7

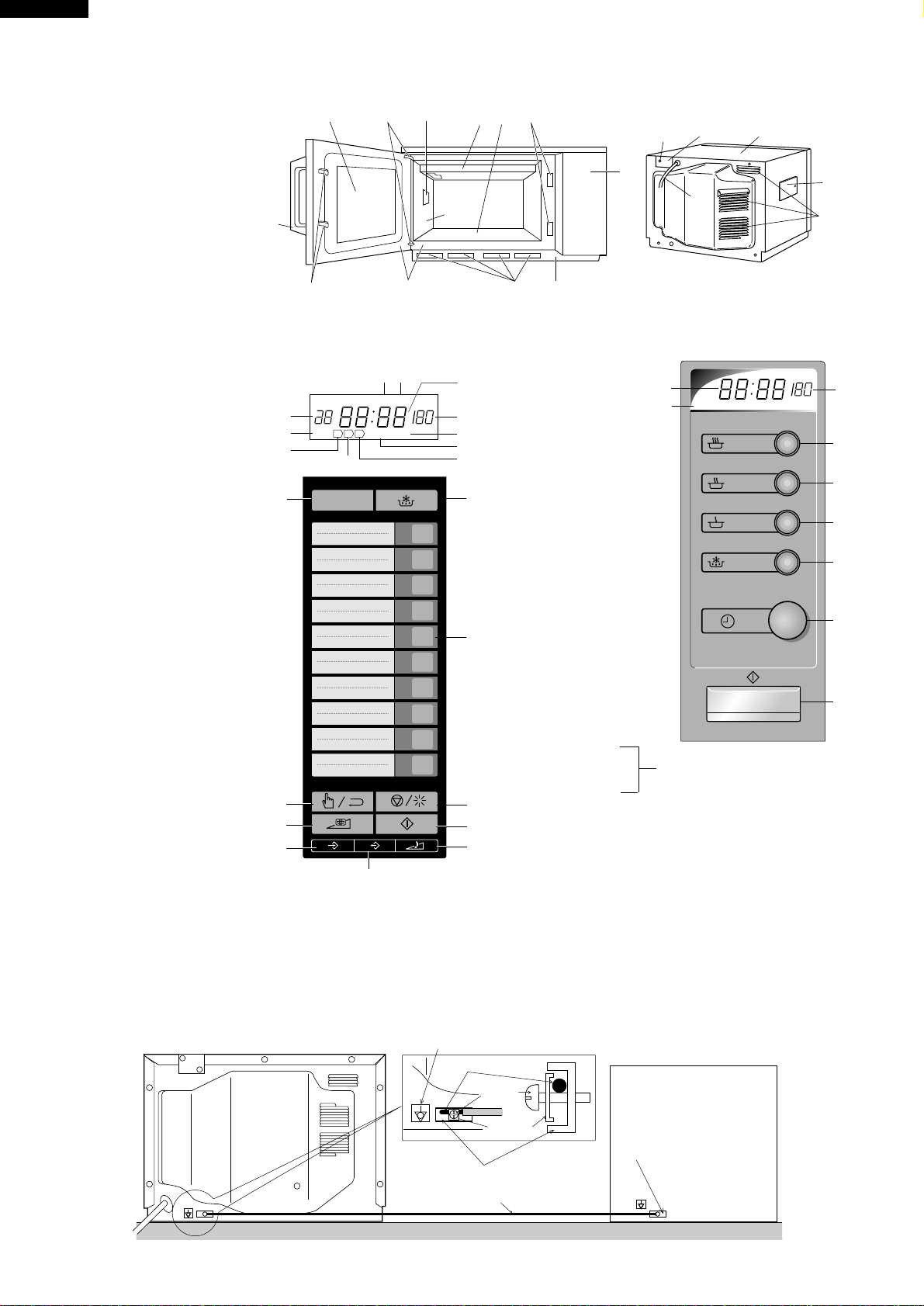

R-22AM

R-23AM

R-23AT

OPERATION SEQUENCE

the two high voltage transformers. The voltage is

convertedtoabout3.3voltsA.C.outputonthefilament

winding and high voltage of approximately 2000 volts

A.C. on the secondary winding.

2. The filament winding voltage (3.3 volts) heats the

magnetronfilamentandthehighvoltage(2000volts)is

senttothevoltagedoubling circuit, where it isdoubled

to negative voltage of approximately 4000 volts D.C..

3. The 2450 MHz microwave energy produced in the

magnetron generates a wave length of 12.24 cm. This

energyischannelledthroughthewaveguide(transport

channel)intothe oven cavity,wherethe food isplaced

to be cooked.

