56-101-01175 Revision I Page | x

LIST OF FIGURES

FIGURE 1 IDENTIFICATION LABEL.......................................................................................... 13

FIGURE 2 OWNER WARRANTY REGISTRATION CARD......................................................... 14

FIGURE 3LIMITED 2 YEAR WARRANTY................................................................................. 15

FIGURE 4 POWER ENTRY MODULE ........................................................................................ 20

FIGURE 5 CASE DIMENSIONS................................................................................................. 21

FIGURE 6 OPTIONAL TRAVEL / SHIPPING CASE.................................................................... 22

FIGURE 7 POWER SUPPLY CABLE......................................................................................... 23

FIGURE 8 DO NOT OBSTRUCT VENTS................................................................................... 23

FIGURE 9 HUMID AIR EXHAUST.............................................................................................. 23

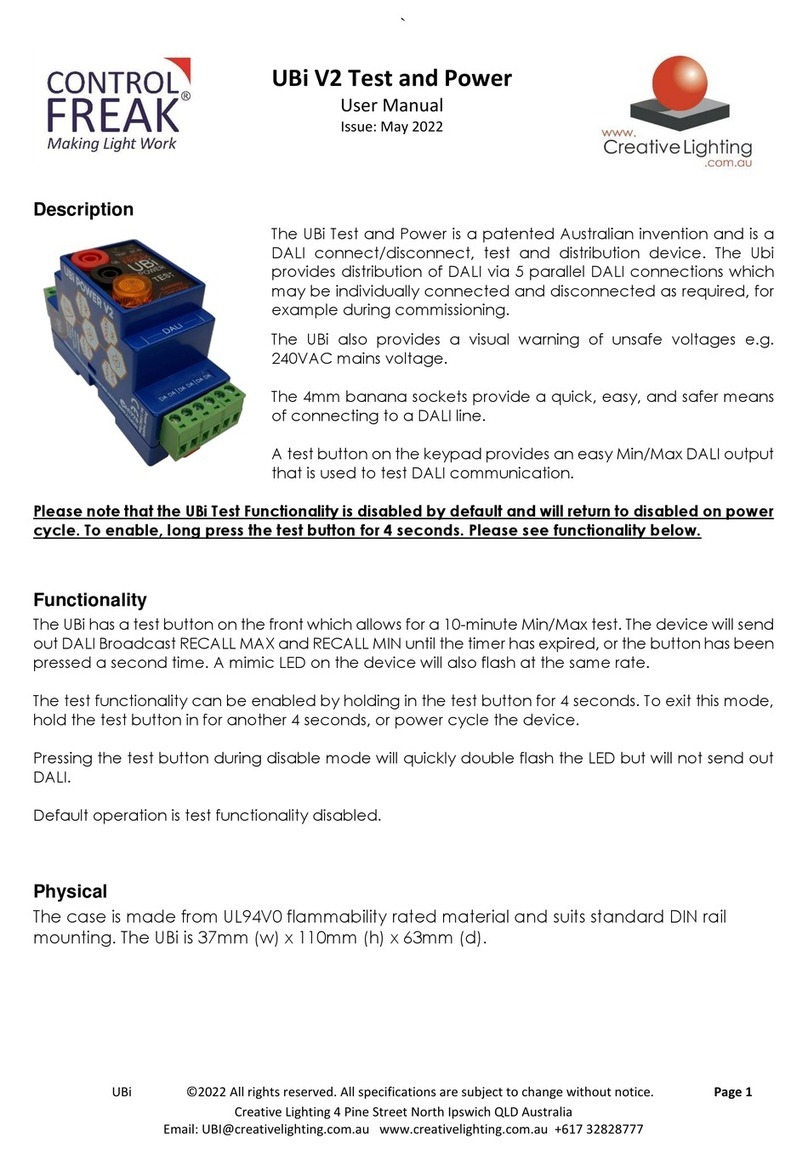

FIGURE 10 DPS1000 PRESSURE CONNECTIONS ................................................................. 24

FIGURE 11 DPS1000 FRONT PANEL........................................................................................ 25

FIGURE 12 INSTRUCTION MANUAL, P/N 56-101-01175......................................................... 27

FIGURE 13 ELECTRICAL CABLE, P/N AE9887-ND.................................................................. 27

FIGURE 14 HOSE KIT ............................................................................................................... 27

