Sharpe SEA ? User manual

It is the responsibility of the customer to determine the suitability of Sharpe®Valves products in their particular application.

Disclaimer: Supplier shall not be liable or responsible for omissions or errors in its bulletin.

IM-SEA-1

10-12-17 / Rev. 1

Page 1 of 16

INSTALLATION, OPERATIONS

AND MAINTENANCE FOR SHARPE®

SEA ELECTRIC ACTUATORS

2701 Busse Road Elk Grove Village, Illinois 60007

Phone: (877) 774-2773

Fax: (708) 562-9250

www.sharpevalves.com

It is the responsibility of the customer to determine the suitability of Sharpe®Valves products in their particular application.

Disclaimer: Supplier shall not be liable or responsible for omissions or errors in its bulletin.

IM-SEA-1

10-12-17 / Rev. 1

Page 2 of 16

OVERVIEW

Sharpe®electric quarter-turn actuators offer a wide range of torque output models. The product

design is based on a self-locking worm drive principal, which provides for a smooth running,

dependable, robust drive system. All models are ISO 5211 compliant and most have a visual

position indicator on top of actuator cover and manual override

LUBRICATION

The gearbox of the Sharpe actuator is enclosed, and it has already been lubricated sufficiently

with high temperature lubricant at the factory sufficient for use for up to two years.

IMPORTANT NOTICES & MAINTENANCE

Notices:

Make sure the voltage is correct before wiring.

Turn off power before for maintenance purposes.

Seal the casing and conduit entrance after wiring to prevent dust or water contamination.

The angle of installation must between 0~180°. Do not install upside down or below the

horizontal.

Do not install when hazardous or explosive gases may be present.

The frequency of open and close is restricted based on duty cycle. Avoid too high

frequency.

When more than one electric actuator needs to operate simultaneously, please connect

individually.

Always connect the ground wire to the inside of the electric actuator.

Not intended for vacuum spaces and avoid installing near explosive atmospheres.

To avoid functional failure caused by statics, do not touch any components on the PCB

with metal tools or bare hands.

Storage:

The actuator should be placed in a clean and dry place, and protected from the weather

and extreme vibration.

If actuator needs be stored outside, it must be protected from excess moisture, dust,

and weather.

It is the responsibility of the customer to determine the suitability of Sharpe®Valves products in their particular application.

Disclaimer: Supplier shall not be liable or responsible for omissions or errors in its bulletin.

IM-SEA-1

10-12-17 / Rev. 1

Page 3 of 16

INSTALLATION

1. Before mounting actuator, verify that the torque requirement is less than the output

torque of the actuator. (The suggested safety factor is 30% of the max. torque of

valve.)

1. For example :

If the maximum valve torque is 80Nm - 80 × 1.3(safety factor) =104 Nm

104Nm <150Nm SEA 13 is OK!

104Nm >90Nm SEA 8 is not OK!

2. Check if the output shaft fits to the stem of valve before inserting into actuator. Please

use mounting plate or adapter to connect if it does not match.

3. Insert output shaft adapter into actuator. Make sure it fits satisfactory.

4. Determine that actuator position, open or closed, matches with position of equipment

prior to mounting. Use manual override to change position if necessary.

5. Remove valve’s manual device and mount on the proper connection.

6. Check again that the valve and actuator are in the same position.

7. Install the actuator to valve directly or with mounting kits, then tighten all screws and

nuts.

8. Remove actuator cover.

9. Wire actuator using the wiring diagram inside cover.

10.Supply power to actuator.

11.Make sure if it is needed to calibrate the fully-open or fully-closed position of the

actuator.

12.If the actuator is modulating type make sure set the required settings.

13.Replace cover and secure cover screws.

It is the responsibility of the customer to determine the suitability of Sharpe®Valves products in their particular application.

Disclaimer: Supplier shall not be liable or responsible for omissions or errors in its bulletin.

IM-SEA-1

10-12-17 / Rev. 1

Page 4 of 16

SPECIFICATIONS

12V/24V

Model

No.