4. Whenthecookingtimeisup,asignaltoneisheardand

the relays RY3+RY4 (for R-23AT)/ RY2+RY3 (for R-

22AM/23AM) go back to their home position. The

circuits to the high voltage transformers T1+T2. The

relay RY1 remains and oven lamp, blower motor and

stirrer motors work for 1 minute.

5. When the door is opened during a cook cycle, the

switches come to the following condition.

CONDITION

DURING DOOR OPEN

SWITCH CONTACT COOKING

(NO COOKING)

1st latch switch COM-NO Closed Open

Monitor switch COM-NC Open Closed

2nd latch switch COM-NO Closed Open

Stop switch COM-NO Closed Open

3rd latch switch COM-NO Closed Open

ThecircuitstothehighvoltagetransformersT1+T2are

cutoffwhenthe 1st latch,2ndlatch,3rd latch andstop

switches SW1+SW2+SW3+SW5aremadeopen.The

blower motor BM, stirrer motors and oven lamp re-

mains on even if the oven door is opened after the

cookingcyclehasbeen interrupted, becausetherelay

RY1 stays closed. Shown in the display is the remain-

ingtime,butthe program is cancellediftheoven is not

started within 3 minutes.

6. MONITOR SWITCH CIRCUIT

The monitor switch SW4 is mechanically controlled by

oven door, and monitors the operation of the 1st latch

switch SW1.

6-1. When the oven door is opened during or after the

cycleofacookingprogram,the1st,2nd,3rdlatchand

stopswitchesSW1+SW2+SW3+SW5mustopentheir

contactsfirst.Afterthatthecontacts(COM-NC)ofthe

monitor switch SW4 can be closed.

6-2. When the oven door is closed, the contacts (COM-

NC) of the monitor switchSW4 must be opened first.

Afterthatthecontacts(COM-NO) ofthe1st, 2nd, 3rd

latchandstopswitchesSW1+SW2+SW3+SW5must

be closed.

6-3. Whentheovendoorisopenedandthecontactsofthe

1st latch switch SW1remain closed, remains closed,

the fuse F2 F6.3A will blow, because the monitor

switch is closed and a short circuit is caused.

MICROWAVE VARIABLE COOKING (for R-23AT)

When the microwave oven is preset for variable cooking

power, the line voltage is supplied to the high voltage

Closing the door activates all door interlock switches (1st

latch switch, 2nd latch switch, 3rd latch switch and stop

switch).

IMPORTANT

Whentheovendoorisclosed,themonitorswitchcontacts

COM-NC must be open. When the microwave oven is

plugged in a wall outlet (230 volts, 50Hz), the line voltage

is suppliedto thepoint A5+A7 inthe controlpanel through

the noise filter. Figure O-1 on page 39

1. The digital display shows .

IDLE CONDITION

When the door is opened, the contacts of the 1st. latch

switchSW1,2nd.latchswitchSW2,3rd.latchswitchSW3

and stop switch SW5 open, initiating the following:

Figure O-2 on page 40

1. Asignalisinputtothecontrolunitenergizingthecoilof

shut-off relay RY-1.

2. The shut-off relay RY-1 contacts close completing

circuits to turn on the oven lamp, blower motor and

stirrer motors.

3. If the door remains open, 60 seconds later the control

unit de-energizes shut-off relay RY-1 turning off the

oven lamp, blower motor and stirrer motors.

When the door is closed, the contacts of the 1st. latch

switchSW1,2nd.latchswitchSW2,3rd.latchswitchSW3

and stop switch SW5 close. With the closing of the stop

switch SW5 contacts, an additional circuit is provided

whichwillpermittheoperationoftheovenwhenoneofthe

touch pads is depressed. Since the control is enabled

through the stop switch SW5, the door must be closed

before the touch pads will be effective. When the door is

closed,afull60secondIDLEconditionisalwaysprovided

for selecting and pressing the desired touch pads. A 60

secondIDLEconditionwillalsofollowtheendofeachcook

cycle.

MICROWAVE COOKING CONDITION

for R-23AT

Touch MANUAL/ REPEAT key and enter a desired

cookingtimewiththetouchingNUMBERkey.Andthen

touch START key.

Function sequence Figure O-3 on page 40

CONNECTED COMPONENTS RELAY

Oven lamp/ Blower motor/ Stirrer motors RY1

High voltage transformer T1 RY3

High voltage transformer T2 RY4

for R-22AM/23AM

Enter a desired cooking time with the turning ELEC-

TRONIC TIMER knob. And then push STARTbutton.

Function sequence Figure O-3 on page 40

CONNECTED COMPONENTS RELAY

Oven lamp/ Blower motor/ Stirrer motors RY1

High voltage transformer T1 RY2

High voltage transformer T2 RY3

1. The line voltage is supplied to the primary winding of