Shanghai Siheng Motor KA Series User manual

- 1/27 -

Shanghai Siheng Motor Co Ltd

www.sihengmotor.com

DANGER

It is forbidden to use the product in flammable and explosive occasions, which can

easily cause injury or fire.

It is forbidden to use the product in places with humidity, direct sunlight, dust, salt

and metal powder.

KA Series AC Servo Driver Manual

Safety notes

Danger means that when used incorrectly, it will lead to

danger and personal injury.

Note: When used incorrectly, it will cause danger, personal

injury and possible damage to equipment.

Prohibition: It means strictly prohibiting the behavior,

otherwise it will lead to equipment damage or can not be used.

Use occasion

Wring

Do not connect 220V driver power to 380 power supply, otherwise it will cause

equipment damage or fire.

Please grounding terminal reliably. Poor grounding may cause electric

shock or fire.

Do not connect the output terminal of driver U-V-W motor to three-phase power

supply, otherwise it will cause casualties or fire.

Driver UVW motor output terminal and motor connection terminal UVW must be

connected correspondingly, otherwise the motor may cause equipment damage

and casualties due to speeding.

Wiring please refer to wire wiring, otherwise it may cause fire.

- 2/27 -

Shanghai Siheng Motor Co Ltd

www.sihengmotor.com

Note

Before starting operation, please make sure that you can start the emergency

switch and shut down at any time.

When commissioning, please separate the servo motor from the machine. After the

action is confirmed, the motor is installed on the machine.

After the servo motor stops and restores instantaneously, do not approach the

machine. The machine may suddenly start again.

Do not switch on or off the power frequently, otherwise it will cause overheating

inside the driver.

O

peration

Function

Stop

When the motor is running, do not contact any rotating parts, otherwise it will cause

casualties.

When the equipment is running, it is forbidden to touch the driver and motor,

otherwise it will cause electric shock or scald.

When the equipment is running, it is forbidden to move the connecting cable,

otherwise it will cause personal injury or equipment damage.

- 3/27 -

Shanghai Siheng Motor Co Ltd

www.sihengmotor.com

Product introduction

1.1 Servo Driver Technical Specification

output power(kW)

0.4~0.8KW

1.0~1.5KW

1.7~2.6KW

Motor rated torque

(N·m)

2~4NM

4~10NM

6~15NM

Input power supply

Sing le- phase or thr ee-

phase AC 50 Hz / 60Hz

(

0.85

~

1.1

)

×

220V

Three-phase AC 50 Hz /60Hz

(

0.85

~

1.1

)

×220V

Use

enviro

nment

temperature

Work: Storage at 0 ~55: -20 ~+80.

humidity

Less than 90 %(No dew)

Vibration

Less than

0.5G

(

4.9m/s

2

),

10 Hz

~

60 Hz(Discontinuous operation)

Control method

Position Control, Speed Control and Torque Control

regenerative braking

Built-in (external when built-in resistance power is insufficient)

Control

characteristics

Velocity Frequency Response:≥200Hz

Velocity fluctuation rate: <0.03 (load 0-100%): <0.02 *0.9-1.1) power

supply voltage

(Value corresponds to rated speed)

Speed ratio:1:5000

Pulse frequency:≤ 500kHz

control input

1 Servo Enablation

2 Alarm Clearance

3 CCW Drive Ban

4 CW Drive Ban

5.Deviation counter clearing/speed selection 1_

6.Instruction pulse prohibition/speed selection 2

7.CCW torque limit

8.CW torque limit

Control output

1. Servo Ready Output,

2. Servo Alarm Output,

3. Positioning Complete Output/Speed Achievement Output

position control

Input mode

(1) Pulse + Direction

(2) (2) Two-Phase A/B Orthogonal Pulse

Electronic

gear ratio

1~32767 / 1~32767(default: 10000:1000, i.e. 1000

pulses per cycle)

Feedback

pulse

10000 Pulse / turn

speed control

4 internal speeds (switching between SC1 and SC2 input signals)

Acceleration and

deceleration function

Parameter setting acceleration and deceleration time 1-10000ms (0r-

1000r/min)

- 4/27 -

Shanghai Siheng Motor Co Ltd

www.sihengmotor.com

Monitoring function

Speed, current position, instruction pulse accumulation, position

deviation, motor torque, motor current, bus voltage, absolute rotor

position, instruction pulse frequency, operation status, input and output

terminal signals, etc.

Protection function

Overspeed, overvoltage and undervoltage of main power supply,

overcurrent, overload, abnormal braking, abnormal encoder, abnormal

control power supply, abnormal position, etc.

