9

25WG3

1.Switch TV to VIDEO MODE, Blue Back:

OFF, Without Video Signal.

2.Connect the oscilloscope to TP851.

(Use a 10:1 probe)

Range: 500mV/div

Sweep Time: 5ms/div

Press "DC" mode

3.Using the remote controller, call

NORMAL mode.

4.Adjust Screen VR so that the tip of

signal reach 2.5Vdc ±0.1Vdc.

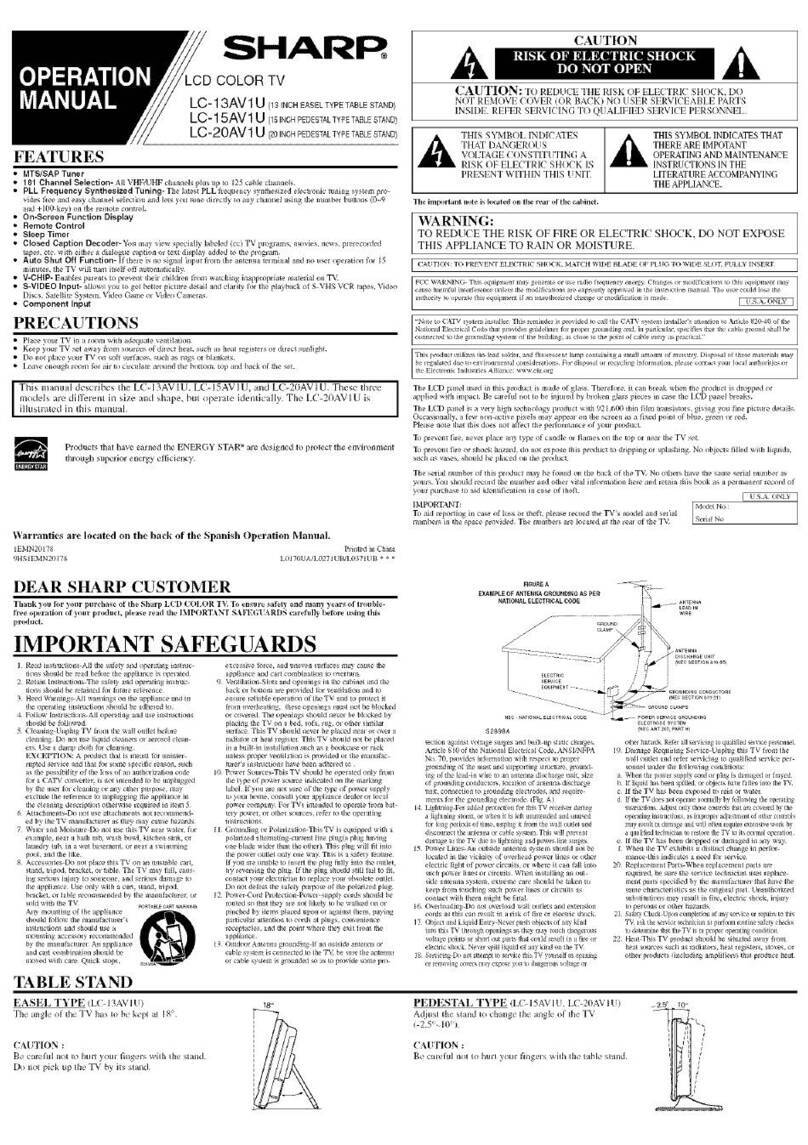

CUT OFF , WHITE BALANCE, SUB - BRIGHT, & FOCUS ADJUSTMENT.

NO

ADJUSTMENT POINT

1

CRT Cut - OFF ADJ.

(I

2

C BUS CONTROL)

ADJUSTMENT CONDITION/PROCEDURE

WAVEFORM OR OTHERS

*Before adjustment ,make

sure that this adjustment

with the initial bus data

"White Point (G)" &

"White Point (B)" are 32.

