SFA Smart Control Box User manual

Smart Control Box

LIVBOITSMART

07.2022

Installation and operating manual

EN

CONTENTS

1. SAFETY .......................................................................................................................17

1.1 Identication of warnings ............................................................................................17

1.2 General points...................................................................................................................17

2. TRANSPORT/DISPOSAL .........................................................................................17

2.1 Transport.............................................................................................................................17

2.2 Disposal...............................................................................................................................17

3. DESCRIPTION............................................................................................................17

3.1 Application.........................................................................................................................17

3.2 Technical data of the control box .............................................................................17

3.3 Technical data of the detection device...................................................................17

3.4 Dimensions.........................................................................................................................17

4. INSTALLATION ..........................................................................................................17

4.1 Wall mounting...................................................................................................................17

4.2 Connection of the oat (Sanifos) and pump cables..........................................17

4.2.1 Preparationoftheconductivewires ................................................................................... 17

4.2.2 Connectorswiringforpumps(Sanipump) ...................................................................... 17

4.2.3 Connectorswiringforoats(Sanifos) ............................................................................... 18

4.2.4 Usingtheterminalblocks ......................................................................................................... 18

4.2.5 ConnectiontotheSmartControlBox................................................................................ 19

4.3 Electrical connection......................................................................................................19

4.4 Connecting the wired external alarm box .............................................................19

4.5 Connection to the BMS .................................................................................................19

5. COMMISSIONING.....................................................................................................20

5.1 Start-up conguration................................................................................................. 20

5.2 Checks to be carried out for the commissioning

of a Sanifos lifting station .......................................................................................... 20

6. OPERATION ..............................................................................................................20

6.1 Presentation of the front of the Box...................................................................... 20

6.1.1 Keyidentication .........................................................................................................................20

6.1.2 Operatinglights............................................................................................................................20

6.2 Using the control box .................................................................................................. 20

6.2.1 Onscreendisplay ........................................................................................................................20

6.2.2 Pumpactivation/deactivation ...............................................................................................20

6.2.3 Navigatingthemenu................................................................................................................... 21

6.3 Presentation of the menus...........................................................................................21

6.3.1 LanguageMenu ............................................................................................................................. 21

6.3.2 LogsMenu........................................................................................................................................ 21

6.3.3 SettingsMenu................................................................................................................................ 22

6.4 Remote wired alarm box .............................................................................................23

6.4.1 Technicaldata................................................................................................................................ 23

6.4.2 Dimensions...................................................................................................................................... 23

6.4.3 Installation ....................................................................................................................................... 23

6.4.4 Operation......................................................................................................................................... 23

6.5 SFA connnect (optional) .............................................................................................23

7. SHUTDOWN ..............................................................................................................23

8. MAINTENANCE ........................................................................................................23

8.1 Resetting the pump log ...............................................................................................23

8.2 Maintenance update......................................................................................................24

9. FAULT FINDING........................................................................................................24

10. FOR PROFESSIONALS ...........................................................................................24

10.1 Return to the start-up screen ....................................................................................24

10.2 Explanation of the LEDs on the electronic board .............................................24

10.3 Learning loops .................................................................................................................24

11. GUARANTEE.............................................................................................................24

EN

17

1. SAFETY

1.1 IDENTIFICATION OF WARNINGS

Meaning

DANGER

This term denes a high risk of danger, which can

lead to death or serious injury, if not avoided.

WARNING

This term denes a medium risk of danger, which can

lead to serious or minor injury, if not avoided.

NOTICE

This term characterises dangers to the machine and

its proper operation.

Warning of a general danger.

The danger is specied by indications given in the

table.

This symbol characterises dangers associated with

the voltage and provides information on voltage

protection.

1.2 GENERAL POINTS

This operating and installation manual contains important instructions

to follow for the tting, operation and maintenance of the XXX control

box. Following these instructions guarantees safe operation and pre-

vents injury and property damage. It always has to be available on site

of operation of the machine/plant.

Not only the general safety instructions mentioned in this main point

on safety have to be observed, but also the special safety instructions

mentioned in the other sections.

Failure to comply with this operating and installation manual will result

in the loss of warranty rights and rights to damages.

2. TRANSPORT/DISPOSAL

2.1 TRANSPORT

For all transportation, the control panel must be switched o (see

7.

Shutdown)

ENVIRONMENTAL TRANSPORT CONDITIONS:

Parameters Value

Relative humidity 85% maxi. (no condensation)

Ambient temperature -10°C to+70°C

2.2 DISPOSAL

The device must not be disposed of as household waste

and must be disposed of at a recycling point for electrical

equipment. The device’s materials and components are re-

usable. The disposal of electrical and electronic waste, re-

cycling and recovery of any form of used appliances con-

tribute to the preservarion of our environment.

3. DESCRIPTION

3.1 APPLICATION

The Smart control box is a monitoring and control box for SFA lifting

stations. It allows the operation and parameterization of the connected

station, as well as the real time consultation of the activity and opera-

tion history.

3.2 TECHNICAL DATA OF THE CONTROL BOX

Parameter Value

Nominal supply voltage 1 ~ 220-240 V AC

Network frequency 50-60 Hz

Protection class IP 54

Power cable Type 1~ version: H07RN-F-3G 1.5 mm2

3~ version: H07RN-F-5G 2.5 mm2

Length 2.5 m

3.3 TECHNICAL DATA OF THE DETECTION DEVICE

• Analog level sensor

• Signal 0-5 V

• Input voltage 0-12 V

3.4 DIMENSIONS

Sanicubic

Sanifos

4. INSTALLATION

DANGER

Submersion of the control device.

