its design

specifications.

3. RECERTIFICATION

The Test Set P/N 101-00420 has a one-year recertification requirement. Maintenance

required by this unit must be performed by qualified technicians in a shop equipped with the

necessary tooling and facilities.

2548H INSTRUCTION MANUAL

56-101-00420 Rev. C Intro

Nov /07 /14 Page 3 of 33

Figure 3 LIMITED WARRANTY STATEMENT

THIS PAGE INTENTIONALLY LEFT BLANK

2548H INSTRUCTION MANUAL

56-101-00420 Rev. C Ch. 1

Nov /07 /14 Page 5 of 33

CHAPTER 1: DESCRIPTION

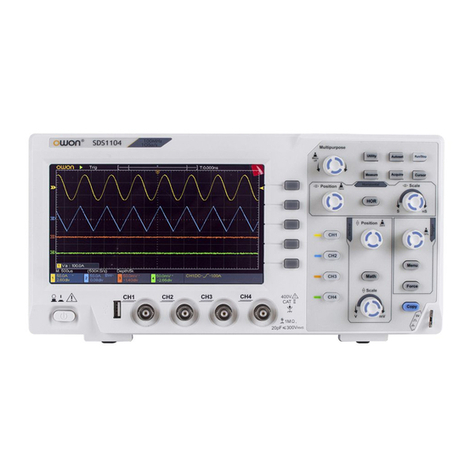

1. PURPOSE

The Barfield 2548H Fuel Quantity Test Set (P/N 101-00420) is specifically designed to

satisfy the need to service guarded, capacitance-type aircraft fuel and oil quantity-measuring

systems. Accuracy and reliability have been optimized together with portability and

convenience. The accuracy of the Test Set (T/S) ensures that manufacturer’s measurement

and calibration requirements are met. The potentials and currents the T/S introduces are

limited to meet all safety precautions. The Test Set’s circuitry components also provide

current limiting in case of a catastrophic failure. Three measurements and two capacitance

simulator functions are provided through the function selector switch.

The standard lead package enclosed with the 2548H Test Set provides all accessories

necessary (except adapter cables) to adapt the adapter cable, aircraft or component to the

Test Set. Please refer to the Barfield Ground Test Equipment catalog for further

information.

Figure 4 2548H FUEL QUANTITY TEST SET

A. Adapter Cables

Each individual Aircraft Fuel Quantity System requires its own particular adapter cable(s)

and the specific instructions. Adapter Cable configurations and interfaces vary widely to

accommodate the variety of fuel systems. There is an extensive selection of adapter

cables manufactured by Barfield Inc. to be used with the 2548H Fuel Quantity Test Set.

Please contact the Barfield Ground Support Test Equipment Sales department or visit

the Barfield website at http://www.barfieldinc.com/ground.html for further information.

2548H INSTRUCTION MANUAL

56-101-00420 Rev. C Ch. 1

Nov /07 /14 Page 6 of 33

B. Carrying Case

The carrying case is made of drawn aluminum for maximum strength. The lid is fitted

with a bracket, which, when closed, contacts the ON/OFF switch if it was left in the ON

position, and moves it to the OFF position.