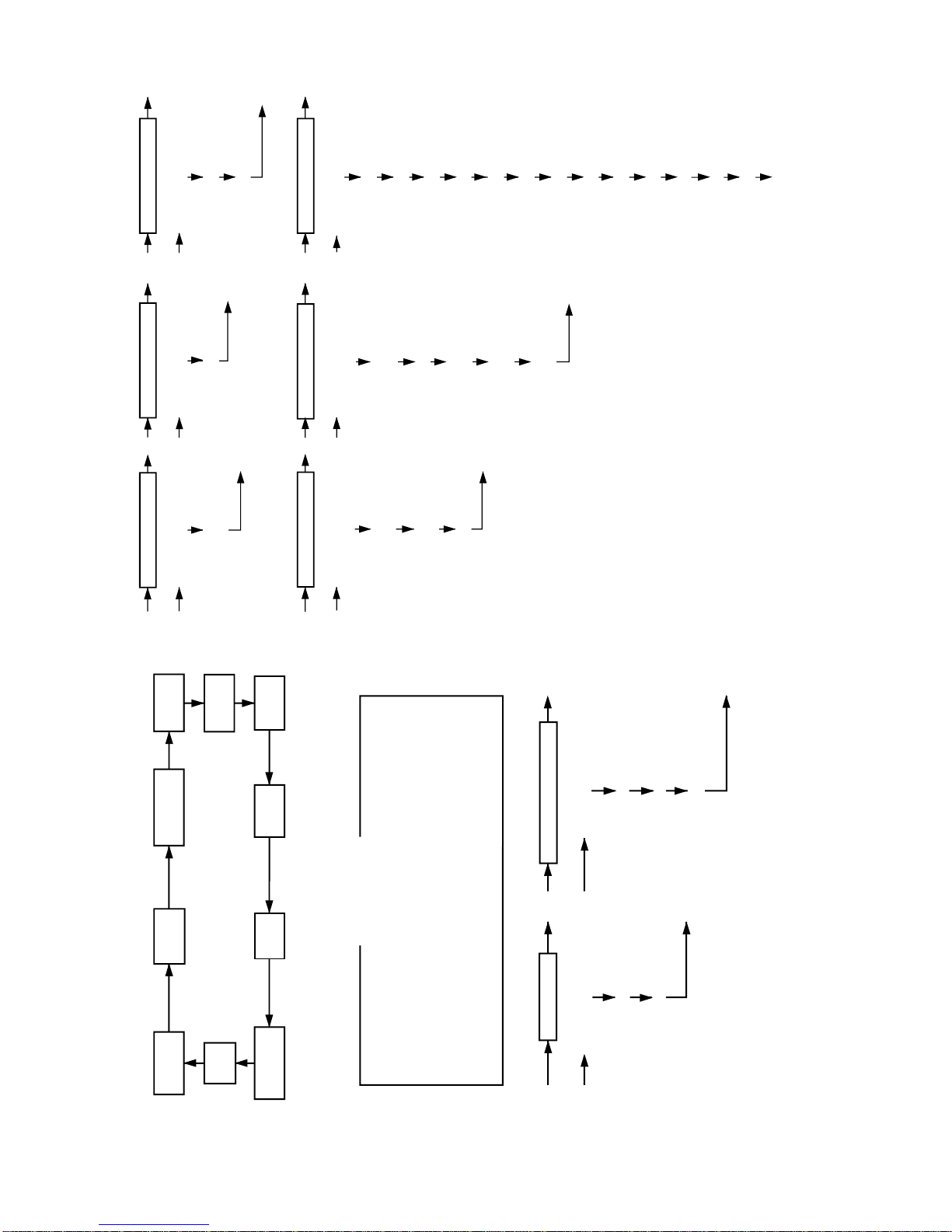

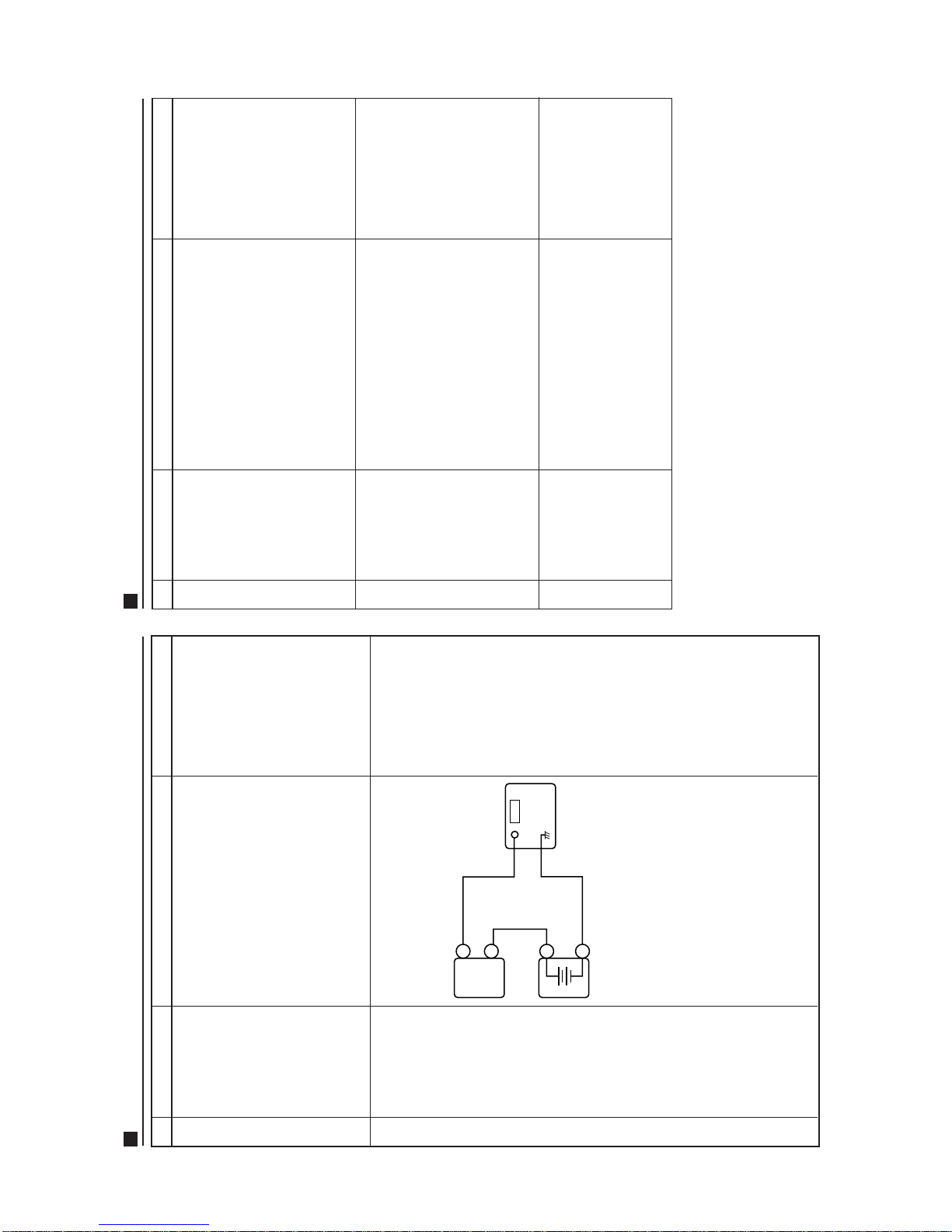

Figure 5

5.Receive the MONOSCOPE PATTERN

signal.

6.Call the "BKGD" in SERVICE mode.

7.Adjust "White Point (G)", "White Point

(B)" data to have a colour temperature

of 12300k (White) Note.

2 White Balance ADJ.

(I

2

C BUS CONTROL)

Note :White Point (G)

UP " 2 " KEY

DOWN " 5 " KEY

White Point (B)

UP " 3 " KEY

DOWN " 6 " KEY

As the above data can be

UP / DOWN.

