9

9-1 9-2

NO ADJUSTMENT POINT WAVEFORM OR OTHERS

5EW -W-50

(I2C BUS CONTROL)

ADJUSTMENT CONDITION / PROCEDURE

(1) Receive Monoscope Pattern Signal

(PAL 50 Hz).

(2) Choose the service data 06 EW -W-50.

(3) Adjust EW -W -50 bus data until the overscan

becomes 10 ± 1.5 %.

6E/W -PAR-50

(I2C BUS CONTROL)

(1) Receive CrossHatch Pattern Signal

(PAL 50 Hz).

(2) Choose the service data 07 E/W -PAR-50.

(3) Adjust the 2nd vertical line from the right

end of the crosshatch pattern so that the

middle 4 blocks are straight.

7UPCOR-P AR

(I2C BUS CONTROL)

(1) Receive CrossHatch Pattern Signal

(PAL 50 Hz).

(2) Choose the service data 10 UPCOR-P A R.

(3) Adjust the 2nd upper vertical line from the

right end of the crosshatch pattern so that the

upper line are straight.

8LOCOR-P AR

(I2C BUS CONTROL)

(1) Receive CrossHatch Pattern Signal

(PAL 50 Hz).

(2) Choose the service data 11 LOCOR-P A R.

(3) Adjust the 2nd lower vertical line from the right

end of the crosshatch pattern so that the

bottom line are straight.