Applicable load inertia

Less than 5 times the inertia of the motor

- 5/27 -

Shanghai Siheng Motor Co Ltd

www.sihengmotor.com

Installation

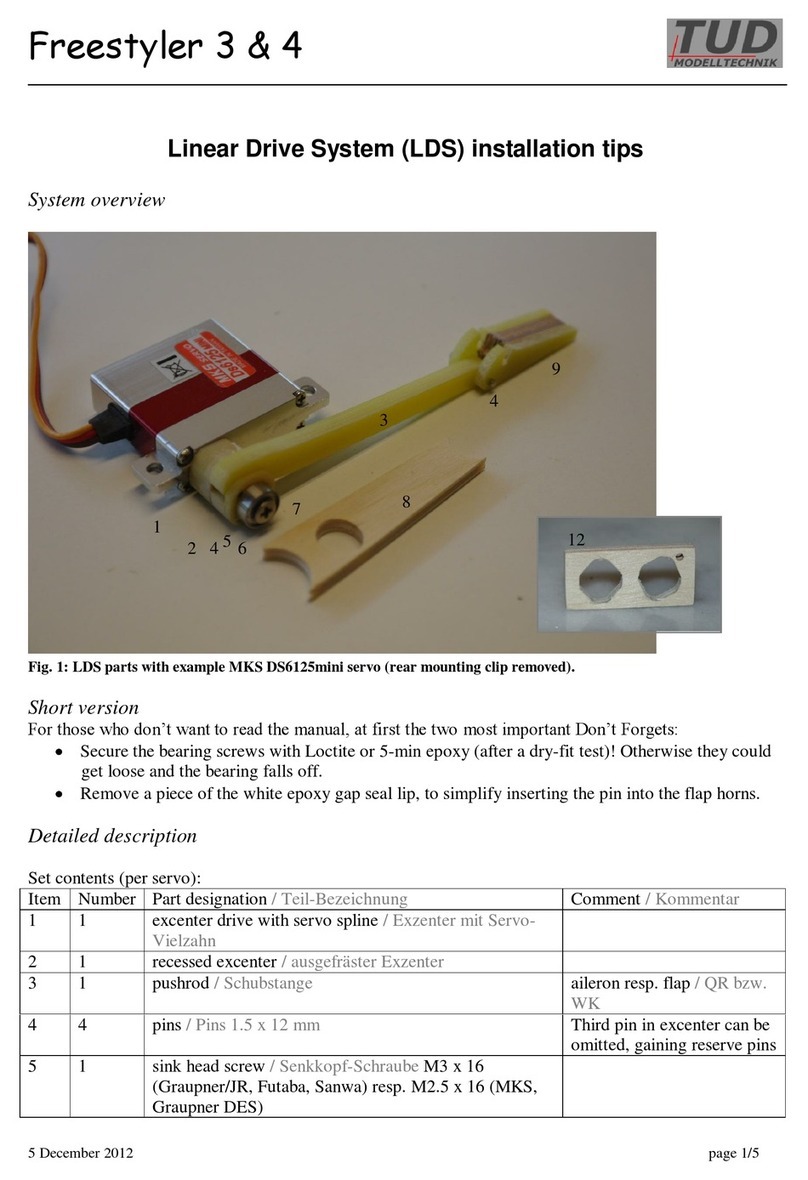

2.1

KA02-KA03 (below 400W) Motor Driver Outward Size Diagram

2.2

KA05 (0.6 ~1 kW)Outward Size Diagram of Motor Driver

- 6/27 -

Shanghai Siheng Motor Co Ltd

www.sihengmotor.com

2.3 KA10 (1.0 ~2.6 kW)Outward Size Diagram of Motor Driver

- 7/27 -

Shanghai Siheng Motor Co Ltd

www.sihengmotor.com

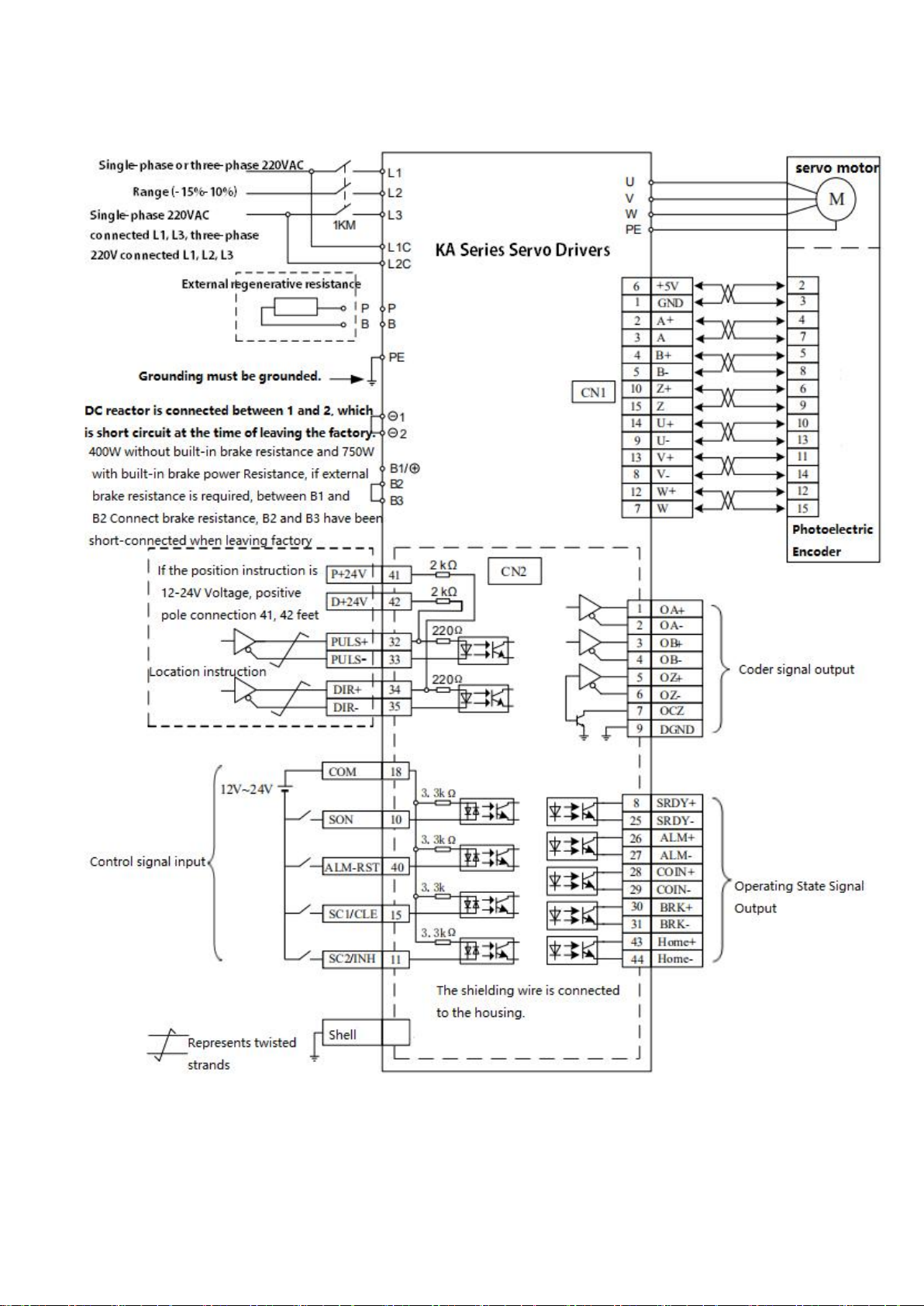

2.2.1

2.4 Standard wiring diagram

Position control mode

Drawing 2-3-1:Position control wiring

- 8/27 -

Shanghai Siheng Motor Co Ltd

www.sihengmotor.com

2.2.2 Speed/Torque Mode Wiring Diagram

Figure 2-3-2: Speed/Torque Mode Wiring

- 9/27 -

Shanghai Siheng Motor Co Ltd

www.sihengmotor.com

2.2.2 Control signal input/output CN2(44 cores terminal )

Control mode is abbreviated as: P stands for position control mode; S stands for speed control mode;

T stands for torque control mode.

Terminal

number

Signal name

Mark

Mode

Function

18

Input Common

End

COM

The common end of the input terminal is used to drive the input optocoupler. It

is connected to 0V or DC 12V-24V, and the current is more than 100mA.

10

Servo Enabling

Input

SON

SON ON: Allows drives to work;

SON OFF: The driver is closed and the motor is in free state. Note 1:

Before calling SON from SON OFF to SON ON,

The motor must be stationary.

Note 2: After calling SON ON, wait for at least 50ms to enter the

command.

40

Alarm clearance

input

ALRS

ALRS ON: Clear system alarm;

ALRS OFF: Keep system alarm.

