SFA ZPS 2.3 Service manual

UK Electronic pump control • Operation and assembly instructions

DE Elektronische Pumpensteuerung • Bedienungs- und Montageanleitung

FR Boîtier de commande de pompes • Mode d'emploi

Controllo elettronico della pompa • Istruzioni per l’uso e la manutenzione

Elektronische pompensturing • Bedien- en montagehandleiding

Control electrónico de bombeo • Instrucciones de manejo y de montaje

Comando eletrónico da bomba • Manual de instruções e de montagem

CONTROL BOX

ZPS 2.3

IT

NL

ES

PT

9002.3

11.19

UNIDOMO®

www.unidomo.de

04621- 30 60 89 0

[email protected]

Mo.-Fr. 8:00-17:00 Uhr

a member of DAIKIN group

English...................................... 3

Deutsch..................................... 17

Français .................................... 33

Italiano ..................................... 47

Nederlands................................ 62

Español..................................... 77

Português ................................. 92

CONTENTS

Copyright / Disclaimer - Control Box ZPS 2.3 Installation and Maintenance Manual - Original operating instructions

All rights reserved. The contents of this document must not be reproduced, modified or disclosed to third parties except upon writ-

ten consent from the manufacturer. This document may be subject to change without notice.

Status of the operating instructions: November 2019

1. SAFETY............................................................. p 4

2. GENERAL INFORMATION.............................. p 4

2.1 Areas of application...............................................p 4

2.2 General characteristics ...........................................p 5

2.3 Technical data .......................................................p 5

3. OPERATION OF THE CONTROL SYSTEM..... p 6

3.1 Operator control panel and operational elements ......p 6

3.1.1 Keys...............................................................p 6

3.1.2 Indications on the display..................................p 7

3.1.3 Normal operation ............................................p 7

3.1.4 Parameter setting .............................................p 8

3.1.5 Information retrieval .......................................p 10

3.1.6 Warnings and notices of malfunction................p 11

3.2 Assembly and electrical connections.......................p 13

3.2.1 Mechanical fixing ..........................................p 13

3.2.2 Mains connection...........................................p 13

3.2.3 Connection of the pump motor.........................p 13

3.2.4 Connection of the external sensors ...................p 15

3.2.5 Signal contacts ..............................................p 15

3.2.6 Utilisation of the internal sensor .......................p 16

3.3 Commissioning of the control system.......................p 16

4. DISPOSAL......................................................p 16

4

1. SAFETY

WARNING

This device can be used by children who are at least 8 years old and

by people with reduced physical, sensory or mental capacities or those

without knowledge orr experience, if they are properly supervised or

if they have been given instrcutions on safely using the device and the

associated risks have been understood. Children should not play with

the device. Children should not clean or perform manintenance ont he

device without supervision.

ELECTRICAL CONNECTIONS:

The electrical installation must be done by a qualified electrical engineer.

The device's power supply must be connected to ground (class I) and protect-

ed by a high sensitivity differential circuit breaker (30 mA). Devices without

plugs must be connected to a main switch on the power supply which discon-

nects all poles (contact separation distance of at least 3 mm). The connection

must be used exclusively to provide the power to the product.

If the power cord is damaged, to prevent possible danger, it must be replaced

by the manufacturer, customer service team or a similarly qualified individual.

Labelling of notes in the operating instructions

Danger

This term defines a high risk of danger, which can lead to death or serious

injury, if not avoided.

WARNING

Warning

This term defines a hazard which could cause a risk to the machine and its

operation, if it is not taken into account

Dangerous area

This symbol characterises hazards that could lead to death or injury.

Dangerous voltage

This symbol characterises dangers associated with the voltage and provides

information on voltage protection.

Property damage

This symbol, in combination with the keyword ATTENTION, characterises

dangers to the machine and its proper operation.

2. GENERAL INFORMATION

2.1 Areas of application

The twin pump control system ZPS 2.3 is principally used for the regulation of liquid levels. For this,

5

various sensors for level measurement can be used: floating switches, dynamic pressure, air bubble

level measurement systems, external 4- 20mA- sensors. The respective sensors to be employed can

be selected via the control program. Then two pumps are directly activated by motor contactors.

The pump changeover can be effected via time-control or level-control.

Furthermore, the following devices for error messages are available: acoustic signaler, 4 relay

alarm contacts potential-free (programmable for: high-water, combined fault, pump on, malfunction

pump, unit okay), safety circuits in the form of a turn-on- and a turn-off-delay, motor current

monitoring systems, motor temperature monitoring systems and flood control sensors guarantee a

safe operation of the pump station.

The control system is operated via 9 short travel key switches, the program settings are displayed

on an LCD display. All settings are saved so that they are available when the control system is

restarted. The display language can be changed.

Besides the actual operational parameters, the control system also saves the controlling process

and the occurring malfunctions in a record which can be displayed on the LCD display.

2.2 General characteristics

• Clear LCD display

• Hand- Stop- Auto- Function

• 1 acknowledgement button, 2 parameter

select buttons

• Menu which can be switched through

• Internal acoustic alarm

• Programmable operation and collective fault

signal potential-free

• Floating flood control potential-free

• Omnibus fault message potential-free

• Setting via short travel key switches

• Operating hours counter

• Maintenance interval counter

• Pump start counter

• Recording of fault protocol

• Electronic monitoring of the motor current

• Programmable turn-on-delay

• Programmable pump follow-up

• Programmable pump changeover interval

• Switchable service- and ATEX- mode

• Internal pressure sensor

• Level indication in cm

• 4 digital inputs for thermostatic switch

• 4 digital inputs for floating switch or reed

sensor

• 1 analogue input for transmitter 4-20mA

• 1 analogue pressure input 0-100(500) mBar

2.3 Technical data

Operating voltage 230V or 400V/AC/50-60 Hz

Voltage of control system 230V/AC/50-60 Hz

Power consumption env. 6VA

Pressure range 0-1mWs

Turn-on-delay 0-180 sec

Follow-up time 0-180 sec

Runtime monitoring 0-300 sec

Turn-on-delay 2 pumps 0-60 sec.

Motor current limitation 0.5- 14A

Fault protocol memory 32 memory positions

Maintenance interval counter 0 – 365 days, adjustable

Operating temperature range -20 - +60°C

Dimensions 180x180x90 mm

Max. pre-fuse 20A

Potential-free alarm contact 3 A max.

Degree of protection IP 65

Housing Polycarbonate

6

3. OPERATION OF THE CONTROL SYSTEM

The electronic pump control is equipped with a key lock. To unlock, please

press and hold (Selection) for 3 seconds. There will be an indication in

the display. Approximately 1 minute after the last actuation of any key the

keyboard will be locked again.

