Sfere SFR-M Series User manual

SFR-M Series

Low-voltage Harmonic Suppression

Reactive Compensation Module

User’ Manual

JIANGSU SFERE ELECTRIC CO., LTD.

2

Thank you for choosing SFR-M series low voltage harmonic suppression reactive

compensation module. In order to make it convenient for you to purchase and use the meter safely,

correctly and efficiently, please read this manual carefully before using the product, and pay

attention to several points as follows.

CAUTION:

◆Make sure only the qualified technicians perform the installation and maintenance;

◆Before performing wiring operation to the meter make sure the input signal and power

supplies are switched off;

◆The proper voltage detecting device shall always be used to determine there is no voltage

in each part of the meter;

◆The electrical parameters supplied to the meter shall be within the rated range;

The following conditions may result in damages or abnormal operation to the meter:

◆Voltage of auxiliary power supply goes beyond the range

◆Frequency of power distribution system goes beyond the range

◆Input polarity of voltage or current is incorrect

◆Removing or connecting the communication plugs with electricity;

◆Connecting terminal wires without following the requirements.

Please don’t touch the terminals

when the meter is in operation!

3

Menu

1.Introduction................................................................................................................................................4

1.1.Compliance with standards.......................................................................................................4

1.2 Overview........................................................................................................................................... 4

2.Model selection.........................................................................................................................................4

3.Technical parameter................................................................................................................................ 5

