9

25R-M100

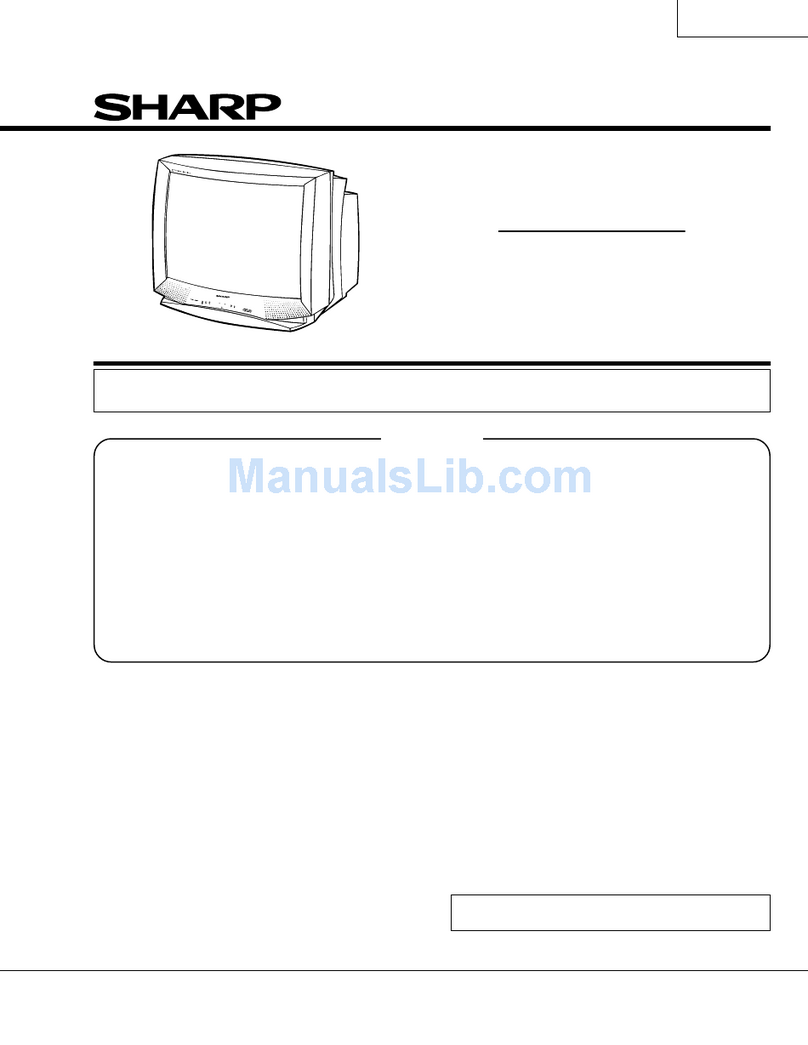

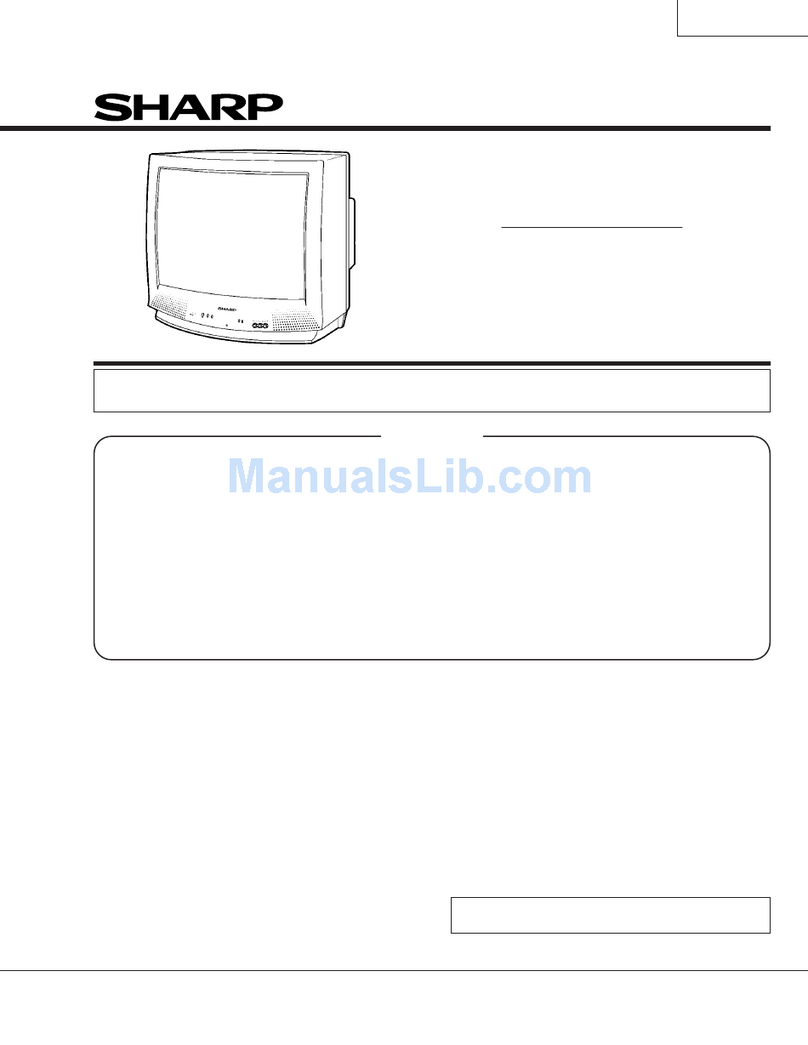

