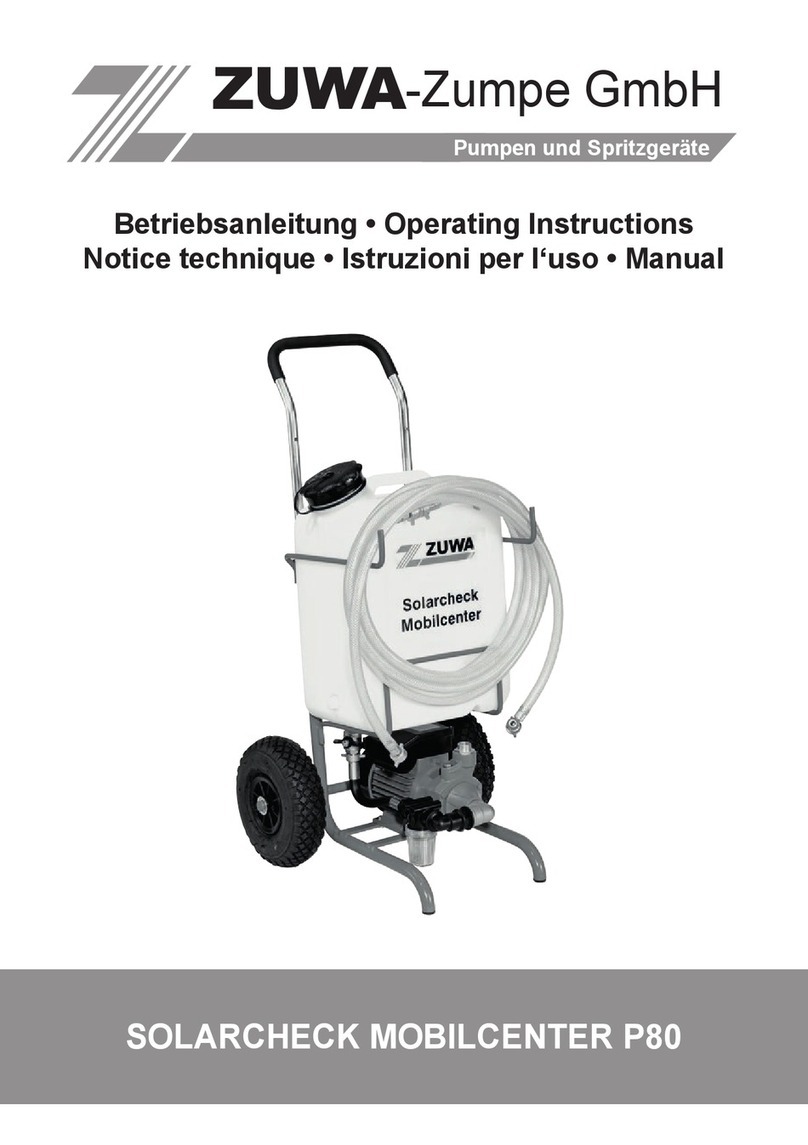

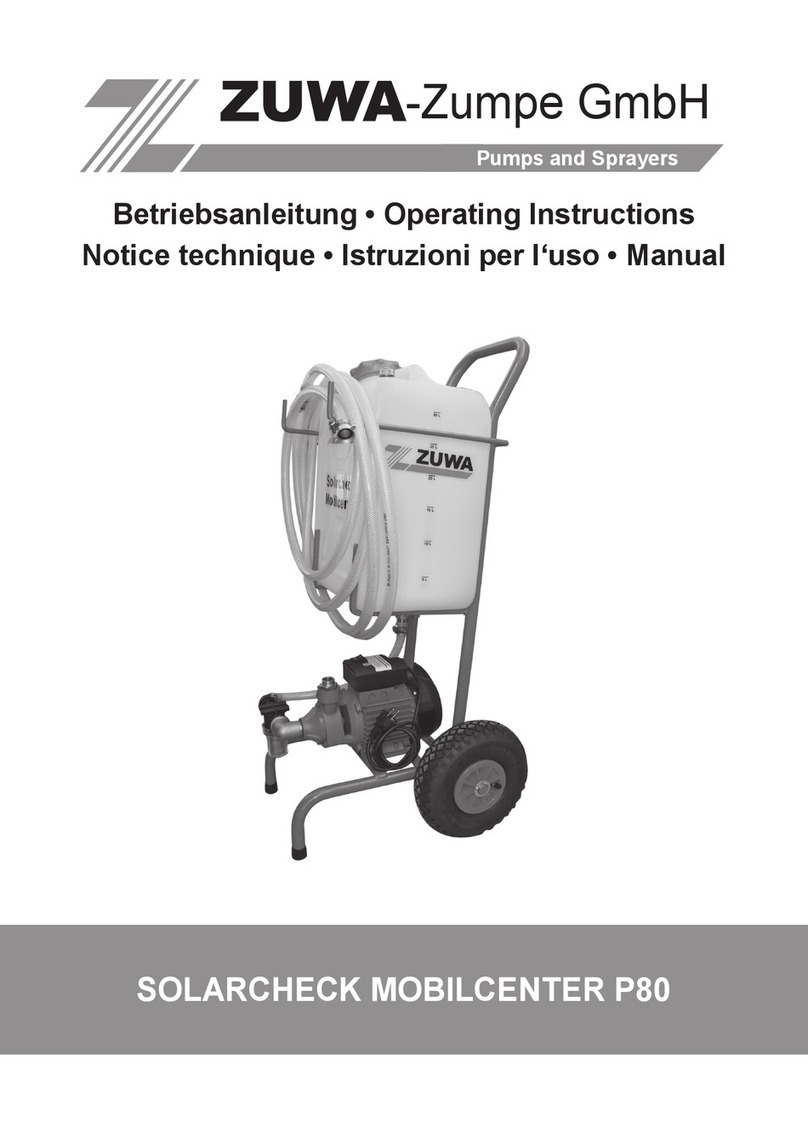

ZUWA SOLARCHECK MOBILCENTER

8

tation.

> p valve (3) between fill and vent valve.

