SFE SIATA User manual

SFE

2

INDEX

4.1 Description of the control panel 6

4.2 Display 7

4.2.1 Display in Service 7

4.2.2 Display in Regeneration 8

Controller spare parts 23

Connection diagrams 29

1-DECLARATION OF CONFORMITY 3

2-General Instructions 4

3-General Features 5

4-Functions 6

Error Message 18

4.2.3 Display during battery operation 8

4.3 General Information before programming 9

4.4 Manual Regeneration 9

4.5 Microswitch search 10

4.6 Salt Recharge 10

4.7 Statistics Menu 10

4.8 Reset eeprom 11

4.9 Power Failure 12

5- Programming 13

5.1 Basic Programming 13

5.2 Advanced Programming 14

5.3 Regeneration Mode displays 17

Hardware Reset 18

7- Installation 19

7.1 Installation with V132/230 19

7.2 Installation with V250 21

3

The products of series

Comply with the following Directives:

2006/42/EC: Machinery Directive

2006/95/EC: Low Voltage Directive

2004/108/EC: Electromagnetic Compatibility

Meet the following technical standards:

EN 61010-1: Safety provisions for electrical measurement, control and laboratory equipment - Part 1:

general provisions.

EN 61000-6-1: Electromagnetic compatibility. Part 6-1: Generic standards - Immunity for residential,

commercial and light industrial environments.

EN 61000-6-2: Electromagnetic compatibility. Part 6-2: Generic standards – Immunity for industrial

environments.

EN 61000-6-3: Electromagnetic compatibility. Part 6-3: Generic standards - Emission for residential,

commercial and light industrial environments.

EN 61000-6-4: Electromagnetic compatibility. Part 6-4: Generic standards – Emission for industrial

environments.

EN 55014-1: Electromagnetic compatibility - Provisions for household appliances, electrical tools and

like equipment. Part 1: emissions.

EN 55014-2: Electromagnetic compatibility - Requirements for household appliances, electrical tools

and like equipment. Part 2: Immunity - Family product standard.

1 - DECLARATION OF CONFORMITY

Timer S F E

4

Read this user and maintenance manual carefully before using the device.

The controller must be installed by qualified personnel; the installation procedures must be

carried out with equipment switched off.

Package and storage

The equipment is packaged in a formed polystyrene frame and contained in a cardboard box. No special

procedures are required for unpacking.

The equipment should be stored in places having the following features:

- temperature in the range -10°C to +60°C;

- relative humidity in the range 30% to 95%.

Installation

The equipment should be installed and commissioned by specialised personnel in compliance with the

regulations in force in the country of use.

The equipment should be installed in a dry place, not directly exposed to the sun, with temperatures

between -10°C and + 60 °C.

Do not power the equipment with a voltage value other than that indicated in this user and maintenance

manual.

Cleaning

The equipment should be cleaned with a dry cloth.

In the case of hard dirt, disconnect the equipment from the power supply network and use a damp cloth.

At the end of the cleaning, restore the electrical connection.

2 - GENERAL INSTRUCTION

5

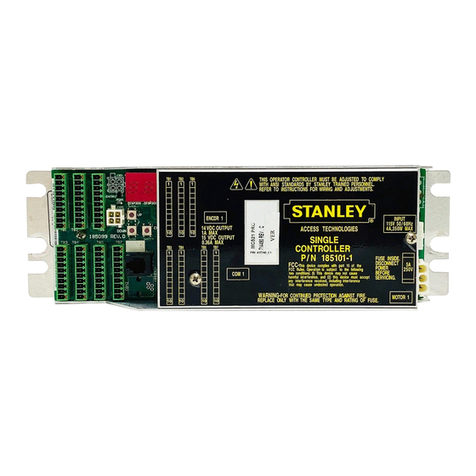

The SFE controller allows the management of softening and filtering systems. The controller is based

on two electronic boards for TC & metered versions SFE is available with 2 different electronic boards:

standard 7930-23 or chlorine cell control 7930-24.

7930-23 – The standard board allows to

program a dry contact relay

7930-24 – This board allows to drive a chlorine

producer

Based on the system configuration, the installer can select the controller settings via software. To this

end, refer to paragraph 5, dedicated to programming.

