Sharp OZ-9600II User manual

Other Sharp Organizer manuals

Sharp

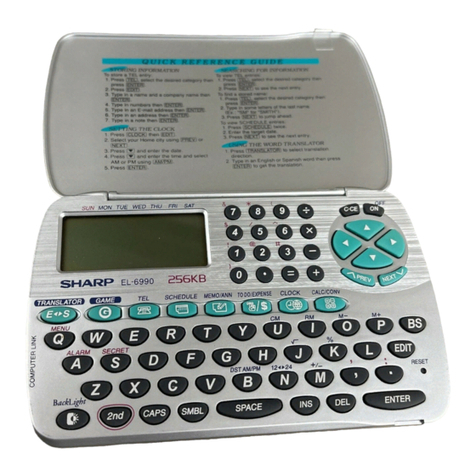

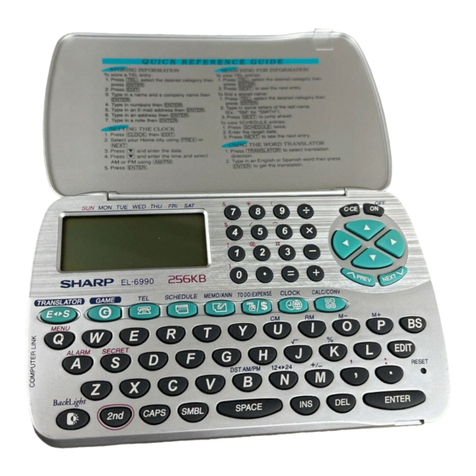

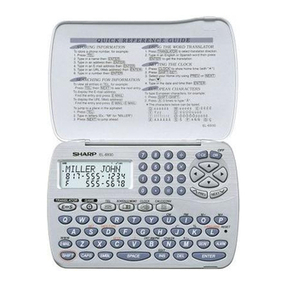

Sharp EL-6990 User manual

Sharp

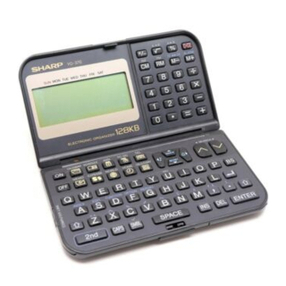

Sharp IQ-8920 User manual

Sharp

Sharp EL-6990 User manual

Sharp

Sharp YO-350CP User manual

Sharp

Sharp Y0-P5 User manual

Sharp

Sharp OZ-590 User manual

Sharp

Sharp EL-6930 User manual

Sharp

Sharp ZQ-2400 User manual

Sharp

Sharp YO190 Operation User manual

Sharp

