Sharp R-6G10 User manual

Other Sharp Microwave Oven manuals

Sharp

Sharp R-9A53 User manual

Sharp

Sharp R-204 Instruction Manual

Sharp

Sharp R-305MR User manual

Sharp

Sharp R-403KKT User manual

Sharp

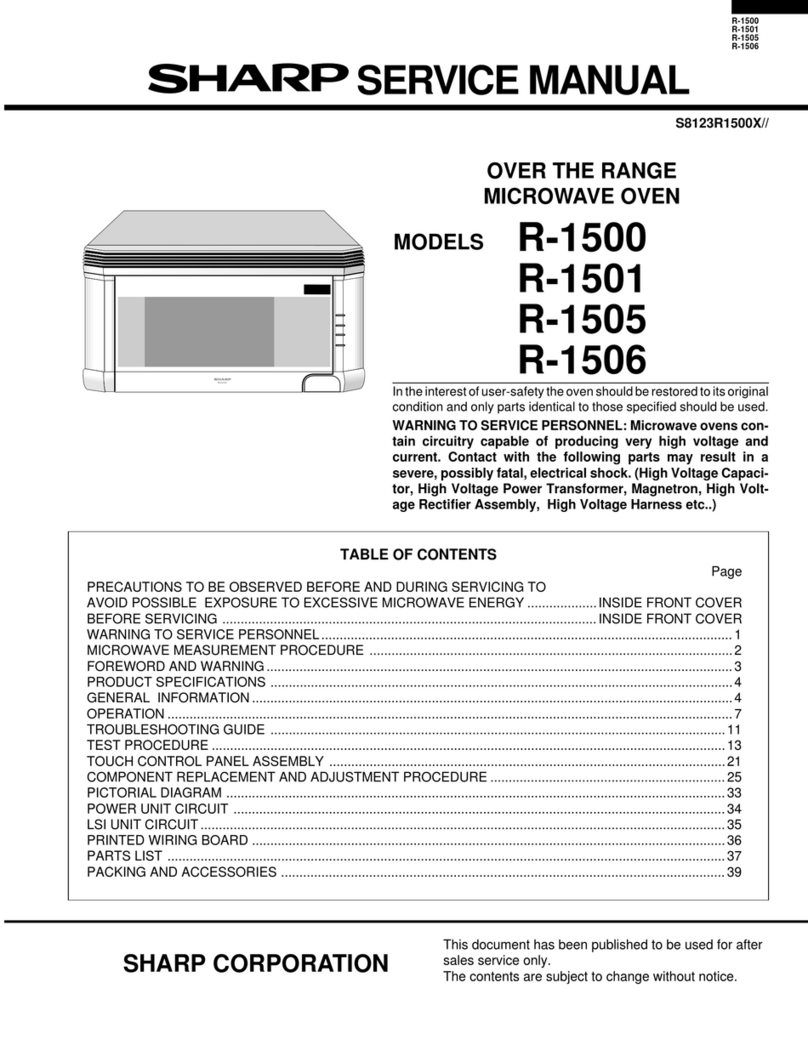

Sharp R-1505F User manual

Sharp

Sharp R-969 Instruction Manual

Sharp

Sharp Carousel R-1872 User manual

Sharp

Sharp Microwave Drawer SMD3070ASY User manual

Sharp

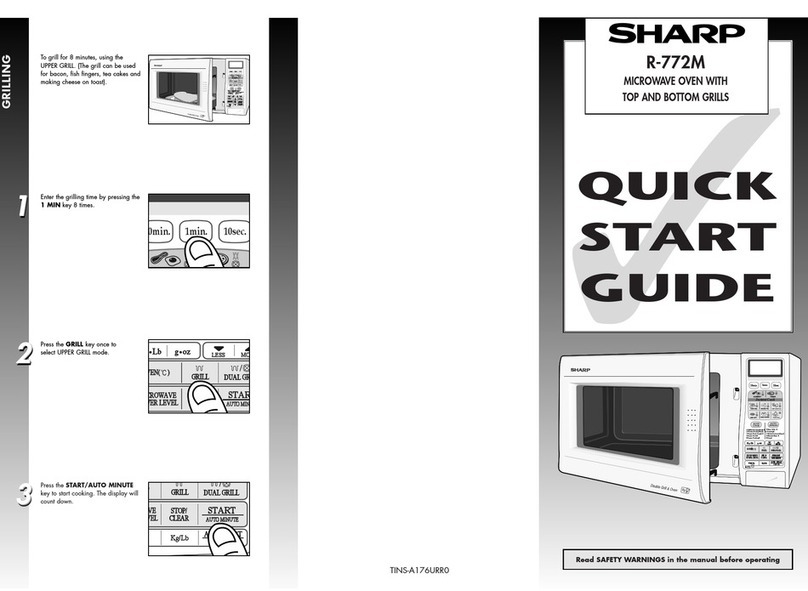

Sharp R-772M User manual

Sharp