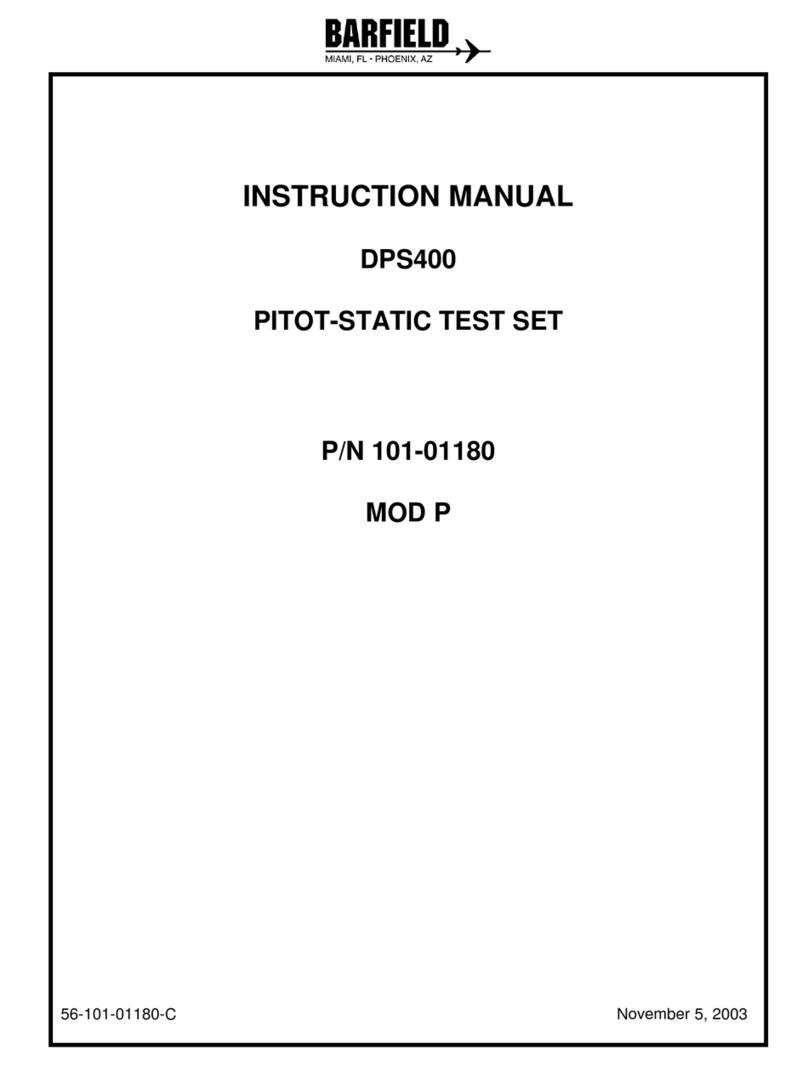

2. 2548H FRONT PANEL COMPONENTS

Note: Refer to Figure 5 for item number identification.

Figure 5 2548H PANEL COMPONENTS

(1) The PRESS TO MEASURE is a pushbutton, which when pressed, activates the bridge

VCC supply and switches the bridge for external use.

(2) The GND banana jack provides a connection to the Test Set’s case ground.

(3) The LO-Z is a polarized BNC receptacle for the LO-Z insulation leak tests.

(4) The HI-Z is a polarized BNC receptacle for the HI-Z insulation leak tests.

2548H INSTRUCTION MANUAL

56-101-00420 Rev. C Ch. 1

Nov /07 /14 Page 7 of 33

(5) TEST FUNCTION is a rotary switch, which selects one (1) of five (5) test functions.

When the Test Set is placed in the CAP SIM 1 or CAP SIM 2 function, the meter may

be substituted for a DC meter-type fuel quantity indicator.

(6) INS TEST POINTS selector switch permits selection of one (1) of six (6) pairs of

different test points for insulation leak tests.

(6A) RANGE selects x1 or x.01 MΩfor display during insulation tests.

(7) The INDICATOR banana jacks are used for indicator input connections for 0-1100 µA

meter testing or substitution.

(8) METER ADJUST is a linear potentiometer, which controls the 0-1100 µA test current

or adjusts the megaohmmeter for infinity (∞), full scale setting. When the INDICATOR

switch is selected, this component provides an adjustable current through the panel

meter to the indicator jacks.

(9) The PANEL METER is a DC taut-band micro ammeter, which provides the 0-1100 µA

current scale, 0-5000 MΩscale and battery condition scale. Its circuitry components

allow adjustments for all test functions from full scale to 1100 µA.

(10) The BATTERY COMPARTMENT contains the batteries or the optional AC power

supply. The four (4) 9V batteries are connected to provide a bipolar 18 VDC supply

that is controlled through the ON/OFF switch. The optional 115 VAC or 230 VAC

power supply assembly is interchangeable with the DC battery supply assembly. The

AC supply is short-circuit protected and warranted by the manufacturer.

(11) ON/OFF is a toggle switch that provides the output battery or AC power supply.

(12) BATT TEST is a pushbutton, which when pressed, connects the panel meter as a full-

scale meter 0-37.4 voltmeter across the battery supply. (The BATT OK measurement

line indicates 24.8V.)

(13) TANK CAP pF thumbwheel assembly selects the capacitance simulator value

between HI-Z COAX and LO-Z TANK jacks or bridge value.

(14) HI-Z COAX, a BNC receptacle, provides a HI-Z connection for the bridge and the

simulators.

(15) LO-Z TANK, a polarized BNC receptacle provides a LO-Z connection for the bridge

and the tank simulators.

(16) LO-Z COMP is a polarized BNC receptacle connection for the compensator simulator.

(17) COMP SIM pF is a 100’s-10’s thumbwheel assembly and a 0-10 pF variable for setting

compensator capacitance between HI-Z COAX and LO-Z COMP.

(18) The COMP CAL is a pushbutton which, when pressed, connects the compensator

simulator to the capacitance bridge.

THIS PAGE INTENTIONALLY LEFT BLANK

2548H INSTRUCTION MANUAL

56-101-00420 Rev. C Ch. 2

Nov /07 /14 Page 9 of 33

CHAPTER 2: CAPABILITIES AND SPECIFICATIONS

1. CAPABILITIES

When the 2548H Fuel Quantity T/S is connected through the appropriate adapter cables,

the following functions may be performed:

Measure capacitance of individual or interconnected tank sensor probes or probe

simulators

Measure the insulation resistance of system wiring, probes, or other discrete test points.

Test the performance of indicators and signal conditioners or bridge amplifiers.

Simulate capacitances representative of empty or full probes or systems, or the added

capacitance effect of the fuel between empty and full.

Substitute the test set meter for DC meter-movement type gauges, and provides

adjustable metered current to test these gauges.