Power supply data:

Transformer model 95-STD1 Primary: 230 Vac

Mains frequency: 50 or 60 Hz ± 2 %

Secondary: 11.5 Vac; 600 mA

Power output for Chlorine producer* 6 Vdc ± 10 %; 800 mA

Dry contact relay data** Max input current:

Input voltage range:

IP protection rate IP30

*Only for board 7930-24

** Only for board 7930-23

3 - GENERAL FEATURES

Technical features

6

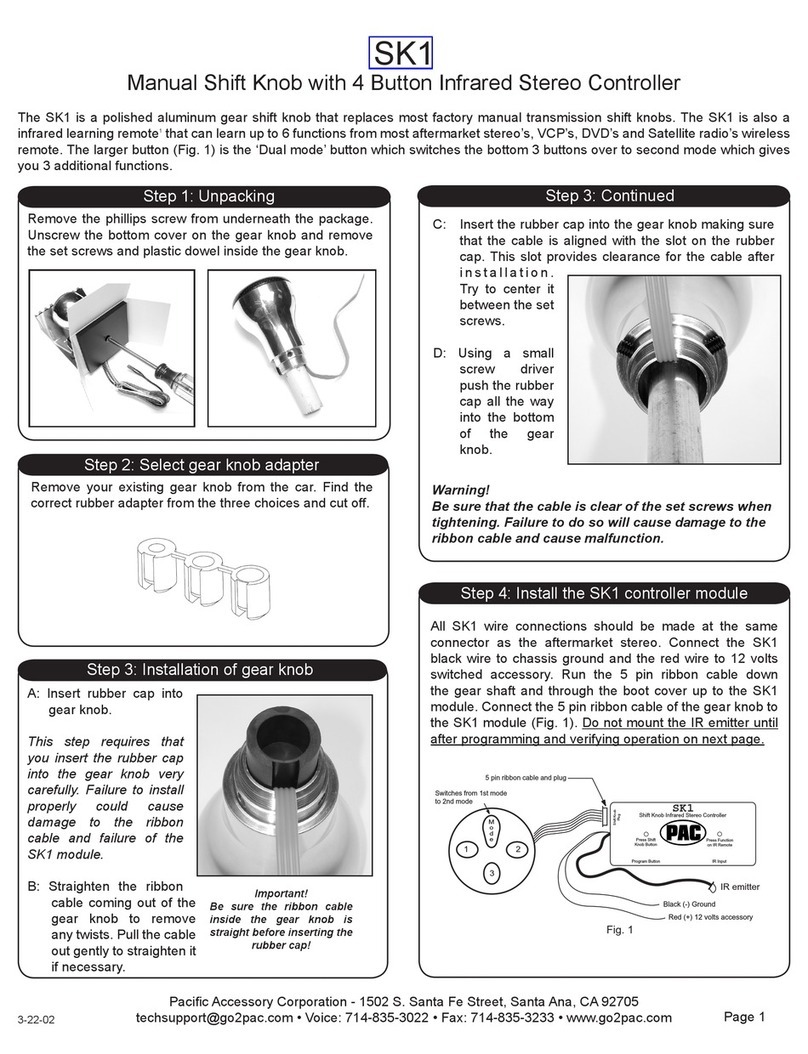

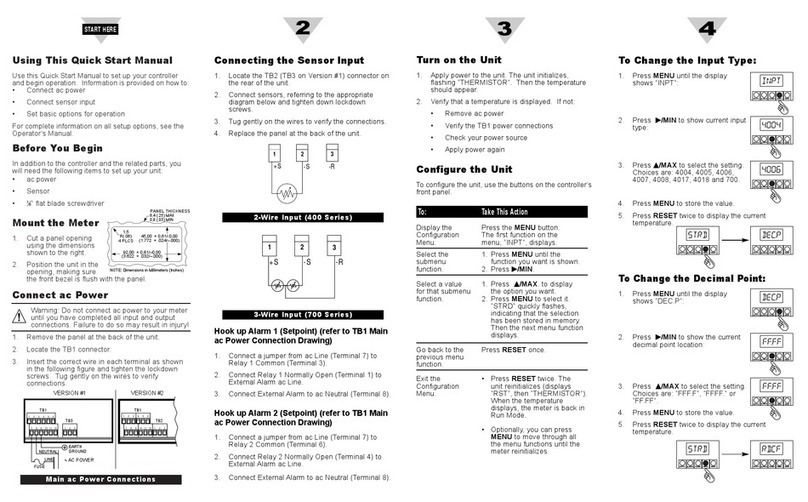

4.1 Control panel description

Buttons description

Description

Key

Down arrow

It is used to edit the displayed value during a

programming step. Press it together with the arrow up

key for 5 seconds to open the advanced settings menu.