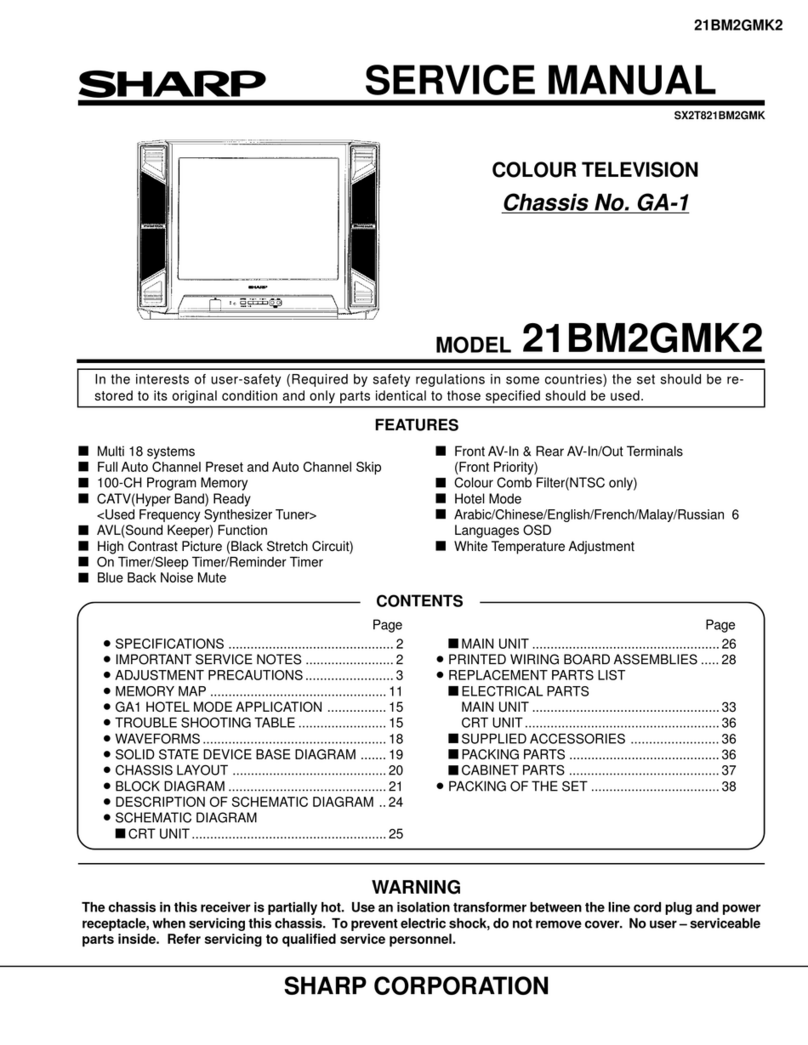

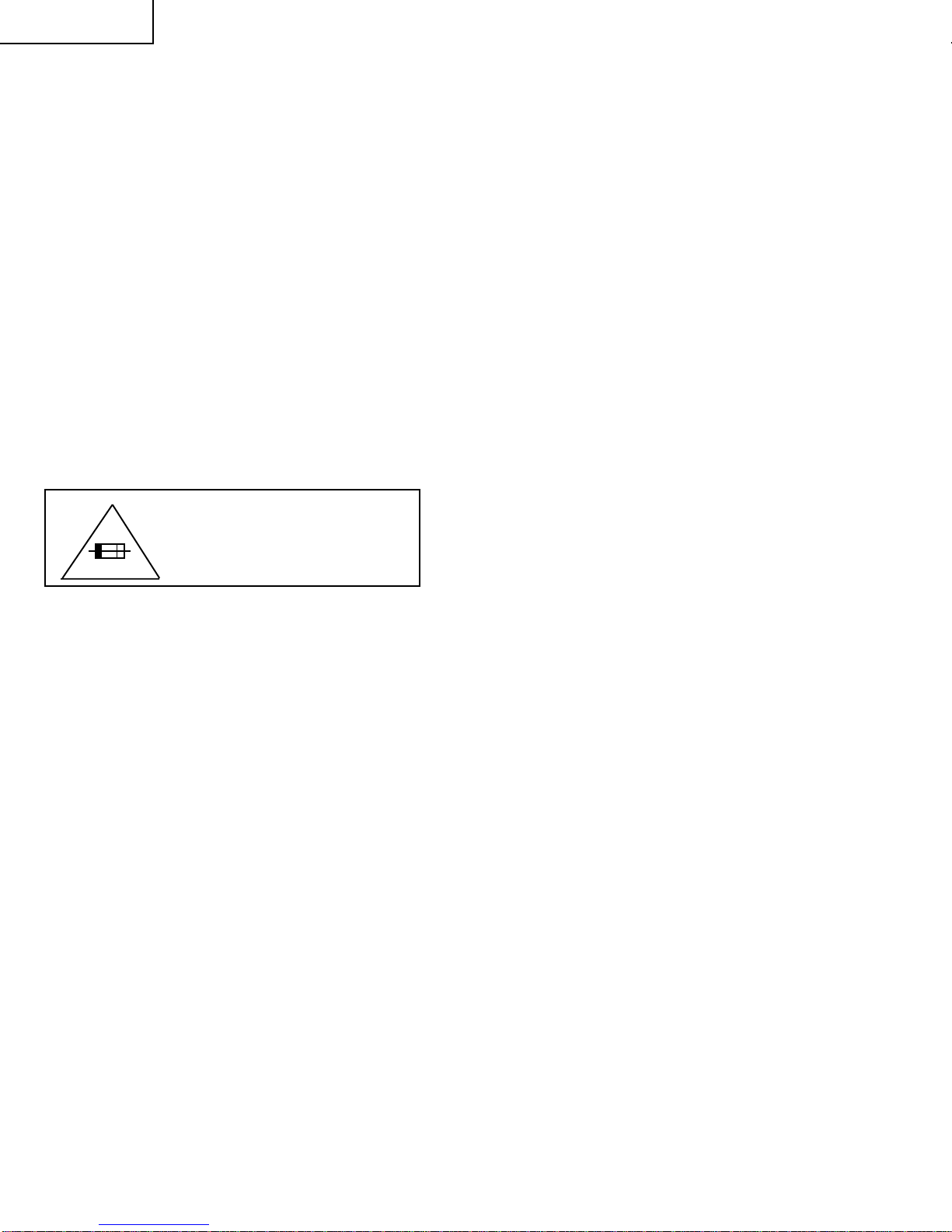

