WELCON Servo Drive Hardware Manual

4 / 21

© 2022 WELCON Systems. All rights reserved.

www.welconsystems.com

CONTENTS

Precautions ..................................................................................................................................................................... 2

Copyright Notice ......................................................................................................................................................... 2

CONTENTS................................................................................................................................................ 4

1. Safety Information ......................................................................................................................... 5

Use environment ......................................................................................................................................................... 6

2. Technical Information .................................................................................................................... 7

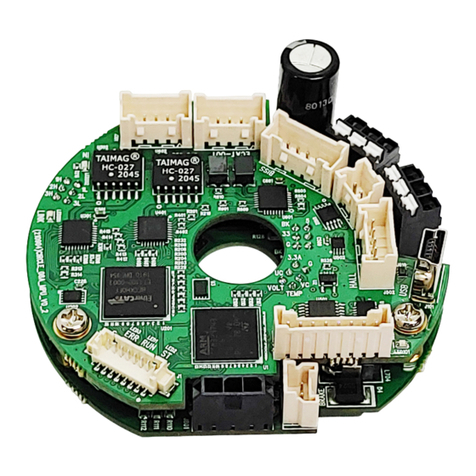

2.1. Mechanical Data .................................................................................................................................................. 7

2.2. Electrical Data ....................................................................................................................................................... 8

3. Wiring ............................................................................................................................................. 10

3.1. Tools ....................................................................................................................................................................... 10

3.2. Connections ........................................................................................................................................................ 10

3.3. Regenerative resistance ................................................................................................................................. 11

3.4. Control Power .................................................................................................................................................... 12

3.5. Motor Power....................................................................................................................................................... 13

3.6. Motor UVW ......................................................................................................................................................... 14

3.7. Digital Encoder (Port A) ................................................................................................................................ 15

3.8. Digital Encoder (Port B) ................................................................................................................................. 16

3.9. GPIO ....................................................................................................................................................................... 17

3.10.CAN ....................................................................................................................................................................... 19

3.11.USB ........................................................................................................................................................................ 20

Question : www.welconsystems.com