Regeneration

Press and release to access the basic settings menu.

Press for 5 seconds to manually start the regeneration.

While programming, it allows switching to the next

parameter.

Up arrow

It is used to edit the displayed value during a

programming step. Press it together with the arrow down

key for 5 seconds to open the advanced settings menu.

4 - OPERATION

7

2

1

6

5

4

3

Key

1. Service status icon;

2. Weekdays icon;

3. Time display mode icon;

4. Programming parameters/regeneration status/time digit;

5. Power supply status icon (if it is enabled it indicates a lack of mains supply and storage of the

programming data to the memory);

6. Regeneration in progress icon.

The LCD display used on the controller shows a series of operation-related data.

The data displayed are:

4.2.1 Display during service

When the module is in operation, the display shows the following information:

• Time: xx:xx with flashing “:”.

• Weekday, if the day of the week is flashing it means that the regeneration is enabled for that day.

• Service icon

• Residual volume and time are displayed alternately, if volume regeneration is enabled.

In service

4.2 Display

8

4.2.2 Display during regeneration

When the module is in regeneration, the display shows the following information:

• During the transition phases nC-|, where n is the number of the regeneration cycle phase, a turning bar

is display to mean that a transition is occurring from a regeneration phase to the next one.

Transition to phase 1

• During the stopping phases nCxx|, where n is the number of the regeneration cycle phase and xx are

the residual minutes before switching to the next phase.

Phase in progress and time remaining before passing to the next step

• Regeneration in progress icon, steady on.

4.2.3 Display during battery operation

When the module is battery supplied, the display shows the following information:

• Time: xx:xx with flashing “:”.

• Weekday, if the day of the week is flashing it means that the regeneration is enabled for that day.

• Service icon

• Residual volume and time are displayed alternately, if volume regeneration is enabled.

• The battery icon is displayed

9

In battery-operated mode, the regeneration is not carried out and the parameters cannot be edited.

Battery-operated status

4.3 General information before programming

The SFE controller allows to manage your installation by a time clock control or by a volumetric control.

The controller will automatically initiate regenerations cycles based upon the programmed regeneration

mode and the programmed parameters.

The SFE controller offers the possibility to manually start regeneration simply by pressing the regeneration

button, as well as initiate a regeneration from an external signal.

The controller is able to receive an external signal for regeneration inhibition, that will block any

regeneration start as long as the inhibit signal is received by the controller.

The SFE controller can manage a chlorine production cell that will be activated during the brine draw cycle

of the regeneration.

Whenever a regeneration has started, the regeneration can be cancelled by pressing button for

5 seconds. The controller will then place the valve back to service position.

4.4 Manual regeneration

To initiate a manual regeneration, press and hold the button for five seconds. The SFE controller

allows choosing whether to start the regeneration immediately or delayed at the programmed time. Here

under are showed the two displayed options, use the buttons to scroll and press to confirm.

Immediate manual regeneration Delayed manual regeneration

10

When Delayed manual regeneration is chosen current day of the week and service icon are going to blink

until regeneration starts

Day of the week and service icon blink to confirm Delayed Manual Regeneration

4.5 Microswitch search

When powering the module may sometimes display F1-| or F2-| where the number indicates if we are

carrying out the first or the second microswitch search attempt, a turning bar is also shown to indicate

that the motor is on. If both searches fail, the message FR01 is displayed.

4.6 Salt recharge

The controller has a counter that is decreased by one at each regeneration. When the counter reaches 0,

a salt alarm is generated. To recharge the counter to the initial value of the parameter SA, press and hold

when the module is in service, “SAL” will flash on the display for 5 seconds and the counter will be

reset to the value setup.

4.7 Statistics menu

The Statistics menu displays some historical data of the module. To open the Statistics menu, press and

hold for 5 seconds.

The following data are displayed:

Data Description

Xxxx Number of regenerations carried out

SAxx Number of residual regenerations before the salt alarm is generated.

FFxx Number of days elapsed since the last regeneration.

