Shakmat Modular Knight's Gallop User manual

ALGO-RHYTHMIC GENERATOR

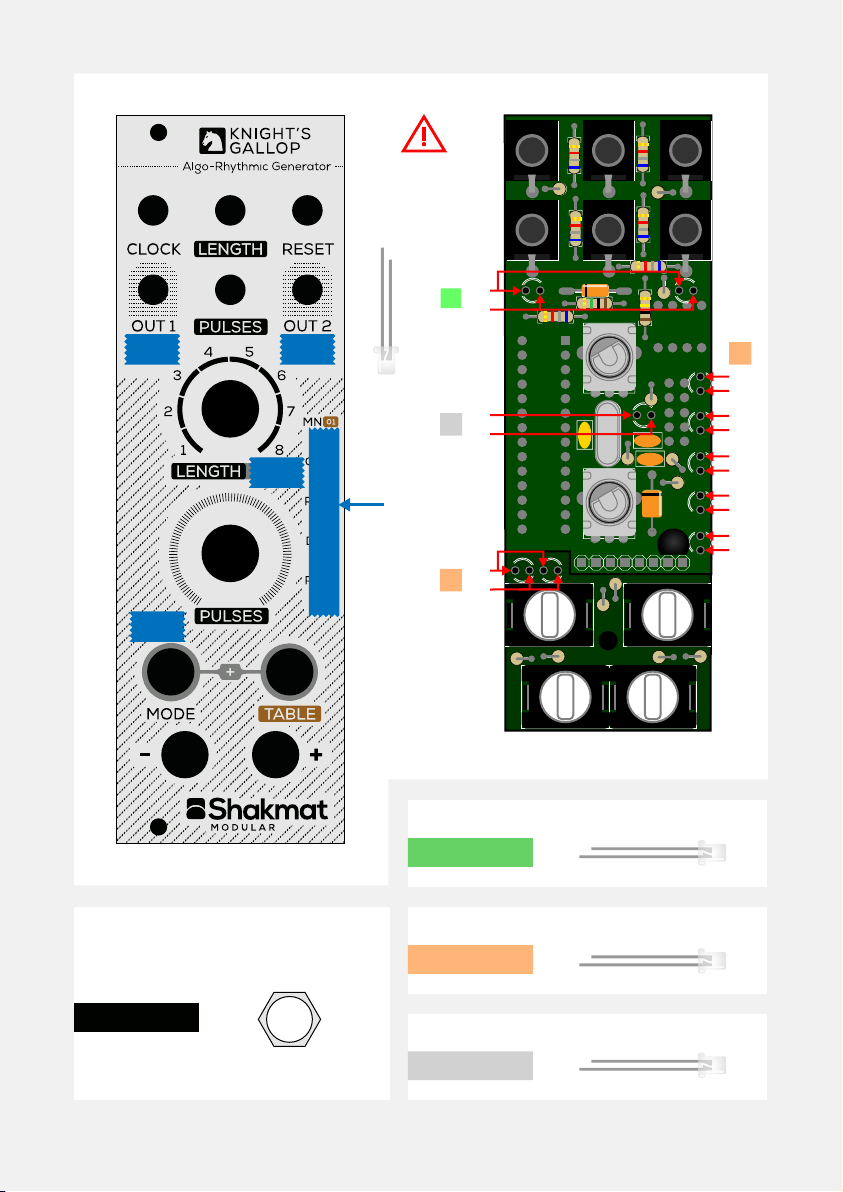

BUILDING GUIDE

KNIGHT’S GALLOP

Table of Contents

01. Components List + Tools

02. PCB Sides

03. Important Note

04. Top PCB Assembly

04_1. Diode 1N4148

04_2. Laying Resistors

04_3. Zenner Diode

04_4. Capacitors

04_5. Quartz

04_6. 78L05 Regulator

04_7. Standing Resistors

04_8. Jack Connectors

04_9. Potentiometers

04_10. IC Sockets

04_11. PCB Male Header

04_12. Power Supply Header

05. Bottom PCB Assembly

05_1. Standing Resistors

05_2. Push Buttons

06. Top & Bottom PCB’s Assembly

07. LED’s Mounting

08. IC’s, Nuts, Bolt & Caps

01. Components List + Tools

Resistors

6,8 kΩ

X6 — Pack 1/5

R7 → R10, R19, R20

100 kΩ

X6 — Pack 2/5

R15, 25, R3 → R6

1 kΩ

X5 — Pack 1/5

R11, R12, R16, R21, R26

1 MΩ

X2 — Pack 2/5

R1, R2

22 Ω

X1 — Pack 1/5

R27

15 kΩ

X1 — Pack 2/5

R14

Capacitors

22 pF

X2 — Pack 2/5

C1 + C2

100 nF

X1 — Pack 1/5

C3

Diodes

1N4148

X1 — Pack 1/5

D1

1N4742 Zenner

X1 — Pack 2/5

D10

Quartz

16 MHz

X1 — Pack 2/5

Q1

Jack Knurled Nuts

X6 — Pack 4/5

on jack connectors

Potentiometers

X2 — Pack 3/5

P1 & P2

Potentiometers Nuts

X2 — Pack 4/5

on potentiometer

Push Buttons

X4 — Pack 3/5

PB1 → PB4

Push Buttons Caps

X4 — Pack 3/5

on push buttons

M3 Panel Nut

X1 — Pack 4/5

on panel screw

M3 Screws

X2 — Pack 4/5

on panel

Chroma Caps Knobs

X2

on potentiometers

Top PCB (big)

X1 — Pack 5/5

Bottom PCB (small)