Risk of electric shock!

Only use the control device in rooms safe from floods.

4.1 WALL MOUNTING

The Smart controm box must be installed indoors, in a place protected

from humidity and frost.

The Smart control box is supplied with a wall bracket.

• Mount the wall bracket horizontally, using the appropriate xings for

your wall.

• Snap the Smart control box onto the bracket.

4.2 CONNECTION OF THE FLOAT (SANIFOS) AND PUMP

CABLES

Cables are connected via waterproof terminal blocks.

4.2.1 Preparation of the conductive wires

Connector

Conductor PE 1~: N, L

3~: L1, L2, L3

Disassembly length y (mm) 33 25

Stripping length x (mm) 8 8

4.2.2 Connectors wiring for pumps (Sanipump)

NOTICE

It is imperative to respect the colours of the wires

when making the connections so as not to cause a mal-

function.

EN

18

Sanifos with Sanipump GR/VX Single-phase version:

: Green/Yellow wire

Position 1: Brown wire

Position 2: Blue wire

Position 3: White wire

Sanifos with Sanipump GR/VX Three-phase version:

: Green/Yellow wire

Position 1: Brown wire

Position 2: Black wire

Position 3: Grey wire

Sanifos with Sanipump SLD (single- or three-phase version):

: Green/Yellow wire

Position 1: Black wire

Position 2: Grey wire

Position 3: Brown wire

Note: The terminal blocks are already mounted on the Sanicubic pump

cables.

4.2.3 Connectors wiring for floats (Sanifos)

Follow this wiring diagram:

Connect the 2 wires to slots 1 and 2, re-

gardless of colour. It is only important to

respect these two locations.

The wiring is identical for the 3 oats.

4.2.4 Using the terminal blocks

Tightening torque: 0,5 Nm

(DIN 5264 A)

4.2.4.1 Assembling the connector

4.2.4.2 Closing the connector

Tightening torque: 1,5 – 2 Nm

4.2.4.3 Opening the connector

EN

19

4.2.5 Connection to the Smart Control Box

4.2.5.1 Connecting and locking the connector

1

4.2.5.2 Unlocking and disconnecting the connector

4.2.5.3 Location of Connector Connections

Sanifos

Pump 1: Pump 1

Pump 2: Pump 2

OFF: Low level oat

ON: High level oat

ALARM: Alarm oat

Sanicubic

Pump 1: Pump 1

Pump 2: Pump 2

PRESSOSTAT: ON/Alarm level

NOTICE

Pulling force on the cables.

Risk of tearing.

Cut the cables to the correct length.

Strip cables and wires.

Never pull or move the cables when they are connected.

Do not exert any constraints, e.g. by bending the

cable too tightly.

4.3 ELECTRICAL CONNECTION

DANGER

Electrical connection work performed by an unqua-

lied personnel.

Risk of electric shock!

The electrical connection must be carried out by a

qualied electrician.

The electrical connection must comply with the stan-

dards in force in the country of installation.

The device’s power supply must be connected to ground (class I) and

protected by a high sensitivity dierential circuit breaker (30 mA) rat-

ed at:

- 25 A for single-phase Sanicubic 2 VX, Sanifos with 2 single-phase

Sanipump SLD,

- 16 A for all other cases.

The connection must be used exclusively to provide the power to the

Smart Control Box.

4.4 CONNECTING THE WIRED EXTERNAL ALARM BOX

The cable from the external alarm box is already connected to the elec-

tronic board.

• Connect the jack to the bottom of the external alarm box.

Note: The power supply of the external alarm box is done through the

Smart box. If the jack plug is incorrectly inserted, the external alarm

box will signal a power failure (see

6.4.4 Operation).

4.5 CONNECTION TO THE BMS

Option of a remote alarm facility : dry contact (no voltage).

3 BMS are available: a BMS with NO (Normally Opened) contact, a BMS

with NC (Normally Closed) contact and a congurable NO BMS (see

6.3.3SettingsMenu

).

This contact opens (Normally Closed contact)/closes (Normally

Opened contact) as soon as the station is in alarm mode and remains

opened/closed as long as the default has not been corrected.

The terminals can be connected to a BMS (Building Management Sys-

tem) system or to a live system (max. AC 250V / 16A, DC 250V / 17A).

• Use one of the pre-holes on the side of the enclosure.

• Open the hole by tapping rmly with a screwdriver.

• Connect the connection cable directly to the circuit board using the

illustrations below:

Location of BMS

Single-phase version: Three-phase version:

Wiring diagrams

Single-phase version:

NO dry contact

NC dry contact

External alarm

2

EN

20

Three-phase version:

NO dry contact

NC dry contact

External alarm

5. COMMISSIONING

5.1 START-UP CONFIGURATION

At the rst start-up, it may be necessary to congure the box by select-

ing the connected station using the and keys:

- the installation tank: [Sani]Cubic 1, [Sani]Cubic 2, [Sani]Fos 500,

[Sani]Fos 610 or [Sani]Fos 1300,

- the type of pump: Brushless, Grinder, Vortex or Solida.

Note: In case of an error or a change in the installation, it is possible to

access this menu (see

10.1Returntothestart-upscreen

)

The operating parameters must then be selected: date, time, language

and brightness of the display.

Note: The date and time must be set correctly for alarm management,

alarm history and maintenance frequencies.

For each conguration screen,

validate the selected setting by

pressing the validation button.

