I.B. 35-557

2 of 45

DISCLAIMER OF WARRANTIES

AND LIMITATION OF LIABILITY

THERE ARE NO UNDERSTANDINGS, AGREEMENTS, REPRESENTATIONS OR

WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, OTHER THAN

THOSE SPECIFICALLY SET OUT BY AN EXISTING CONTRACT BETWEEN THE

PARTIES. ANY SUCH CONTRACT STATES THE ENTIRE OBLIGATION OF SELLER.

THE CONTENTS OF THIS DOCUMENT SHALL NOT BECOME PART OF OR MODIFY

ANY PRIOR OR EXISTING AGREEMENT, COMMITMENT OR RELATIONSHIP.

The information, recommendations, descriptions and safety notifications in this

document are based on Cutler-Hammer’s experience and judgement with respect to

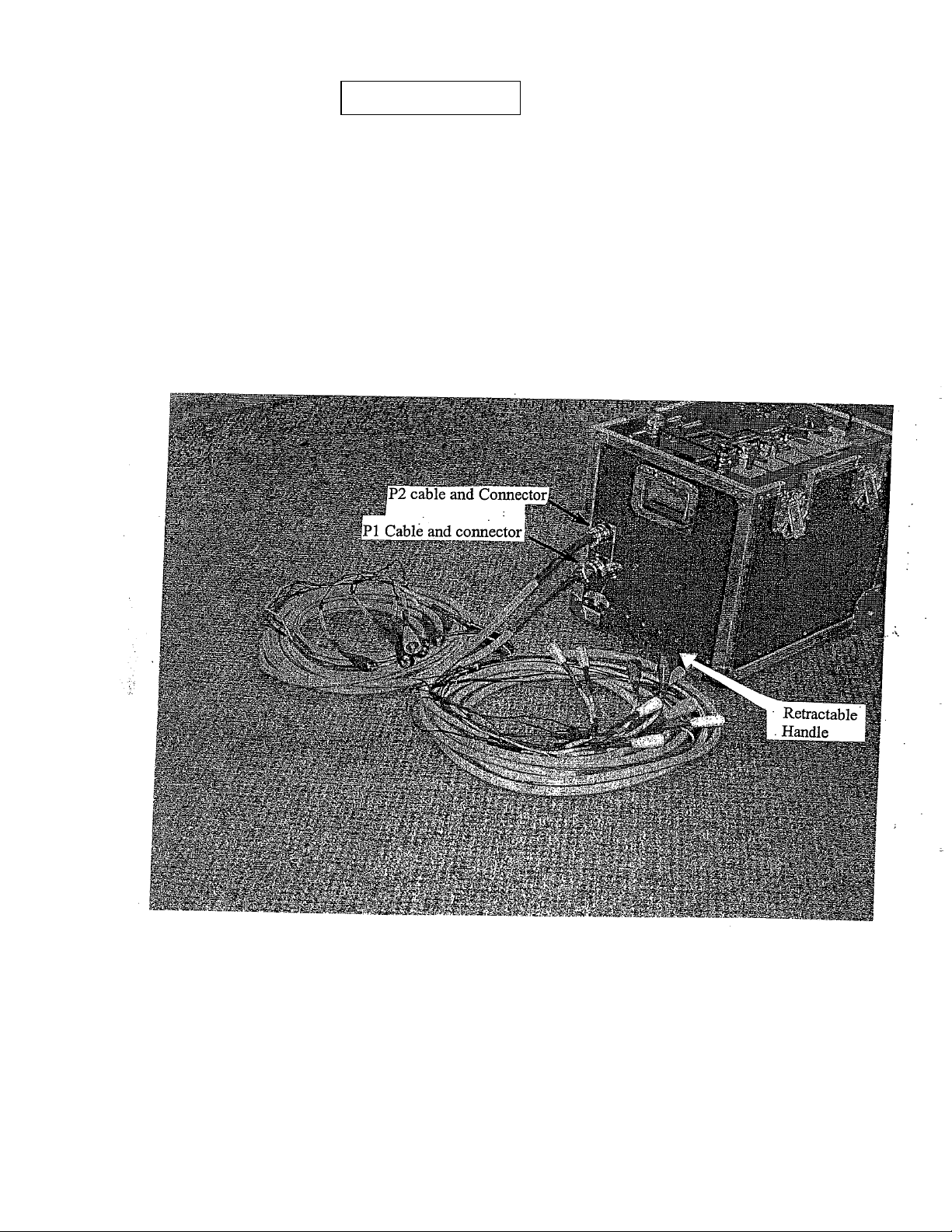

the HWT-500 TEST SET. THIS INFORMATION SHOULD NOT BE CONSIDERED TO BE

ALL-INCLUSIVE OR COVERING ALL CONTINGENCIES. If further information is

required, Cutler-Hammer should be consulted.

NO WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING WARRANTIES OF

FITNESS FOR A PARTICULAR PURPOSE OR MERCHANTABILITY, OR WARRANTIES

ARISING FROM COURSE OF DEALING OR USAGE OF TRADE, ARE MADE

REGARDING THE INFORMATION, RECOMMENDATIONS, DESCRIPTIONS AND

SAFETY NOTATIONS CONTAINED HEREIN. In no event will Cutler-Hammer be

responsible to the user in contract, in tort (including negligence), strict liability or

otherwise for any special, indirect, incidental or consequential damage or loss

whatsoever including but not limited to damage to or loss of use of equipment, plant

or power system, cost of capital, loss of profits or revenues, cost of replacement

power, additional expenses in the use of existing power facilities, or claims against

the user by its customers resulting from the use of the information,

recommendations, descriptions and safety notations contained herein.

Please read instruction book I.B. 35-557 carefully before attempting to use the HWT-500.

Any questions regarding the HWT-500 Test Set or its instruction booklet may be answered by calling the

Cutler-Hammer Network Protector toll-free number: 1-800-525-6821.

Failure to follow instructions contained within the instruction booklet and addendum could result in severe

personal injury, death, and/or product or property damage and will void any warranties, expressed or implied.

These instructions do not purport to cover all possible contingencies that may arise during

installation, operation, or maintenance, and all details and variations of this equipment. If further

information is desired by purchaser regarding his particular installation, operation or maintenance of

his equipment, the local Cutler-Hammer representative should be contacted.