X1 — Pack 5/5

Aluminum Panel

X1

Power ribbon Cable

X1

Tools

Soldering Iron

Solder

Cutting Pliers

Masking Tape

LED’s

White LED

X1 — Pack 1/5

L+ LED

Amber LED

X7 — Pack 2/5

LED M1 → LED M5,

LED SM1 + LED SM2

Green LED

X2 — Pack 3/5

LED1 + LED2

IC’s

8 Pin IC Socket

X1 — Plastic Tubbing

ICS1

LM358 OpAmp

X1 — Plastic Tubbing

on ICS1

28 Pin IC Socket

X1 — Plastic Tubbing

ICS2

ATMEGA328

X1 — Plastic Tubbing

on ICS2

78L05

X1 — Pack 1/5

IC3

Miscellanous

Power Supply Header

X1 — Pack 3/5

PSH1

PCB Male Header

X1 — Pack 3/5

PH1

Jack Connectors

X6 — Pack 3/5

J1 → J6

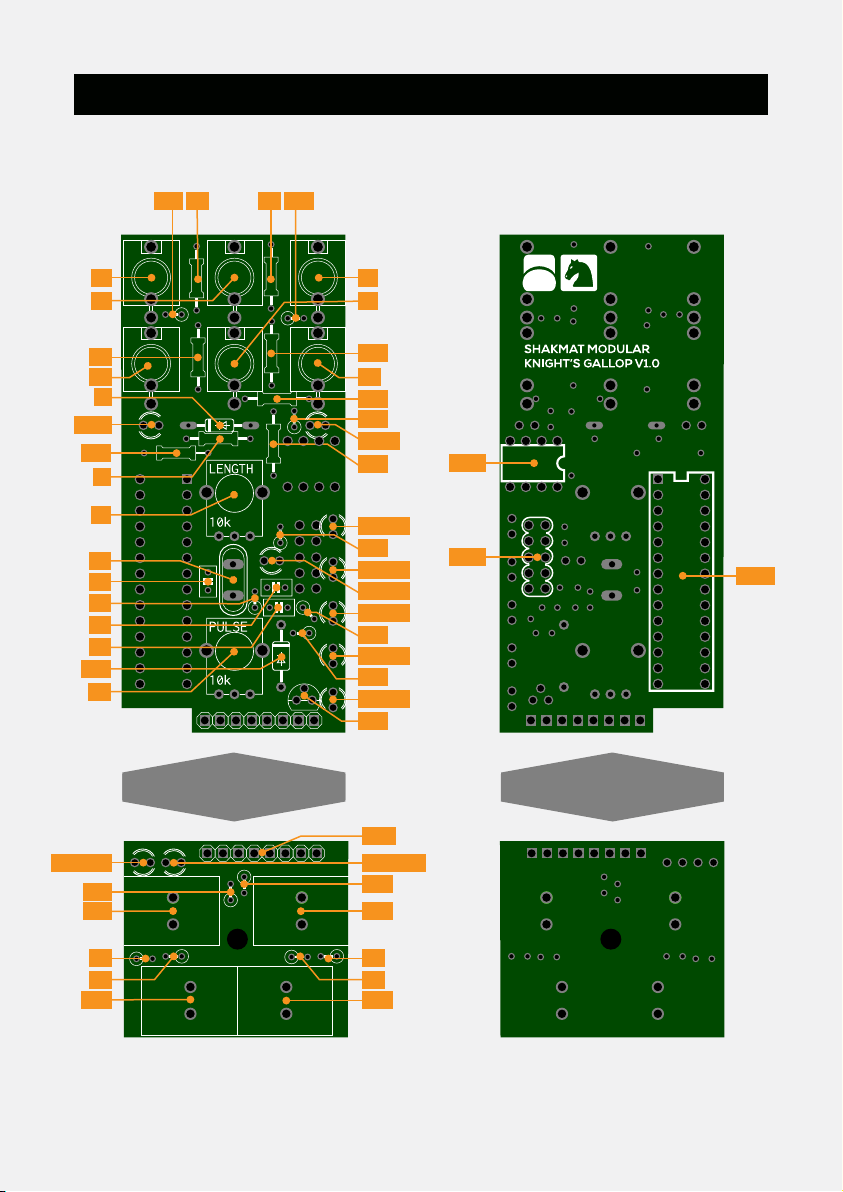

02. PCB Sides

Front Rear

R9R26 R16

R10

R20

R25

R14

R12

R27

L+ LED

LED2

R7

J4 J6

R8

R15

LED M1

LED M2 PSH1

ICS1

ICS2

LED M3

LED M4

LED M5

IC3

J1 J3

J2

D1

R2

R19

P1

P2

C3

C1

C2

D10

R1

Q1

J5

LED1

R3

PB1

PB2

R11

LED SM1

R5

R4

PB3

PB4

R21

PH1

LED SM2

R6

If you feel you're going to build this kit without looking at the steps, just

remember that it is very important to join the two PCB’s in a strict

parallel alignment. If you don't want the final build to have hard to press

buttons, please pay attention to that. We also recommand to have a look

to the steps 04_9 that require unexpected cuts for the potentiometers.

Don’t split the packs open & mix components, somes are virtually indistin-

guishable (like the 3 different color LED that all appear clear when inac-

tive). We strongly recommand to only take the component(s) you need

and let the other in their corresponding pack.