On the last screen (see oppo-

site), press the conrmation

button one last time to start the

Smart box operation.

5.2 CHECKS TO BE CARRIED OUT FOR THE

COMMISSIONING OF A SANIFOS LIFTING STATION

• Set the language, date and time.

• Dene the use of the station: Individual, Collective or Commercial.

• Check that the quick connectors are correctly connected to the

Smart unit.

• Check that the led on both pumps are green.

• Check the power supply voltage on the display.

• Fill the tank with water via the connected sanitary appliances.

• Check that the pumps switch on automatically at the set water level.

• Check that the water operating intensity of the pumps, shown on the

display, is between

– 4 and 7 A with Sanipump GR, Sanipump VX (single-phase and

three-phase), Sanicubic 1, Sanicubic 2, Sanicubic 2 VX three-phase,

– 6 and 12 A with Sanicubic 1 VX single-phase, Sanicubic 2 VX sin-

gle-phase,

– 7 and 10 A with Sanipump SLD single-phase,

– 3 and 5 A with Sanipump SLD three-phase.

• Check the correct operation of the motors in forced operation.

• Check that the wired alarm box is switched on.

• Check the level of water in the tank at the end of the cycle:

–Sanicubic: the water level must be below the longest dip tube.

–Sanifos with Sanipump VX or Sanispump SLD: the water level

must be above the pump cover plate.

–Sanifos with Sanipump GR: the water level is +/- 10 cm from the

bottom of the tank.

• Set the delay time accordingly.

• Set the delay for the start of the auxiliary pump. Measure the dura-

tion of an ON-OFF cycle and enter a value equal to at least 2 times

the ON-OFF cycle value.

• Check that the data has been correctly recorded by the Smart box

(log, pumping time…).

6. OPERATION

6.1 PRESENTATION OF THE FRONT OF THE BOX

6.1.1 Key identification

Current switch

Enter Key

Back

Navigation

Activation/deactivation of the

pumps

Pump operation

indicator light

Forced operation of pumps

6.1.2 Operating lights

The light is green when the pump is activated.

The light is red when the pump is deactivated (by a manual lockout or

automatically following a fault).

6.2 USING THE CONTROL BOX

6.2.1 On screen display

6.2.1.1 Normal operation

Time

Pump current

Power output

SC_2VX

6.2.1.2 Alarm display

SC_2VX

ALARM

Alarm indicator in real time,

with identication of the

problem detected for quick

maintenance.

A special window giving the

alarm type and the alarm

time remains open for some

time.

As soon as the fault disap-

pears, return to the general

screen on which an alarm

notication appears. To re-

move the alarm notication,

simply press one of the two

forced-on buttons. Details of

the alarms can be consulted

in the alarm log.

6.2.2 Pump activation/deactivation

In the case of maintenance or replacement of a pump, it is possible to

deactivate each pump independently.

indicator light

SC_2VX

P1

P2

SFA

SC_2VX

ALARM

EN

21

6.2.3 Navigating the menu

SC_2VX

P1

P2

SFA

Pressing the “Enter” key

takes you to the main

menu:

SC_2VX

你好 Hello

Bonjour

Ciao HALLO

HO

LA

Navigation through the menus and submenus is done using the arrow

keys, Enter and Back:

Entrering the menu

or

to the previous menu

P1

P2

SFA

SC_2VX

你好 Hello

Bonjour

Ciao HALLO

HO

LA

6.3 PRESENTATION OF THE MENUS

6.3.1 Language Menu

SC_2VX

你好Hello

Bonjour

CiaoHALLO

HO

LA

Allows you to choose the

language used in the interface.

Enter the “Languages” menu by pressing the “Enter” key.

P1

P2

SFA

SC_2VX

你好Hello

Bonjour

CiaoHALLO

HO

LA

Language

English

Then press (previous language)

and (next language) to scroll

through the available languages.

• Press to conrm the

choice.

• Press to return to the

main menu.

6.3.2 Logs Menu

SC_2VX

你好Hello

Bonjour

CiaoHALLO

HO

LA

Allows:

- consult the alarm logs,

- consult the pump operation

log,

- consult the operating levels of

the level sensors,

- consult the software versions.

• Enter the “Logs” menu by pressing the “Enter” key.

• Then press and to scroll through the submenus. Conrm with

to enter the submenu.

6.3.2.1 Alarm logs

Possibility to consult the history of the last 32 alarms.

SC_2VX

Logs

alarm

Date of last alarm

Time of last alarm

SC_2VX

• Then press (previous alarm) and (next alarm) to scroll through

the alarm messages.

• Press to return to the main menu.

No modications are possible.

The oldest alarms are automatically deleted when the number of

searchable alarms is exceeded.

6.3.2.2 Pumps operation

Allows you to view the operating information of the pumps.

SC_2VX

Logs

SC_2VX

_

ump 1

ump 2

an

• Press to return to the main menu.

No modications are possible.

The resetting of the pump counter is reserved for professionals (see

8.1

Resettingthepumplog

)

6.3.2.3 Sensors operation

Allows to consult the activation height of the level sensors ON, OFF

(for Sanifos) and ALARM.

SC_2VX

Logs

Sanifos

SF_610

Sanicubic

SC_2VX

EN

22

SC_2VX

6.3.2.4 Consulting software versions and configuration

Allows you to consult:

- the tank-pump combination (Model) selected for the installation,

- the software versions for the control box’s motherboard and the

screen card. This may be necessary in case of maintenance or interven-

tion on the enclosure.