Lxxxxxx Overall volume treated (in litres).

Xx:xx Day and time of the last regeneration carried out, the regeneration icon is on.

Xx:xx Day and time of the second last regeneration carried out, the service icon is on.

Xx:xx Day and time of the third last regeneration carried out service and regeneration icons are on simultaneously.

End End of the statistics.

189x Software release and revision.

11

The treated volume is displayed on a running string so as to allow reading a number greater than 9999.

Press to switch parameters .

The date and time information for the last regenerations carried out are only available if regenerations

have been carried out.

While the statistics are displayed, the regeneration icon is on, if not otherwise indicated.

4.8 Reset eeprom

To reset the eeprom to the default values, proceed as follows. In the service condition (regeneration cycle

not running and clock displayed):

- To open the Statistics menu, press and hold for 5 seconds.

- Press and release the

- Press and release the

- Press and release the

- Press and hold the for about 5 seconds

The display shows “rSt” for a few seconds; this means that the eeprom has been reset to the default

values.

NOTE: this procedure does not reset statistical data.

12

The following conditions may occur in the event of a power failure:

-

The power failure occurs during the standby phase, during a parameter reset phase, during the statistics

analysis phase. In all these cases, the module returns to stand by and displays the clock with the

battery on icon, meaning a power failure. If the power failure occurs during a parameter reset, the reset

is closed without saving any changes made and at the end of the power failure it will be necessary to

go to parameter reset again and make the changes.

- The power failure occurs during a phase transition or a microswitch search. In this case, the module

still displays the current phase, the battery icon is turned on to indicate the blackout, the turning bar

is blocked to indicate that the motor has stopped. At the end of the power failure, the motor restarts

to complete the movement.

- The power failure occurs during a phase of the regeneration cycle. In this case, the module still displays

the current phase, the battery icon is turned on to indicate the power failure, the time count down is

stopped. At the end of the power failure, the stoppage time count is restarted and the process goes to

the next step.

- The power failure occurs during an alarm. In this case, the module still displays the alarm and the

battery icon is turned on to indicate the power failure. At the end of the power failure, the module

remains in alarm status.

4.9 Power failure

13

5.1 Basic programming

The most common operating parameters are set in the basic menu. To access the basic menu, press and

release the button. The basic menu contains the following parameters:

DATA DESCRIPTION DEFAULT MIN - MAX

Hour format setting as 12 or 24 hours. Press or to edit

this parameter.

24H 12H – 24H

Current time. The current time is displayed flashing, together with

the day of the week, fixed. Press or to edit.

00:00 00:00

23:59

Day of week. The current day is displayed flashing, together with

the current time, fixed. Press or to edit.

Mo N.A.

Days enabled for regeneration. The display shows “dx y” where x is

the day of the week (1-7) and y shows whether the selected day is

enabled for regeneration “1” or not, “0”. For every enabled day, the

top of the display shows the relevant flashing icon.

Press to edit the setting of the selected day (x),

press to enable or disable the selected day (y).

All enabled N.A.

Regeneration time. Regeneration start time when a delayed time or

cubic metre start is enabled. Press or to edit.

2:00 00:00

23:59

End of the programming. N.A. N.A.

Press to switch parameters.

While the parameters are being edited, the regeneration icon is on and flashing.

5 - PROGRAMMING

14

5.2 Advanced programming

The module operating parameters are set in the advanced menu. Press and at the same time for

5 seconds to open this menu.

DATA DESCRIPTION DEFAULT MIN - MAX

Regeneration start mode:

0 - Regeneration start at the time set during the enabled days.

1 - Regeneration start at the time set after the volume

treatment in the enabled days.

2 - Immediate start at the end of the volume treatment in the

enabled days.

3 - Start at intervals. Regeneration starts every 1-2-3-4-8-

12 hours. Regeneration starts when the hour strikes, so if

regeneration is enabled every two hours, it will be carried out

at 0:00, 2:00, 4:00 and so on. NOTE: the first regeneration is

carried out at the time set in the basic menu. This function is

available during the enabled days.

Press or to edit.

0 0-3

01 Interval time between regenerations. Press or to edit.

This parameter is displayed after the start up mode only if an

interval start has been selected (SH-03).

1 1-12

Prescale of the volumetric meter. Press or to edit. The

parameter is composed of the integer part and of the decimal

part, separated by the decimal point.