Max Torque

Speed

(90°)

Motor

Power

12V DC/AC

24V DC/AC

Nm

lb-in

Run

Start

Lock

Run

Start

Lock

SEA 3

35

310

15s

10W

1.9A

2.0A

2.8A

1.1A

1.1A

1.6A

SEA 4

50

443

20s

10W

1.3A

1.5A

2.8A

0.8A

0.9A

1.6A

SEA 8

90

797

15s

40W

3.4A

5.2A

16.5A

2.2A

4.5A

14.5A

SEA 13

150

1328

22s

40W

4.4A

4.9A

16.5A

2.4A

5.0A

14.5A

SEA 35

400

3540

16s

80W

16.1A

16.1A

33.0A

8.5A

9.2A

30.0A

SEA 44

500

4425

22s

80W

14.1A

13.5A

33.0A

7.5A

9.0A

30.0A

SEA 57

650

5750

28s

80W

12.3A

12.5A

33.0A

7.0A

8.5A

30.0A

SEA 88

1000

8850

46s

80W

6.8A

7.8A

30.0A

SEA 132

1500

13275

46s

80W

25A

26A

59A

8.1A

8.0A

30.0A

SEA 177

2000

17700

58s

80W

8.8A

11.0A

26.0A

SEA 221

2500

22125

58s

80W

28A

60A

59A

11.8A

11.0A

26.0A

SEA 265

3000

26550

58s

220W

15.1A

11.0A

33.0A

SEA 310

3502

31000

58s

220W

17.8A

12.0A

33.0A

Single Phase

Model

No.

Max Torque

Speed

(90°)

Motor

Power

110V Current

220V-240V Current

Nm

lb-in

60

Hz

50

Hz

Run

Start

Lock

Run

Start

Lock

SEA 3

35

310

12s

13s

10W

0.6A

0.6A

0.7A

0.3A

0.4A

0.4A

SEA 4

50

443

20s

24s

10W

0.6A

0.6A

0.7A

0.3A

0.4A

0.5A

SEA 8

90

797

15s

17s

40W

1.0A

1.8A

1.6A

0.5A

0.8A

0.9A

SEA 13

150

1328

22s

26s

40W

1.2A

1.8A

1.6A

1.0A

1.2A

0.9A

SEA 35

400

3540

16s

18s

80W

1.9A

3.8A

3.6A

1.1A

2.0A

2.2A

SEA 44

500

4425

22s

25s

80W

2.0A

3.8A

3.6A

1.1A

2.0A

2.2A

SEA 57

650

5750

28s

31s

80W

2.1A

3.8A

3.6A

1.1A

2.0A

2.2A

SEA 88

1000

8850

46s

55s

120W

3.1A

8.5A

9.0A

1.4A

4.1A

5.0A

SEA 132

1500

13275

46s

55s

120W

3.3A

9.0A

9.0A

1.6A

4.4A

5.0A

SEA 177

2000

17700

58s

70s

180W

3.3A

5.8A

5.9A

2.1A

3.8A

3.6A

SEA 221

2500

22125

58s

70s

180W

4.0A

6.5A

5.9A

2.3A

4.0A

3.6A

SEA 265

3000

26550

58s

70s

180W

4.5A

3.5A

5.9A

2.5A

4.2A

3.6A

SEA 310

3502

31000

58s

70s

220W

4.0A

8.0A

7.5A

2.4A

4.4A

4.8A

Note:

RUN= Operating; START= Start to operate; LOCK= When you input power to the actuator and the actuator can’t operate.

It is the responsibility of the customer to determine the suitability of Sharpe®Valves products in their particular application.

Disclaimer: Supplier shall not be liable or responsible for omissions or errors in its bulletin.

IM-SEA-1

10-12-17 / Rev. 1

Page 5 of 16

TRAVEL CAM & LIMIT SWITCHES ADJUSTMENT

The travel cams are set to control the open and closed position of the

valve. LS1 & LS2 limit the maximum range by disabling the electric

motor.

LS3 & LS4 are optional. They allow external equipment to confirm

that the valve has reached the fully open and fully closed positions.

IMPORTANT: If LS3 & LS4 are fitted, they should be set to trip

prior to LS1 & LS2 to avoid over-travel.

A 2.5mm hex keywill be required to adjust cam settings.

Travel Cam Adjustment –SEA 3

It is the responsibility of the customer to determine the suitability of Sharpe®Valves products in their particular application.

Disclaimer: Supplier shall not be liable or responsible for omissions or errors in its bulletin.

IM-SEA-1

10-12-17 / Rev. 1

Page 6 of 16

TRAVEL CAM & LIMIT SWITCHES ADJUSTMENT (cont.)

Travel Cam Adjustment –SEA 4

Travel Cam Adjustment –SEA 8 - SEA310

It is the responsibility of the customer to determine the suitability of Sharpe®Valves products in their particular application.

Disclaimer: Supplier shall not be liable or responsible for omissions or errors in its bulletin.