SC_2VX

Logs

SC_2VX

HW:

SW:

2.2

3.3.0

2.2

3.7.1

Logs>Version

Model: SANICUBIC 2 VX BLDC

Motherboard Screenboard

10.1Returntothestart-up

screen

to change the model.

• Press to return to the main menu.

This information cannot be changed.

6.3.3 Settings Menu

SC_2VX

你好Hello

Bonjour

CiaoHALLO

HO

LA

Allows you to:

- set the date and time,

- adjust the brightness of the

display, activate/deactivate the

audible alarm,

- set the pump delay time,

- set the delay time for the aux-

iliary pump to start,

- select the frequency of mainte-

nance,

- set the BMS parameters

6.3.3.1 Setting the date

The date setting is particularly important for alarm management and

maintenance monitoring.

SC_2VX

Settings

Date

P1

P2

SFA

SC_2VX

Settings>Date

• Then press and to select the value.

• Then press and to switch from day to month and month to

year.

• Press to conrm the choice.

• Press to return to the main menu.

6.3.3.2 Setting the hour

The hour setting is imporant for alarm management.

SC_2VX

Settings

Hour

P1

P2

SFA

SC_2VX

Settings>Hour

• Then press and to select the value.

• Then press and to switch from hour to minute and minute to

second.

• Press to conrm the choice.

• Press to return to the main menu.

6.3.3.3 Various

SC_2VX

Settings

Various

Then press and to scroll

through the submenus. Conrm

with to enter the submenu.

Brightness adjustment

Allows you to adjust the brightness of the display during use.

SC_2VX

Settings>Various

SC_2VX

Settings>Various

• Press and to select the value.

• Press to conrm the choice.

• Press to return to the main menu.

Enable/disable audible alarm

Selects whether the alarm notication (display of an alarm window) is

accompanied by an audible signal.

SC_2VX

Settings>Various

SC_2VX

Settings>Various

• Press and to choose between «Enable» or «Disable».

• Press to conrm the choice.

• Press to return to the main menu.

6.3.3.4 Setting the Stop delay time

The stop delay time is an additional pumping time when the pump’s

stop level has been reached. It allows the tank to be emptied as much

as possible and optimises the pumping of surface matter.

SC_2VX

Settings

Stop delay

SC_2VX

Settings>Stop delay

Mode: Manual

Duration: 2s

details see

10.3Learningloops

• Press and to choose between «Manual» and «Automatic».

• Press and to switch from Mode to Duration.

• Press and to choose the duration.

• Press to conrm the choice.

• Press to return to the main menu.

Note:

- If the automatic management mode has been chosen, the “Duration”

parameter cannot be modied.

- If Sanipump SLD was selected, the value is 0 s and cannot be changed.

6.3.3.5 Setting the start of the auxiliary pump

When one of the pumps is running continuously, the second pump is

activated after the time set in this menu to support the rst pump. This

activation of the auxiliary pump corresponds to an abnormal case (e.g.

a hydraulic problem on the 1st pump) and will cause the automatic de-

activation of the 1st pump.

To be relevant, the set time must be at least twice the duration of a

normal ON-OFF cycle.

EN

23

SC_2VX

Settings

P_aux start

SC_2VX

Settings>P_aux start

Activation after: 1m05s

• Then press and to select the value.

• Press to conrm the choice.

• Press to return to the main menu.

6.3.3.6 Setting the maintenance frequency

SC_2VX

Settings

Maintenance

Indicates when the next mainte-

nance is due. A reminder on the

display will appear on the sched-

uled date.

The maintenance frequencies are dierent depending on the area of

use of the station (according to EN12056-4):

- collective: 3 months;

- commercial: 6 months;

- individual: 12 months.

Changing the type of use:

SC_2VX

Settings>Maintenance

Suivante: APRIL 2021

Usage: Commercial (+6 mois)

Important: Validating a use type

for the installation resets the

maintenance counter to 0.

• Then press (previous use) and (next use) to select the intensi-

ty of use for the station.

• Press to conrm the choice.

• Press to return to the main menu.

6.3.3.7 BMS

The BMS (Building Management System) menu allows setting the con-

ditions for the congurable BMS NO (Normally Open). It is possible to

set a voltage or current condition for its operation. By default, the BMS

is set to “Disable”.

SC_2VX

BMS

Settings

P1

P2

SFA

SC_2VX

Settings>BMS

• Press to switch from «Disable» to «Enable»

• Press to conrm the choice.

SC_2VX

U< 180V

Settings>BMS

Condition:

PARAMETER

• Press and to change the setting.

• Press and to switch from Parameter to Condition then from

Condition to the value.

• Press to conrm the choice.

• Press to return to the main menu.

6.4 REMOTE WIRED ALARM BOX

6.4.1 Technical data

Audio and visual information

5 m cable length

Protection index: IP44

6.4.2 Dimensions

6.4.3 Installation

• The alarm box must be installed indoors, in a damp-free location.

• The alarm signal must always be visible to the user.

Note: It does not require an independent power supply. The power sup-

ply is provided by the Smart box. In the event of a power cut, the bat-

tery of the alarm box takes over.

6.4.4 Operation

alarm

Reset

The red general alarm LED indicates that there is an alarm in the Smart

Control Box. The alarm unit sounds as long as the fault is present. To

stop the alarm, press the reset button under the alarm unit or solve the

problem on the Smart Control Box.