Note: The alarm with fault code greater than 8 can not be cleared by this

method. It needs power off and maintenance, and then power on again.

15

Instruction pulse

forbidden input

INH

P

INH ON: instruction pulse input is prohibited;

INH OFF: instruction pulse input is valid.

Speed Selection 1

Input

SC1

S

In the speed control mode, the combination of SC1 and SC2 is used to select

different internal speeds.

SC1 OFF, SC2 OFF: Internal speed 1

SC1 ON, SC2 OFF: Internal Speed 2 SC1 OFF, SC2 ON: Internal Speed 3

SC1 ON, SC2 ON: Internal Speed 4

Note: The values of internal velocities 1-4 can be modified by parameters.

11

Speed Selection 2

Input

SC2

S

Counter clearing

CLE

P

CLE ON: When position control, position deviation counter is cleared.

8

Servo ready output

SRDY+

SRDY ON: The control power supply and main power supply are normal, the

driver does not alarm, the servo is ready to output ON (output on);

SRDY OFF: The main power supply is not closed or the driver has an alarm.

The servo is ready to output OFF (output cut-off).

25

SRDY-

26

Alarm output

ALM+

ALM ON: Servo driver without alarm, output ON, output on;

ALM OFF: Servo driver has alarm, output OFF, output cut-off.

27

ALM-

28

L o c a t i o n

c o m p l e t i o n

o u t p u t

( p o s i t i o n

c o n t r o l mo d e ) ;

V e l o c i t y

a r r i v a l

t r a n s p o r t

O u t p u t ( s p e e d

c o n t r o l mo d e ) ;

COIN+

P

COIN ON: When the position deviation counter value is in the set positioning

range, the positioning completes the output ON (output conduction),

otherwise the output OFF (output cut-off).

SCMP ON: When the speed reaches or exceeds the set speed,

Speed reaches output ON (output on), otherwise output OFF (output cut-off).

29

COIN-

S

- 10/27 -

Shanghai Siheng Motor Co Ltd

www.sihengmotor.com

Terminal

number

Signal name

Mark

Mode

Function

30

Mechanical Brake

Release Output

BRK+

This port can be used to control the brake when the motor has a mechanical brake

(power-loss retainer).

BRK ON: The brake transmitter is electrified, the brake is invalid, and the motor can

run.

BRK OFF: The brake is powered off, the brake is effective, the motor is locked and

can not run.

Note: The BRK function is controlled by the driver.

31

BRK-

32

Instruction Pulse

Position Input

PULS+

P

Determine the angle and speed of the motor.

33

PULS-

34

Directional input of

instruction pulse

SIGN+

P

Determine the rotation direction of the motor。

35

SIGN-

20

Analog Speed

Torque Instruction

Input

AS+

S

Differential mode, the input impedance of 10 k Ω - 10 v ~ + 10

v input range

19

AS-

T

22

simulation

AGND

Analog input ground wire

1

Encoder A

Phase Signal

Output

OA+

ABZ differential drive output of encoder (26LS31 output,equivalent to RS422);

Non-insulated output (non-insulated)

2

OA-

3

Encoder B-

phase signal

output

OB+

4

OB-

5

Encoder Z-

phase signal

output

OZ+

6

OZ-

7

Encoder Z-phase

collector open-

circuit output

CZ

In the upper computer, theZ-phase signal pulse is usually very narrow. Please use a

high-speed optocoupler to receive it.

9

Encoder Ground

Wire

GND

Encoder common ground wire

- 11/27 -

Shanghai Siheng Motor Co Ltd

www.sihengmotor.com

2.2.2 encoder signal input terminal CN1(15cores terminal)

Terminal number

Signal name

Mark

Mode

6

5V Power supply

+5V

Servo motor encoder with +5 power supply and common ground;