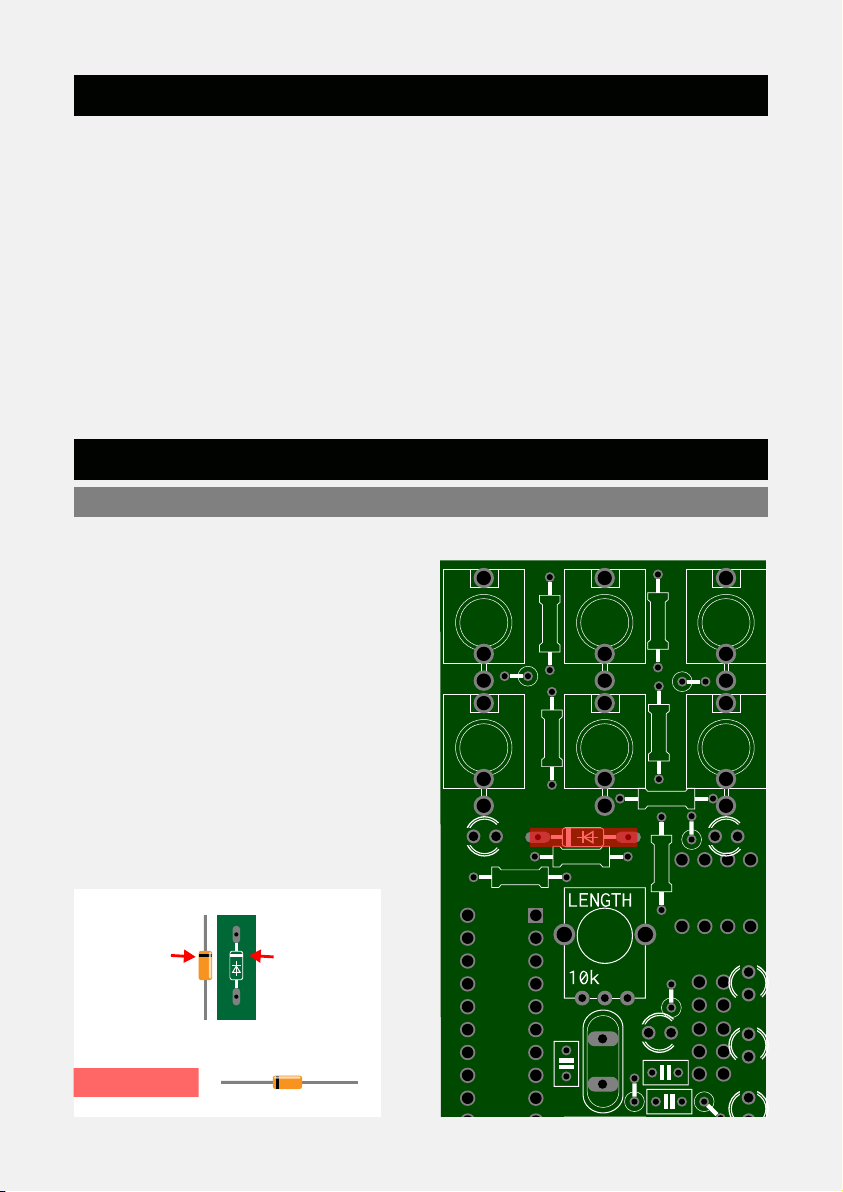

This build has two dierent

diodes : a tiny one and a bigger

one. This steps only concern

the 1N4148, that´s to say the

tiny one. Please note that the

diode orientation has to match

the PCB silkscreen. The white

line on the silkscreen has to

match the black bar on the

component, as on the

following picture.

03. Important Note

04. Top PCB Assembly

04_1. Diode 1N4148

White line

on PCB

Black line on

component

1N4148

X1 Pack 1/5

As in step 4_1, be carefull to the

diode polarity. You’ve to match the

silkscreen and component black line.