*12300k x=272

y=275

(Minolta Colour Analyzer

CA-100)

8.Receive the "CROSSHATCH

PATTERN" Signal.

9.Call the "SUB BRI" in SERVICE mode.

10.Adjust the "SUB-BRI" bus data, so that

the No. 2 line inside the window area

will disappear.

Note: Before starting this adjustment,

warm up the unit for 30 minutes or

longer at a beam current of 1200 ~

1300µA.

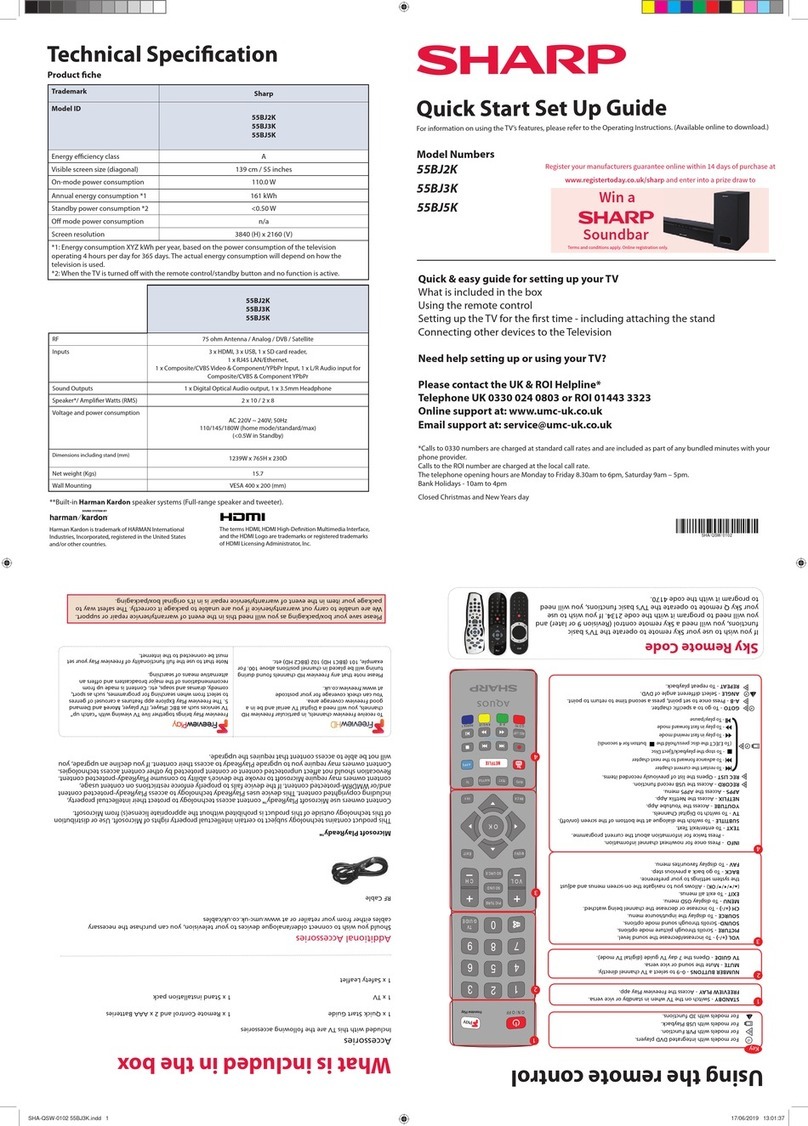

3 SUB- BRIGHT ADJ.

(I

2

C BUS CONTROL)