The automatic key lock after 1 minute can be deactivated in the menu, e.g. to

aid with maintenance works. The keylock is enabled with the service mode

switched-off only

3.1 Operator control panel and operational elements

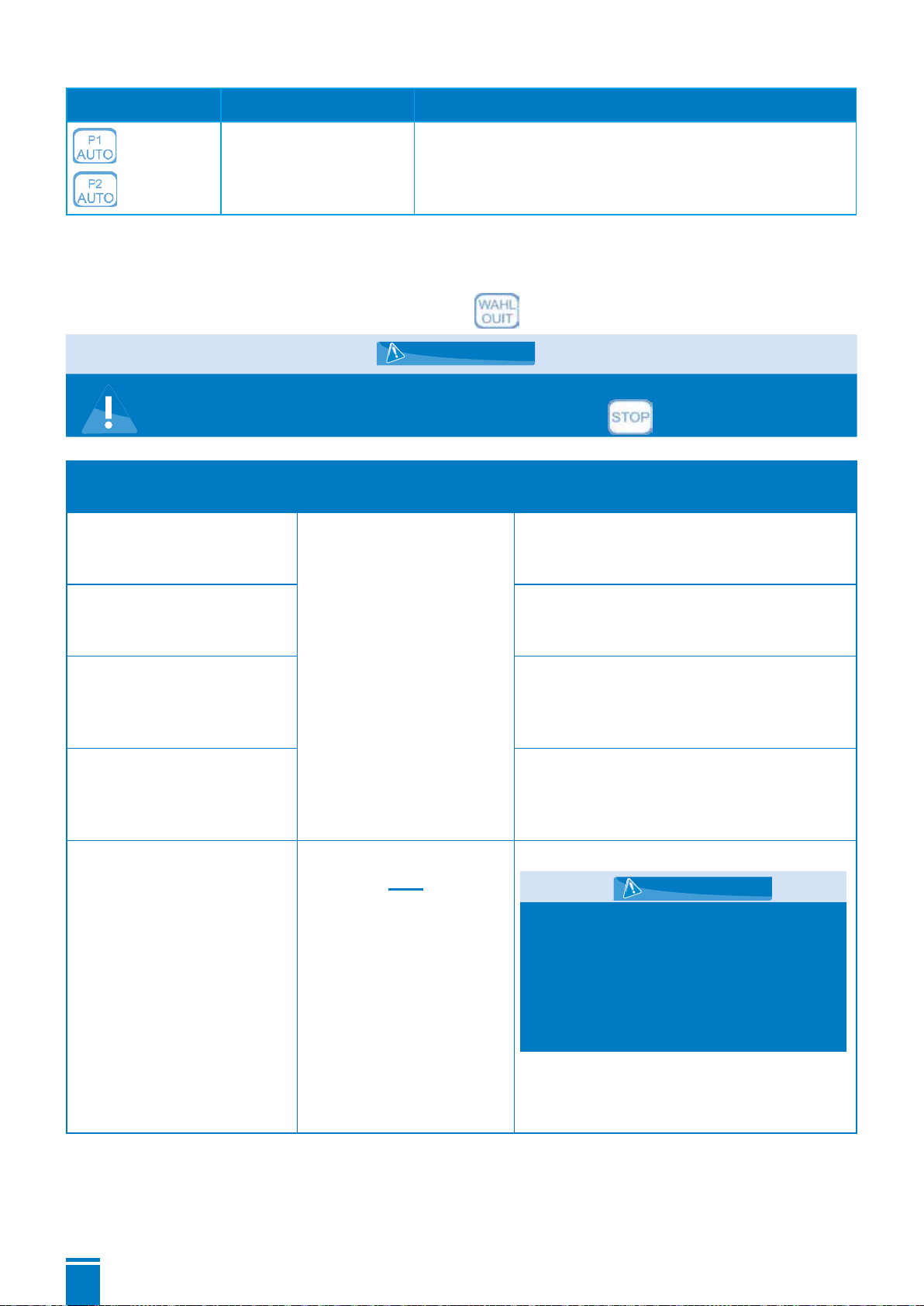

3.1.1 Keys

(MANUAL)

By pressing this key, the preferred pump is switched on without delay. Except for

the motor monitoring, no other function of the program is enabled.

The green LED ③of one pump flashes. ATTENTION : If the ATEX mode is enabled,

the pump can only be started if the turn-on level is exceeded !

The green LED is flashing. ATTENTION : The pump will be switched after 2

minutes. A restart of the pump is possible immediately.

Stops the pump motor without follow-up. The green LED goes out.

The pumps are actuated via the level evaluation of the selected sensor (see

point 3.1.4). All monitoring and safety functions are executed according to the

presetting.

③Signal-LED indicating when the pump is

operating :

- green: pump is on

- red: fault

② Short travel

key switches

① LCD display

(2 lines with 16

characters)

7

By pressing one of these two keys, the menu is switched to the next menu item in

the indicated direction.

If the menu is enabled, (see key SELECTION ), the set values can be modified

via those keys (some modifications are only possible in the operating mode

“Stop”). The more you press the key, the faster it scrolls.

(Selection/

Stop)

By pressing this key, the set values in the active menu are enabled. The activated

text will start to flash (modification mode) and can be modified by usin

g

.

By repeatedly pressing these keys, the set value becomes permanent (flashing

stops), which means that it will be saved even if the control system is turned off.

3.1.2 Indications on the display

Normal operation :

During operation of the control system, the upper line of the LCD display indicates the actual liquid

level or the switching status of the floating switch. In the lower line of the display, information about

the actual operational status of the control system of the pumps P1 and P2 will appear. If one pump

is running, the active motor current and the operating condition are displayed alternately. In case

of failure, the actual failure status is displayed (see point 3.1.6). The LEDs of the pump will flash

with a red light.

Parameter setting :

In the upper line, the designation of the parameter is displayed; the lower line displays the current

value of the parameter. The values can be modified by using the keys and as described

in 3.1.1.

Information retrieval :

Information values such as maintenance intervals, operating hours, pump starts and fault list can

be displayed and modified in the same way as the control parameters. Only the fault list saves 32

positions respectively. The recording is carried out by means of a shift register, which means that

the earliest error is deleted automatically.

3.1.3 Normal operation

During normal operation, the three operating modes are indicated on the display as follows.

Pressed key 2nd line on display Signification

Hand 1 P1 4,7A

Hand 2 P2 0,0A

The pump P1 and the pump P2 have been switched on

manually.

Stop 1 P1 0,0 A

Stop 2 P2 0,0 A

The pump motors are switched off. The level evaluation,

including the flood control, remains enabled.

The pump motor is not activated during

flooding alarm.

WARNING

8

Pressed key 2nd line on display Signification

Auto P1 4,7A

Auto P2 0,0A

The pumps are switched on or off, according to the level

requirement. Here, pump P1 is active at the moment.