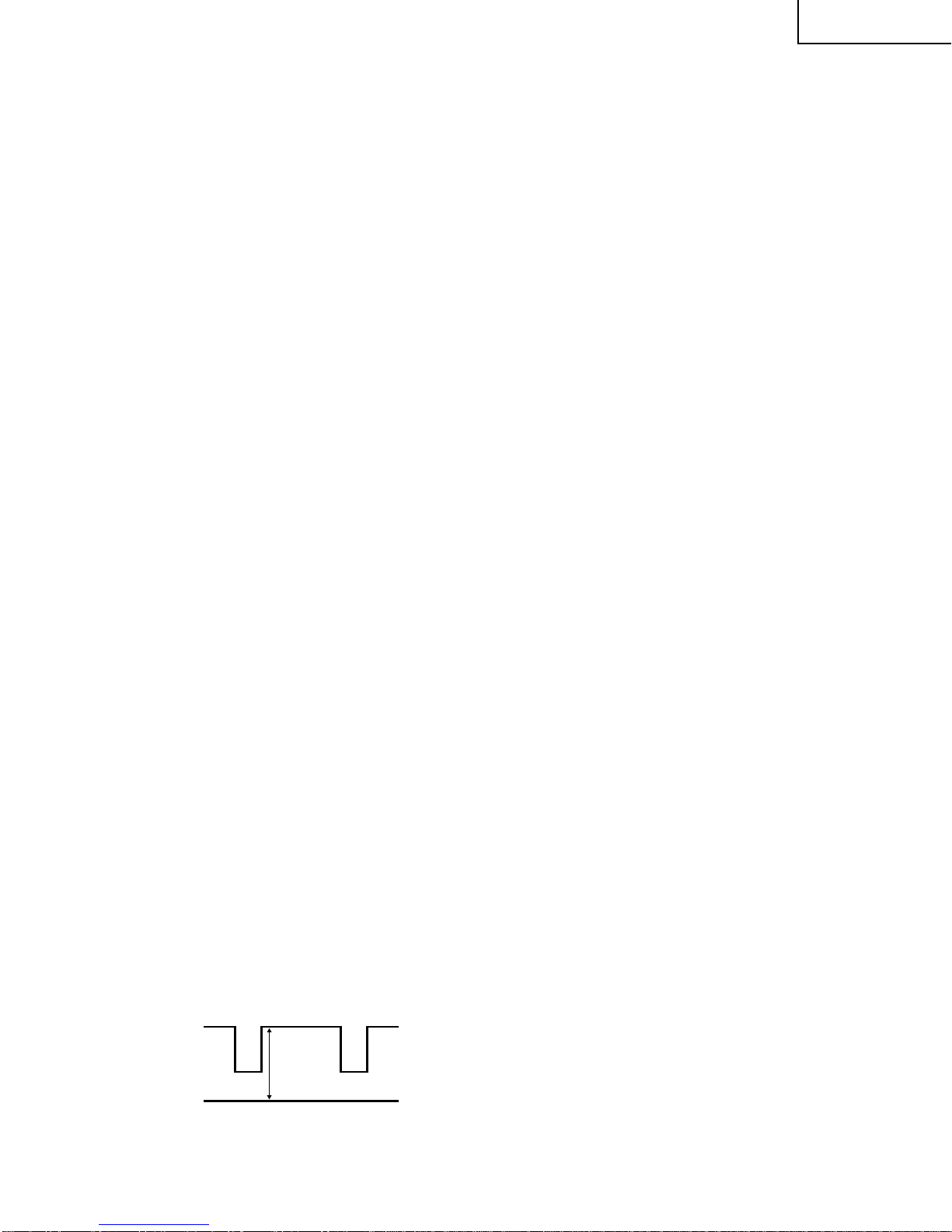

Figure B: WAVEFORM FOR SCREEN ADJUSTMENT

2.35Vdc

GND

ËSERVICE ADJUSTMENT

Note: Before making the service adjustment, make the

bus data settings.