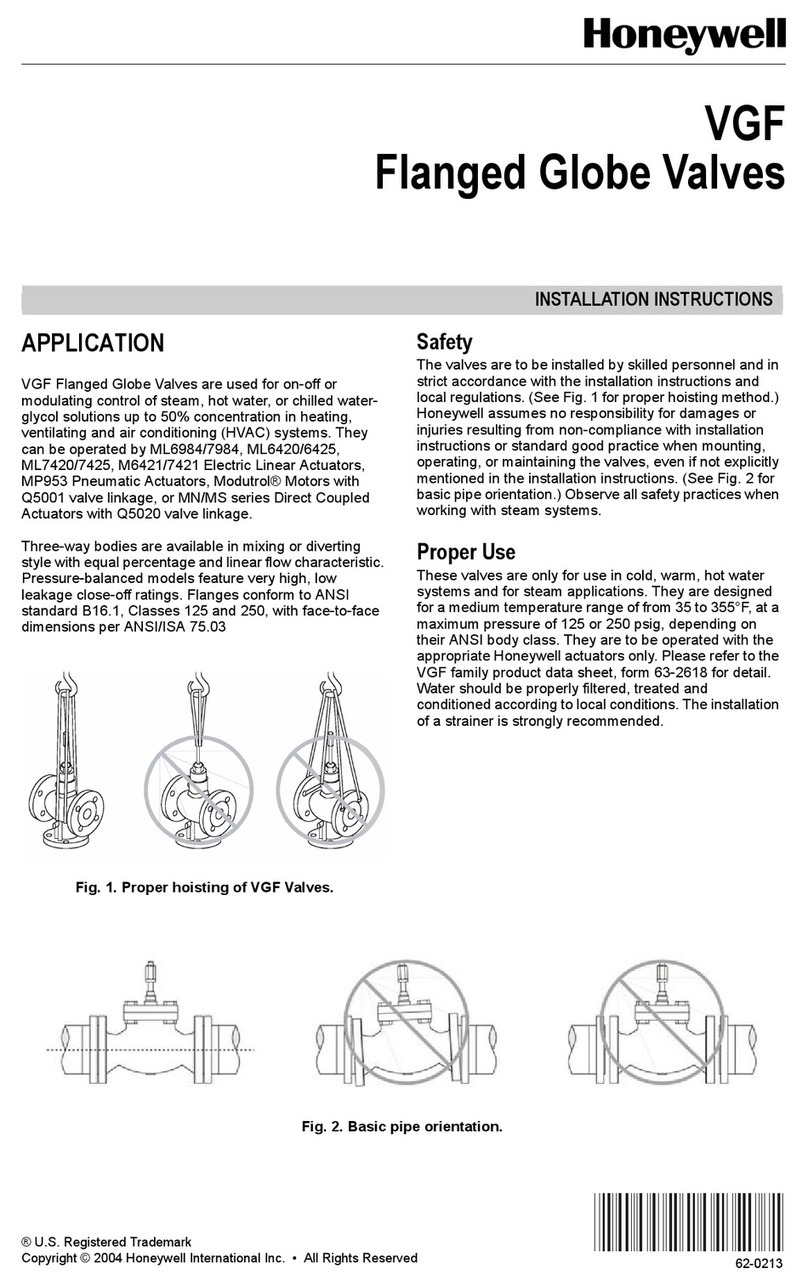

4.Installation and wiring..............................................................................................................................6

4.1 Outline dimension............................................................................................................................6

4.2 Installation method.......................................................................................................................... 7

4.3 Accessories

Accessories.......................................................................................................................................7

4.4 Typical wiring.................................................................................................................................... 7

5. Operation.....................................................................................................................................................9

5.1 Using method of buttons on digital display panel...................................................................... 9

5. 2 Enter and exit programming status............................................................................................. 9

6. Panel description and measurement information display................................................................. 11

7. Common problems and solutions......................................................................................................... 15

8.Ordering specification and contact method............................................................................. 16

4

1.Introduction

1.1.Compliance with standards

GB/T 15576-2008 Low voltage reactive power compensation assemblies

GB/T 22582-2008 Power capacitors—Low-voltage power factor correction banks

JB/T 9663-1999 Low-voltage reactive power automatic compensation controller

1.2 Overview

SFR-M series low voltage intelligent power capacitor modules take two △type compensation

capacitors or one Y type compensation capacitor as main body and are highly integrated with

compound switch, microprocessor and other function modules. Due to their modularity structure,

they have such advantages as small volume and easy maintenance. SFR-M series power

capacitor modules are mainly used for reactive power compensation in the fields where harmonics

are not very serious. They are suitable for local compensation, dispersion compensation and

centralized compensation. This series of products adopt double zero-crossing switch technology

to make sure there is no over voltage or high inrush current during capacitor switching so as to

prolong capacitor life and switch life. SFR-M series capacitor modules have many protection

functions such as capacitor internal temperature protection, grid harmonic content protection, over

current protection, over voltage protection and three phase unbalance protection which make

them more reliable. This series of products adopt a using method of building blocks. If many

capacitors are used, one of them will become the master automatically, and others will become

slaves. Then a reactive automatic control system is built. If some of the slaves fail, they will exit

the system automatically without influencing other slaves; if the master fails, it also will exit the

system automatically, and then another new master appears and a new control system is built.

Meanwhile, SFR-M series capacitor modules are integrated with some functions of power meters

which can measure conventional electrical parameters of the power system.

2.Model selection

Reactance rate %

SFR M □□ □

Abbreviation for company name

Rated voltage, Unit V

Value of first group capacitor, Unit kvar

Product design number

Value of second group capacitor, Unit kvar

Power capacitor series

Note: total compensation for rated voltage 480V(P7) or 525V(P14), and separate compensation

for rated voltage 280V(P7) or 300V(P14).

5

Compensation

mode

Capacity

(kvar)

Remarks

Three phase total

compensation

20+20

Two channel

total

compensation

20+10

Two channel

total

compensation

10+10

Two channel

total

compensation

10+5

Two channel

total

compensation

40

Single channel

total

compensation

30

Single channel

total

compensation

20

Single channel

total

compensation

15

Single channel

total

compensation

10

Single channel

total

compensation

Phase separate

compensation

30

20

10

Table 1 Product model list (special specifications can be customized)

3.Technical parameter

Function

Technical parameter

Feature (accuracy)

Measurement

Current

≤0.5 %(within the range 20%~120% of rated

current)

Voltage

≤0.5 %(within the range 50%~120% of rated

voltage)

Power

≤1%

Power factor

±0.01

Switching mode

Zero-crossing switch

6

Compensation

operation

Working voltage

AC 380V±20%,distortion rate≤5%

Max. working current

1.35*In

Switching inrush

current

≤

22

*In

Switching times

100 万次

Host protection

Over voltage

1.2*Un (can be set)

Under voltage

0.8*Un(can be set)

Harmonic exceeding

can be set

Local protection

Over current

can be set

Over temperature

55℃(can be set)

Unbalance

50%(can be set, only for total compensation)

Control setting

Control parameter

Target power factor, switching threshold, delay time

etc.