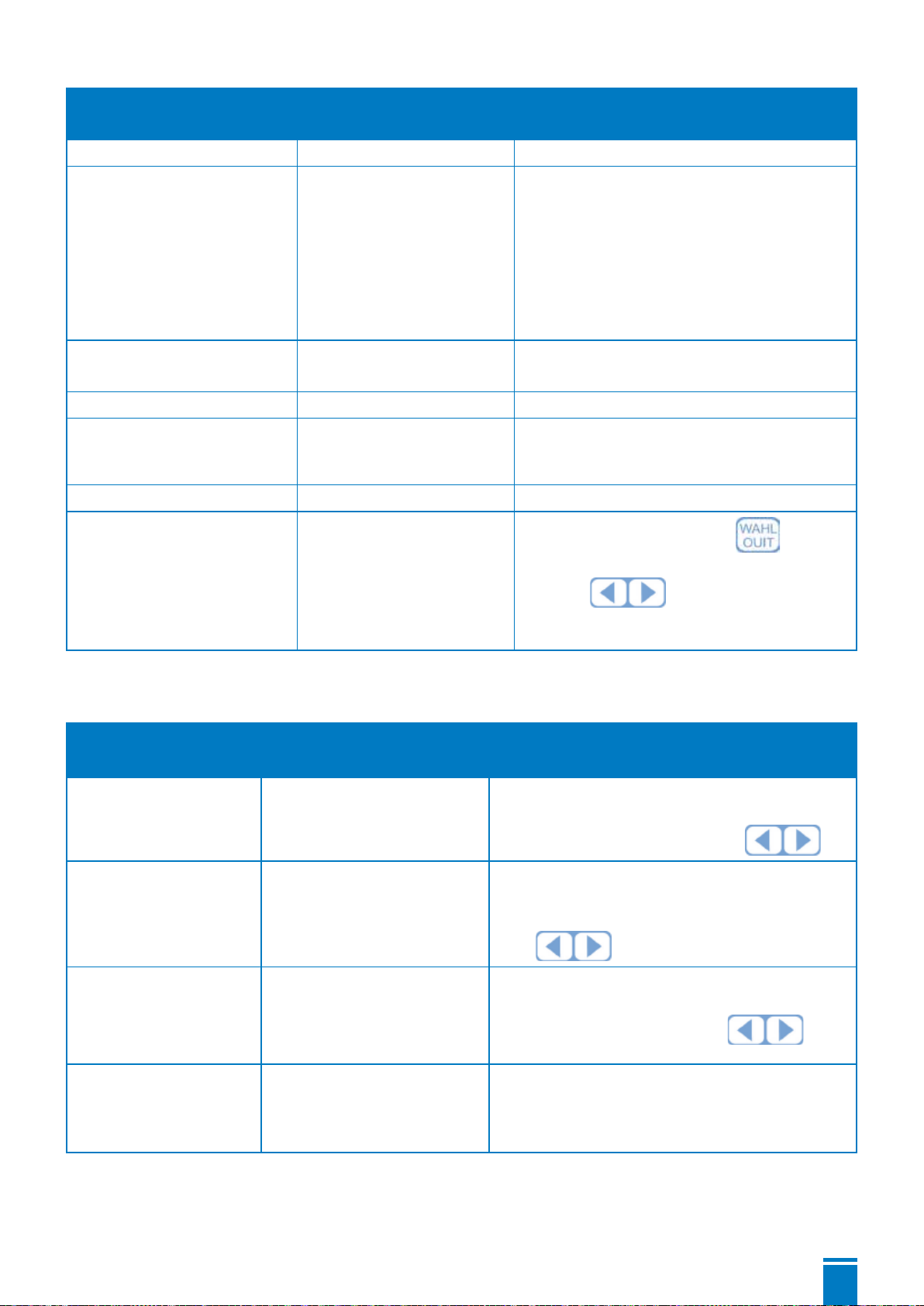

3.1.4 Parameter setting

The following table shows the setting options and the effects of the individual parameters. A

parameter can be selected via the menu selection (see point 3.1.1).

For reasons of safety, the modification mode for the parameters can

only be enabled in the "Stop"- operation (key ).

1st line on display 2nd line on display

(set value) Signification

base load OFF Base load off ≤ Peak load

off

and

Base load on ≤ Peak load

on

Stop level base load.

Modifications only during Stop-

operation!

base load ON Start level base load.

Modifications only during Stop-

operation!

peak load OFF Stop level peak load, 2nd pump will switched

off.

Modifications only during Stop-

operation!

peak load ON Start level peak load, 2nd pump will

switched on.

Modifications only during Stop-

operation!

high water

(High water HW)

Peak load on < HW

and

HW ≤ final value of level

sensor

Flooding- alarm- level

Additionally, this level is constantly

evaluated on the input for the

floating switch HW, independent

from the selected level transmitter.

Thereby, if necessary, 2 different

HV-levels can be realised with 2

different transmitters.

Modification only possible in Stop-

mode !

WARNING

WARNING

9

1st line on display 2nd line on display

(set value) Signification

run-time

(Run-time change after)

is deactivated

until 300 sec.

At transgression of the adjusted time during

base load operation pumps do change.

‘IS DEACTIVATED’ effects that each

modification occurs only after reaching the

level ‘BASE LOAD OFF’.

This function may be used to monitor the

flow rate of the pump.

Here unto a time above the normal pump-

down time has to be adjusted. A switch

occurs if the requested pump has not

pumped down under the switch-on point

within the adjusted time. After 3 consecutive

the error "Run-time Alarm" occurs.

delay time 0 to 180 sec The turn-on delay of the pump only functions

after a restart of the control system (e.g.

after a power failure). With “normal” switch

operation via the levels N1 and N2, this

setting is not relevant.

This function may be used to avoid the

simultaneous switch-on of several pumping

stations after a mains failure.

overrun 0-180 sec. After having reached the turn-off level, the

pumps are still running for the adjusted

amount of time.

Interpump delay 0 to 60 sec. When both pumps are requested at the

same time, the second pump will be

switched on after the adjusted time, e.g. to

avoid mains overload.

pumps together - is activated

- is deactivated

If this function is deactivated, only one

pump works, e.g. to avoid overload of the

wastewater system.

max. current P1

max. current P2

0,0 to 14,0 A If the adjusted value is reached, the

monitoring system of the pump motor current

effectuates the shutdown of the pump,

accompanied by a notice of malfunction.

The malfunction has to be acknowledged

manually by pressing the key .

Attention : If the nominal current is

adjusted to 0 A no monitoring of the motor’s

charging rate occurs !

24 hours start is activated

is deactivated

Pump P1, P2 are briefly started if no request

occurs by the switch-on level within 24

hours.

If the ATEX mode is enabled, the 24h

starting is only taking place if the turn-off

level is exceeded.

10

1st line on display 2nd line on display

(set value) Signification

acoustic alarm is activated

is deactivated

The internal acoustic transmitter is switched

on or off. This setting has no influence on

the potential-free alarm signal.

interval alarm is activated

is deactivated

The alarm relay for the non-floating alarm

contact is synchronized or produces a

permanent signal.

pump changeover is activated

is deactivated

If the pump changeover is enabled a

changeover of the pumps occurs after each

pump down.

P1: therm.fault

P2: therm. fault

Thermostatic switch

P1 TH1 control loop

TH2 control loop

P2 TH3 control loop

TH4 control loop

is activated

is deactivated

The evaluation of the thermal contacts TH1

and TH3 (control loop) can be deactivated.