FIGURE 15 ANTENNA, P/N 126-00001...................................................................................... 28

FIGURE 16 CARRYING BAG, P/N 195-00021............................................................................ 28

FIGURE 17 AN4 CAPS WITH LANYARD, P/N 176-00001 (OPT-A)........................................... 28

FIGURE 18 POWER ON INITIALIZATION DISPLAY .................................................................. 29

FIGURE 19 DEFAULT 2-CHANNEL (DUAL PS, PT) MODE ...................................................... 31

FIGURE 20 OPTIONAL 1-CHANNEL (PT ONLY) MODE............................................................ 31

FIGURE 21 TEST SET CONFIGURATION INFORMATION DISPLAYED................................. 32

FIGURE 22 DISPLAY SETUP AERONAUTICAL MENU ........................................................... 33

FIGURE 23 TARGET VALUE KEYPAD SCREEN...................................................................... 34

FIGURE 24 DISPLAY SETUP: 4-PARAMETER FORMAT ......................................................... 34

FIGURE 25 DISPLAY SETUP:2-PARAMETER FORMAT......................................................... 35

FIGURE 26 DISPLAY UNITS –FOR AERONAUTICAL MODE.................................................. 35

FIGURE 27 DISPLAY UNITS –FOR PRESSURE UNITS MODE .............................................. 36

FIGURE 28 LEAK TESTING MENU........................................................................................... 36

FIGURE 29 LEAK RATE TIMER RESULTS............................................................................... 37

FIGURE 30 SELECT ATP LEAK TEST PROFILE...................................................................... 38

FIGURE 31 ATP LEAK TEST - PARAMETER PROFILE SCREEN............................................ 39

FIGURE 32 ATP LEAK TEST RESULTS SCREEN.................................................................... 39

FIGURE 33 GO TO GROUND CONFIRM SCREEN................................................................... 40

FIGURE 34 CONCLUSION OF GO TO GROUND ..................................................................... 40

FIGURE 35 CONCLUSION OF GO TO GROUND ..................................................................... 41

FIGURE 36 SETUP 1................................................................................................................. 41

FIGURE 37 ALTITUDE CORRECTION SCREEN ...................................................................... 42

FIGURE 38 ALTITUDE CORRECTION ON-AIRCRAFT............................................................. 43

FIGURE 39 ALTITUDE CORRECTION KEYPAD........................................................................ 43

FIGURE 40 TEST SET CONFIGURATION, UPDATED ALTITUDE CORRECTION................... 44

FIGURE 41 SETUP 1 CONTROL MODE(S)............................................................................... 44

FIGURE 42 SETUP 2 - SELECTING LIMIT FILE TO EDIT......................................................... 45

FIGURE 43 SETUP 2 –EDIT CUSTOM LIMITS......................................................................... 46

FIGURE 44 DELETE CUSTOM LIMITS ..................................................................................... 47

FIGURE 45 BACKLIGHT ADJUSTMENT................................................................................... 48

FIGURE 46 DPS1000 FRONT PANEL........................................................................................ 49

FIGURE 47 INITIALIZATION DISPLAY...................................................................................... 50

FIGURE 48 LEAK TESTING MENU(S) ...................................................................................... 52

FIGURE 49 SELECTING ATP LEAK TEST PROFILE............................................................... 53

FIGURE 50 LEAK TEST PROFILE - PARAMETERS SCREEN ................................................ 53

FIGURE 51 MEASURE TIME VS LEAK TIME............................................................................ 54