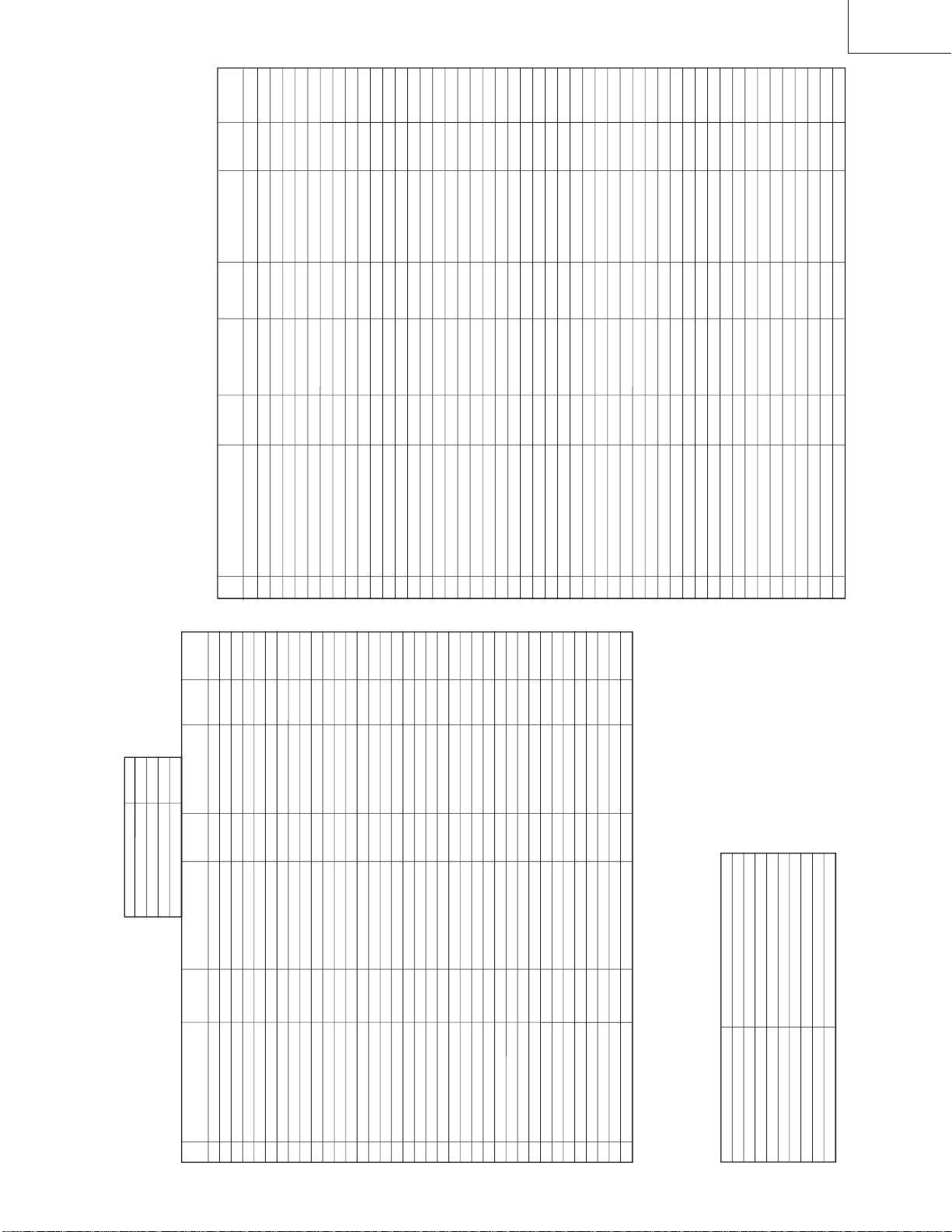

49 DATAILS LIMIT 0 ~ 15 PKLM COMB/AI PKLM 8 4

50 OUTLINE DFF FREQ. 0 ~ 1 YDO COMB/AI YDO 0 1

51 OUTLINE CORING 0 ~ 7 RCOR COMB/AI RCOR 5 4

52 OUTLINE CORRECTION 0 ~ 15 RMY COMB/AI RMY 14 14

53 DATAILS OUTLINE 0 ~ 255 GAINA COMB/AI GAINA 64 90

54 YNR CORING 0 ~ 7 BLC COMB/AI BLC 4 0

55 CHROMA BPF TV 0 ~ 3 BPS T COMB/AI BPS T 0 3

56 CHROMA BPFAV 0 ~ 3 BPS A COMB/AI BPS A 0 0

57 Y-DELAY TV 0 ~ 7 YDL T COMB/AI YDL T 4 4

58 Y-DELAY AV 0 ~ 7 YDLA COMB/AI YDLA 3 3

59 V OUTLINE LIMIT 0 ~ 15 VPL COMB/AI VPL 8 8

60 V OUTLINE CORING 0 ~ 15 KOA COMB/AI KOA 2 7

61 V OUTLINE DETECT 0 ~ 1 YHO COMB/AI YHO 1 1

62 YNR DETECT GAIN 0 ~ 3 YNG COMB/AI YNG 2 0

63 YNR CORING 0 ~ 15 COR COMB/AI COR 8 1

64 B-STRETCH REFLECT 0 ~ 3 APSL COMB/AI APSL 1 1

65 B-STRETCH THRE 0 ~63 APMN COMB/AI APMN 20 20

66

PEDESTAIL CORRECTION

0 ~ 7 PHD COMB/AI PHD 6 6

67 B-STRETCH INITIAL 0 ~ 31 APA COMB/AI APA 6 4

68 AI ON/OFF 0 ~ 1 AION COMB/AI AION 0 1

69 HISTGRAM LIMIT 0 ~ 63 LMT COMB/AI LMT 12 15

70 Y-MIN DETECT GAIN 0 ~ 3 MNSL COMB/AI MNSL 2 1

71 Y-MIN LIMIT 0 ~ 63 MINLT COMB/AI MINLT 32 32

72 BASE AMOUNT 0 ~15 BSE COMB/AI BSE 15 15

73 Y-MIN DETECT OFFSET 0 ~15 MNOFT COMB/AI MNOFT 6 9

74 APL LAST GAIN 0 ~ 1 APGA COMB/AI APGA 1 1

