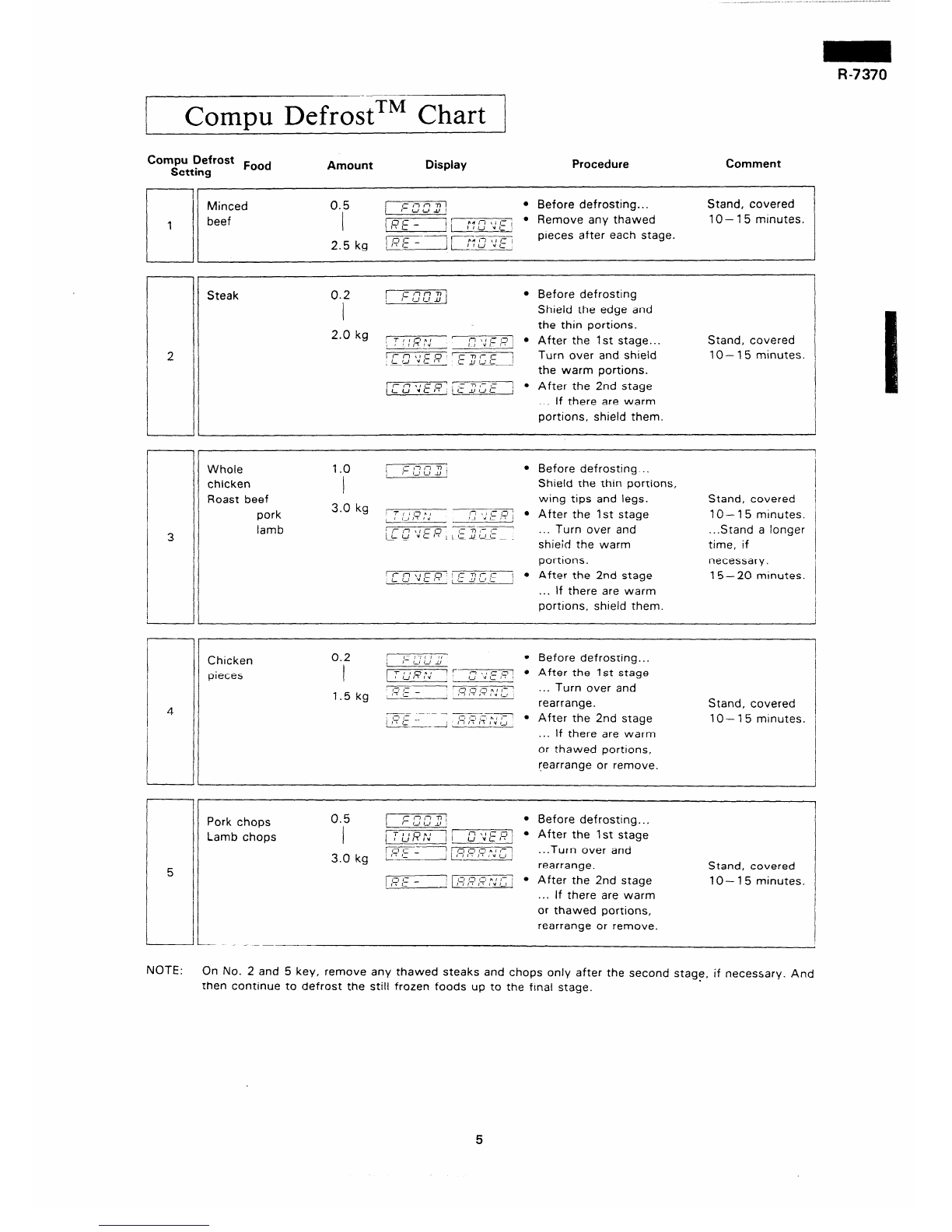

R-7370

Compu DefrostTM Chart

Compu Defrost Pood

Setting Amount Display Procedure Comment

7

Minced

beef

0.5 r r ii r-7T1I

I- CJLJJJ/ l Before defrosting.. . Stand, covered

I ICE - 1r

i r*n \,,-,

1I1-l Yc l Remove any thawed 10 - 15 minutes.

2 5 kg \Fijf:;7“::‘; pieces after each stage.

L

Steak 0.2 1 :=&Tu”] l Before defrosting

I Shield the edge and

2.0 kg , the thin portions.

T : I f-rAI

: , l-7\ , /- n

-81-T’” IJ ”1:87

1 l After the 1st stage...

x

, I- nticO 1

c-nit= I Turn over and shield

L ‘J ” ,- I* i LI1-li the warm portions.

’ I- 1-l*1C 0 ’ i c I, ,J t

- 7 /- -

LU <Cl’ ,, I l After the 2nd stage

... If there are warm

portions, shield them.

Stand, covered

lo- 15 minutes.

Whole

chicken

Roast beef

pork

lamb

1.0 /- r-ln ii

i- ,J L, JJ l Before defrosting ..

I Shield the thin portions,

3.0 kg 2 wing tips and legs. Stand, covered

Trin*,

2 ,JI?lti ‘7 /, ,- ,I ;

f-1 d,I IL l After the 1st stage 10 - 15 minutes.

lf-~~:E,q. ry-zz---

) 11J.lr-1c’ ... Turn over and ...Stand a longer

shieid the warm time, if

portions. necessary.

/ I- n \, I= 0 117 I- I= ’

i ,J ”L It / a- 1J,-I,- j l After the 2nd stage 15- 20 mtnutes.

... If there are warm

portrons, shield them.

7r 1

Chicken

pieces

0.2

I * r-m : ~~~~~~h”,“f~~~~~~~~

k

1.5 kg ‘:?E - 1213,I n,I- ’ ... Turn over and

f I tI ,\ I”r-, rearrange.

I

I

Stand, covered

i’ ‘- 7=x--Tyy=- .

/,si-- ii r-l IT h ,” ,J After the 2nd stage lo- 15 minutes.

... If there are warm

or thawed portrons,

rearrange or remove.

NOTE:

Pork chops

Lamb chops

0.5 /--T-m-y l Before defrosting...

I ‘1 17klcu’ l

/I UVLI’ , After the 1st stage

3.0 kg /r_7c_i 1,-I n I-’ nI I-

; ,I ,- / / r71: IT I”, I , ...Turn over and

- rearrange. Stand, covered

--

/y ;= - m l After the 2nd stage IO- 15 minutes.

... If there are warm

or thawed portions,

rearrange or remove.

On No. 2 and 5 key, remove any thawed steaks and chops only after the second stage, if necessary. And

then continue to defrost the still frozen foods up to the final stage.

5