Peripheral unit

parameters

Current transformer ratio

Network interface

Pluggable data line, internal network protocol.

Mechanical

installation

Outline dimension

280mm×290mm×370(430)mm

Installation dimension

295mm×350(410)mm

Weight

≤ 45kg

Environment

temperature

Working temperature

-25℃~50℃

Storage temperature

-25℃~55℃

Altitude

<2000m

4.Installation and wiring

4.1 Outline dimension

Outline dimension

Length(L)mm

Width (W)mm

Height

(H)mm

Distance

between

fixing poles

mm

Φ6

Total compensation

series

SFR-M-2020-P7(14)

430

280

290

295×410

SFR-M-2010-P7(14)

430

280

290

295×410

SFR-M-1010-P7(14)

430

280

290

295×410

SFR-M-1005-P7(14)

430

280

290

295×410

SFR-M-0505-P7(14)

430

280

290

295×410

SFR-M-40-P7(14)

370(430)

280

290

295×350(410)

SFR-M-30-P7(14)

370(430)

280

290

295×350(410)

SFR-M-20-P7(14)

370(430)

280

290

295×350(410)

SFR-M-15-P7(14)

370(430)

280

290

295×350(410)

SFR-M-10-P7(14)

370(430)

280

290

295×350(410)

7

Separate

compensation series

SFR-M-30-P7(14)

370(430)

280

290

295×350(410)

SFR-M-20-P7(14)

370(430)

280

290

295×350(410)

SFR-M-15-P7(14)

370(430)

280

290

295×350(410)

SFR-M-10-P7(14)

370(430)

280

290

295×350(410)

SFR-M-05-P7(14)

370(430)

280

290

295×350(410)

4.2 Installation method

For good heat radiation, make sure horizontal distance between two modules is not less than

50mm, and vertical distance is enough for using screw driver. Usually three layers of modules can

be installed in ordinary GGD cabinet (800mm*1000mm*2200mm ). One of the three layers

contains three modules, so that three layers contain nine modules.

4.3 Accessories

Accessories

4.3.1 The specification of pressing joints is 16mm2. It is used for 10~1616mm2 lines. Every total

compensation module is equipped with three joints, and every separate compensation module is

equipped with four joints.

4.3.2 Pluggable data line is used to connect modules or module and other accessories for

networking. There are three specifications which are 0.7-meter, 1.0-meter and 2.5-meter.

0.7-meter line is used to connect two adjacent modules on same layer; 1.0-meter line is used to

connect modules on adjacent layers; 2.5-meter line is used to connect controller module.

2.5-meter line is also used to connect host cabinet and auxiliary cabinet in a same system. If

customer needs pluggable data line with other length, please specify when ordering.

4.3.3 Secondary Current Transformer is an optional unit which is used for primary current (5A)

sampling in bus line of incoming cabinet. The transformer is necessary when customer only use

SFR-M series low voltage harmonic suppression reactive compensation module. Usually SFR-M

series modules are defaulted to be equipped with reactive power compensation controller

(WGK-31-203), which make it not necessary to equip secondary current transformers to the

module.