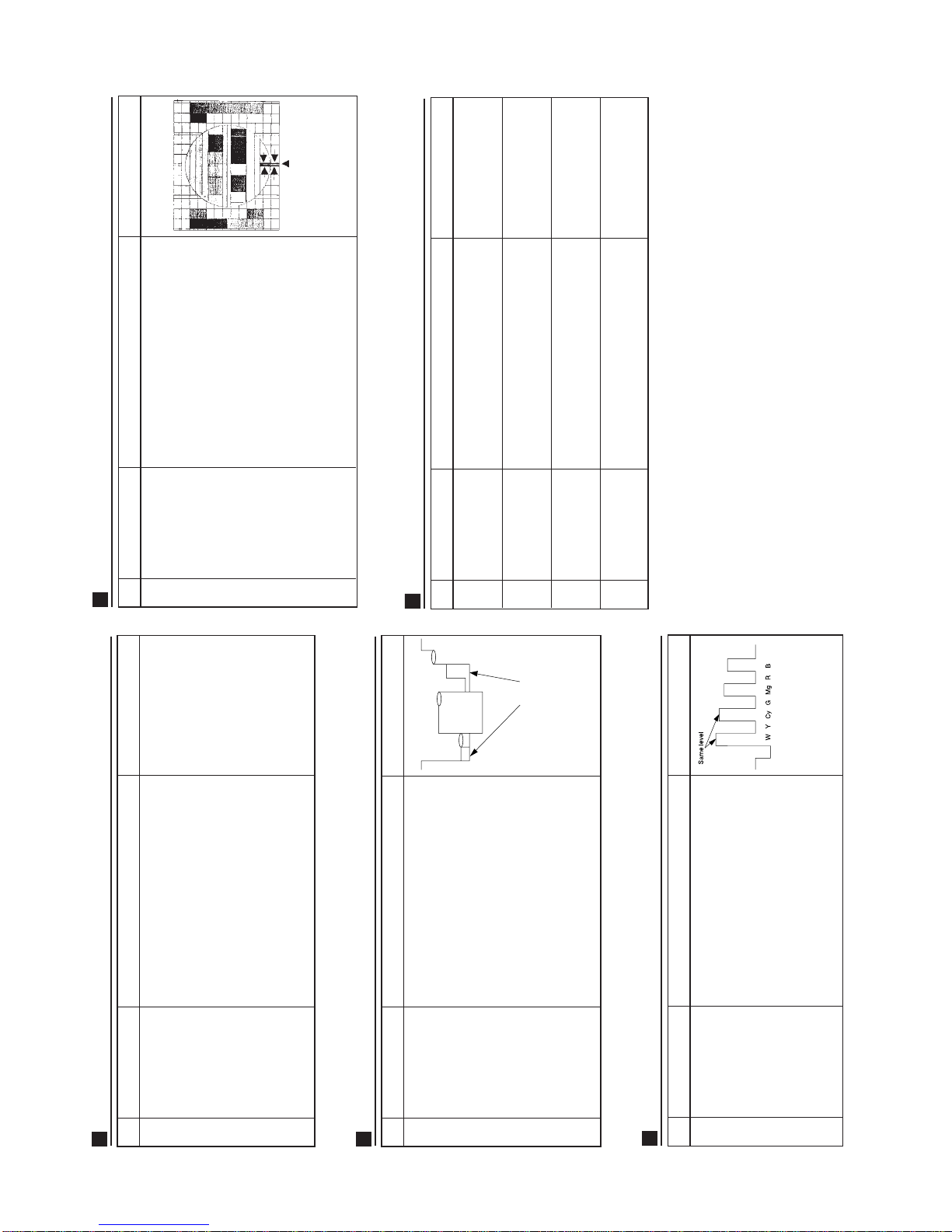

Figure 6

11.Receive the "MONOSCOPE PATTERN"

Signal.

12.Press P-NORMAL key.

13.Connect the DC Milliammeter between

TP601 (-) and TP602 (+). (Full Scale:

3.0 mA Range).

14.Beam current Must be 1200 ±100µA.

4 BEAM CURRENT

CHECK

1.

Receive the "MONOSCOPE PATTERN"

signal.

2.

Using the remote control, call NORMAL

mode.

3.

Adjustthe FOCUS controlsothat theshaded

area of screen be in optimal focus.

