8

R-409EW

R-410EK

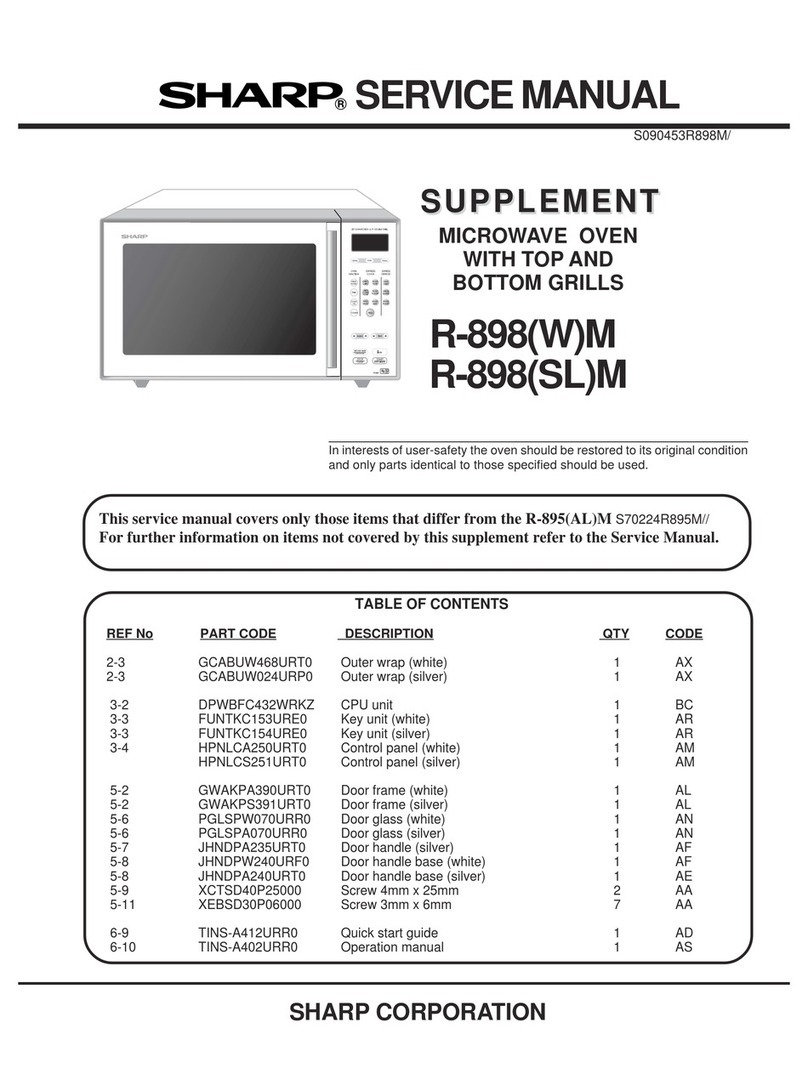

R-410EW DESCRIPTION AND FUNCTION OF COMPONENTS

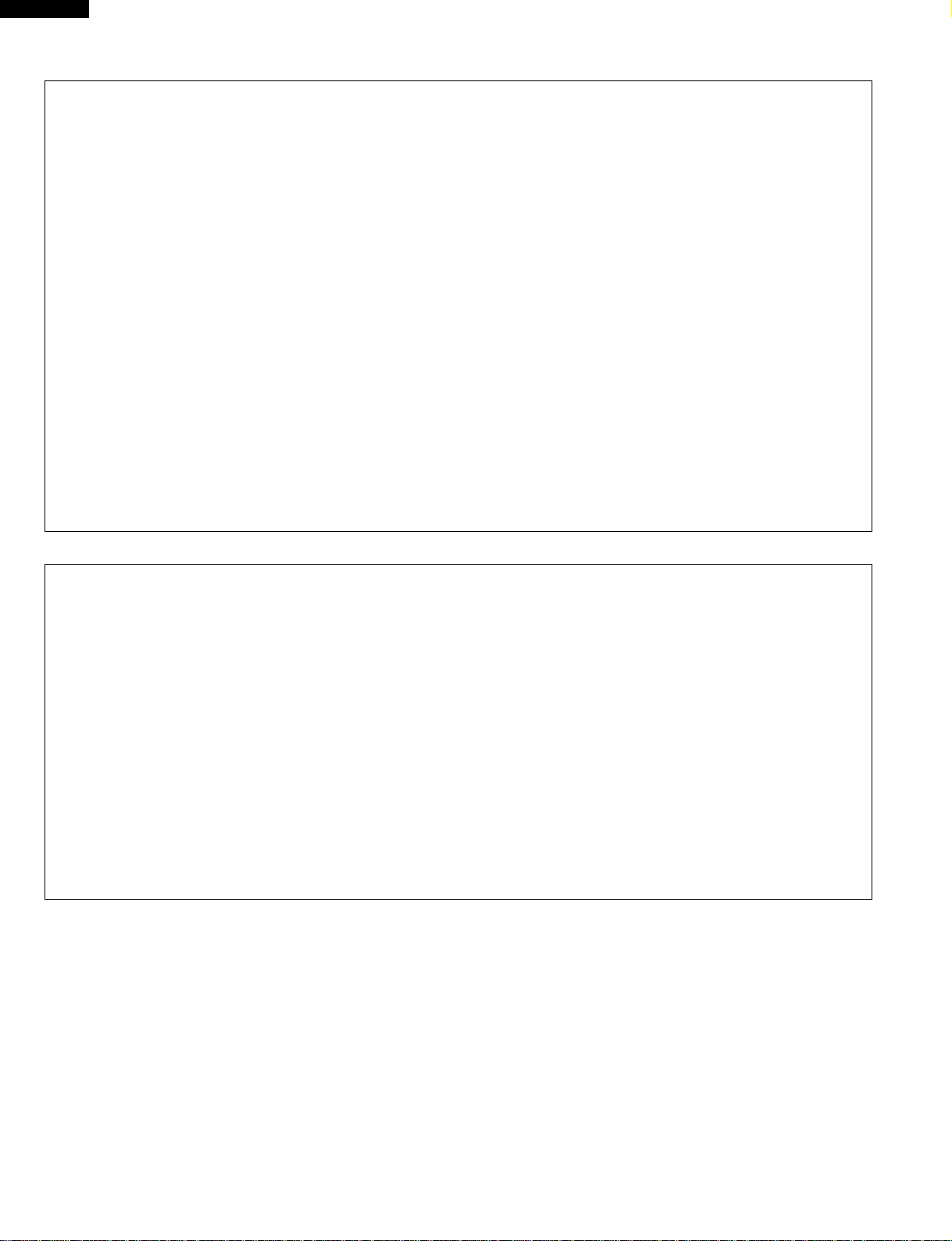

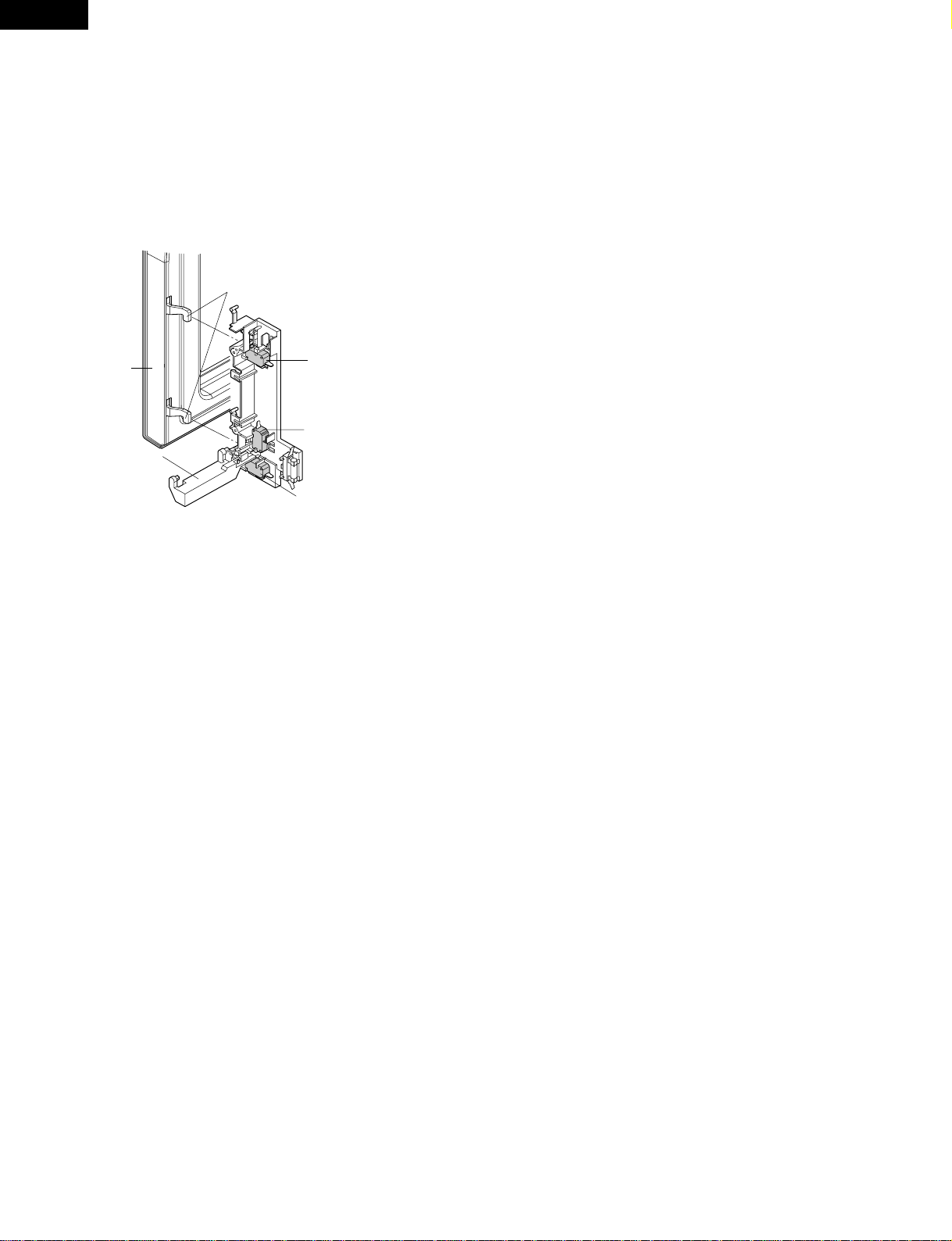

DOOR OPEN MECHANISM

Thedoorisopenedbypushingtheopenbuttononthecontrol

panel, refer to the Figure D-1. When the open button is

pushed, the open button pushes up the switch lever, and

then the switch lever pushes up the latch head. The latch

heads are moved upward and released from latch hook.

Now the door will open.

Figure D-1. Door Open Mechanism

DOOR SENSING AND SECONDARY INTERLOCK

SWITCHES

The secondary interlock switch is mounted in the lower

positionofthelatch hookandthedoorsensingswitchinthe

primaryinterlocksystemismountedintheupperpositionof

thelatchhook.Theyareactivatedbythelatchheadsonthe

door. When the door is opened, the switches interrupt the

power to all high voltage components. A cook cycle cannot

take place until the door is firmly closed thereby activating

both interlock switches. The primary interlock system con-

sists of the door sensing switch and primary interlock relay

located on the control circuit board.

MONITOR SWITCH

Themonitorswitchisactivated(thecontactsopened)bythe

latch head on the door while the door is closed. The switch

is intended to render the oven inoperative, by means of

blowing the monitor fuse, when the contacts of the primary

interlock relay (RY2) and secondary interlock switch fail to

open when the door is opened.

Functions:

1. Whenthedoorisopened,themonitorswitchcontactclose

(totheONcondition)duetotheirbeingnormallyclosed.At

this time the primary interlock relay (RY2) and secondary

interlock switch are in the OFF condition (contacts open)

due to their being normally open contact switches.

2. As the door goes to a closed position, the monitor switch

contactsarefirstopenedandthenthedoorsensingswitch

and the secondary interlock switch contacts close. (On

openingthedoor,eachoftheseswitchesoperateinversely.)

3. If the door is opened, and the primary interlock relay

(RY2) and secondary interlock switch contacts fail to

open,themonitorfuseblowssimultaneouslywithclosing

of the monitor switch contacts.

CAUTION: BEFORE REPLACING A BLOWN MONITOR

FUSE TEST THE DOOR SENSING SWITCH,

PRIMARYINTERLOCKRELAY(RY2),RELAY

(RY1), SECONDARY INTERLOCK SWITCH

AND MONITOR SWITCH FOR PROPER OP-

ERATION.(REFERTOCHAPTER"TESTPRO-

CEDURE").

NOTE: MONITOR FUSE AND MONITOR SWITCH ARE

REPLACED AS AN ASSEMBLY.

TURNTABLE MOTOR

The turntable motor rotates the turntable located on the

bottomofthe oven cavity, so thatthefoodson the turntable

cookevenlyduringcooking.Theturntablemayturnineither

direction.

COOLING FAN MOTOR

Thecoolingfanmotordrivesabladewhichdrawsexternalcool

air.Thiscoolairisdirectedthrough the airvanessurrounding

themagnetronandcoolsthemagnetron.Thisairischannelled

throughtheovencavitytoremovesteamandvaporsgivenoff

from the heating foods. It is then exhausted through the