Pressing joint Secondary current transformer Pluggable data line

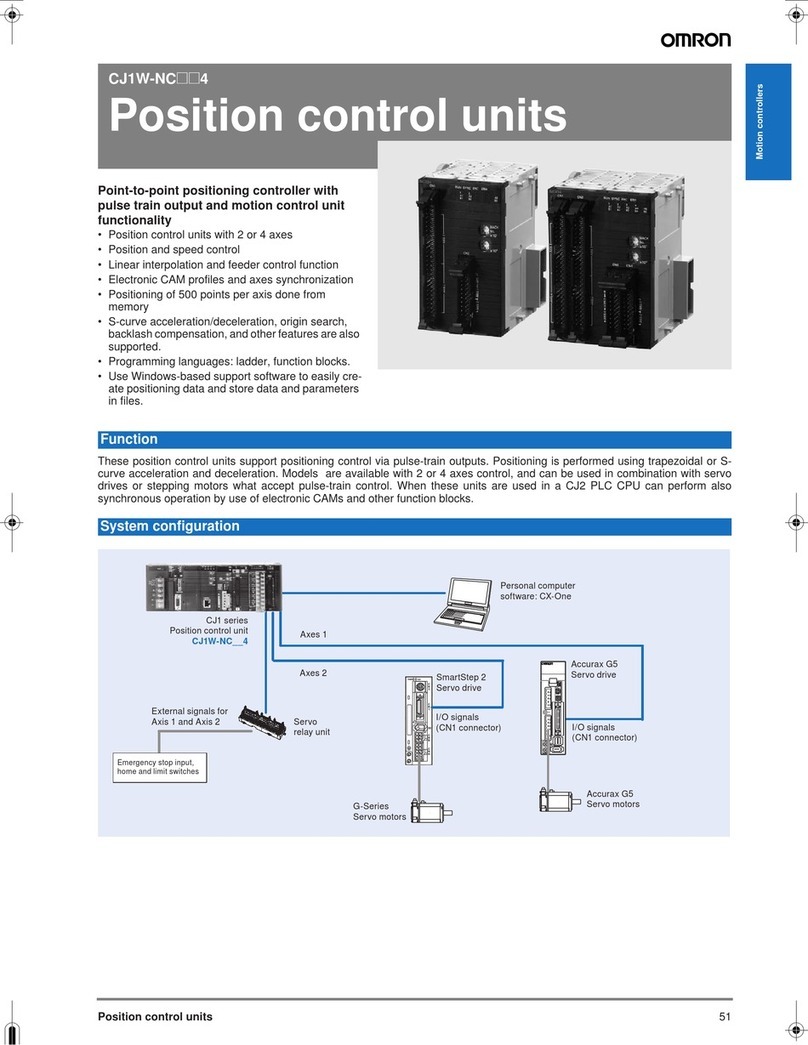

4.4 Typical wiring

①Compensation module can be used alone. When it is used alone, it should be equipped

with a secondary current transformer for each system. If there is no separate module in a system,

single phase current transformer is suitable, otherwise, please equip three phase current

transformer in that system. Current transformer is connected to Phase B current of incoming

cabinet and any one of the modules in the cabinet. It is suggested to connect the current

8

transformer to the module with smallest number.

②Compensation module also can be equipped with controllers. If there is no separate

compensation module in a system, WGK-31-203-G compensation controller is suitable, otherwise,

please equip WGK-31-203-F compensation controller in that system.

SFR-M series modules are connected with WGK-31-203 compensation controller by

specialized pluggable data line. One WGK-31-203 controller can be connected up to 32 SFR-M

series modules. Controller and capacitor modules can realize automatic networking by adopting

internal protocol. Common System configuration and wiring diagram are shown in following

diagrams.

UA

UB

UC

HL1

HL2

UA

UB

UC

Pluggab le data

line interface

4IA*

5IA

Seconda ry

current

of cabinet

(≤5A)

WGK-31-20□-G

SFR series

(total

compensation)

Controller

GND

Capacitor status indication light(380V)

UC

UB

13

14

UB

Wiring diagram for total compen sation modu le system with controller

1

2

L

N

Power supply

AC/DC80~270V

SFR series

(one total

compensation)

SFR series

(total

compensation)

Capacitor status indication

light(380V)

Pluggab le data

line interface

Pluggab le data

line interface

UA

UB

UC

HL1

HL2 GND

UA

UB

UC

HL1

HL2 GND

UN

UA

UB

UC

4IA*

5IA

11

12

WGK-31-20□-F

13

14

IB*

IB

6

7

IC*

IC

8

9

UNUB

1

2

L

N

UA

UB

UC

UA

UB

UC

UA

UB

UC

UN

UA

UB

UC

UN

HL1

HL2 GND

HL1

HL2

HL1

HL2

HL3

GND GND

Pluggable data

line interface

Pluggable data

line interface

Pluggable data

line interface

SFR series

(total

compensation)