+B Adjustment

(1) For the chassis with the +B adjustment control

1. Receive a good local channel.

2. Select VIDEO ADJUSTMENT RESET on the

menu to get the video reset.

3. Connect a DC voltmeter between the +B line (at

SWtransformer) ofR611 andthe groundterminal.

4. Adjust R738 so that the voltmeter should read

128.5+0.5V/-0.25V.

(2) For the chassis without the +B adjustment

control

1. Receive a good local channel.

2. Select VIDEO ADJUSTMENT RESET on the

menu to get the video reset.

3. Connect a DC voltmeter between the +B line (at

SWtransformer) ofR611 andthe groundterminal.

4. Make sure that the voltmeter reads 128.5±1.5V.

Video Level (TV Det Video Level)

Adjustment

1. Receive a good local channel.

2. Enter the service mode signal category and select

the service adjustment "S02".

3. Set the data value to "02" first, then adjust the data

to "04". (If out of spec, readjust the data in the range

of "00" to "07" to obtain a normal contrast level.)

RF AGC Adjustment

1. Receive a good local channel.

2. Enter the service mode signal category and select

the service adjustment "S01".

3. Set the data value to point where no noise or beat

appears.

4. Select another channel to confirm that no noise or

beat appears.

Note: You have to exit the service mode first to

select another channel.

Screen Adjustment

1. Connect to oscilloscope probe between TP854 and

ground of the CRT unit.

2. Receive a good local channel.

3. Enter the service mode Signal category and set the

service adjustment "S04" to step 30. Then select the

service adjustment "S12" and set the data value to

"00"tosetthecolor leveltothe minimumlevel.(record

the original data first). You may skip this step, if you

selected a B/W picture or monoscope pattern. Set

alsothe "S05/S06/S07"datato minimumlevel ("00").

4. Select the service adjustment "S03" and set the data

valueto "01"to turnoffthe luminancesignal (Y-mute).

5. Select the service adjustment "S14" and adjust the

data value to obtain 2.35 volts as shown in Figure B.

6. Adjust the master screen control until the raster

darkens to the point where raster is barely seen.

7. Adjusttheserviceadjustment "S05"red, "S06"green,

"S07" blue to obtain a good grey scale with normal

white at low brightness level.

8. Selecttheservice a adjustment"S03" and resetdata

to"00". Selectthe serviceadjustment"S12"andreset

data to obtain normal color level.

9. Remove probe and reset the master screen control

to obtain normal brightness range.

White Balance Adjustment

1. Receive a good local channel.

2. Select the service adjustment "S12" and set the data

value to "00" to set the color level to the minimun.

You may skip this step, if you selected a B/W picture

or monoscope.

3. Alternatelyadjustthe serviceadjustmentdata of"S08"

and "S09" until a good grey scale with normal white

is obtained.

4. Select the service adjustment "S12" and reset data

to obtain normal color level.

Sub-Picture Adjustment

1. Receive a good local channel.

2. Make sure the customer picture control is set to

maximum.

3. Enter the service mode and select the service

adjustment "S10".

4. Adjust the data value to achieve normal contrast

range.

Sub-Tint Adjustment

1. Receive a good local channel.

2. Setthecustomertint controlto thecenterof it’srange.

3. Enter the service mode and select the service

adjustment "S11".

4. Adjust "S11" data value to obtain normal fresh tones.

Sub-Color Adjustment

1. Receive a good local channel.

2. Make sure the customer color control is set to center

position.

3. Enter the service mode and select the service

adjustment "S12".

4. Adjust "S12" data value to obtain normal color level.

Sub-Brightness Adjustment

1. Receive a good local channel.

2. Make sure the customer brightness control is set to

center position.

3. Enter the service mode and select the service

adjustment "S13".

4. Adjust "S13" data value to obtain normal brightness

level.