If this contact is open, the pump is shut

down and a fault is signalled. After the

contact TH1/TH3 (clipping circuit) has

cooled down and been closed again, the

pump restarts automatically.

After cooling down, the activation of the

pump in case of malfunction TH2/TH4 can

only be effected by acknowledging the

malfunction by pressing the key .

This contact can not be deactivated by

means of the software. If the pump is not

equipped with thermal contacts, a bridge

has to be inserted as a substitution for TH2/

TH4.

phase error is activated

is deactivated

The energization of all the 3 phases and the

proper phase sequence at the mains input

are monitored.

To be disabled for 230 V pumps.

ATEX - Mode is activated

is deactivated

If the ATEX mode is enabled, it is not

possible to switch on the pump if the turn-off

level is under-run. This also applies for the

HAND function and the 24h starting.

service mode is activated

is deactivated

If the service mode is disabled, it is

not possible to set the parameters. The

modification mode is only possible for the

service mode itself.

level controller

(=Level control)

intern. converter

float switch

4-20mA Interface

Level measurement via dynamic pressure

measurement

Level measurement via external sensor

Level measurement via floating switch

intern. converter matching

(=calibration) By pressing the key sequence

, the zero point of

the internal converter is adjusted. The

adjustment has to be carried out while

the pilot tube is emerged (with barometric

pressure). This adjustment is to be carried

out by a service technician only.

11

1st line on display 2nd line on display

(set value) Signification

20 mA => level 1 - 1250 cm Final value of the sensor at 20 mA

Signal contact 1-4 Possible signals :

- Fault high water

- Collective fault

- Pump 1 on

- Pump 2 on

- Fault pump 1

- Fault pump 2

- system OK

Kind of signal on contacts 1-4

The collective fault signal can be timed

Language Deutsch

English, etc...

Setting of the menu language

DD.MM.YYYY hh:mm see adjustments Date and time

Keylock on / off The keylock can be disabled. The key lock is

enabled with the service mode switched-off

only.

WLAN reset Disabled

Fault protocol - - - After having pressed the key , the

protocol can be paged through by pressing

the keys .It is not possible to

change the data. The last 32 malfunctions

are saved in chronological order.

3.1.5 Information retrieval

The following table shows the signification of the operational data of the control system :

1st line on display 2nd line on display

(informational value) Signification

up time hours: X

(in hours)

Shows the cumulative operating times of the

control system in hours. The value can be

reset to 0 by pressing the keys .

total pump hours P1/P2 XXXX/XXXX

(in hours)

Shows the cumulative runtimes of the

pumps in hours. The value can be reset to 0

(separately for both pumps)by pressing the

keys .

pump starts P1/P2 XXXX/XXXX

(in number)

Shows the number of pump starts. The

value can be reset to 0 (separately for both

pumps) by pressing the keys .

next maintenance within days:XXXX

(in days)

Shows the number of days until the next

maintenance. The information is saved at

intervals of 4 hours. The initial value can be

preset between 365 and 0 days.

12

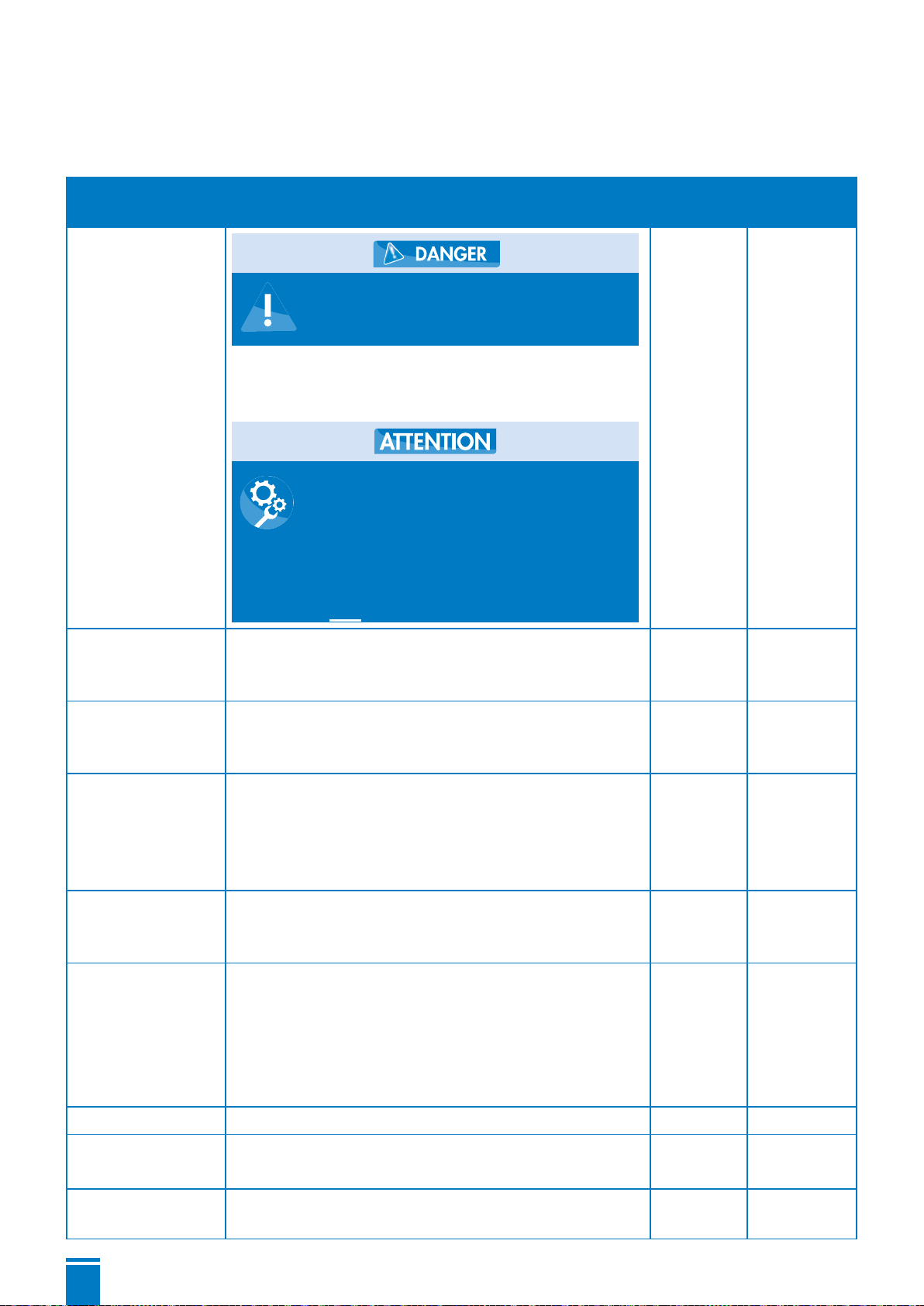

3.1.6 Warnings and notices of malfunction

The following warnings and notices of malfunction can be indicated on the display. In the fault

protocol, the data will be recorded :

2nd line on

display Signification Alarm Protocol

signal

Fault load

Current flow below 0,5 A. Either

no pump is connected, or a

phase is lacking.