IM-SEA-1

10-12-17 / Rev. 1

Page 7 of 16

TRAVEL CAM & TORQUE SWITCHES ADJUSTMENT

Travel Cam Adjustment –SEA 8 - SEA310

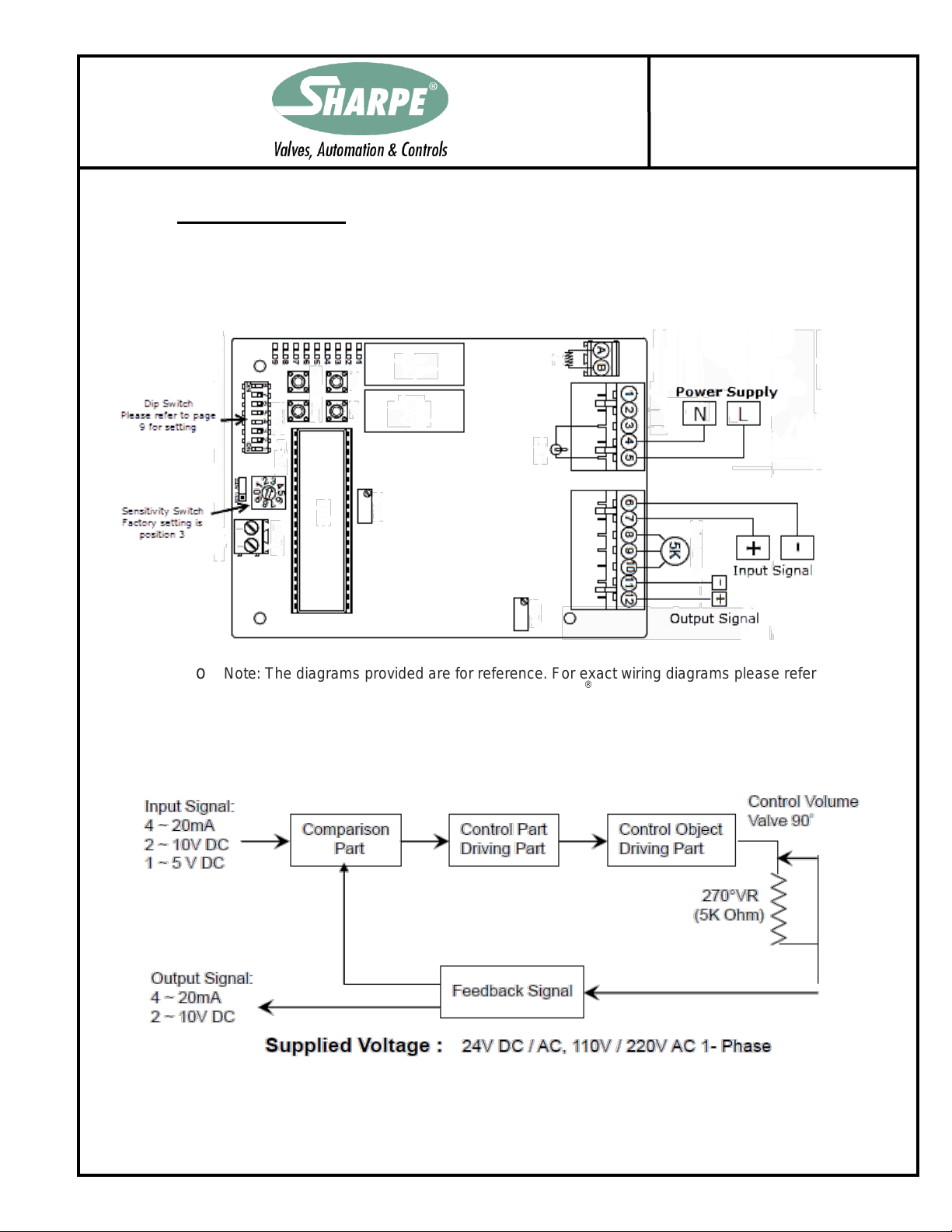

MODULATING CONTROL BOARD

INTERFACE

SEA 3 –SEA4

It is the responsibility of the customer to determine the suitability of Sharpe®Valves products in their particular application.

Disclaimer: Supplier shall not be liable or responsible for omissions or errors in its bulletin.

IM-SEA-1

10-12-17 / Rev. 1

Page 8 of 16

MODULATING CONTROL BOARD

INTERFACE (cont.)

SEA 8 –SEA 310

o Note: The diagrams provided are for reference. For exact wiring diagrams please refer to the

manual provided with the actuator or contact Sharpe®directly.