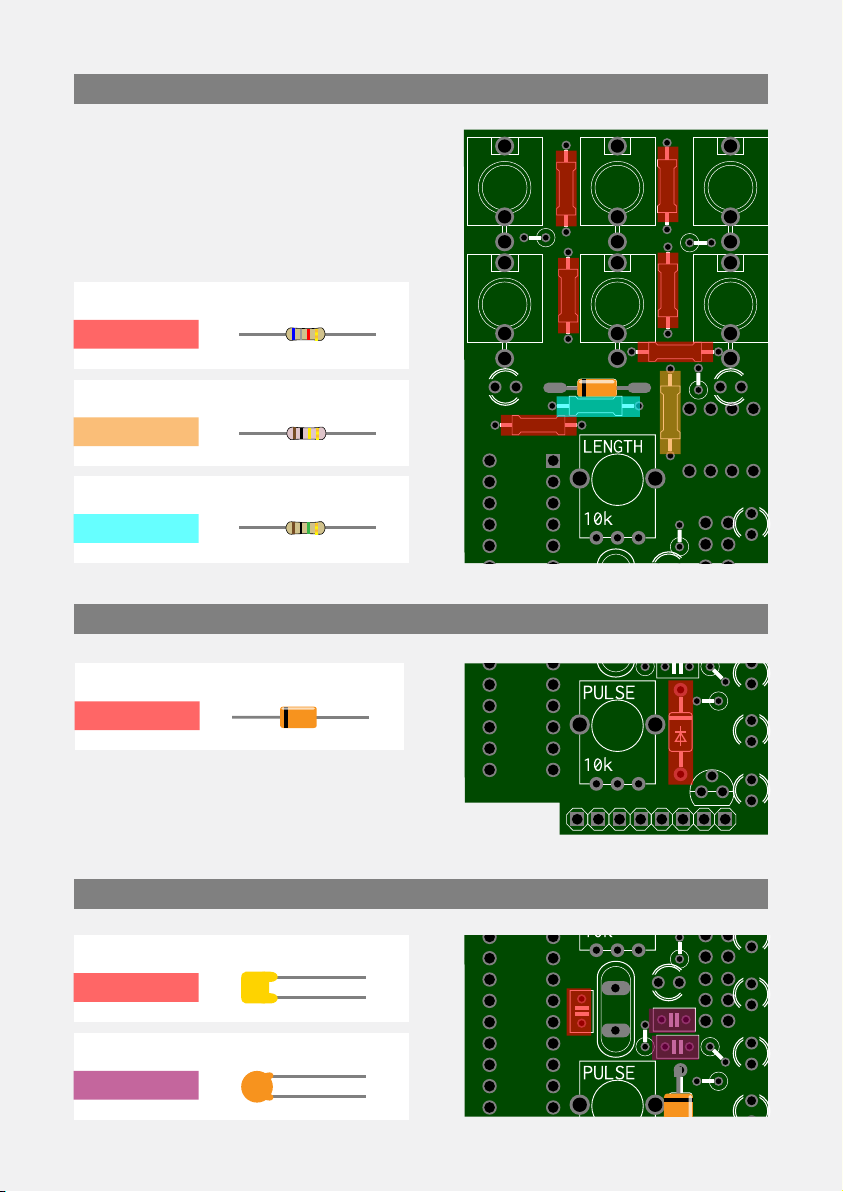

Here's a picture of the top PCB with

placement of the resistors by

values. There’s no polarity to

observe with resistors.

04_4. Capacitors

04_2. Laying Resistors

04_3. Zenner Diode

6.8k

100k

1M

X6

A

B

C

X1

X1

Zenner

X1

100nF

22pF

X1

A

B

X2

Pack 1/5

Pack 2/5

Pack 2/5

Pack 2/5

Pack 1/5

Pack 2/5 B

B

A

A A

A A

A

ACB

Only one leg of the

resistors have to be

bent before solde-

ring. Don’t bend the

leg too high or it will

cause short-circuit

with the panel.