When the cable is longer, multiple parallel connection should be used

to reduce the line voltage drop。

1

Power common

0V

2

Encoder A+ input

A+

It is connected with photoelectric encoder A+

3

Encoder A- input

A-

Connect with photoelectric encoder A-

4

Encoder B+ input

B+

Connected with photoelectric encoder B+

5

Encoder B- input

B-

Connected with photoelectric encoder B-

10

Encoder Z+ input

Z+

connected with the photoelectric encoder Z+

15

Encoder Z- input

Z-

Photoelectric encoder Z- phase connection

14

Encoder U+ input

U+

Photoelectric encoder U+ phase connection

9

Encoder U- input

U-

Photoelectric encoder U- phase connection

13

Encoder V+ input

V+

Photoelectric encoder V+ phase connection

8

Encoder V- input

V-

Photoelectric encoder V- phase connection

12

Encoder W+ input

W+

Photoelectric encoder W+ connected

7

Encoder W- input

W-

Connected with the photoelectric encoder W-

Shell

Frame Ground

FG

Shield ground terminal

- 12/27 -

Shanghai Siheng Motor Co Ltd

www.sihengmotor.com

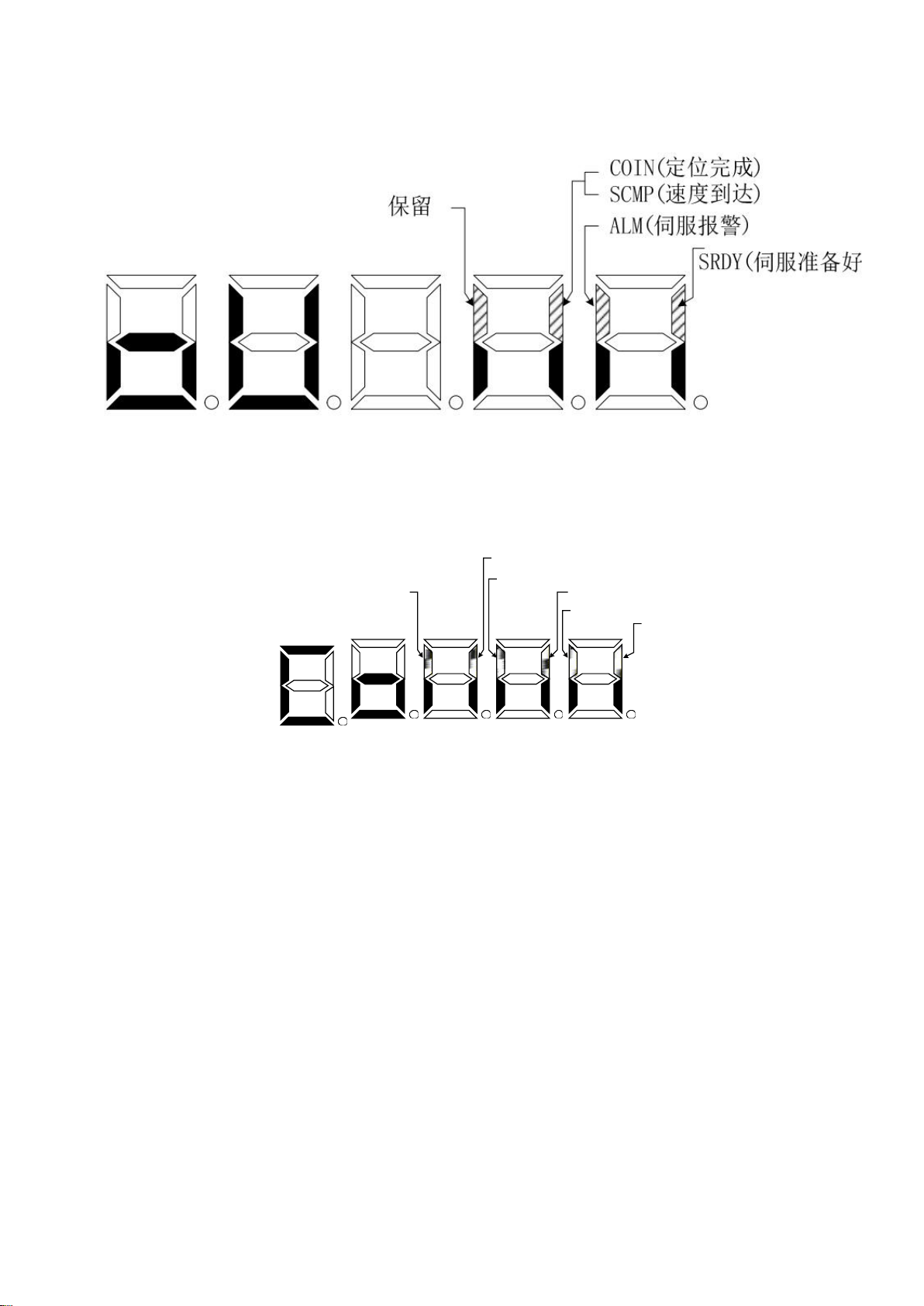

Chapter 3 display and panel operation

3.1 Panel shows

The operating interface of the servo driver is composed of 5 LED digital tubes and 5 keys, which

can be used for the state display and parameter setting of the servo driver. The interface layout

is as follows:

Key function description

Button

Button

name

Function

MODE

MODE

Switch the status monitoring mode/parameter mode/alarm mode and

return to the previous menu.