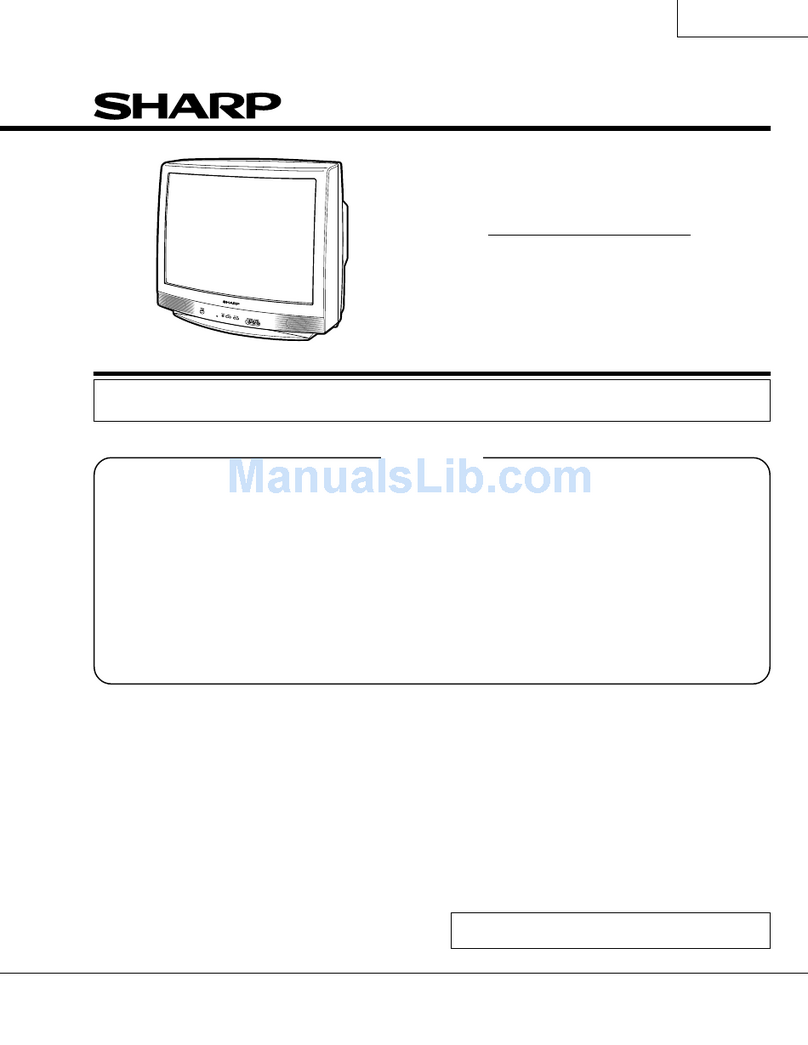

5 FOCUS ADJ.

Figure 7

1.Receive the 50Hz "MONOSCOPE

PATTERN" signal.

2.Call the "V-SIFT 50" in SERVICE mode.

3.Increase or decrease the "V-SIFT 50"

by using Volume UP/DOWN key to

adjust or align the screen center with

the CRT’s geometrical center.

4.Receive the 60 Hz "MONOSCOPE

PATTERN" signal.

5.Call the "V-SIFT 60" in SERVICE mode.

6.Increase or decrease the "V-SIFT 60"

by using Volume UP/DOWN key to

adjust or align the screen center with

the CRT’s geometrical center.

V-SHIFT 60

(I

2

C BUS CONTROL)

1.Receive the "MONOSCOPE PATTERN"

signal.

2.Call the "V-AMP" in SERVICE mode.

3.Increase or decrease the "V-AMP" by

using the volume UP/DOWN key to

adjust the Vertical size until it is 8.5%

overscan.

3 V-AMP

(I

2

C BUS CONTROL)

OVER SCAN: 8.5% ±1.5 %

1.Receive the 50Hz "MONOSCOPE

PATTERN" signal.