Sharp ZQ-190 User manual

Sharp

Sharp EL-6190 User manual

Sharp

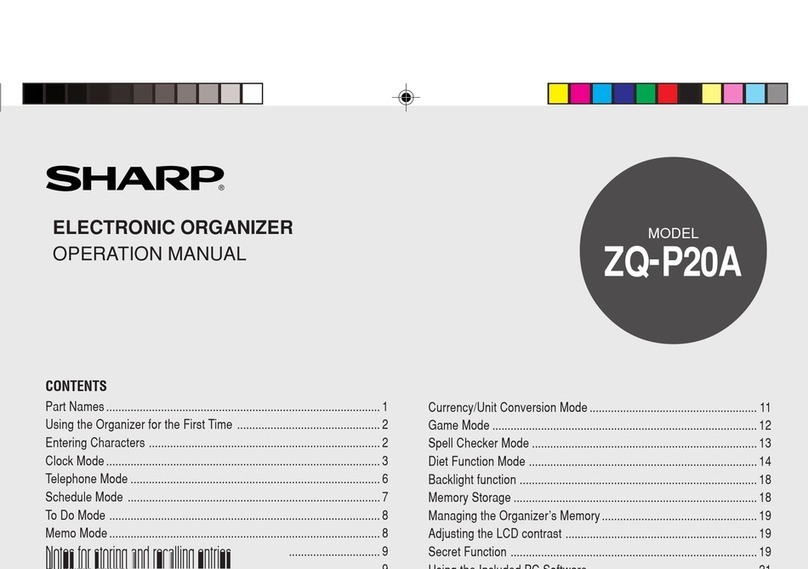

Sharp ZQ-P20A User manual

Sharp

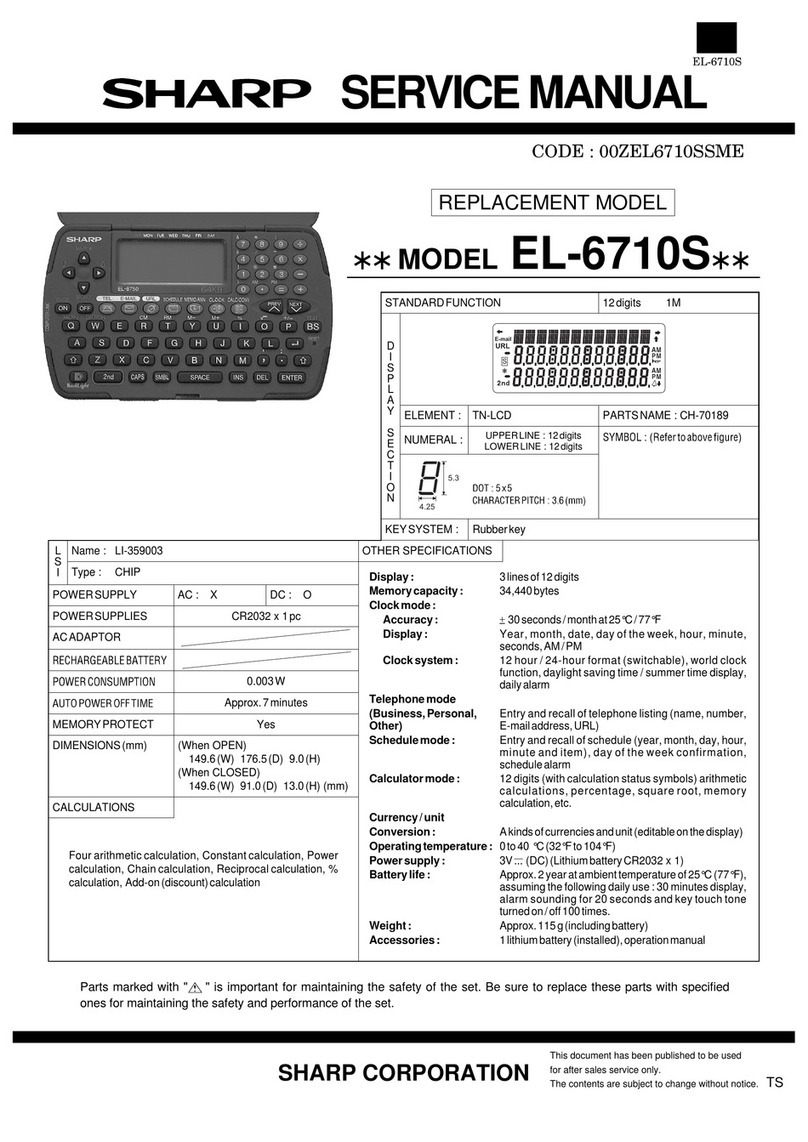

Sharp EL-6710S User manual

Sharp

Sharp EL-6420 User manual

Sharp

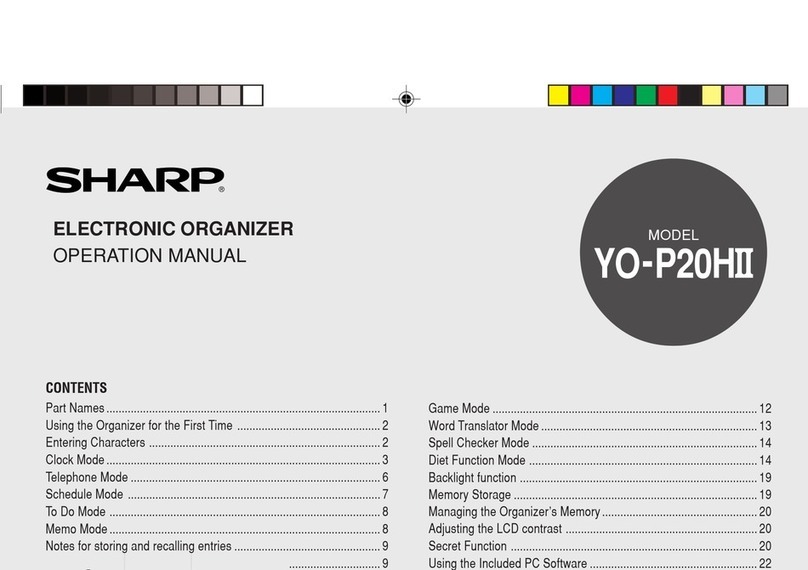

Sharp YOP20HII - 1MB Electronic Organizer User manual

Sharp

Sharp ZQ-290 User manual

Sharp

Sharp EL-6850 User manual

Sharp

Sharp ZQ-4300 User manual

Sharp

Sharp OZ-800 User manual

Sharp

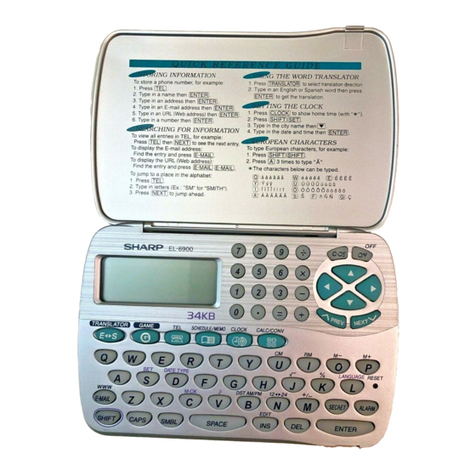

Sharp EL-6900 User manual