SFR series

(total

compensation)

SFR series

(separate

compensation)

Secondary

current

of cabinet

(≤5A)

Controller

Power supply

AC/DC80~270V

Capacitor status indication

light(380V) Capacitor status indication light(380V)

Wiring diagram for total compensation module and separate

compensation module combined system with controller

9

*

*

UN

UA

UB

UC

UB

UA

UB

UC

UA

UB

UC

HL1

HL2 GND

HL1

HL2 GND

Pluggable data

line interface

SFR series

(total

compensation)

SFR series

(total

compensation)

Capacitor status indication

light(380V)

Wiring diagram for total compensation module and separate

compensation module combined system without controller

Secondary

current

of cabinet

(≤5A)

Secondary

current

transformer

5. Operation

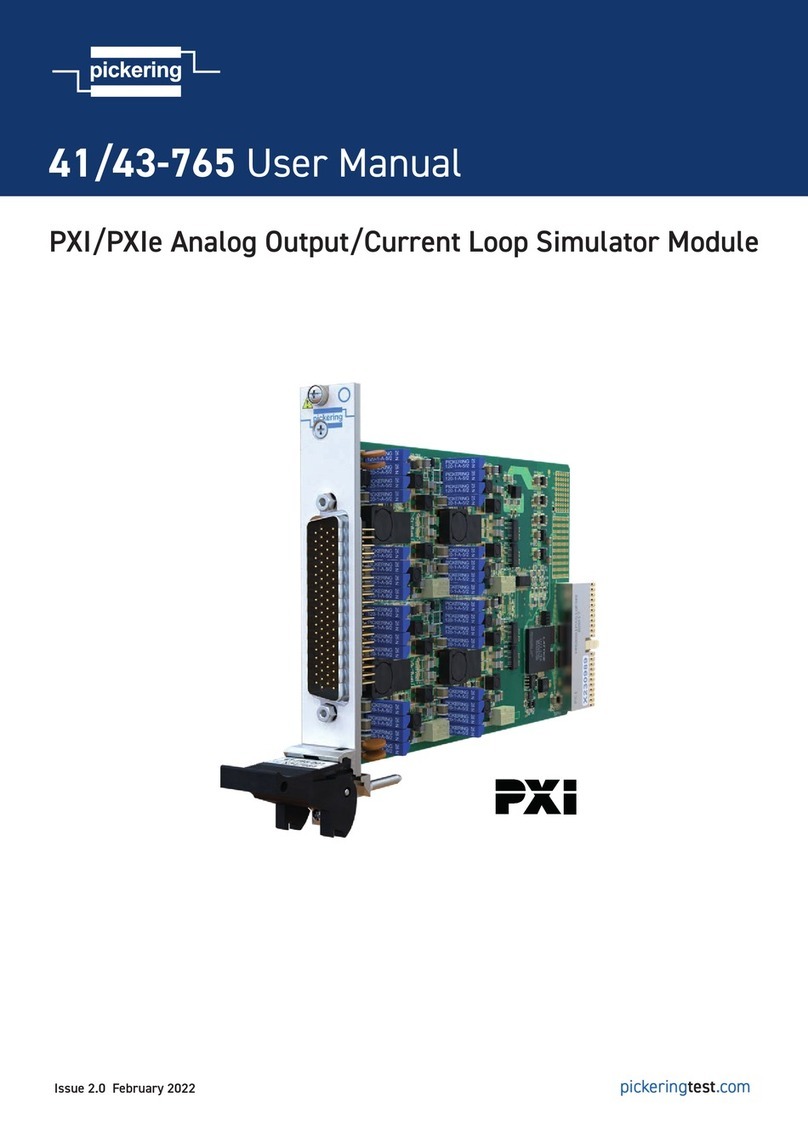

5.1 Using method of buttons on digital display panel

This interface is composed of the following three buttons.

and buttons are used separately for switching menus and changing numbers; +

combined is used for canceling an operation; is used for entering a menu and confirming

an operation.

The method for change data at digital display interface is as follows.

button is used to select a bit which is the flashing one;

button is used to change the numbers from 0 to 9 at selected bit.