The yellow «mains» LED indicates the power supply status of the alarm

unit:

– light on steady = Smart Control Box on mains supply

– ashing and buzzer = power failure on the Smart Control Box. Af-

ter 1 minute, the siren is discontinued.

The alarm box can be completely switched o by pressing and holding

the reset button (*).

6.5 SFA CONNNECT (OPTIONAL)

The SFA connect option allows, thanks to your WiFi box, to link your

Smart box to a Smartphone application. It is then possible to remotely

consult the operating information of your lifting station (power supply

check, maintenance status...) and to be informed in real time of alerts

by notication or email. Please refer to the manual delivered with SFA

Connect.

7. SHUTDOWN

The Smart control box has a battery to keep the unit powered up in

case of a power failure.

When switching o the Control Box, the power supply to the box must

be switched o as well as this battery to allow the system to be pow-

ered down. 2 possibilities exist:

• During the 30 seconds following the powering up of the unit, switch-

ing the current switch to the OFF position allows a complete shutdown.

• Press the “Back”, “P1” and “P2” keys simultaneously.

8. MAINTENANCE

8.1 RESETTING THE PUMP LOG

It may be necessary to reset a pump’s operating counters to 0, e.g. if

the pump is changed.

Press the “Enter” and “P1” (or “P2” depending on the pump) keys si-

multaneously.

The 3 parameters (number of starts, maximum pumping time and total

running time) are then reset to 0 for the pump in question.

EN

24

8.2 MAINTENANCE UPDATE

SC_2VX

The icone

Once the maintenance has been done, enter a new frequency setting (see

6.2.3Navigatingthemenu

): the

new maintenance date is set and the icon disappears.

9. FAULT FINDING

Alarm message on the dis-

play Possible cause Remedy

No AC No power supply. Check power supply.

Turn the current switch into position ON (I)

Pump P1 switched OFF Pump 1 deactivated

(activation lamp lights up red).

Reactivate the pump by pressing the activation button.

In case of automatic deactivation, check the alarm log to verify

the cause of the problem.

Pump P2 switched OFF Pump 2 deactivated

(activation lamp lights up red).

Reactivate the pump by pressing the activation button.

In case of automatic deactivation, check the alarm log to verify

the cause of the problem.

No pump activated Pumps deactivated

(activation lamps light up red).

Reactivate the pumps by pressing the activation buttons.

In case of automatic deactivation, check the alarm log to verify

the cause of the problem.

Levels sensors fault

Clogged sensor Clean the sensor, unclog the compression chambers.

Remove deposits in the tank.

Blocked sensor Check that the oats move freely.

Remove deposits in the tank.

Incorrect wiring of the sensors. Check the wiring of the sensor terminals.

Incorrect connection of the sensors. Check the correct location of the oat connection on the casing.

Incorrect position of the oats on the rail. Check the position of the oats.

Float defective. Contact after-sales service.

P1 I=0 Amp

P2 I=0 Amp

Pump disconnected. Check pump connection.

Check the wiring of the pump terminals.

Thermal break.

Pump connection occurs automatically after a delay.

Thermal break is a symptom of a malfunction that requires a

thorough check.

Defective pump. Check the pump.

P1 hydraulic issue

P2 hydraulic issue

Problem pump cover plate.

Impeller problem. Check pump hydraulics.

Clogged pipe. Check the discharge pipe.

Shut-o valve closed Open the shut-o valve

P1 I>Imax

P2 I>Imax

Blockage of the pump. Check for foreign bodies

Motor failure Contact after-sales service.

Evacuation issue Unable to evacuate water from the

station.

Check for clogged discharge pipe.

Check that the shut-o valve is open.

Check that both pumps are working properly.

10. FOR PROFESSIONALS

10.1RETURN TO THE START-UP SCREEN

You can return to the settings made when the device was commis-

sioned by pressing the 4 arrow keys , , and .

In particular, the choice of the connected station can be changed.

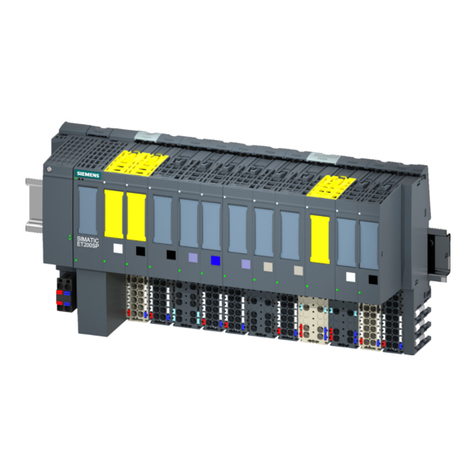

10.2 EXPLANATION OF THE LEDS ON THE ELECTRONIC

BOARD

ALARM BOX

LOOP P2

CCMOS

CONNECT COM

IOT CABLE ONLY

BMS2 RM BMS1 NC BMS1 NO

FLOOD SENSOR

N / C / L

N / C / L

LOOP P1

AC POWER

SCREENBOARD

N / L

CLR CMOS

OFF/ALARM/ON

BMS2

BMS1 NO

BMS1 NC

Green LED

Pumps

Red LED

BMS

Blue LED

Sensors

Note: The pho-

tograph below

is used as an

example. In-

deed, the lo-

cation of the

LEDs may vary

but the col-

ours and their

indications are

identical to

all electronic

boards.

NOTICE

If the enclosure has been opened, take care not to

pinch or pull the cable when refitting the front panel.

10.3 LEARNING LOOPS

The management of the delay time in “Automatic” mode is not ad-

justable. It is calculated using a learning loop that averages the last 5

switch-ons.

