Quick installation guide - MicroFlex e190

3

Quick installation guide -

MicroFlex e190

Introduction

This guide contains the very basic information

about the mechanical and electrical installation

of the MicroFlex e190 drive module. For

complete documentation see the

MicroFlex e190 User’s Manual (code:

3AXD50000037326 [English]).

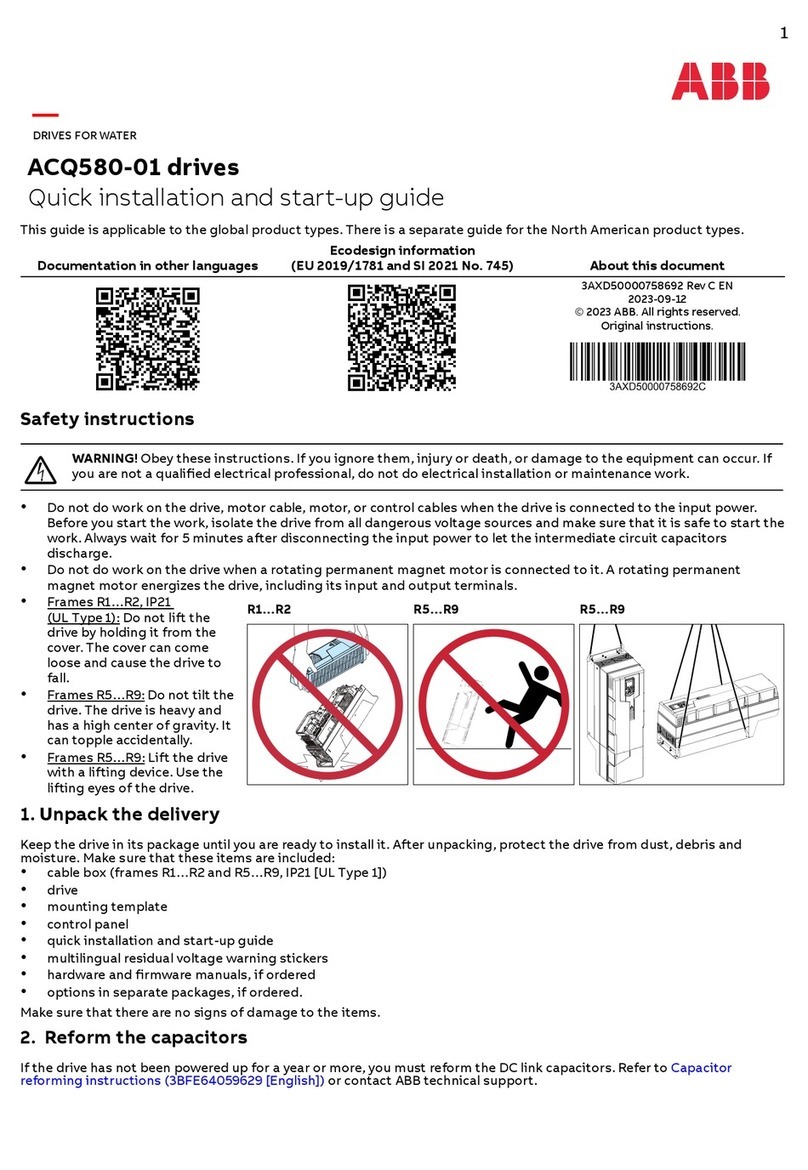

Safety instructions

WARNING! All electrical

installation and maintenance work on

the drive should be carried out by

qualified electricians only.

WARNING! Operation of this

equipment requires detailed

installation and operation instructions

provided in the Installation/Operation

manual intended for use with this product. It

should be retained with this device at all times.

A hard copy of this information may be ordered

at +358 10 22 11 or your local ABB sales office.

Never work on the drive, the braking chopper

circuit, the motor cable or the motor when input

power is applied to the drive. After

disconnecting input power, always wait for 5

minutes to let the intermediate circuit

capacitors discharge before you start working

on the drive, control cabling, motor or motor

cable. Even when input power is not applied to

the drive, externally supplied control circuits

may carry dangerous voltages. Always ensure

by measuring that no voltage is actually

present.

• A rotating permanent magnet motor can

generate a dangerous voltage. Lock the

motor shaft mechanically before connecting

a permanent magnet motor to the drive, and

before doing any work on a drive system

connected to a permanent magnet motor.

• The MicroFlex e190 is an IP20 (UL open

type) drive to be used in a heated, indoor

controlled environment. The drive must be

installed in clean air according to enclosure

classification. Cooling air must be clean, free

from corrosive materials and electrically

conductive dust. See the User’s Manual for

detailed specifications.

• The MicroFlex e190 must be installed where

the pollution degree according to UL and EN

61800-5-1 shall not exceed 2.

• The maximum ambient air temperature is:

1.6 A model: 45 °C (113 °F) at rated current.

The current is derated for 45 to 50 °C (113 to

122 °F). See user’s manual.

3 A - 9 A models: 55 °C (131 °F) at rated

current. No current derating is required.

• Motor overtemperature sensing is not

provided by the drive.

• The drive is suitable for use in a circuit

capable of delivering not more than 5,000

rms symmetrical amperes, 240 V maximum,

when protected by CC class fuses, rated

max. 20 A.

• The cables located within the motor circuit

must be rated for at least 75 °C (167 °F) in

UL-compliant installations.

• Use 75 °C copper wiring only.

• The input cable must be protected with

fuses. Suitable IEC (class gG) and UL (class

CC) fuses are listed in the Technical data

section of the MicroFlex e190 User’s

Manual.

• Integral solid state short circuit protection

does not provide branch circuit protection.

For installation in the United States, branch

circuit protection must be provided in

accordance with the National Electrical Code

(NEC) and any applicable local codes. To

fulfill this requirement, use the UL classified

fuses.