5. 2 Enter and exit programming status

5.2.1 Enter programming status

In display interface, press button to enter password authentication interface. User can

press or button to input the password (the user’s password is defaulted as 0001). After

inputting the password, press button to enter programming interface. Note: if the interface

does not change after pressing button, that means the password is wrong.

5.2.2 Exit programming status

After return to first level menu of programming, press + at the same time, and then

SAVE-YES appears. Now there are three options.

(1)Press button to save modified data and exit;

(2)Press + at the same time to stay in programming status;

(3)Press button to change to SAVE-NO, and then press button to exit without

saving modified data.

10

5.3 Programming examples

(1) The following operation process shows and example for system setting.

(2)The following operation process shows and example for setting internal network

address.

Note: there should not be same network addresses in a control system.

11

(3)The following operation process shows an example for module switching parameters (Usually

it is not needed to set these parameters only if there is no controller.)

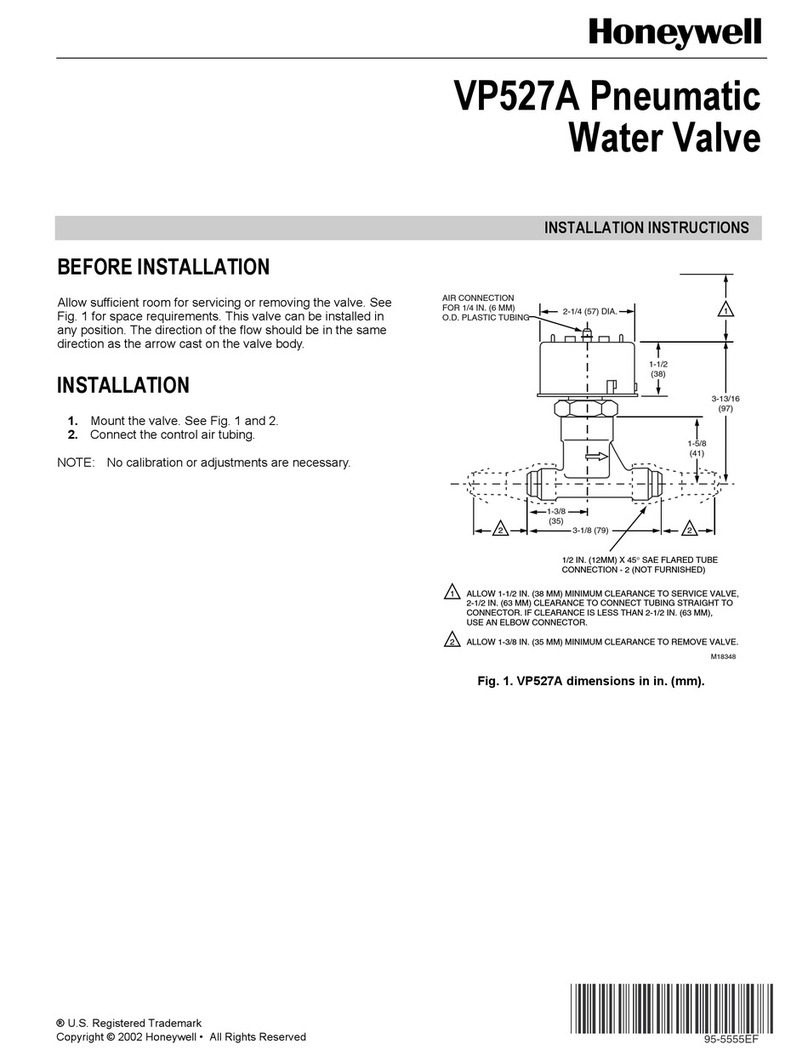

6. Panel description and measurement information display

12

1. C1 and C2 indication lights show the switching and running status of two capacitor

modules; if Fault indication light is on, that means the power capacitor module is in protection

status.

2. Three-row code segment LCD shows measured electrical information such as present

status of power capacitor module, capacity, temperature and electrical parameters.

3. Dial switch is composed of Test and Work. Test is used to simulate switch in and cut off of

power capacitor module through compensation controller; Work means the capacitor module

working normally.