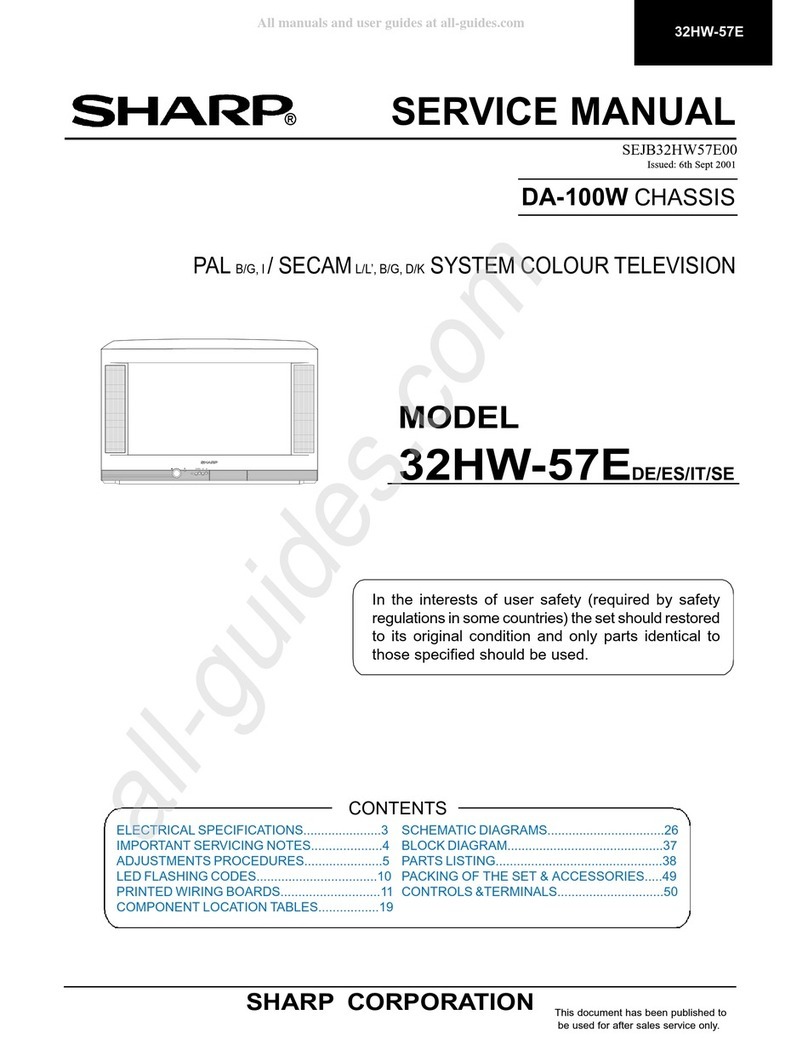

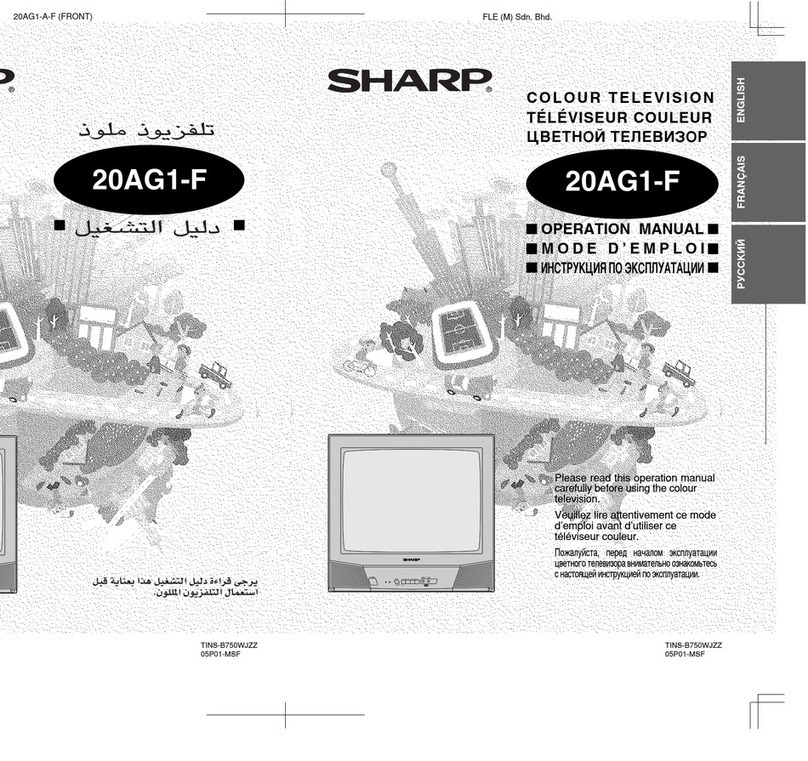

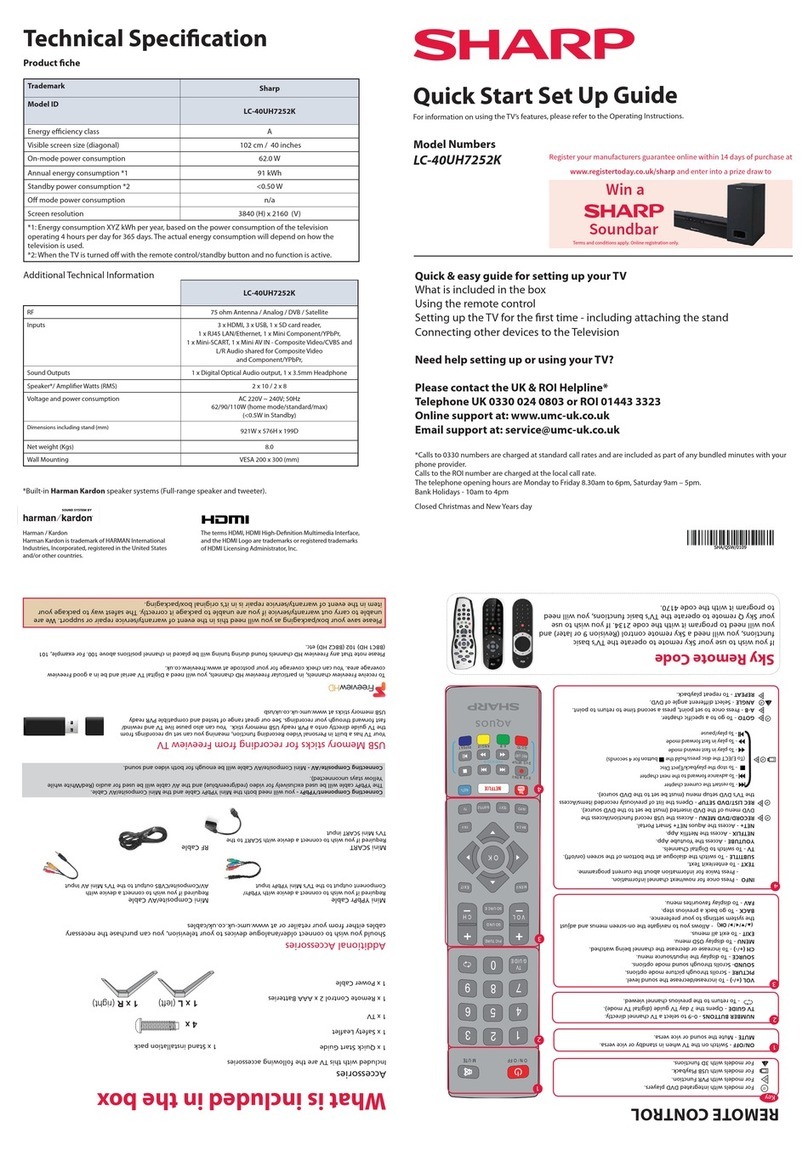

9H-BOW

(I2C BUS CONTROL)

(1) Receive CrossHatch Pattern Signal

(PAL 50 Hz).