2. SPECIFICATIONS

INSULATION

Range: 0 to Infinity (∞) in two scales:

5 to 5000 MΩ

50 kΩto 50 MΩ

Accuracy: ±5% of reading nominal, but not in excess of ±2% of scale length all

through range

Applied Voltage: 10 VDC nominal

Current 50 nA maximum

INDICATOR

Range: 0-1100 µA in 10 µA increments

Accuracy: ±1% of full scale

CAPACITANCE BRIDGE

Range: 0 to 999.9 pF in 0.1 pF increments

Accuracy: ± (0.1% of reading + 0.1 pF)

Signal: 400 Hz at 5.7 V RMS nominal

2548H INSTRUCTION MANUAL

56-101-00420 Rev. C Ch. 2

Nov /07 /14 Page 10 of 33

2. SPECIFICATIONS (continued)

CAPACITANCE SIMULATORS

Tank Range: 0 to 999.9 pF in 0.1 pF increments

Accuracy: Same as Capacitance Bridge

COMP Range: 10-400 pF continuously adjustable

Accuracy: Set with Capacitance Bridge

Maximum Input 75 V RMS, 220 V peak-to-peak (above 3 kHz, Tank Simulator limit

decreases proportionately to 10 V RMS at 25 kHz)

INPUT POWER

Batteries Four (4) Each, 9V Batteries

External Power 115V or 230V

50-400 Hz AC Optional

3. PHYSICAL DATA

In. Cm.

Height 5.3 13.5

Width 12.2 31.0

Depth 10.4 26.4

Lbs. Kg

Weight 7.0 3.2

2548H INSTRUCTION MANUAL

56-101-00420 Rev. C Ch. 3

Nov /07 /14 Page 11 of 33

CHAPTER 3: OPERATION

1. GENERAL INFORMATION

Fuel Quantity Indicating Systems provide the crew with an accurate display of the remaining

fuel. The quantity of fuel shows on the fuel quantity indicator(s) in the flight compartment.

The Fuel Quantity Indicating System includes the amplifier or signal conditioners (also

known as the amplifiers) and the probe(s)/transmitter(s) that are installed in each tank (also

knows as the Tank Unit). A Tank Unit is a capacitor. It consists of two (2) conductive tubes

separated by an air gap, or a combination of air and fuel. The Unit is connected to terminals

that are, in turn, connected to the amplifier. This unit measures the fuel mass or weight.

The volume or weight is determined by the dielectric constant of the insulating air or fuel, or

air/fuel mixture in the tank; then, fed to other units for refinement or amplification before

being displayed on the indicator.

Note: For more complete and detailed information on specific Fuel Quantity Systems, refer

to the appropriate Aircraft/System Maintenance Manuals.

A. Stray Capacitance Compensation

A certain amount of stray capacitances exists within the Test Set (T/S). This could be

caused by exposure of unshielded lead wire at connecting points or capacitance

between switch contacts and between any HI-Z to LO-Z conductors (which cannot be

effectively shielded from one another.

These stray capacitances change from one function to another due to the addition or

subtraction of circuitry and, due to the differences in the mechanical position of movable

contact switches. A mounted circuit on the meter PC board compensates these stray

capacitances. To ensure accurate results, adapter harness stray capacitances should

be subtracted from the measured values and calibration settings.

2548H INSTRUCTION MANUAL

56-101-00420 Rev. C Ch. 3

Nov /07 /14 Page 12 of 33

B. Methods of Calibration

There are two (2) methods of Fuel Quantity System calibration:

Method 1:Dry Tank (PREFERRED)

Method 2:Wet Tank (ALTERNATE)

(1) Method 1 (Preferred)

The Dry Tank method of calibration is done without fuel in the tank(s) and with

the Tank Unit(s) dry. A capacitance value is substituted for an equivalent amount

of fuel (full) in the tanks. The indicator is then adjusted to display this full level of

fuel. (This method is more accurate since the indicator’s zero (0/ ) indication is set

to the actual empty tank value thus ensuring the integrity of the system’s empty

level.)

(2) Method 2 (Alternate)

The Wet Tank method of calibration is done with fuel in the tanks. The Tank Unit

is “electrically” removed from the Fuel Quantity Indicating System. Simulated

values for both EMPTY and FULL adjustments are made to the indicator. The

actual empty setting is questionable. Accuracy is sacrificed by using simulated

values.

However, if correct, current dry tank capacitance values are available for the

aircraft by serial number, these values should be used for the indicator EMPTY

adjustment. The user may than add the ADD FOR FULL value to the current dry

tank value to get the FULL adjustment value. (Refer to the Aircraft Maintenance

manual.)

Note: Method 2 should be used only as a TEMPORARY measure. Method 1

should then be done at a more suitable time.

Other manuals for 2548H

1

This manual suits for next models

1

Table of contents

Other barfield Test Equipment manuals

barfield

barfield DPS400 User manual

barfield

barfield TT-1000A Operator's manual

barfield

barfield 1811D Series Operator's manual

barfield

barfield DPS1000 Operator's manual

barfield

barfield 2311FA Operator's manual

barfield

barfield DPS1000 Operator's manual

barfield

barfield 1811GA Series Operator's manual

barfield

barfield 1811NG Operator's manual

barfield

barfield TT-1000A Operator's manual

barfield

barfield DFQ40K Operator's manual