Sharp Carousel R-395Y User manual

Sharp

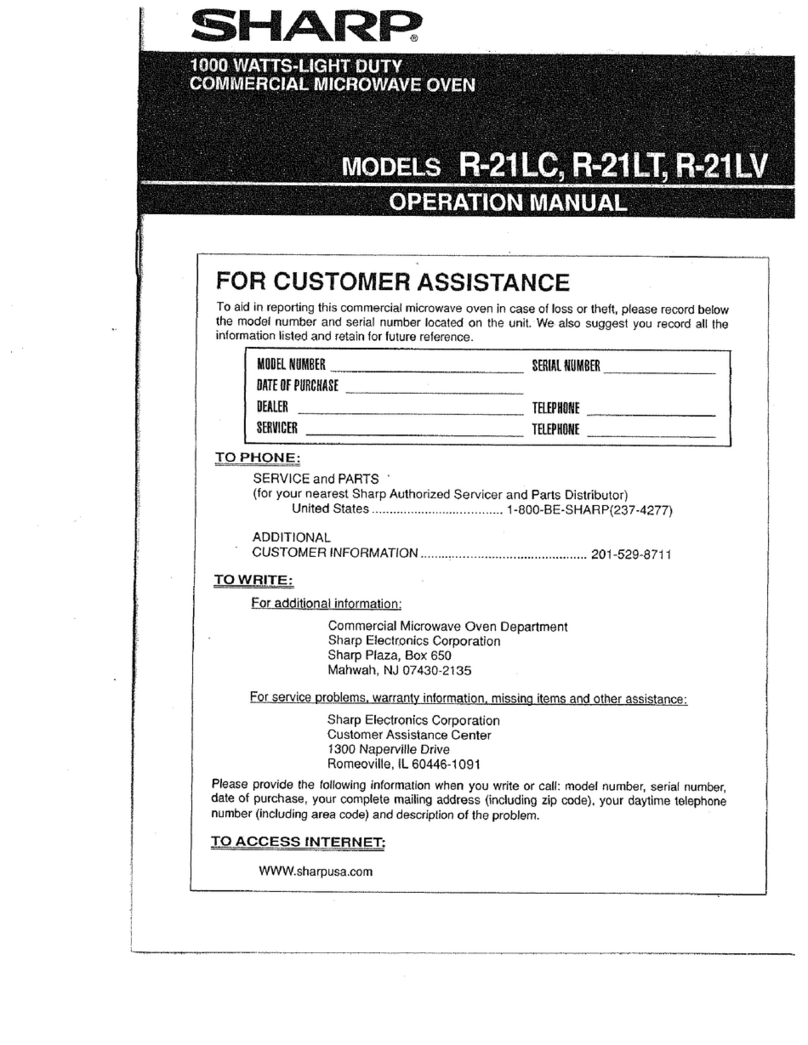

Sharp R-21LC User manual

Sharp

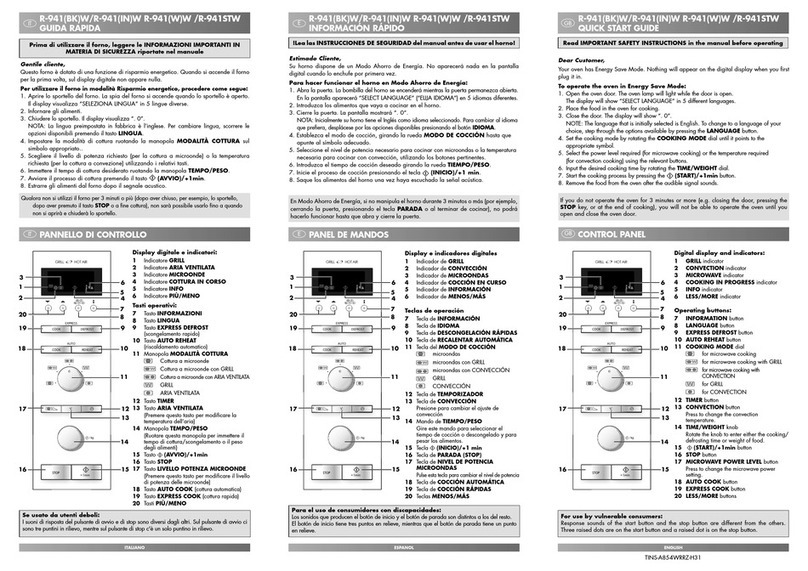

Sharp R-941(BK)W User manual

Sharp

Sharp R-22JT User manual

Sharp

Sharp KB6002LS - 1.0 cu. Ft. Microwave Drawer Assembly instructions

Sharp

Sharp R-300BW User manual

Sharp

Sharp R-222 Instruction Manual

Sharp

Sharp R-861M User manual

Sharp

Sharp Carousel SMC1662DS User manual

Sharp

Sharp YC-MS31E User manual

Sharp

Sharp R-68ST User manual