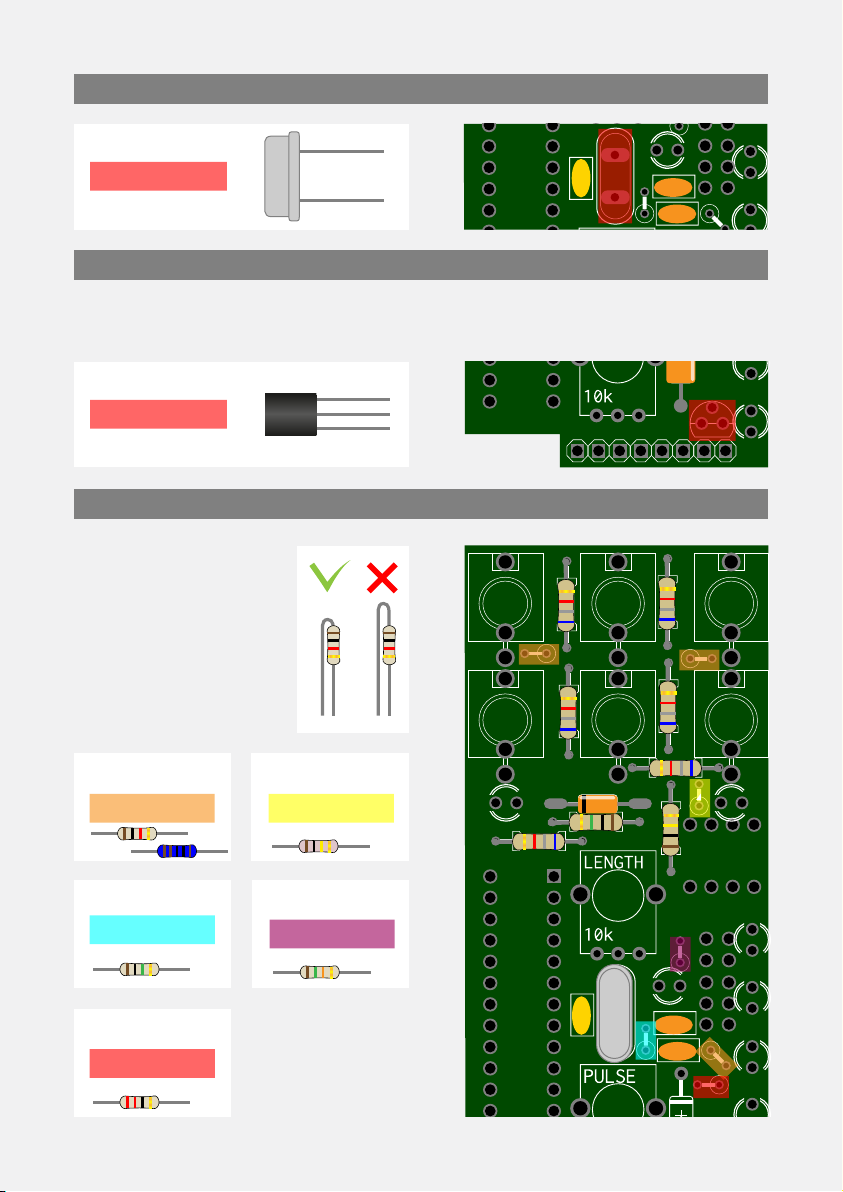

Bend the middle leg of the 78L05. Then place the component on the PCB,

the flat side of it has to correspond to the flat side of the silkscreen.

04_5. Quartz

16 MHz

X1 Pack 2/5

78L05

X1 Pack 1/5

04_6. 78L05 Regulator

04_7. Standing Resistors

1k 100k

1M B

C

D

X3 Pack 1/5

X1 Pack 2/5

X1 Pack 1/5

X1 Pack 2/5

15k

X1 Pack 2/5

22

EE

AA

D

B

A

A

C

OR

There are 6 jack connectors, that

have to sit tight and flush with the

PCB. Be sure to push them all the

way through before soldering.

04_8. Jack Connectors

04_9. Potentiometers

X2 Pack 3/5

First you'll have to remove a little piece on the potentiometer as shown in

the picture. Then, you can place and solder them.

Cut

X6 Pack 3/5

Jack

Now, let’s flip the PCB and conti-

nue. We’re going to solder the two

ICs sockets. Be attentive to their

orientation. The red lines on the

picture show the right position.

04_10. IC Sockets

04_11. PCB Male Header

X1 Pack 3/5

Header

The PCB header is also mounted on the back of the top PCB. For now we

are taking care of the short legs side of the header. Be very carefull with

this piece : it has to lay completely flat with the PCB and perfectly perpen-

dicular. We recommand you to place de header and solder one leg then

verify it’s alignment before soldering the seven remaining legs.

X1 Plastic Tubbing

04_12. Power Supply Header

X1

Header

05. Bottom PCB Assembly

05_1. Standing Resistors

05_2. Push Buttons

1k

100k

A

B

X2

X4

Pack 1/5

Pack 3/5

Pack 2/5

AA

Button

X4 Pack 3/5

four buttons, then flip the PCB and

press it against your table in order

to ensure that every button is well

placed.