2. Call the"H-SIFT 50"IN SERVICE MODE.

3. Increase or decrease the "H-SIFT 50" by

usingtheVolumeUP/DOWNkeytoadjust

or align the left, and right sides of screen

are equal overscan size.

4.Receive the 60Hz "MONOSCOPE

PATTERN" signal.

5. Call the"H-SIFT 60"IN SERVICE MODE.

6. Increase or decrease the "H-SIFT 60" by

usingtheVolumeUP/DOWNkeytoadjust

or align the left and right sides of screen

are equal overscan size.

4 H-SHIFT 50

(I

2

C BUS CONTROL)

H-SHIFT 60

(I

2

C BUS CONTROL)

SPEC: ±2mm

SPEC: ±2mm

1.Receive the "MONOSCOPE PATTERN"

signal.

2.Call the "V-SLOPE" in SERVICE mode.

3.Increase or decrease "V-SLOPE" by

using Volume key so that the center line

of picture matches with the edge of

blanking line.

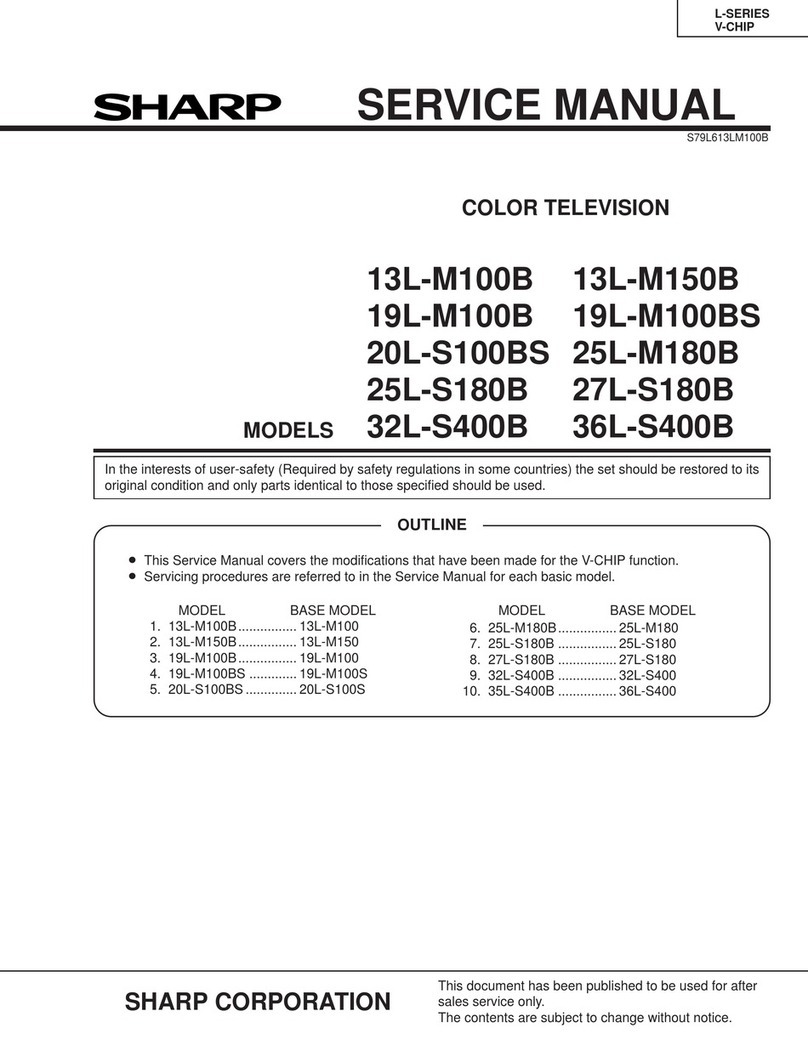

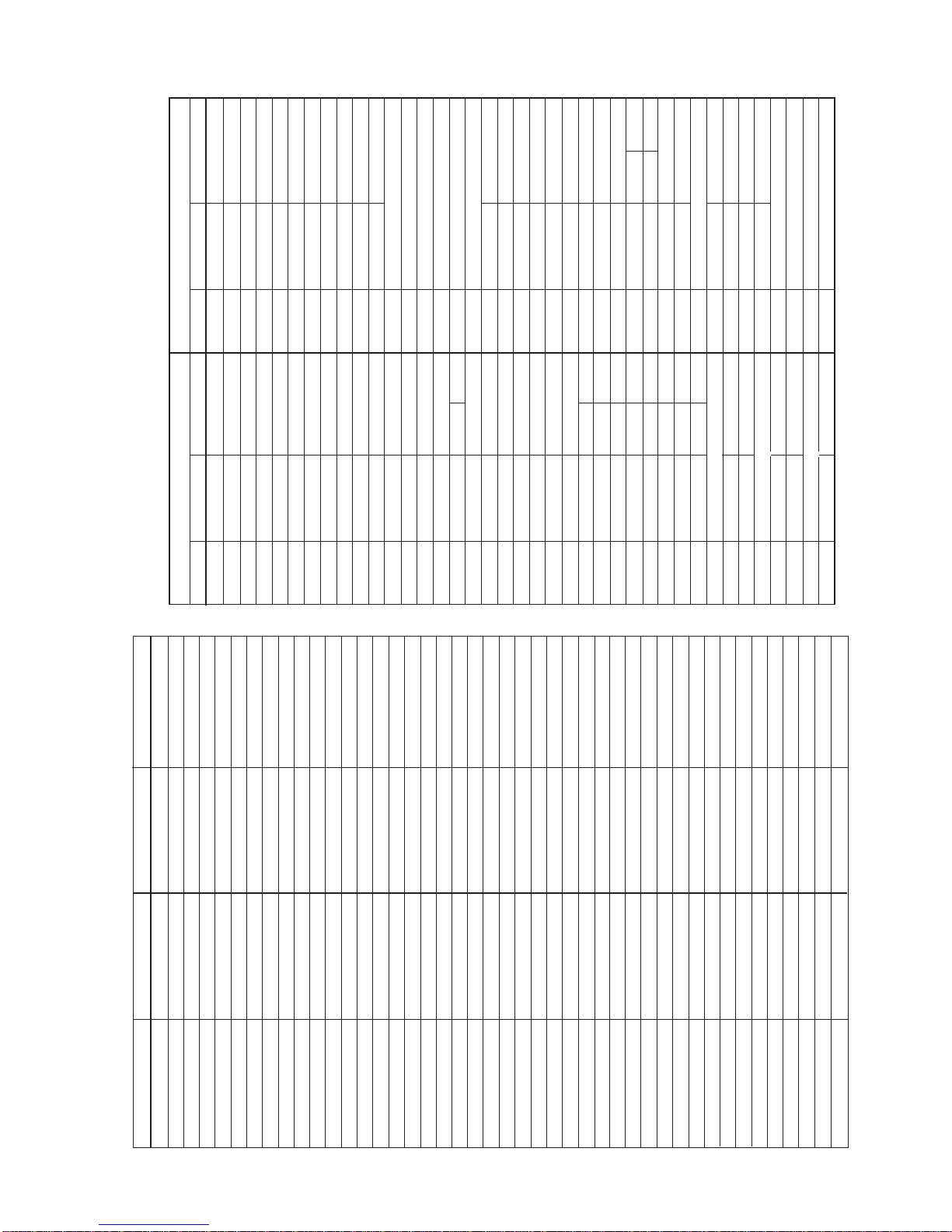

HORIZONTAL, VERTICAL, DEFLECTION LOOP ADJUSTMENT.

NO

ADJUSTMENT POINT

1 V-SLOPE ADJ.

(I

2

C BUS CONTROL)

ADJUSTMENT CONDITION/PROCEDURE

WAVEFORM OR OTHERS

SPEC: ±1

SCANNING LINE

2 V-SHIFT 50

(I

2

C BUS CONTROL)