4. Three buttons are used for switching between display interfaces and programming.

Display information

button is used to switch between different interfaces. The information of each interface is

shown in the following list.

Interfaces

Content

Description

Host-slave

mode, No. and

quantity of

capacitor

modules, total

module quantity

In first row , HoSt shows this

module is the host module; SLAV

shows this module is a slave

module;

In econd row, the number

following CH shows the No. of

module;

In third row, the number

following AL shows the totoal

quantity of modules in network.

Note: if the host is in this interface,

press and buttons together

to realize networking.

Capacity

The left picture shows the

capacity of module.

Temperature

The left picture shows the

temperature of two compensation

modules.

13

The left picture shows the

temperature of separate

compensation module.

Three phase

current

The left picture shows the value

of current in compensation status.

Three phase

voltage

The left picture shows the value

of bus line voltage.

Input current

The left picture shows the

current of incoming cabinet (only

effective in host module).

Active power

The left picture shows the active

power of incoming cabinet (only

effective in host module).

14

Reactive power

The left picture shows the

reactive power of incoming cabinet

(only effective in host module).

Total apparent

power

The left picture shows the total

apparent power of incoming cabinet

(only effective in host module).

Power factor

The left picture shows the power

factor of incoming cabinet (only

effective in host module).

Harmonic

content

The left picture shows the

voltage and current harmonic

content of incoming cabinet (only

effective in host module).

Protection

alarm

Er01:Over voltage protection, return

to normal automatically;

Er 02:Under voltage protection,

return to normal automatically;

Er 03:Over current protection, need

to be reset;

Er 04:Over temperature protection

for first module, return to normal

automatically;

Er 05:Over temperature protection

for second module, return to normal

15

automatically;

Er 06:Three phase unbalance

protection, need to be reset;

Er 07:Harmonic voltage protection

THDu%, return to normal

automatically;

Er 08:Harmonic current protection

THDi%, return to normal

automatically;

Er 09:Internal fault, need to be

reset.

7. Common problems and solutions

7.1 Automatic switch in after power on

The compound switch inside a module is defaulted to be open, but it may become closed

because of vibration in transportation. In this case, user needs to connect the module to grid

which can bare the current of that module to make it reset.

7.2 External indication light on after module power on; External indication light off after module

power off.

First, please confirm the type of module. If the module is total compensation type, the

common end of external indication light should be connected to Ub; if the module is separate

compensation type, the common end of external indication light should be connected to Un.

Second, the connection of external indication light is right. In this case, user needs to check

the phase sequence of wires connected to the module and make it the same with the printed

diagram on module.

Note: It is normal that the external indication light is in false light status.

7.3 Other abnormal situation.

Please contact our technical service department and describe the field situation clearly. Our

technicians will provide solution according to your description. If the problem can not be solved

after communication, we will send technicians to solve the problem at field.

7.4 Switching test

Switching tests are divided into two kinds which are simulation switching test and normal

switching test according to switching effects. The difference between these two kinds of tests is

that in simulation switching test, the capacitor module is not really switched in, so there is no large

current, but in normal switching test, the capacitor module is switched in and there will be large

current. Please select the testing method according to practical situation so as not to burn the wire

or cause accidents.

①Controller simulation switching test

1)Change the dial switch on the capacitor module to Test;

2) Control the switching of capacitor module through compensation controller. Meanwhile the

indication lights will react. If the indication light is on, that means the capacitor module is switched

16

in; if the indication light is off, that means the capacitor module is switched off.

②Controller normal switching test

1) Change the dial switch on the capacitor module to Work;

8.Change the power factor of circuit. Controller will control the real switching of capacitor modules

according to power factor. If the indication light on capacitor module and external indication light

are on, that means the capacitor module is switched in; if the indication light on capacitor module

and external indication light are off, that means the capacitor module is switched off.

8.Ordering specification and contact method

Please write down the model of product in your order. There are default settings for each

capacitor module. If you need other setting, please specify it in your order. The example of order is

as follows,

Model:SFR-MXD-2020/450

Other:External controller WGK-31-203-G

This manual suits for next models

22

Table of contents