This malfunction can be suppressed, if for the

motor current monitoring 0.0A are set in the menu

“current limitation“.

If both pump currents are set

to 0,0A, the control system is

running in the test mode. The

pumps are not deactivated. All

functions of the control system

are enabled. The motor current

is not monitored.

Yes Last

Fault pump 1

Fault pump 2

The motor current monitoring system has detected

an exceedance of the set limit value and has shut

down the pump motor.

Yes IP1

Fault high water The HW-sensor reports an alarm and switches on

the pump. The HW-malfunction acknowledges itself

when the turn-on level is reached again.

Yes HW

Fault

I<3mA

The external sensor is selected, but the current

is <3mA. There might be a disconnection, or

the sensor might be defective. The malfunction

acknowledges itself when the sensor current is

within the normal range.

Yes I<3mA

Fault

SW

The floating switches are connecting in the wrong

sequence (e.g. the lower floating switch is open

when the upper floating switch closes).

Yes SW

Pump 1

Fault TH1

Fault TH2

Pump 2

Fault TH3

Fault TH4

Activation of the thermal control of the pump

motor. The malfunction TH1 and TH3 acknowledge

themselves after the motor has cooled down; TH2

and TH4 have to be acknowledged manually.

Yes Pump 1

TH1

TH2

Pump 2

TH3

TH4

Phase fault A phase of the power supply has failed. Yes Dreh

Fault

ATEX

The ATEX mode is activated and the level is below

the switch-off point of the selected pump. Yes Atex

Run-time alarm The runtime monitoring of the pump has been

exceeded 3 times in succession. Yes Time

13

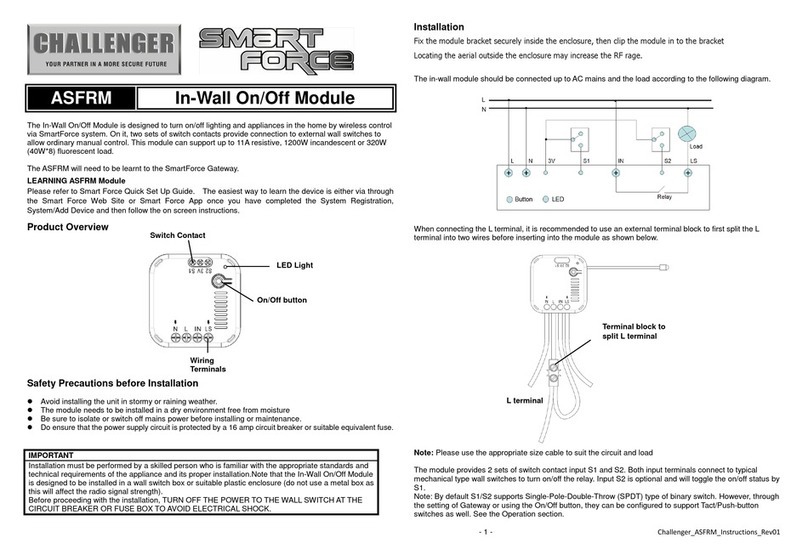

3.2 Assembly and electrical connections

All electrical connections are to be established by an authorised

professional only. Settings and adjustments on the control system

as well as the commissioning of the control system are to be

carried out by qualified persons only.

3.2.1 Mechanical fixation

The control system has to be fixed on an even surface. In order to fasten the control system, the

housing cover has to be opened.

3.2.2 Mains connection

The left cable gland is intended for the cable entry of the mains cable. The separate cables are

to be clamped into the spring terminals in the manner described below. According to the motor

which is used, a single-phase or a three-phase connection can be established.

The power supply has to be secured by an independent all-pole

fuse which can be switched off (max. 20 A).

3.2.3 Connection of the pump motor

Either mono-phase or three-phase motors may be connected according to the below shown

connection diagram.

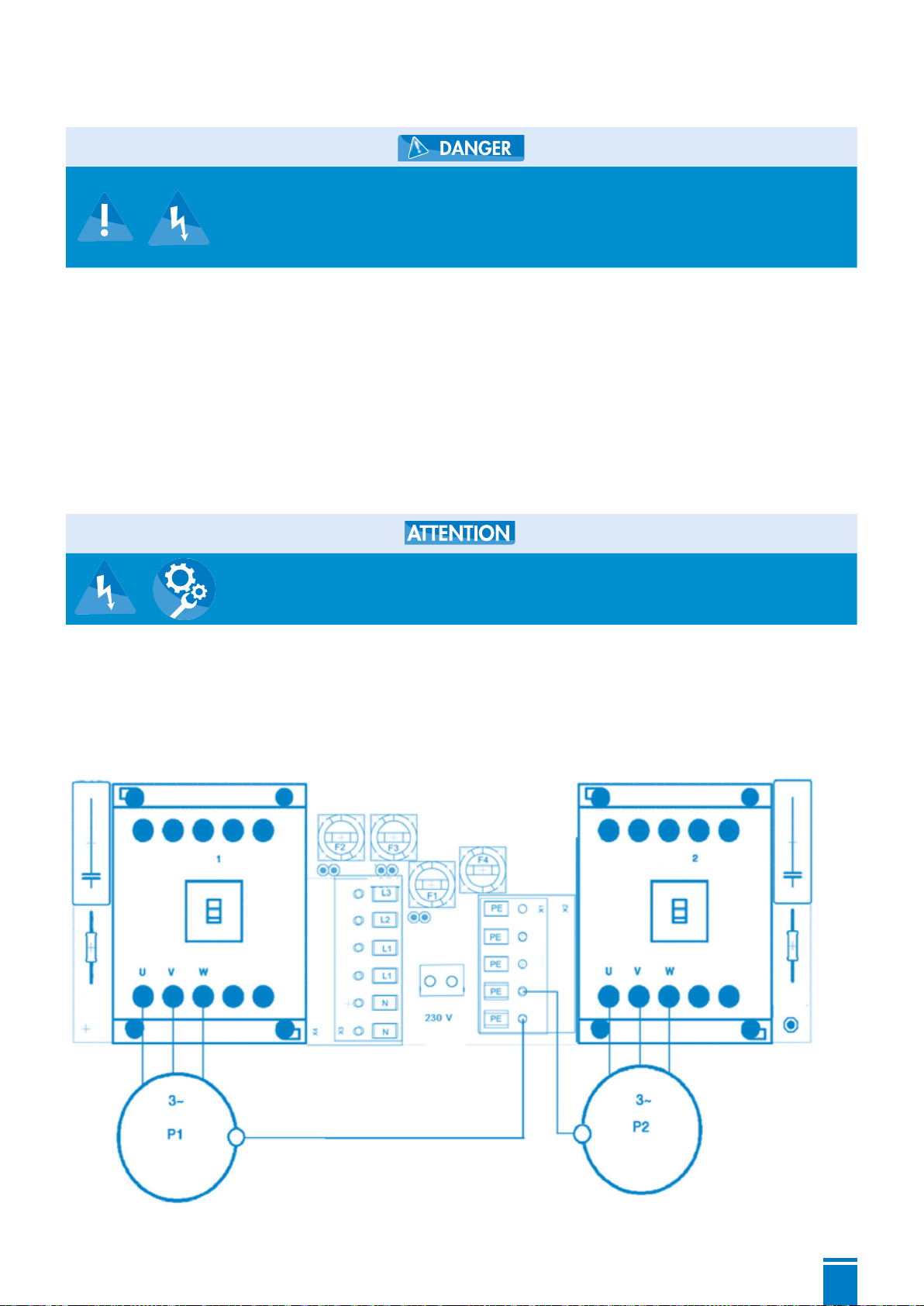

Connection of a 3-phase Motor :