exhausting air vents at the oven cavity.

MONITOR FUSE

1. Themonitorfuseblowswhenthecontacts(COM-NO)of

theprimaryinterlockrelay(RY2)andsecondaryinterlock

switchremainclosedwiththeoven door openandwhen

the monitor switch closes.

2. If the wire harness or electrical components are short-

circuited, this monitor fuse blows to prevent an electric

shock or fire hazard.

CAVITY TEMPERATURE FUSE

The cavity temperature fuse located on the top of the oven

cavity,isdesignedtopreventdamagetotheovenbyfire.Ifthe

foodloadisovercooked,byeithererrorincooktimeordefect

in the control unit, the cavity temperature fuse will open.

Undernormaloperation,thecavitytemperaturefuseremains

closed. However, when abnormally high temperatures are

reachedwithintheovencavity,thecavitytemperaturefusewill

open at 302OF(150OC) causing the oven to shut down.

NOTE: This is fuse. It does not reset.

Magnetron TEMPERATURE FUSE

Themagnetrontemperaturefuselocatednearthemagnetron

is designed to prevent damage to the magnetron if an over

heatedconditiondevelopsinthetubeduetocoolingfanfailure,

obstructed air guide, dirty or blocked air intake, etc.

Under normal operation, the magnetron temperature fuse

remains closed. However, when abnormally high tempera-

tures are reached within the magnetron, the magnetron tem-

perature fuse will open at 302OF(150OC) causing the oven to

shut down.

NOTE: This is fuse. It does not reset.

Door Sensing

Switch

Monitor Switch

Switch Lever

Secondary Interlock

Switch

Latch Heads

Door