(2) Choose the service data 9 H-BOW .

(3) Adjust the 2nd vertical line from the end of the

crosshatch pattern until line is straight

(4) Please refer Figure 9.1

10 H-P AR

(I2C BUS CONTROL)

(1) Receive CrossHatch Pattern Signal

(PAL 50 Hz).

(2) Choose the service data 8 H-P AR.

(3) Adjust the 2nd vertical line from the end of the

crosshatch pattern line is straight

(4) Please refer Figure 10.1

11 EW -TRAP

(I2C BUS CONTROL)

(1) Receive CrossHatch Pattern Signal

(PAL 50 Hz).

(2) Choose the service data 12 EW -TRAP .

(3) Adjust the 2nd vertical line from the right

end of the crosshatch pattern so that the

D1 (center area of the second vertical

line - edge of screen) and D2 (top area of

the second vertical line - edge of screen)

are same.

H-P AR

Figure 9.1

Figure 10.1

H-BOW

D2

D1

4. SCREEN, WHITE BALANCE, SUB-BRIGHTNESS & SUB-CONTRAST ADJUSTMENT

NO ADJUSTMENT POINT WAVEFORM OR OTHERS

1SCREEN

ADJUSTMENT

(I2C BUS CONTROL)

ADJUSTMENT C ONDITION / PROCEDURE

(1) Make sure the following items are in INITIAL

DATA before adjust CR T cutoff

(a) 15 DRI-RS = 32

(b) 16 DRI-GS = 32

(c) 17 DRI-BS = 32

(d) 18 CUT -RS = 16

(e) 19 CUT -GS = 16

(f) 20 CUT -BS = 16

(f) 21 SUB BRI = 24

(g) 22 SUB CON = 59

(h) 32 CUT OFF = 25

(i) 35 BLOC= 4

(2) Switch TV to video mode, blue back off, with

no signal and press R/C to set picture into

normal condition.

(3) G o to service mode, select item 31 VSD

(dark screen display)

(4) Adjust the Screen so that cut-off line appear in

low bright, then judge that whether the cut-off

line appear in Red or Green or Blue color, in

this condition between CUT -RS & C UT -GS &

cut-BS, fix the data of the color appear in

cut-off line and adj the other two cut-off data

(Note 1) so that cut-off line color become white.

(5) Turn the screen VR of FBT s o that cut-off line

just disappear

(1) WHITE (HIGH BEAM)

(In Window Pattern Signal)

First use Minolta Color Analyzer CA100, let the

gun point at Dark White position (as drawing

attach), Adj SUB-BRI until LUMINANCE Y

become 4 cd/m2 , then let the gun point at

White position (as drawing attach), Adj SUB-

CON until LUMINANCE Y become: 150 cd/m2.

Adj the DRI-RS & DRI-BS until the axis of color

temperature become

12300 K X : 0.272 , Y : 0.275

(2) DARK WHITE (LOW BEAM)

Let the gun point at Dark White position, if

the color temperature data shift away from

the data adjusted in Item 1 Screen

adjustment, adjust CUT -RS, CUT GS

& C UT -BS.

Please fix the first colour appears in Screen

adj item step (4) is fixed, adj the other two

so that to obtain the similar axis as above.

**Repeatstep1&2togetaregulated

position

Note 1:

During service mode select

key.

31VSD

(Dark Display),

up

Screen If the vertical line

does not appear, Please press vol

*Note : Signal using W/B Pattern

Generator SX-1006 (IW ATSU)

or equivalent.

Window Pattern Signal output

level are as above:

2WHITE BALANCE ADJ

(to be done after

screen adj)

(I2C BUS CONTROL)

WINDOW PATTERN SIGNAL

White

50% IRE5.5% IRE 9.5% IRE

Dark

White

°