Pump

Small-scale

consumer

Mains connection

230 V

Protective conductor

Pump

14

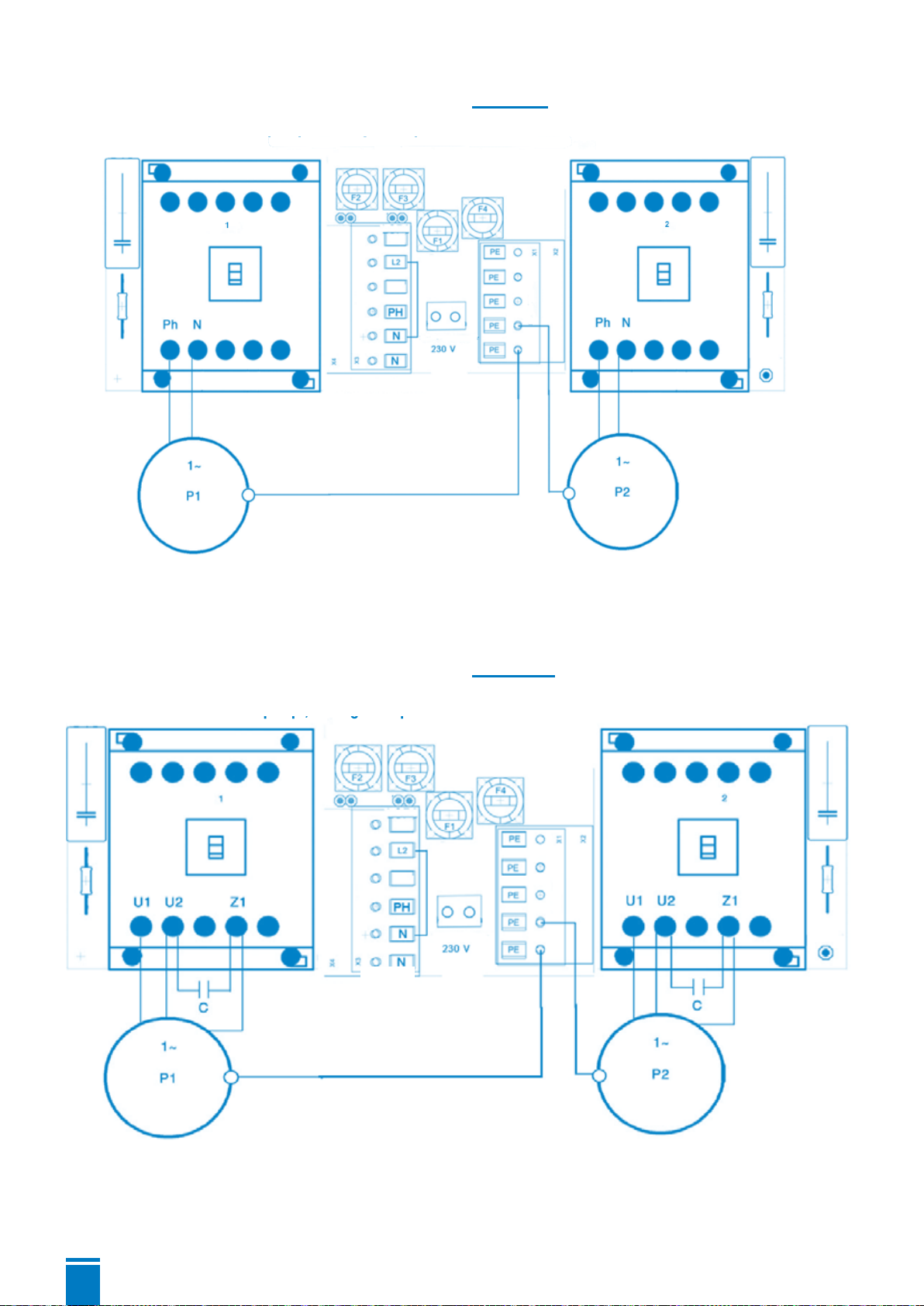

Connection of a single-phase Motor with internal capacitor :

Pump

Small-scale

consumer

Mains connection

Protective conductor

As for 230V pumps, a bridge is required between N - L2 in the mains connection

Pump

Connection of a single-phase Motor with external capacitor :

Pump

Small-scale

consumer

Mains connection

Protective conductor

As for 230V pumps, a bridge is required between N - L2 in the mains connection

Pump

For 230V pumps, a bridge between N-L2 is required in the mains connection.

For 230V pumps, a bridge between N-L2 is required in the mains connection.