75 APL LIMIT LAST GAIN 0 ~ 63 APLT COMB/AI APLT 10 32

76 APL SWITCH LAST GAIN 0 ~ 127 APDT COMB/AI APDT 37 10

77 LOW APL COL LEVEL 0 ~ 63 APC COMB/AI APC 28 10

78 LOW APL COL GAIN 0 ~ 3 CAS COMB/AI CAS 0 2

79 HIGH APLCOL LEVEL 0 ~ 63 APU COMB/AI APU 54 5

80 HIGH APLCOL GAIN 0 ~ 3 CUS COMB/AI CUS 2 2

81 PRESCALE SCART 0 ~ 127 PRE S NICAM PRESCALE 24 24

82 PRESCALE FM/AM 0 ~ 127 PRE F NICAM PRESCALE 10 10

83 PRESCALE NICAM 0 ~ 127 PRE N NICAM PRESCALE 63 24

84 AUTO VOLUME CORR 0 ~ 3 AVC NICAM PRESCALE 0 0

85 VOLUME NICAM BG 0 ~ 127 BG L NICAM VOLUME 127 113

86 VOLUME NICAM I 0 ~ 127 I L NICAM VOLUME 127 103

87 VOLUME NICAM DK 0 ~ 127 DK L NICAM VOLUME 127 95

88 VOLUME IGR BG 0 ~ 127 IGR L NICAM VOLUME 127 125

89 VOLUME FM 0 ~ 127 FML NICAM VOLUME 127 125

90 OSD H-POSITION 0 ~ 127 OSD-H - - 26 25

91 TEXT H-POSITION 0 ~ 127 TEXT-H - - 34 10

92 TEXT V-POSITION 0 ~ 63 TEXT-L - - 35 37

93 VSM GAIN(AVM1) 0 ~ 7 VG1SP1 1 CHIP VSM GAIN 3 7

94 GAMMA POINT(AVM1) 0 ~ 3 G-POINT1 1 CHIP GAMMA POINT 3 2

95 TREBLE(AVM1) 0 ~ 60 TRE1SP1 SOUND TREBLE 25 31

96 BASS(AVM1) 0 ~ 60 BASS1SP1 SOUND BASS 25 28

97 SURR EFECT(AVM1) 0 ~ 15 EF1SP1 SOUND SURR LEVEL 15 10

98 SURR LOOP(AVM1) 0 ~ 1 LO1SP1 SOUND LOOP 0 0

99 VSM GAIN(AVM2) 0 ~ 7 VG1SP2 1 CHIP VSM GAIN 5 4