An increasing delay time is the symptom of a drop in output ow and

may therefore indicate a fault in the discharge installation (clogging, etc.).

11. GUARANTEE

Smart Control Box is guaranteed for 2 years for parts and labour, sub-

ject to correct installation, use and maintenance of the unit.

77

Sanicubic 3~ (400 V)

78

• Brown, Marron, Braun, Marrón, Marrone, Castanho, Bruin, Hnědá, Brun, Ruskea, Brązowy, Maro, Коричневый, Brun, 棕色

• Red, Rouge, Rot, Rojo, Rosso, Vermelho, Rood, Červená, Rød, Punainen, Czerwony, Roșu, Красный, Röd, 红色

• Green/Yellow, Vert/Jaune, Grün/Gelb, Verde/Amarillo, Verde/Giallo, Verde/Amarelo, Groen/Geel, Zelená/Žlutá, Grøn/Gul, Vihreä/Keltainen, Zielona/

Żółty, Verde/Galben, Зеленый/Желтый, Grön/Gul, 绿色/黄色

• Blue, Bleu, Blau, Azul, Blu, Azul, Blauw, Modrá, Blå, Sininen, Niebieski, Albastru, Голубой, Blå, 蓝色

• White, Blanc, Weiß, Blanco, Bianco, Branco, Wit, Bílá, Hvid, Valkoinen, Biała, Alb, Белый, Vit, 白

• Black, Noir, Schwarz, Negro, Nero, Preto, Zwart, Černá, Sort, Musta, Czarny, Negru, Черный, Svart, 黑色

Sanifos 3~ (400 V)