15

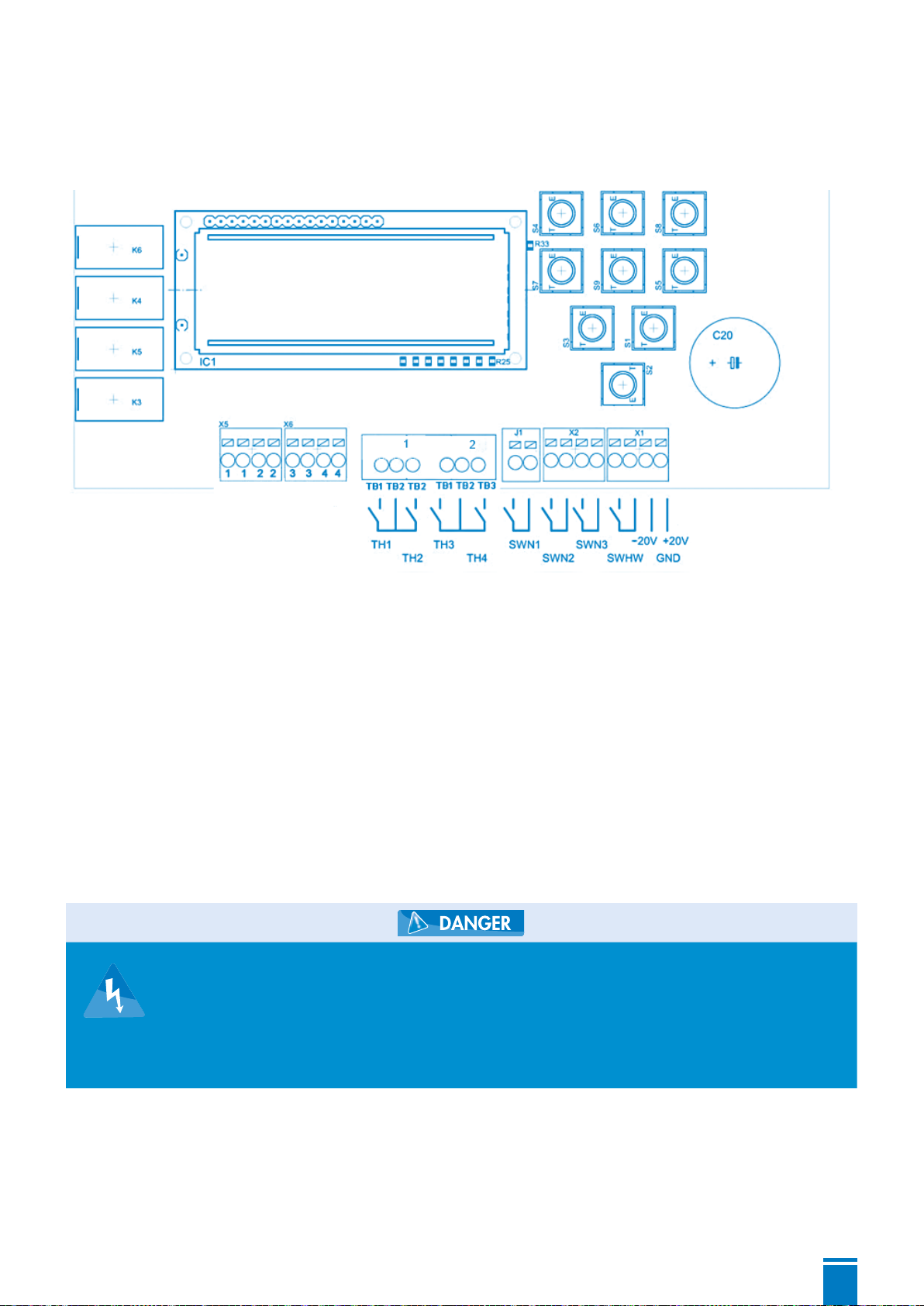

3.2.4 Connection of the external sensors

The external sensors are connected by means of the terminal strip on the upper circuit board.

The active sensor can be selected in the menu “level control” and “therm. malfunction”.

If the thermostatic switches TH2 and TH4 are not necessary, bridges have to be inserted on those

contact points. The thermostatic switches TH1 and TH3 can be deactivated via the menu therm.

malfunction.

The floating switches have to close when they are floating on the surface. The floating switches

have to be connected floatingly. The required signal voltage is generated in the control system and

amounts to 5V.

Assignment of the float switches:

SWN1 = pumps 1 and 2 off

SWN2 = pump on

SWN1 = peak load 2nd pump switched on

SWHW = high water alarm

For the usage in explosion-prone areas, either floating switches with the

corresponding permission, or intrinsically safe cut-off relays have to be

used.

The external sensor has to supply a measurement current between 4

and 20mA. The final value of 20 mA can be adjusted in the menu, so the

indication may occur in cm.

3.2.5 Utilisation of the internal sensor

An internal sensor, a pressure sensor 0 to 10 kPa is used (0 to 1mWs, 0 to 100 mbar). Other

measurement ranges can be realised on demand. On the lower side wall, a hose screw connection

6/8mm is located which is intended for the connection of the immersion pipe. The sensor used

is designed as a differential pressure converter, so that barometric variations are eliminated. The

De-energized

open

De-energized

closed

Pump Pump

Signal contacts

Floating

Use the 20 V output for

external 4-20 mA sensor only

16

menu item “internal converter – adjustment” serves for the accurate adjustment of the zero point.

In order to equalise possible air leaks inside the pneumatic level

measuring device, the pilot tube has to be fully emerged from the water

after completion of the pumping process. For this purpose, the adjustment

of a follow-up time of the according duration is necessary. Alternatively,

the small-size compressor set for the air bubbler level measurement

system can be used.

3.2.6 Signal contacts

The 4 potential-free signal contacts are located in the upper circuit board (left).

The 4 signal contacts are free programmable: the contacts 1 and 2 are opened in case of power

failure and the contacts 3 and 4 are closed in case of power failure.

If the power supply of the control is okay, then the signal contacts are closed in case of a fault or

signal.

3.3 Commissioning of the control system

After the complete connection of the pump cables, the mains power supply and the level sensor,

the parameters can be set after the mains voltage has been applied. Only trained personnel are

allowed to set those parameters.

Now the plant can be commissioned by pressing the key . During the conduction of several

test runs, the set switch points have to be checked, and, if necessary, corrected.

Checking of the control system without pumps :

In order to be able to check the control system without a pump, the following standard settings are

required :

1. Connect the control system to a single-phase network (connection of N and L1)

2. Set motor current limitations for both pumps to 0.0 A

3. Switch off rotary field

4. Bridge thermal contacts TH2 AND TH4

5. Disable thermic error for pump 1 and pump 2.

If the respective level sensors are connected, all program functions can be checked without having

to connect the pumps.

4. DISPOSAL

Only for EU-countries

Do not dispose of the control system with the regular household garbage!

According to the European directive 2012/19/EG about waste electric and

electronic equipment and the transposition into national law, used electric tools.

have to be collected separately and recycled in an environmentally compliant

manner.

ZUSAMMENFASSUNG

Copyright / Impressum - Installations-, Wartungs- und Montageanleitung Control Box ZPS 2.3 - Originalbetriebsanleitung - Alle

Rechte vorbehalten

Die Inhalte dieses Dokuments dürfen nicht ohne schriftliche Genehmigung des Herstellers verbreitet, reproduziert, geändert oder

an Dritte weitergegeben werden. Dieses Dokument kann ohne vorherige Ankündigung geändert werden.

Stand der Betriebsanleitung: November 2019

1. SICHERHEIT ...................................................p 18

2. ALLGEMEINE ANGABEN .............................p 18

2.1 Anwendungsgebiete.............................................p 18

2.2 Merkmale ...........................................................p 19

2.3 Technische Daten .................................................p 19

3. BEDIENUNG DER STEUERUNG...................p 20

3.1 Bedientableau und Bedienelemente........................p 20

3.1.1 Tasten...........................................................p 20

3.1.2 Display- Anzeigen..........................................p 21

3.1.3 Normalbetrieb...............................................p 21

3.1.4 Parametereinstellung.......................................p 22

3.1.5 Informationsabruf...........................................p 25

3.1.6 Warnungen und Störmeldungen.......................p 26

3.2 Montage und elektrische Anschlüsse.......................p 27

3.2.1 Mechanische Befestigung................................p 27

3.2.2 Netzanschluss................................................p 27

3.2.3 Anschluss des Pumpenmotors...........................p 27

3.2.4 Anschluss der externen Sensoren......................p 29

3.2.5 Verwendung des internen Sensors ....................p 30

3.2.6 Meldekontakte...............................................p 30

3.3 Inbetriebnahme der Steuerung ...............................p 30

4. ENTSORGUNG...............................................p 31

18

1. SICHERHEIT

ACHTUNG

Dieses gerät darf nicht von kindern, personen mit eingeschränkten

physischen, sensorischen und geistigen fähigkeiten, sowie personen

ohne technische einweisung verwenset werden. Die bedienung

sowie der sichere gebrauch sind nur nach ordnungsgemäßer

einweisung oder unter aufsicht von eingewiesenen personen

statthaft.

