CONTENTS

CHAPTER 1. BEFORE SERVICING

[1] GENERAL IMPORTANT INFORMA-

TION ........................................................... 1-1

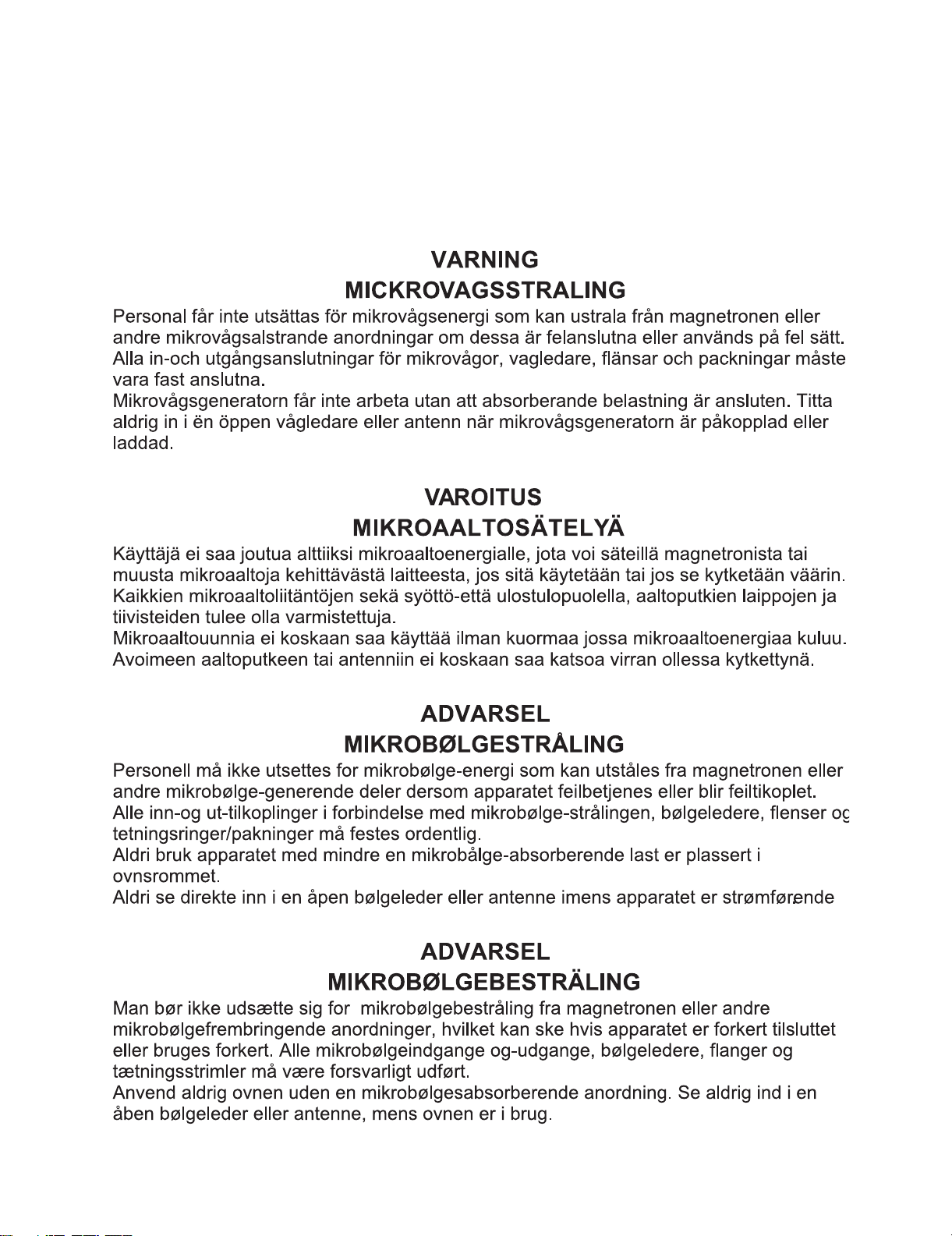

[2] WARNING................................................... 1-1

[3] CAUTION MICROWAVE RADIATION ........ 1-2

CHAPTER 2. WARNING TO SERVICE PERSON-

NEL

CHAPTER 3. PRODUCT DESCRIPTION

[1] SPECIFICATIONS ...................................... 3-1

[2] APPEARANCE VIEW ................................. 3-1

[3] INSTALLATION INFORMATION ................. 3-2

CHAPTER 4. OPERATION

[1] DESCRIPTION OF OPERATING SE-

QUENCE .................................................... 4-1

[2] DESCRIPTION AND FUNCTION OF

COMPONENTS .......................................... 4-2

CHAPTER 5. TROUBLESHOOTING GUIDE

CHAPTER 6. TEST PROCEDURES

[1] A: MAGNETRON TEST .............................. 6-1

[2] B: POWER TRANSFORMER TEST ........... 6-2

[3] C: HIGH VOLTAGE RECTIFIER (1)