Table of contents

Other SFA Control Unit manuals

Popular Control Unit manuals by other brands

EOS

EOS ECON H2 Assembly and operating instructions

Homematic IP

Homematic IP HmIP-MOD-TM quick start guide

Belden

Belden lumberg automation LioN-P 0980 ESL 300... manual

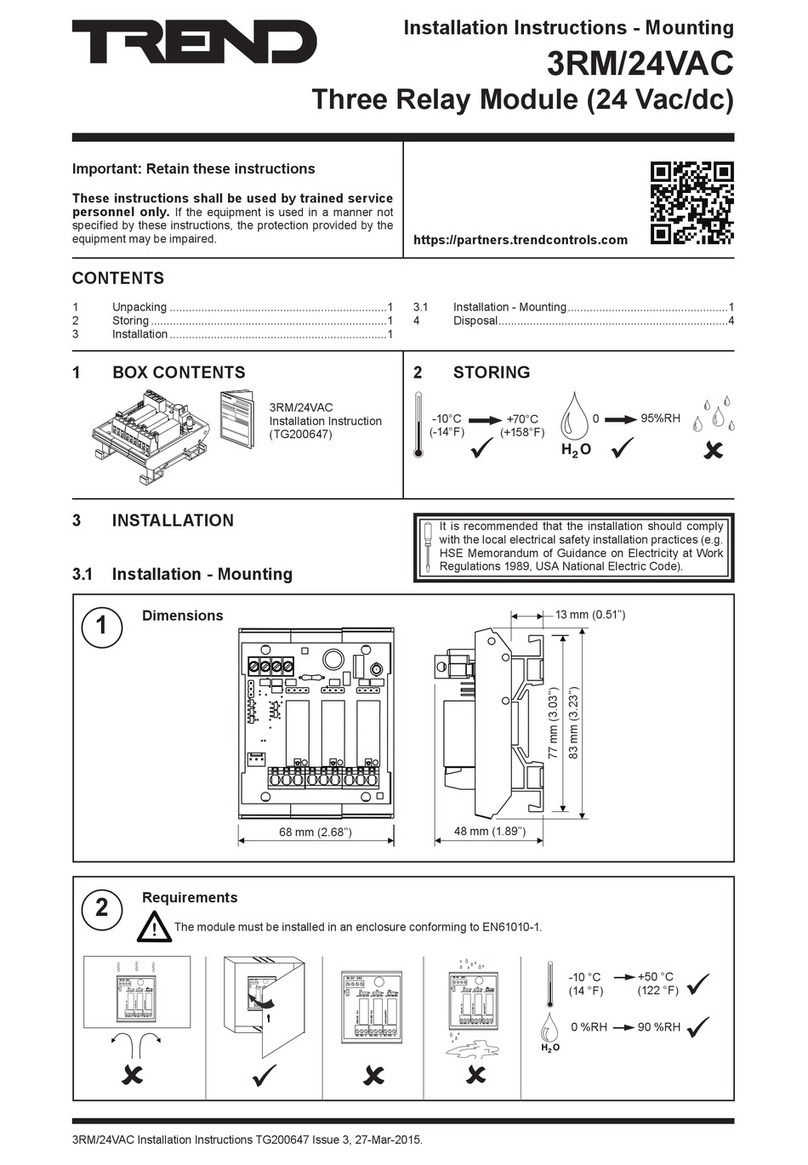

TREND

TREND 3RM/24VAC Installation Instructions-Mounting

VAT

VAT 61228-KAGG-0002 Installation, operating, & maintenance instructions

Sentiotec

Sentiotec Pro-C2 Instructions for installation and use

