SJFS810VWH

9

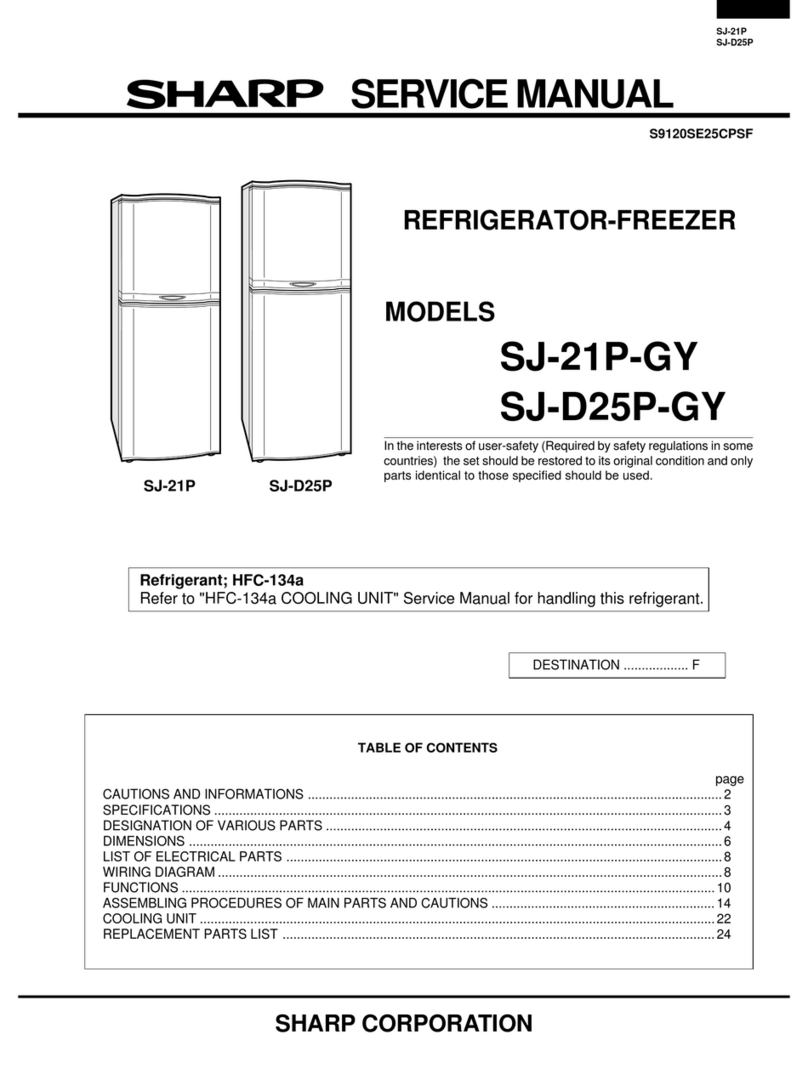

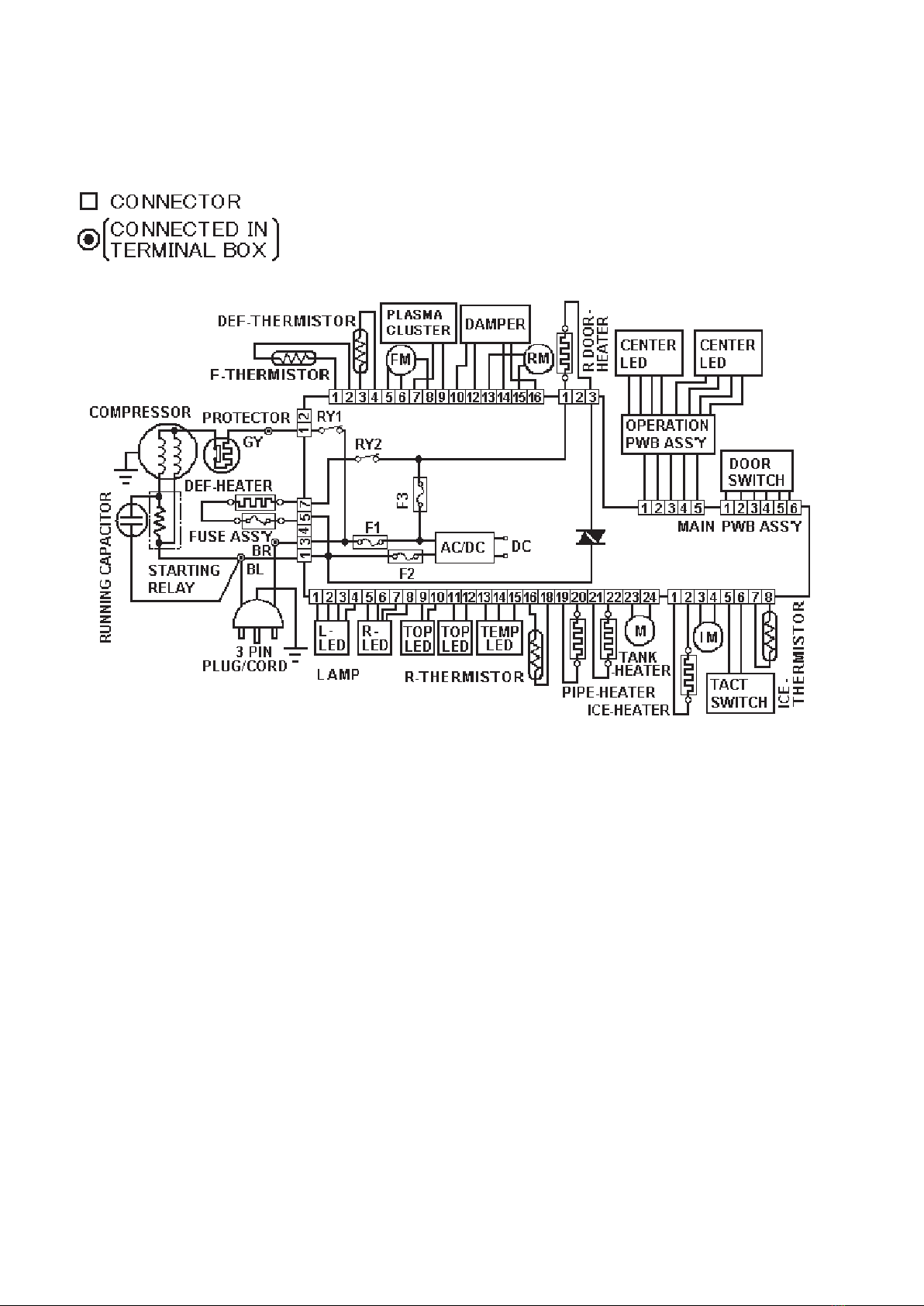

[6] LIST OF ELECTRICAL PARTS

ITEMS PARTS CODE TYPE NAME RATING SPECIFICATIONS

R thermistor RH-HXA158CBZZ -DC5V R0=6.4kΩ,B(0)=3811

F /DEF thermistor RH-HXA108CBZZ -DC5V (F)R0=6.4kΩ,B(0)=3811

(DEF)R0=15kΩ,B(0)=3811

Damper ass'y DTHM-A031CBKZ -DC12V -

R fan motor RMOTRA095CBZZ D08A-12PM05(K) DC12V -

F fan motor RMOTRA096CBZZ FBA12J15V XD DC15V -

Fuse ass'y FFS-TA087CBK Z SF70E 250V 10A Working temp. : 73 ℃

Defrost heater FHETBA193CBZZ -220V-240V286Ω 185W at 230V

LR LED PWB ass'y FPWB-B270CBKZ -DC25mA White LED Lamp 18pcs × 2lines

TOP LED PWB ass'y FPWB-B268CBKZ -DC50mA White LED Lamp 6pcs × 2lines

Multicolor PWB ass'y FPWB-A940CBKZ -Blue LED:DC15mA

Orange LED:DC20mA

Blue LED:1pcs

Orange LED:1pcs

Door switch PWB FPWB-A917CBKZ -DC5V -

Ice maker ass'y DVM A -A127CB K Z -DC12V

Ice thermistor RH-HXA157CBZZ -DC5V R0=6.0kΩ,B(0)=3811