▲

multiply

Add monitor code, parameter number or set value, long press can

increase quickly.

▼

Reduce

Reduce the monitoring code, parameter number or set value, long press

can quickly reduce.

Shift

When setting parameters, press this key to move the selected flicker bit

to the left by one.

SET

Confirm

Go to the next menu, or save the Settings.

Numerical indication

The numerical value USES 5 digital tube displays. The minus sign in front of the

numerical value indicates a negative number. If it is a 5-digit negative number,

all decimal points are lit to indicate a negative number. Some display items are

preceded by an affix character, and if the number of digits is too long to occupy

the position of the prefix character, the prefix character will not be displayed,

only the value.

- 13/27 -

Shanghai Siheng Motor Co Ltd

www.sihengmotor.com

3.2 state monitoring

When the servo driver is powered on, the display will display "Pr. On" for about one

second, and then automatically enter the status monitoring mode. A total of 21 display

state, the user with the, key to select the required display state. You can also change the

value of P00.03 and select the display state of the display after the servo drive is

powered on.

Speed(r/min)

当前位置低4位(脉冲)

当前位置高4位(×10000 脉冲)

位置指令低4位(脉冲)

位置指令高4位(×10000 脉冲)

位置偏差低4位(脉冲)

位置偏差高4位(×10000 脉冲)

电机转矩(%)

电机电流(A)

直线速度(m/min)

当前控制方式 ←

位置指令脉冲频率(kHz)

速度指令(r/min)

转矩指令(%)

一转中转子绝对位置(脉冲)

输入端子状态

输出端子状态

编码器输入信号

运行状态

报警代码

保留

电机速度1000r/min

当前位置125806脉冲

位置指令125810脉冲

位置偏差4脉冲

Torque 70%

电机电流

2.3A

直线速度5.000m/min

控制方式 0

位置指令脉冲频率

12.6kHz 速度指令 -

35r/min

转矩指令 -20%

转子绝对位置

3265 输入端子

输出端子

编码器信号

运行状态 :正在运行

9号报警

U 0

3-2-1 Monitor mode operation block diagram

D -PoS

D -PoS.

D -CPo

D -CPo.

D -EPo

D -EPo.

D -trq

D - I

↓ ↑

D -Cnt

D -Frq

D - CS

D - Ct

D -APo

D - In

D - oUt

D - Cod

D - rn

D -Err

D - rES

D -SPd

D -LSP

Err 9

rn- on

Cod ||||||

oUt ||||

In||||||||

A 3265

t. -20

r. -35

F 12.6

Cnt 0

L 5.000

Enter

I 2.3

t 70

E. 0

E 4

C. 12

C 5810

P. 12

P 5806

r 1000

- 14/27 -

Shanghai Siheng Motor Co Ltd

www.sihengmotor.com

[note 1] r 1000, r is the motor speed code, 1000 means the motor speed is anti-

clockwise 1000r/min, if it is clockwise, negative speed -1000 will be displayed. The

units are r/min.

[note 2] both position feedback pulse POS and position instruction pulse CPO are

values amplified by input electronic gears. The motor encoder feedback position

quantity is composed of POS. (high 4 bits) + POS (low 4 bits) :such as: P

12x1000=125806pcs pulse.

Similarly, the pulse amount of position instruction is also composed of CPO. (high

4 bits) + CPO (low 4 bits),Such as C. 12x10000+C5810=125810pcs pulse

When the encoder is fixed, the Z pulse is fixed as the zero pulse position. D-apo display motor encoder

The pulse value of the output position signal deviating from the zero pulse. If the number of lines of the

encoder is 2500, the display range is 0~9999.

[note 4] the display of input terminal is shown in figure 3-2-2, the display of output terminal is shown in figure

3-2-3, and the display of encoder signal is shown in figure 6-5

Input terminal display (stroke lights up means ON and OFF means OFF)

- 15/27 -

Shanghai Siheng Motor Co Ltd

www.sihengmotor.com

3-2-3 Output terminal display (stroke ON, OFF)

U phase

编码器

V相编

码器W

相

编码器Z相

编码器B

相

编码器A相

3-2-4 Encoder signal display (stroke ON means ON, OFF means OFF)

【Note 5】running state is denoted as:

Rn-oF:The main circuit is not charged and the servo system is not running;

Rn-CH:The main circuit has been charged, and the servo system is not running (the

servo system does not enable or alarm exists).