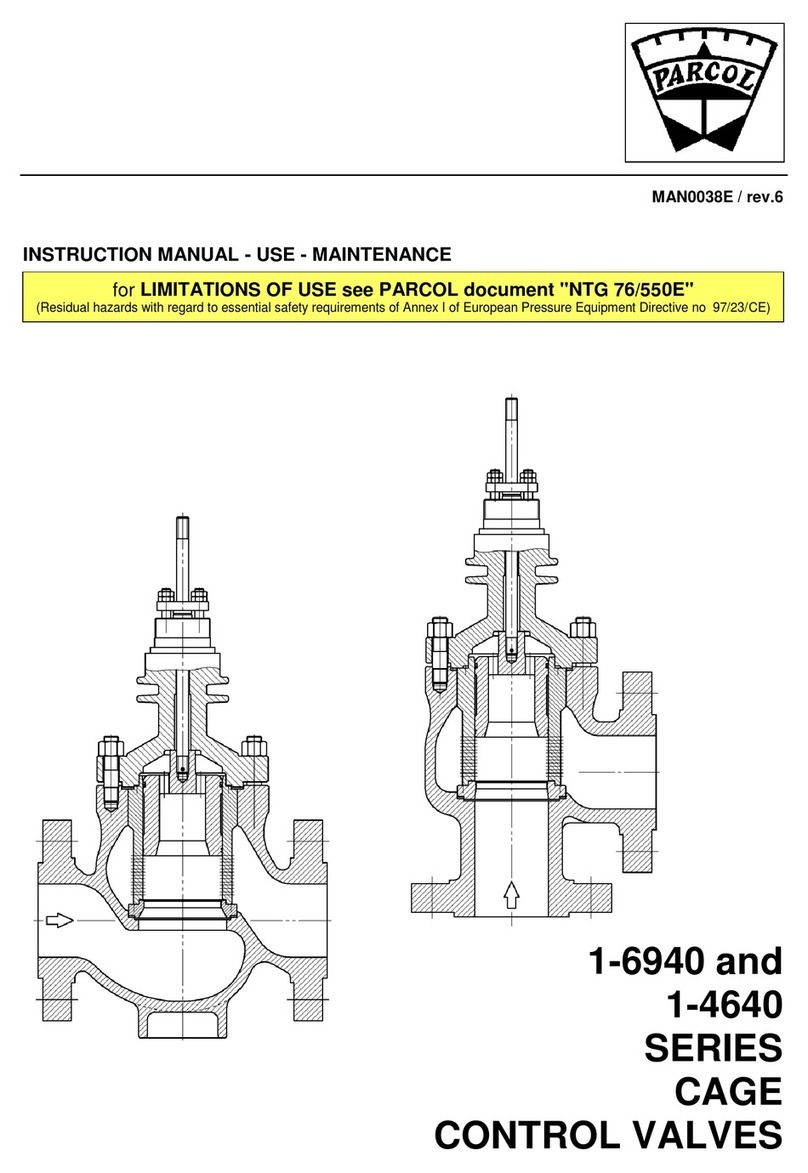

PARCOL

PARCOL 1-6940 Series instruction manual

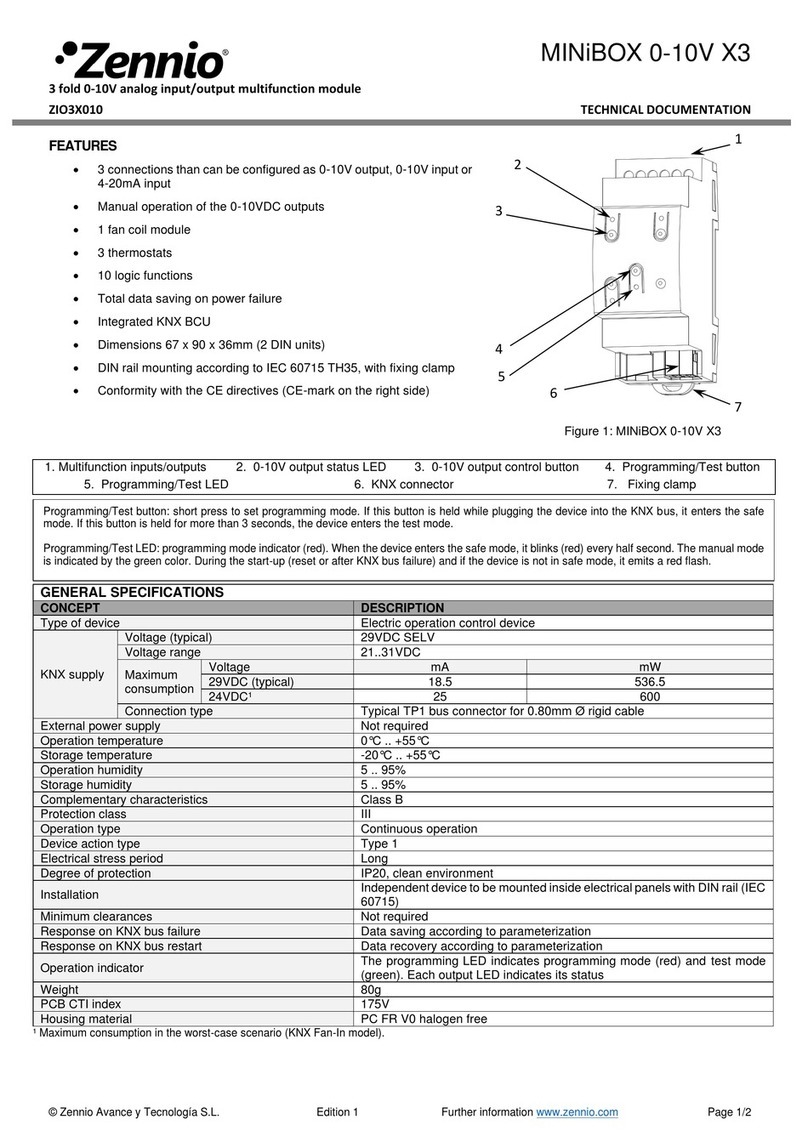

Zennio

Zennio MINiBOX 0-10V X3 Technical documentation

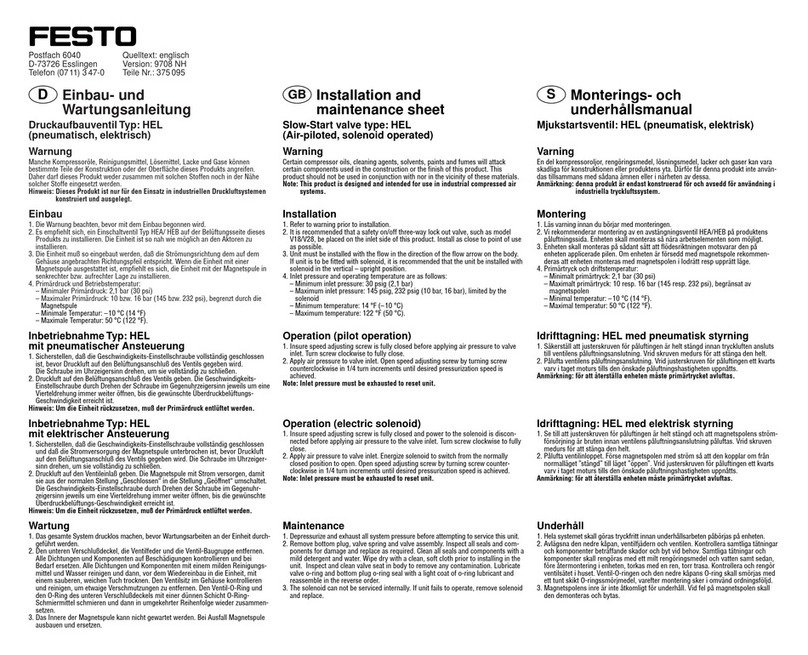

Festo

Festo HEL Series Installation and maintenance sheet

Eaton

Eaton Cutler-Hammer Durant PRESIDENT Series Installation and operation manual

Comelit

Comelit Simplebus1 UT1010 Technical manual

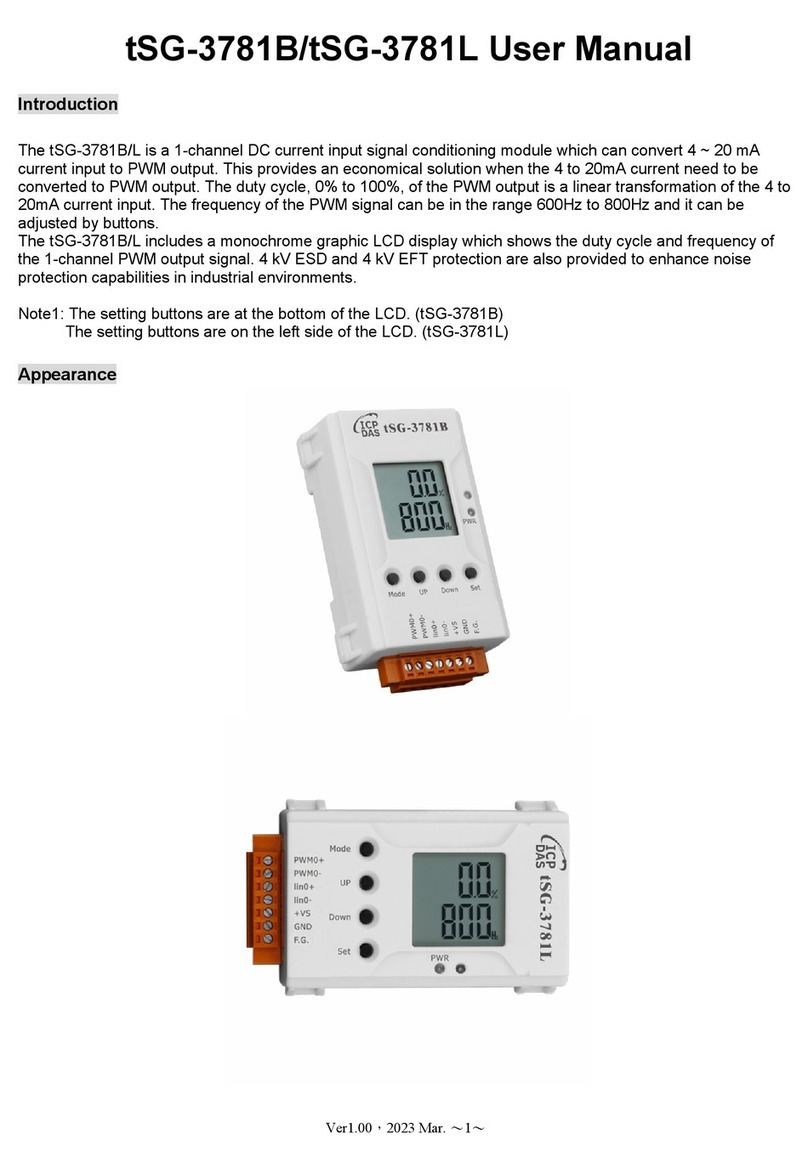

ICP DAS USA

ICP DAS USA tSG-3781B user manual