This parameter is displayed after the start up mode only if a

volume start has been selected (SH-01 or SH-02).

14.0 00 - 99.9

Volume to be treated (expressed in litres) before starting

the regeneration. Press or to edit. Thousands and

hundreds are modified first, once they are properly set, press

to switch to the tenths and units setting. This parameter

is displayed after the prescaler only if a volume start has been

selected (SH-01 or SH-02).

NOTE: See note 2 to calculate the volume of treatable water

between two subsequent regenerations.

28000 1000 - 9999

Duration of the first regeneration cycle stop (minutes). Press

e to edit. If the parameter is set to off, the stop will be

skipped and the system will directly go to the next stop.

5 Of-99

Duration of the second regeneration cycle stop (minutes). Press

or to edit. If the parameter is set to off, the stop will

be skipped and the system will directly go to the next stop.

30 Of-99

15

DATA DESCRIPTION DEFAULT MIN - MAX

Duration of the third regeneration cycle stop (minutes). Press

or to edit. If the parameter is set to off, the stop will

be skipped and the system will directly go to the next stop.

5 Of-99

Duration of the fourth regeneration cycle stop (minutes). Press

or to edit. If the parameter is set to off, the stop will

be skipped and the system will directly go to the next stop.

5 Of-99

Number of regenerations before a salt alarm is generated. Press

or to edit.

NOTE: See note 1 to calculate the number of regenerations

before a salt alarm is generated.

10 00-99

Days of interval for the mandatory regeneration. Press

or to edit. If this parameter is set to Of, the function is

disabled.

NOTE: This type of regeneration is carried out at the

regeneration time even on non enabled days.

14 Of-14

Frequency of the mains 50 or 60 Hz. Press or to edit. 50 50-60

Duration of the cycle end pulse, this parameter can take values

from 1 to 99 minutes. Press or to edit .(only with 7930-23

board)

FC01 01-99

Chlorine driver activated (only with 7930-24 board) FCCL N.A.

UdIF Volume not restored

UIMM Volume restored

Confirm with . The volume remaining will be kept in

memory or restored to the programmed value, after exiting the

programming. (SH 1 or SH 2)

UdIF N.A.

End of the programming N.A. N.A.

Press to switch parameters.

While the parameters are being edited, the regeneration icon is on and flashing.

16

The following formula is used to calculate the number of regenerations before a salt alarm is generated:

SA=(M.xxx)*1000

SA = (M.xxx) * 1000

(L.xxx) x (G.xxx)

where:

M.xxx: amount (in kg) of salt found in the brine tank;

L.xxx: volume of resin, expressed in litres (l);

G.xxx: amount of salt (in grams) required to regenerate 1 litre of resin, (g/l).

The result of the formula gives the number of regenerations before generating a salt alarm and must be

typed, rounded down to the closest integer (for example 15.4 must be rounded to 15), in the advanced

menu.

Note 2: calculation of the volume of treatable water between two

regenerations.

The following formula is used to calculate the volume of treatable water (in litres) between two subsequent

regenerations:

Vtreatable-water = (L.xxx) x (C.xx) x 1000

(d.xxx - do.xx)

where:

d.xxx: incoming water hardness, in French degrees (°f);

do.xx: desired outgoing water hardness, in French degrees (°f);

C:xx: exchange capacity of the regenerating resin used (expressed in °f x m3/l or in grams of CaCO3);

L.xxx: volume of resin, expressed in litres (l).

The result of the formula gives the volume of treatable water (in litres) between two regenerations and

must be typed, rounded down to the closest integer (for example 34.6 litres must be rounded to 34 litres),

in the advanced menu.

Note that the desired outgoing water hardness value must be compatible with the

provisions of the regulations in force where the controller is used.

Note 1: calculation of number of regenerations before a salt alarm is

generated.