The buttons are easy to plug & solder but they need to be thoroughly

pushed on the PCB. Before soldering, we recommand to place the

BBB B

OR

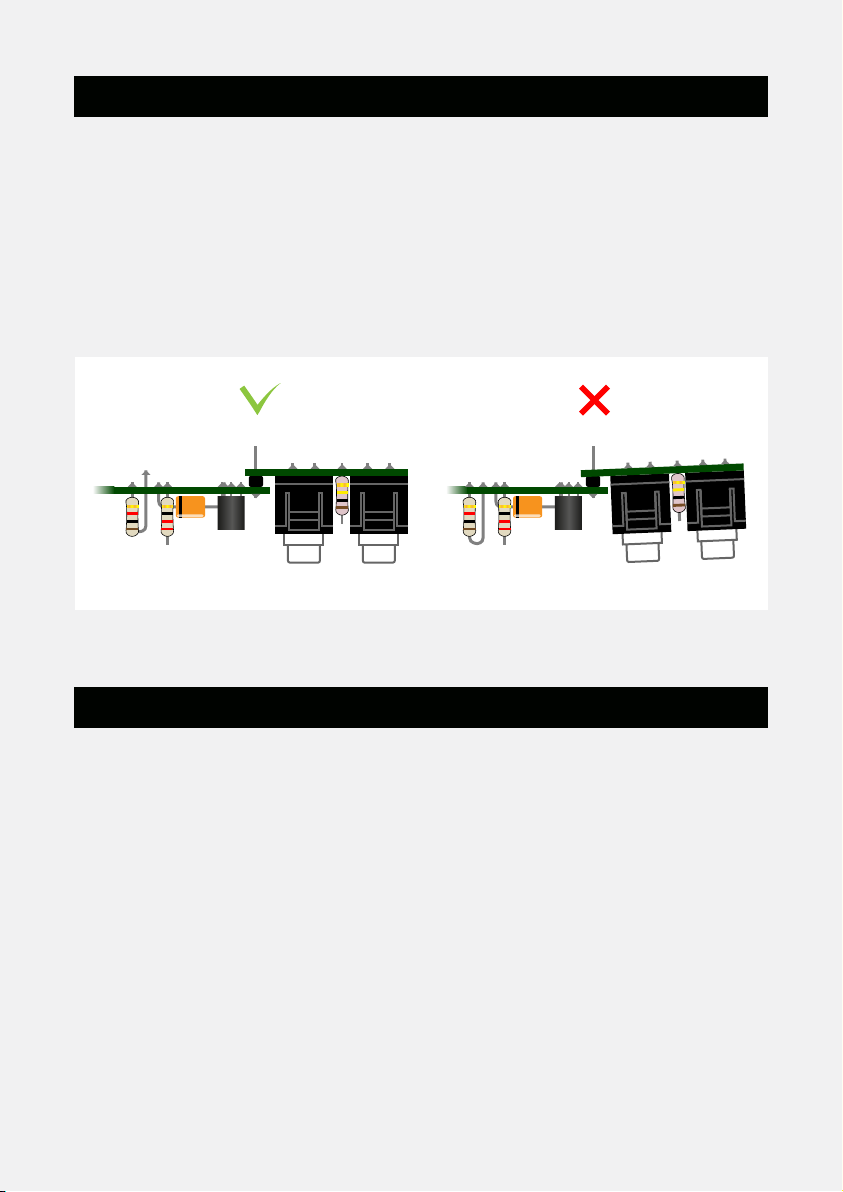

06. Top & Bottom PCB’s Assembly

07. LED’s Mounting

Be very carefull that the header you’re soldering is well passed through all

the bottom PCB holes and that the two PCB’s are perfectly horizontal. If

there is a gap between the header and the PCB’s, or if they’re not correc-

tly aligned, the push button could be pourly placed and hard to press.

As you did before, we recommand you to only solder one pin of the

header and check the alignment before soldering the seven other pins.

To get well soldered LED flush with the panel, you need to assemble the

front panel to the PCB. We recommand you to do this by finger tighten-

ning the two hex nuts on the potentiometers.

A good way to do this is to use masking tape to cover the panel LED holes.

Therefore you can place the LED on the PCB, assemble them with the

potentiometer nuts and push LED’s through the panel until they sit flush

and stick to the tape. Then you can solder them.

Be carefull with the LED polarity, the long leg is always the positive side.

Please refer to the following picture to know wich LED goes where. You

also need to pay attention to not mix LED’s from different packs, when

inactive the clear LED’s are very hard to differenciate from each other.