100 GAMMA POINT(AVM2) 0 ~ 3 G-POINT2 1 CHIP GAMMA POINT 2 2

101 TREBLE(AVM2) 0 ~ 60 TRE2SP1 SOUND TREBLE 30 30

102 BASS(AVM2) 0 ~ 60 BASS2SP1 SOUND BASS 32 30

103 SURR EFECT(AVM2) 0 ~ 15 EF2SP1 SOUND SURR LEVEL 15 10

104 SURR LOOP(AVM2) 0 ~ 1 LO2SP1 SOUND LOOP 0 0

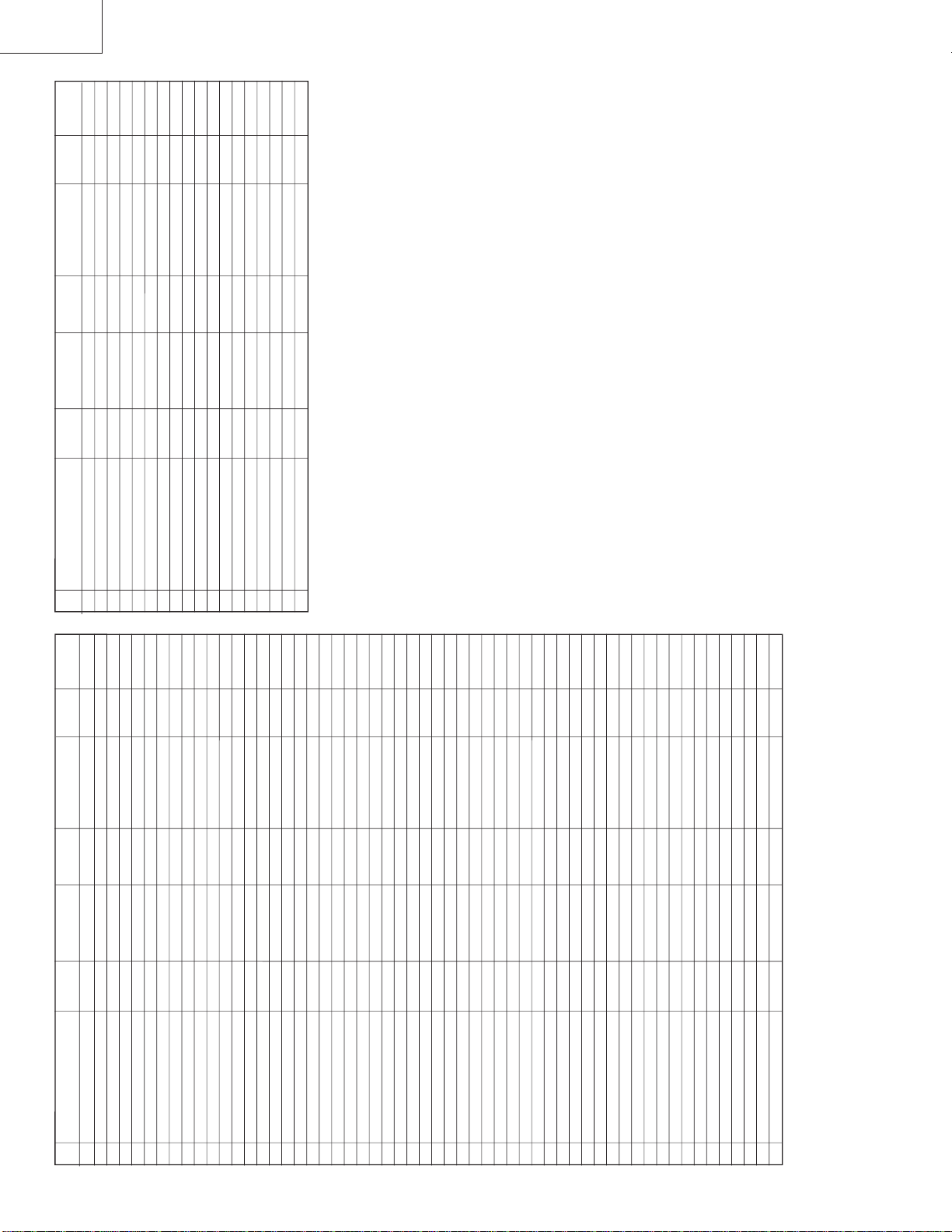

No. EEPROM SETTING DATA OSD IC DATA SETTING INITIAL

SETTING

LENGTH DATA DATA

105 VSM GAIN(AVM3) 0 ~ 7 VG1SP3 1 CHIP VSM GAIN 7 7

106 GAMMA POINT(AVM3) 0 ~ 3 G-POINT3 1 CHIP GAMMA POINT 1 2

107 TREBLE(AVM3) 0 ~ 60 TRE3SP1 SOUND TREBLE 35 32

108 BASS(AVM3) 0 ~ 60 BASS3SP1 SOUND BASS 35 30

109 SURR EFECT(AVM3) 0 ~ 15 EF3SP1 SOUND SURR LEVEL 15 10

110 SURR LOOP(AVM3) 0 ~ 1 LO3SP1 SOUND LOOP 0 0

111 S-BOOST MER 0 ~ 255 MER - - 127 80

112 S-BOOST MEL1 0 ~ 255 MEL1 - - 180 150

113 S-BOOST MEL2 0 ~ 255 MEL2 - - 195 156

114 S-BOOST MEL3 0 ~ 255 MEL3 - - 210 163

115 S-BOOST MEL4 0 ~ 255 MEL4 - - 225 165

116 S-BOOST MEL5 0 ~ 255 MEL5 - - 240 170

117 S-BOOST MEL6 0 ~ 255 MEL6 - - 255 180

118 S-BOOST START POINT 0 ~ 255 SSTP - - 25 21

119 S-BOOST STOP POINT 0 ~ 255 SSPP - - 45 60

120 SIBOOST STEP POINT 0 ~ 255 SSTEP - - 5 7

121 AUDIO AGC 0 ~ 1 SUR AGC SOUND AGC 1 1

122 NICAM FM 0 ~ 255 NICAM FM SOUND NICAM 80 80

No. EEPROM SETTING DATA OSD IC DATA SETTING INITIAL

SETTING

LENGTH DATA DATA