Rn-on:The main circuit is charged and the servo system is running

- 16/27 -

Shanghai Siheng Motor Co Ltd

www.sihengmotor.com

3.2 Parameter setting

In the menu of the first layer, press [MODE] key to switch to then use Parameter setting mode, and

then use 【▲】、【

▼】button select different parameter groups P00~P05.

Press [SET] key to enter the second layer "parameter number" menu, and use【▲】and【▼】

keys to select different parameter Numbers. Press "SET" key to display the parameter values,

the parameter value of lowest twinkle, twinkle with "◄" button can be moved, with the【▲】or

【▼】key can modify the parameter values. Press [SET] key to save the modified value,

which will be immediately reflected into the control. After that, press【▲】and 【 ▼ 】button to

continue to modify the parameters. After the modification, press [MODE] button to return to the

parameter selection menu. If you are not satisfied with the value being modified, do not press the

[SET] key to confirm. You can press the [MODE] button to cancel, restore the original value of

the parameter, and return to the parameter selection menu.

3-3-1 Parameter setting operation block diagram

Restore parameter default value operation

The operation steps are as follows:

1. Change the password parameter P00.00 to

385, i.e. P00.00 =385.

2. Search the motor model code corresponding to

the current motor according to appendix A, and

input the motor model code into the parameter

P00.01.

3. Modify the parameter P03.07 to 1, and press

[SET] key to restore the default value of the motor.

Then power on again, using the default

parameters of the motor.

P00.

- 17/27 -

Shanghai Siheng Motor Co Ltd

www.sihengmotor.com

Chapter 4 parameters and functions

4.1 list of parameters

The factory values in the following table take the servo driver of 110sjt-m02030 (2N•m,

3000r/min) motor as an example. Relevant parameters of different motors are different。

P00 Parameters

Parameters No

Name

Setting rage

factory

default

Unit

Application way

P00.00

Password

0~9999

315

P,S

P00.01

Motor model code

0~69

60*

P,S

P00.02

Software version (read only)