STROMANSCHLUSS :

Die elektrische Montage muss von einem Elektrotechniker realisiert werden.

Die Versorgungsleitung des Geräts muss geerdet (Klasse I) und durch einen

hochempfindlichen Schutzschalter (30 mA) geschützt sein. Geräte ohne Steckdose

müssen an einen Hauptschalter an das Stromnetz angeschlossen werden, der

die Trennung aller Pole gewährleistet (mindestens 3 mm Kontaktabstand). Der

Anschluss darf ausschließlich der Stromzufuhr des Geräts dienen.

Wenn das Stromkabel beschädigt ist, muss es vom Hersteller, seinem Kundendienst

oder ähnlich qualifiziertem Fachpersonal ersetzt werden, um Gefahren zu vermei-

den.

Kennzeichnung von Hinweisen in der Betriebsanleitung

Gefahr

Dieser Begriff definiert eine Gefahr mit erhöhtem Risiko, das zum Tod oder

schweren Verletzungen führen kann, wenn sie nicht vermieden wird.

Warnung

Dieser Begriff definiert eine Gefahr, die zu einem Risiko für die Maschine und

ihren Betrieb führen kann, wenn sie nicht vermieden wird.

Gefahrenbereich

Dieses Symbol warnt in Kombination mit einem Schlüsselwort vor Gefahren,

die zum Tod oder zu Verletzungen führen können.

Gefährliche elektrische Spannung

Dieses Symbol warnt in Kombination mit einem Schlüsselwort vor Gefahren

der elektrischen Spannung und informiert über den Schutz vor elektrischer

Spannung.

Sachschäden

Dieses Symbol warnt in Kombination mit dem Schlüsselwort ACHTUNG vor

Gefahren für die Maschine.

2. ALLGEMEINE ANGABEN

2.1 Anwendungsgebiete

Die Doppelpumpensteuerung ZPS 2.3 wird vorwiegend zur Regulierung von Flüssigkeitsniveaus

19

eingesetzt. Dabei können verschiedene Fühler zur Niveauerfassung eingesetzt werden:

Schwimmschalter, Staudruck, Lufteinperlung, externe 4- 20mA- Sensoren. Die jeweils zum Einsatz

kommenden Fühler können im Steuerprogramm ausgewählt werden. Motorschütze steuern dann

direkt zwei Pumpen an. Der Pumpenwechsel kann dabei zeit- oder niveaugesteuert erfolgen. Zwei

einstellbare Schaltniveaus gestatten den gleichzeitigen Betrieb beider Pumpen.

Weiterhin stehen folgende Einrichtungen zur Störungsmeldung zur Verfügung:

akustischer Signalgeber, 4 Relaismeldekontakte potentialfrei frei programmierbar (für Hochwasser,

Sammelstörung, Pumpe ein, Störung Pumpe, Anlage in Ordnung), Sicherheitsschaltungen in Form

vonEinschalt-undAusschaltverzögerung,Motorstromüberwachung,Motortemperaturüberwachung

und Hochwassersensoren gewährleisten einen sicheren Betrieb der Pumpenanlage.

Die Bedienung der Steuerung erfolgt über 9 Kurzhubtasten, die Programmeinstellungen werden

über ein LCD- Display angezeigt. Sämtliche Einstellungen werden gespeichert und stehen beim

Neustart der Steuerung wieder zur Verfügung. Die Landessprache im Display ist umschaltbar.

Die Steuerung speichert neben den eigentlichen Betriebsparametern auch den zeitlichen

Steuerungsverlauf und die auftretenden Fehler in einem Protokoll, das im LCD-Display angezeigt

werden kann.

2.2 Merkmale

• LCD- Klartext- Anzeige

• Hand- Stopp- Auto- Funktion je Pumpe

• 1 Quittierungstaster,

2 Parameterauswahltaster

• Durchschaltbares Menü

• Interner akustischer Alarm

• Programmierbare Betriebs-und

Störmeldungen potentialfrei

• Einstellung über Kurzhubtaster

• Betriebsstundenzähler

• Wartungsintervallzähler

• Pumpenstartzähler

• Fehlerprotokollaufzeichnung

• Elektronische Überwachung des

Motorstromes

• Programmierbare Einschaltverzögerung

• Programmierbarer Pumpennachlauf

• Programmierbares Pumpenwechsel- Intervall

• Schaltbarer Service- und ATEX- Mode

• Interner Drucksensor

• Füllstandsangaben in cm

• 4 digitale Eingänge für Thermoschalter

• 4 digitale Eingänge für Schwimmschalter

oder Reedfühler

• 1 Analogeingang für Geber 4-20mA

• 1 analoger Druckeingang 0- 100(500) mBar

2.3 Technische Daten

Betriebsspannung 230V oder 400V/AC/50- 60 Hz

Steuerspannung 230V/AC/50-60 Hz

Leistungsaufnahme env. 6VA

Druckbereich 0-1mWs

Einschaltverzögerung 0-180 sec

Nachlaufzeit 0-180 sec

Pumpenwechselintervall 0-300 sec

Einschaltverz. 2 Pumpe 0-60 sec.

Motorstrombegrenzung 0,5- 14A

Störprotokollspeicher 32 Speicherpositionen

Wartungsintervallzähler 0 – 365 Tage, einstellbar

Temperatureinsatzbereich -20 - +60°C

Abmessungen 180x180x90 mm

max. Vorsicherung. 20A

Alarmkontakt potentialfrei 3 A max.

Schutzgrad IP 65

Gehäuse Polycarbonat

Table of contents

Languages:

Other SFA Control Unit manuals

Popular Control Unit manuals by other brands

AWID

AWID SENTINEL-SENSE ADB-510 Installation & operation manual

Emerson

Emerson Fisher 167DA instruction manual

Burkert

Burkert 2301 Series operating instructions

phytron

phytron phyMOTION PIDM01.1 TRANSLATION OF THE ORIGINAL GERMAN MANUAL

Wistron NeWeb

Wistron NeWeb DHUK-SY22 user manual

Brand Hydraulics

Brand Hydraulics FG52 Installation & user guide

Aerotech

Aerotech UFM-ST Hardware manual

Bosch

Bosch Professional GCY 42 Original instructions

Hewalex

Hewalex CKF 3325 installation manual

Federal Signal Corporation

Federal Signal Corporation Serial Interface Module Installation and programming instructions

Bosch

Bosch IO-BOX32 manual

SG Wireless

SG Wireless SGW101 Series manual