17

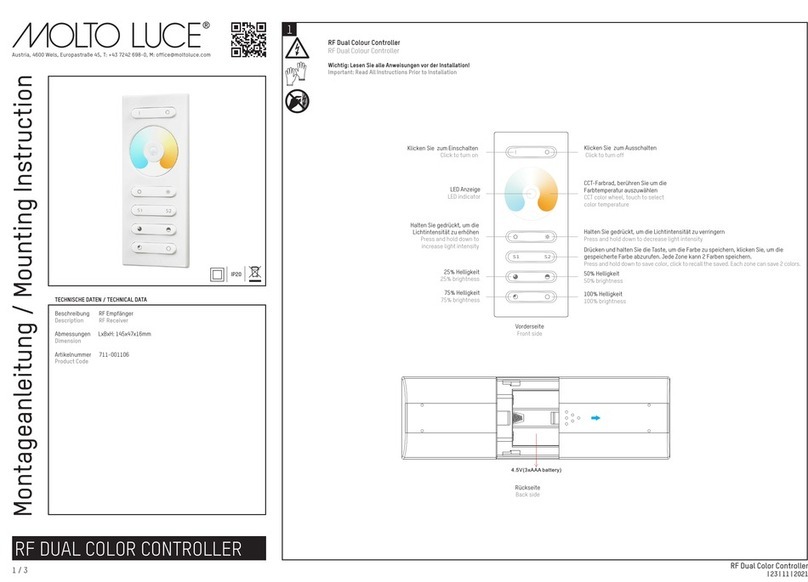

5.3 Programmamable Regeneration Modes

18

The following error messages may be displayed during operation:

Salt alarm, the brine tank is empty. Press any key to acknowledge this alarm

and reset the salt alarm counter to the programmed value. No regenerations are

carried out during the salt alarm.

Microswitch alarm. The module cannot find the service position. No regenerations are

carried out during the microswitch alarm.

The SFE controller is fitted with a hardware reset button located on the board itself close to the display

and not directly reachable by the user.

Button to reset the SFE board

After a hardware reset, the time on the display flashes until any button is pressed.

Hardware reset button

ERROR MESSAGES

RESET HARDWARE

19

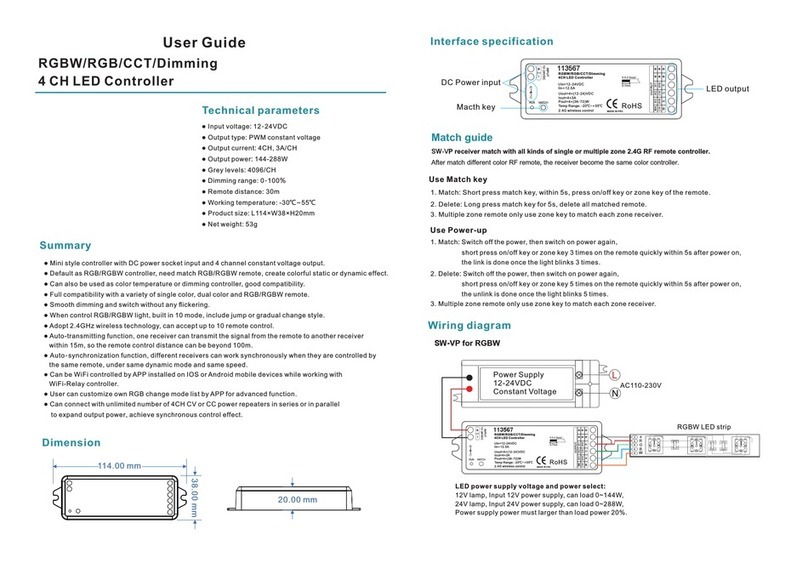

7.1 Installation with V132/V230 Valves

No additional accessories are required to fix the controller to the valve.

7 - INSTALLATION

The SFE controller may be installed on the following of SIATA valves:

V132, V230, V250 (with the accessory 5191-P).

NOTE: a whole series of accessories is available for installation on the following

valves: V240, V260, V360.

20

Exploded view of the SFE controller on the V132 valve

Key:

1 Valve v132

2 Self-threading screw din 7981c st 2.9x16 (code 101)

3 Support with electronic board and cam for twin pilot

4 Self-scraping screw din 7981c st 2.9x25 (code 104)

5 Cover timer (code 81-pb2)

22

2

5

4

321

Table of contents

Other SFE Controllers manuals

Popular Controllers manuals by other brands

Weathermatic

Weathermatic smartline SL800 owner's manual

Dometic

Dometic 9600023541 Installation and operating manual

Panasonic

Panasonic GM1 Series Reference manual

Rockwell Automation

Rockwell Automation Allen-Bradley AADvance T9110 Solutions handbook

Epson

Epson S1R72U16 Support manual

Evco

Evco EVF205 quick start guide