AND/OR (2) TEST ...................................... 6-2

[4] D: HIGH VOLTAGE CAPACITOR (C1)

AND/OR (C2) TEST.................................... 6-3

[5] E: SECONDARY INTERLOCK SWITCH

(SW1) AND/OR (SW2) TEST ..................... 6-3

[6] F: PRIMARY INTERLOCK SYSTEM

TEST........................................................... 6-3

[7] G: MONITOR SWITCH (SW3) AND/OR

(SW4) TEST................................................ 6-3

[8] H: FUSE F8 TEST ...................................... 6-4

[9] I: WEAK POINT (FOR FAN MOTOR OR

EXHAUST FAN) TEST................................ 6-4

[10] J: WEAK POINT (IN NOISE FILTER)

TEST........................................................... 6-4

[11] K: TEMPERATURE FUSE TEST ................ 6-4

[12] L: MAGNETRON THERMISTOR TEST...... 6-4

[13] M: EXHAUST THERMISTOR TEST ........... 6-4

[14] N: NOISE FILTER TEST............................. 6-5

[15] O: KEY UNIT TEST .................................... 6-5

[16] P: CONTROL UNIT TEST .......................... 6-5

[17] Q: POWER UNIT TEST .............................. 6-6

[18] R: RELAY UNIT TEST ................................ 6-6

[19] S: ANTENNA SENSOR TEST .................... 6-7

[20] T: MICROWAVE SENSOR TEST................ 6-7

CHAPTER 7. TOUCH CONTROL PANEL ASSEM-

BLY

[1] SPECIAL FUNCTION FOR SERVICING..... 7-1

[2] SERVICING FOR BRINTED WIRING

BOARDS..................................................... 7-7

CHAPTER 8. PRECAUTIONS FOR USING LEAD-

FREE SOLDER

CHAPTER 9. COMPONENT REPLACEMENT AND

ADJUSTMENT PROCEDURE

[1] WARNINGS ................................................ 9-1

[2] OUTER CASE AND REAR COVER RE-

MOVAL........................................................ 9-1

[3] POWER TRANSFORMERS (1) AND/

OR (2) REMOVAL....................................... 9-2

[4] MAGNETRONS (1) AND/OR (2) RE-

MOVAL........................................................ 9-2

[5] MAGNETRON THERMISTOR ASSEM-

BLY REPLACEMENT ................................. 9-2

[6] HIGH VOLTAGE CAPACITOR AND

HIGH VOLTAGE RECTIFIER ASSEM-

BLY REMOVAL ........................................... 9-2

[7] POWER SUPPLY CORD REPLACE-

MENT.......................................................... 9-3

[8] HOW TO RELEASE THE POSITIVE

LOCK CONNECTOR. ................................. 9-3

[9] EXHAUST FAN REMOVAL......................... 9-3

[10] FAN MOTORS REMOVAL .......................... 9-4

[11] ANTENNA MOTORS (UPPER AND

LOWER) REMOVAL ................................... 9-4

[12] POWER UNIT REMOVAL........................... 9-4

[13] CONTROL PANEL ASSEMBLY AND

CONTROL UNIT REMOVAL....................... 9-4

[14] RELAY UNIT REMOVAL............................. 9-4

[15] DOOR SENSING SWITCH (SW5)/SEC-

ONDARY INTERLOCK SWITCHES

(SW1, SW2) AND MONITOR SWITCH-

ES (SW3, SW4) REPLACEMENT .............. 9-5

[16] OOR SENSING SWITCH (SW5)/SEC-

ONDARY INTERLOCK SWITCHES

(SW1, SW2) AND MONITOR SWITCH-

ES (SW3, SW4) ADJUSTMENT ................. 9-5

[17] DOOR REPLACEMENT ............................. 9-5

[18] DOOR DISASSEMBLY ............................... 9-6

[19] OVEN LAMP AND LAMP SOCKET RE-

MOVAL........................................................ 9-8

CHAPTER 10. MICROWAVE MEASUREMENT

CHAPTER 11. TEST DATA AT A GLANCE

CHAPTER 12. CIRCUIT DIAGRAMS

[1] Oven Schematic........................................ 12-1

[2] Figure S-1. Pictorial Diagram.................... 12-3

[3] Figure S-2. Switching Power Supply Unit

Circuit........................................................ 12-6

[4] Figure S-3. Relay Unit Circuit ................... 12-7

[5] Figure S-4. Control Unit/ Antenna sen-

sor/ Microwave Sensor Circuit .................. 12-8

[6] Figure S-5. Printed Wiring Board .............. 12-9

Parts List