Masking

tape

LED

POLARITY

+-

+

-

+

+

-

-

+

-

+

-

+

-

+

-

+

-

Green

Amber

White

X2

A

B

C

X7

X1 Pack 1/5

Pack 2/5

Pack 3/5

Nuts

X2 Pack 4/5

A

C

B

B

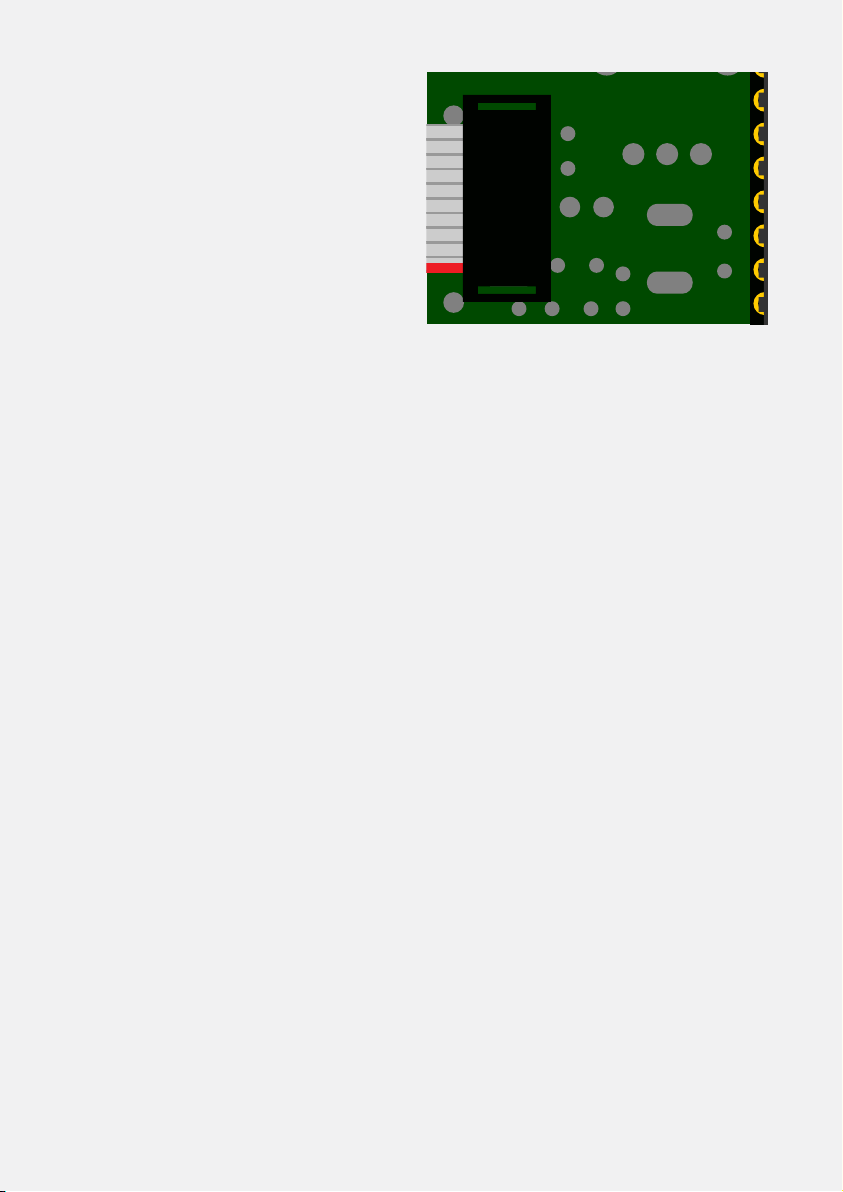

08. IC’s, Nuts, Bolt & Caps

It’s now time to plug the IC’s in their sockets. Make sure the IC orientation

matches the socket orientation as on the following picture.

You can now place the six knurled nuts on the jack connectors and the M3

nut on the screw that is mounted on the back side of the panel. The func-

tion of this nut is to retain the bottom PCB to retreat when the buttons

are pushed.

Do not screw the M3 nut to far or it will push the bottom PCB out of it’s

parallelism with the top PCB and interfer with the buttons caps. Just

tighten it until it sits flush with the bottom PCB. To prevent this nut to

move over time, we recommand you to put a small amount of nail polish

on it. Some glue will also do the trick but can be very problematic to

remove if you need to unscrew this nut. Finally, mount the four buttons

caps and two potentiometers knobs. That’s it, you’ve finished !

X2 Plastic Tubbing

X6 Pack 4/5

X1 Pack 4/5

X4 Pack 3/5 X2

www.shakmatmodular.com

Plug the power cable and make

sure the red side of the ribbon

matches the -12V on the PCB.

Now let's plug the module in your

system and test it. The module

LEDs doesn't blink if the module

isn't running. So don't panic if

the modules seems quiet when

nothing is connected to it.

A fast and easy way to check if the module is working is to feed the clock

input with a trig gate signal and mangle with the potentiometers, both

LEDs should be blinking.

If ever you get some troubles or questions, send us an email at

support@shakmatmodular.com.

To download the Knight’s Gallop User Manual, go to our website and

navigate to the support section.

-12V

Table of contents