*

*

P,S

P00.03

Initial display state

0~20

0

P,S

P00.04

Control Strategy Choice

0~8

0

P,S

P00.05

Velocity proportional gain

5~2000

150*

Hz

P,S

P00.06

Velocity integral time constant

1~1000

80*

P,S

P00.07

Torque command filter

1~500

30

%

P,S

P00.08

Speed detection low pass filter

1~500

120

%

P,S

P00.09

Position proportional gain

1~1000

50

1/s

P

P00.10

Position feed forward gain

0~100

0

%

P

P00.11

Position feed forward low pass filter

cutoff frequency

1~1200

300

Hz

P

P00.12

Position command pulse frequency

divider molecule

1~32767

10000

P

P00.13

Position order pulse frequency

divider denominator

1~32767

1000

P

P00.14

Position instruction pulse input mode

0~1

0

P

P00.15

Reverse the direction of the position

command pulse

0~1

0

P

P00.16

Positioning completion range

0~30000

20

Pulse

P

P00.17

Location out of tolerance detection

range

0~30000

200

×100

Pulse

P

P00.18

Location error not valid

0~1

0

P

P00.19

Position order smoothing filter

0~30000

100*

0.1ms

P

- 18/27 -

Shanghai Siheng Motor Co Ltd

www.sihengmotor.com

P01 Parameters

Parameters No

Name

Setting rage

factory

default

Unit

Application way

P01.00

Invalid driver forbidden input

0~1

0

P,S

P01.01

JOG operating speed

-3000~3000

120

r/min

S

P01.02

Acceleration and deceleration time

constant

1~10000

500*

ms

S

P01.03

Maximum speed limit

0~6000

3600

r/min

P,S

P01.04

Internal velocity 1

-3000~3000

0

r/min

S

P01.05

Internal velocity 2

-3000~3000

100

r/min

S

P01.06

Internal velocity 3

-3000~3000

300

r/min

S

P01.07

Internal velocity 4

-3000~3000

-100

r/min

S

P01.08

Reach the speed

0~3000

500

r/min

S

P01.09

reserve

P01.10

Internal CCW torque limitation

0~300

300*

%

P,S

P01.11

Internal CW torque limits

-300~0

-300*

%

P,S

P01.12

External CCW torque limit

0~300

100

%

P,S

P01.13

External CW torque limits

-300~0

-100

%

P,S

P01.14

Speed trial operation, JOG operation

torque limit

0~300

100

%

S

P01.15

reserve

- 19/27 -

Shanghai Siheng Motor Co Ltd

www.sihengmotor.com

P02 Parameters

Parameters No

Name

Setting rage

factory

default

Unit

Application way

P02.00

Analog speed command gain

10~3000

300

r/min/V

S

P02.01

Reverse direction of analog speed

command

0~1

0

S

P02.02

Analog speed command zero offset

compensation

-500~500

0

S

P02.03

Analog speed command has no

control action area

-500~500

0

S

P02.04

Analog speed command filter

1~1000

300

Hz

S

P02.05

Analog torque command gain

1~300

30

%/V

T

P02.06

Reverse direction of analog torque

instruction

0~1

0

T

P02.07

Analog torque instruction zero offset

compensation

-500~500

0

T

P02.08

Maximum speed limit for torque

control

0~4000

2500

r/min

T

P02.09

Analog torque command filter

1~1000

300

Hz

T

P02.10

The lower 4-bit input terminal

enforces the ON control word

0~15

0

ALL

P02.11

High 4 bit input terminal force ON

control word

0~15

0

ALL

P02.12

Reverse control word for lower 4 bit

input terminal

0~15

0

ALL

P02.13

Reverse control word for high 4 bit

input terminal

0~15

0

ALL

P02.14

Reverse control word for output

terminal

0~15

0

ALL

P02.15

Input terminal to dither the time

constant

1~1000

16

0.1ms

ALL

P03 Parameters

Parameters No

Name

Setting rage

factory

default

Unit

Application

way

P03.00

Speed trial run

0~1

0

S

P03.01

JOG Run

0~1

0

S

P03.02

Encoder zero operation

0~1

0

ALL

P03.03

Open loop operation

0~1

0

ALL

P03.04

The initial detection point of software

overcurrent

30~100

90

%

ALL

P03.05

Software overcurrent detection time

10~10000

300

0.1ms

ALL

P03.06

SON servo actuation

0~1

1

ALL

P03.07

System parameters initialized

0~1

0

ALL

- 20/27 -

Shanghai Siheng Motor Co Ltd

www.sihengmotor.com

4.1.1

Parameters function

4.1.2

P00 Parameters

Parameters

No

Name

Function

parame

ter

scope

P00.00

Password

①Used to prevent parameters from being modified by mistake. In general, when you need to

set parameters, first set this parameter to the required password, and then set parameters.

After debugging, set this parameter to 0 at last

to ensure that the parameter will not be modified by mistake in the future.

②Password classification, corresponding to user parameters, system parameters and all

parameters.

③Change the motor model code parameter (P00.01) must use the model code password,

other passwords cannot change this parameter.

④User password is 315, model code password is 385.

0~9999

P00.01

Motor

model

code

①Corresponding to the same series of different power levels of servo drivers and motors

②The parameter default values of different motor model codes are different. When restoring

the default parameter function, the correctness of this parameter must be guaranteed.

③When EEPROM alarm (no. 20) appears, it must reset this parameter after repairing, and

then restore the default parameter. Otherwise, the servo drive will not work properly or

damage.

④When changing this parameter, set the password (P00.00 parameter) to 385 before

changing this parameter.

⑤See this chapter for the detailed meaning of the parameters

0~69

P00.02

software

version

You can view the software version number, but you can't change it.

*

P00.03

Initial

display

state

Select the display status of the display after the servo driver is powered on. 0: Display motor

speed;

1: Display the current position 5 bits lower;

2: Display the current position 5 bits high;

3: Display position instruction (instruction pulse accumulation) is 5 bits lower;

4: Display position instruction (instruction pulse accumulation) is 5 bits high;

5: Display position deviation is 5 bits lower;

6: Display position deviation is 5 bits higher;

7: Display motor torque;

8: Display motor current;

9: Display linear velocity;

10: Display control mode;

11: Display position instruction pulse frequency;

12: Display speed instructions;

13: Display the Torque Instruction;

14: Display the absolute position of the rotor in one turn.

15: Display input terminal status;

16: Display output terminal status;

17: Display input signal of encoder;

18: Display the running status;

19: Display alarm code;

20: Reserve.

0~20

This manual suits for next models

6

Table of contents

Popular Servo Drive manuals by other brands

Delta

Delta ASDA-A+ quick start guide

Coolmay

Coolmay C100E manual

National Instruments

National Instruments NI 9505E Operating instructions and specifications

Rockwell Automation

Rockwell Automation Allen-Bradley Kinetix 300 2097-V31PR0 user manual

YASKAWA

YASKAWA Sigma-V Series user manual

LinMot

LinMot C1450 VS-1S Series installation guide