Gear pump FGER-A014CBZZ -DC12V -

Ice cube heater FHETBA389CBZZ -DC24V12W(48Ω) -

Tank heater FHETBA390CBZZ -DC24V1.0W(576Ω) -

Water pipe heater RHETBA388CBZZ -DC24V2.8W(206Ω) -

Rd-heater RHETBA391CBZZ -230V6.32W(8365Ω) -

Plasmacluster unit CKITTA159AKKZ -DC15V 4.55kV p-p (Second wave)

Compressor FCMPLA441CBKZ NX1120Y 220-240V / 50Hz Cooling capacity : 232W

Maincoil:13.9Ω

Aux.coil:17.9Ω

(at 25 ℃)

Starting relay (PTC relay) RSTT-A245CBZZ PTH7M150MD2 -15Ω(at25℃)

Overload Relay (Protector) RHOG-A302CBZZ 4TM222NFBYY-53 -Open/Close : 120/61℃

Running capacitor RC-EZA250CBZZ - 230V (220-240V) 400V4μF

Main PWB ass'y FPWB-B090CBKZ - 220-240V 50/60Hz -

Operation panel PWB ass'y FPWB-A909CBKZ -DC24V -

Handle PWB upper ass'y FPWB-A905CBKZ -DC10V RGB LED Lamp : 1pcs

Handle PWB lower ass'y FPWB-A907CBKZ -DC10V RGB LED Lamp : 1pcs

:Unexchengeable parts or Independently unexchangeable parts.

Common

Main coil Aux. coil