u

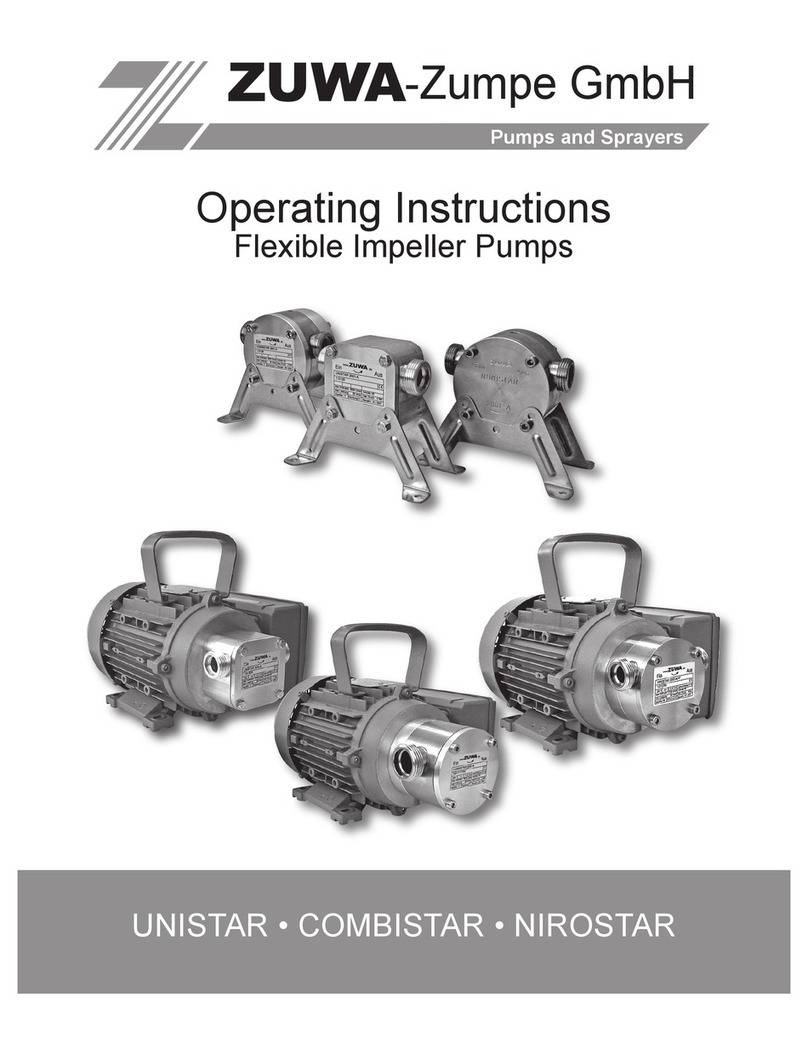

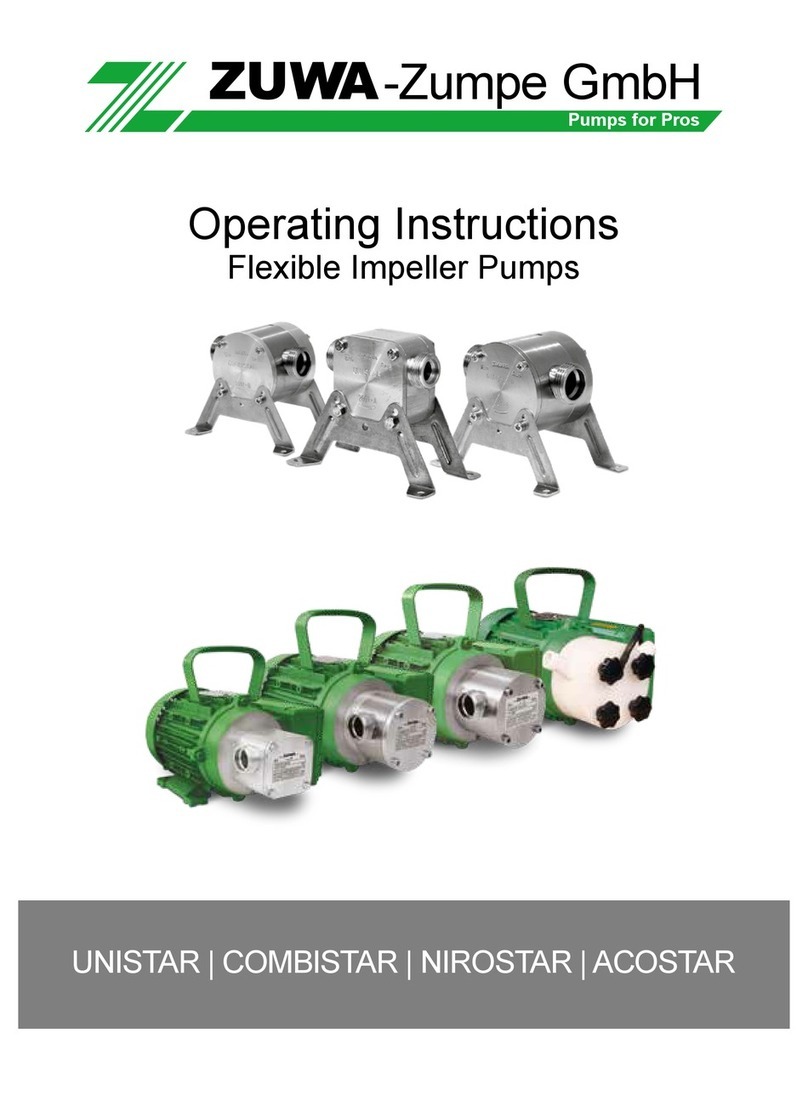

check Mobilcenter UNISTAR 2000-A:

n release the pressure that is

d let the

Afte filling hose easily from the fill valve.

ose from fill and vent valve.

piece in order to

5. End of operation

3

1

2

After filling and flushing the solar system:

> Switch off pump.

> Close fill and vent valve (1+2) at the solar s

Open sto

Ca tion: Collect escaping pumped media in a

container.

Only Solar

By opening the drain valve at the pump outlet you ca

generated between pump outlet and fill valve when flushing the pipe:

> Turn the green handwheel of the drain valve at the pump outlet an

remaining liquid run out.

r that you can unscrew the

Solarcheck Mobilcenter all types:

> Unscrew filling hose and return h

> Screw open hose ends together with the provided connecting

avoid dripping or escaping of fluid during transport.

6. Maintenance

Dange

Danger of death due to electric shock

connect the drive from the power

r > Prior to work on the pump, always dis

supply.

Caution

Danger of environmental damage due to hazardous pumped media

lly> Collect escaping pumped media and dispose of according to the loca

applicable regulations.

6.1 Connections

> Check regularly if hose couplings are tight.

suction side of the pump to filter out sold and

rainer and clean both with rinsing water

6.2 Cleaning the filter

There is a built-in fine filter on the

welder residues. Check the vision panel at the filter regularly and clean the filter

when you see dirt deposits on the strainer.

> Screw off the filter casing, remove the st

or compressed air.