PAGE 13

PAGE 12

MAINTENANCE

1. Always maintain the pump in a clean condition, checking regu-

larly for loose bolts etc.

2. Clean the air filter once every 50 hours of use (or more often in

unusually dusty conditions) as follows. Clean the foam filter ele-

ment with domestic detergents and clean the mesh element by

knocking against a solid object or blow out any dust with a high

pressure air jet. Never operate the pump without the air cleaner

installed as this would cause premature wear to the engine.

3. Replace the spark plug after the first month or every 50 hours

of use. Check when installing that the spark plug has the cor-

rect clearance by measuring with a feeler gauge and adjusting

the side electrode as required. Clearance should be 0.70-

0.80mm. The recommended spark plug is RK34200/168F.

CHANGING THE OIL

The oil in the engine should be changed after the first 20 hours use

and thereafter every 6 months or 100 running hours. Remove the

dipstick and drain plug and then drain the oil. Re-fill and check the

level.

ENVIRONMENTAL PROTECTION

One of the most damaging sources of pollution is oil. Do not throw

away used oil with domestic refuse or flush down a sink or drain.

Take it to your local waste disposal site.

STORAGE & HANDLING

After use, drain the pump body whenever there is danger of freez-

ing, and if the pump has been used with contaminated or salty

water, It should be thoroughly flushed with clean water following

use, both inside and out and drained before replacing the drain

plug. Always transport the pump with the fuel cock turned off and

keep the unit level to prevent any fuel from spilling.

If the pump is not to be used for some time, it should be flushed

thoroughly with clean water, and drained completely before storing

in a clean dry environment. Additionally, it should be prepared

as follows:

1. Drain the fuel tank and carburettor completely by opening the

drain plug in the carburettor float chamber and draining all

remaining fuel into a suitable container ensuring the fuel shutoff

valve is open.

2. Remove the spark plug, and pour 2-3 teaspoons of light oil into

the cylinder through the spark plug hole.

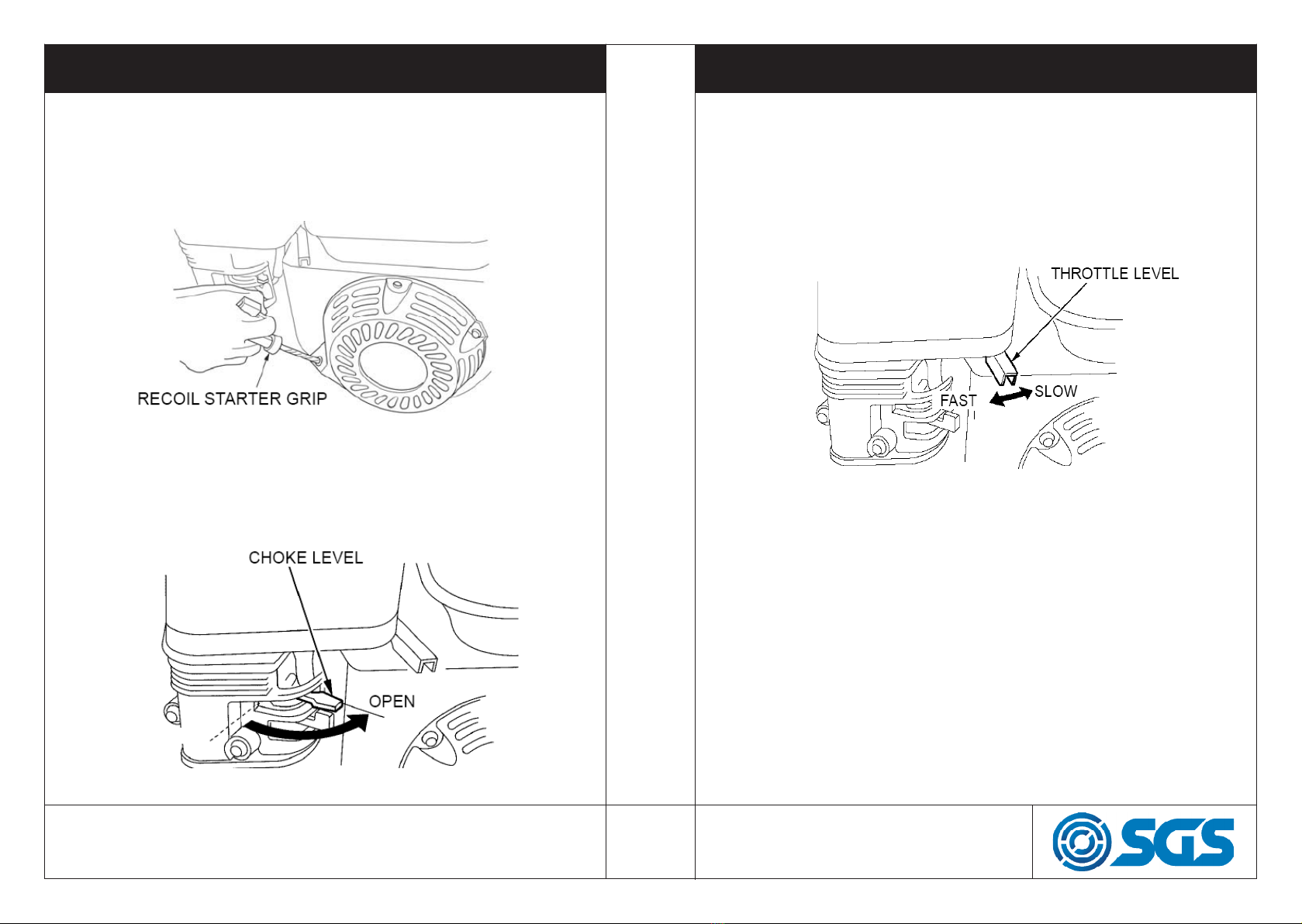

3. Pull the starter recoil rope slowly 2 or 3 times so that the oil is

deposited on the cylinder walls and replace the spark plug. For

longer term storage, use the starter to turn the engine until

the triangle mark on the starter wheel lines up with the starter

screw hole. In this location both the inlet and exhaust valves are

closed which may prevent the engine from suffering internal

corrosion during storage.

WWW.SGS-ENGINEERING.COM