MODULATING CONTROL BOARD PROCEDURE

It is the responsibility of the customer to determine the suitability of Sharpe®Valves products in their particular application.

Disclaimer: Supplier shall not be liable or responsible for omissions or errors in its bulletin.

IM-SEA-1

10-12-17 / Rev. 1

Page 9 of 16

DIP SWITCH SETTING

IMPORTANT: DO NOT ALTER SWITCH POSITIONS WHILE ACTUATOR HAS POWER

S1 & S2:

o INPUT SIGNAL SELECT

4~20m/A set 1-ON / 2-OFF.

1~5V set 1-OFF / 2-OFF.

2~10V set 1-OFF / 2-ON

S3 & S4 & S5:

o OUTPUT SIGNAL SELECT

2-10V set 3-ON / 4-OFF / 5-ON.

4-20m/A set 3-OFF / 4-ON / 5-OFF.

It is the responsibility of the customer to determine the suitability of Sharpe®Valves products in their particular application.

Disclaimer: Supplier shall not be liable or responsible for omissions or errors in its bulletin.

IM-SEA-1

10-12-17 / Rev. 1

Page 10 of 16

DIP SWITCH SETTING (cont.)

Position Select:

o S6 ON

4mA, 2V, 1V = valve fully-open.

20mA, 10V, 5V = valve fully-closed.

S7 & S8 –Position Select when input signal fails

- Valve fully-closed set 7-ON / 8-OFF.

- Valve fully-open set 7-OFF / 8-ON.

- Valve stops set 7-ON / 8-ON or 7-OFF/ 8-OFF.

o S6 OFF

-closed.

-open.

S7 & S8 –Position Select when input signal fails

- Valve fully-closed set 7-OFF / 8-ON.

- Valve fully-open set 7-ON / 8-OFF.

- Valve stops set 7-ON / 8-ON or 7-OFF/ 8-OFF.

Even if S6 is adjusted, the feedback signal will not change.

SENSITIVITY SWITCH

Setting

o When switch is set to “1”:

The Highest Sensitive and the 0~90 degree can be divided up

to around 50 times movement.

o When switch is set to “0”:

The Lowest Sensitive and the 0~90 degree can be divided up

to around 10 times movement.

o The sensitivity decreases 5 times movement by sectors from SW1 to

SW2, SW2 to SW3, SW3 to SW4 and so on.

It is the responsibility of the customer to determine the suitability of Sharpe®Valves products in their particular application.

Disclaimer: Supplier shall not be liable or responsible for omissions or errors in its bulletin.

IM-SEA-1

10-12-17 / Rev. 1

Page 11 of 16

OPEN AND CLOSE SETTING

(SEA 3 & SEA 4)

The settings are set at factory, though in some cases re-set may be required when a

particular rate of signal is requested

Settings for OPEN and CLOSE

o The function of VR

Adjust output signal/input signal

- VR1—Adjust 10V, 20mA (Input signal: fully-open)

- VR51—Adjust 10V, 20mA (Output signal: fully-open)

- VR2 —Adjust 2V, 4mA (Input signal: fully-closed)

- VR52 —Adjust 2V, 4mA (Output signal: fully-closed)

Note: If it is necessary to adjust VR51 and VR52, VR1 and VR2 also need to be adjusted accordingly.

o Rotate VR1 counterclockwise until a light click is heard, then supply 10V (or

20mA) to modulating board. Slightly rotate VR1 clockwise until green LED keeps

on. Adjust VR51 to complete.

VR51:

-

-

o Rotate VR2 clockwise until a light click is heard, then supply 2V (or 4mA) to

modulating board. Slightly rotate VR2 counterclockwise until red LED keeps on.

Adjust VR51 to complete.

VR52:

-

-

It is the responsibility of the customer to determine the suitability of Sharpe®Valves products in their particular application.

Disclaimer: Supplier shall not be liable or responsible for omissions or errors in its bulletin.

IM-SEA-1

10-12-17 / Rev. 1

Page 12 of 16

OPEN AND CLOSE SETTING (cont.)

(SEA 8 & SEA 310)

The settings are set at factory, though in some cases re-set may be required when a

particular rate of signal is requested

Open Setting

o Keep pressing “SET” for 2 seconds, then LD 9 comes on, it will enter to the

manual mode.

o Keep pressing “UP” until actuator runs to fully-open position, LD2 comes on,

then supplies the input signal (5V or 10V or 20mA).

o Press “MODE” once. The OPEN setting is completed.

Close Setting

o Keep pressing “DOWN”, until actuator runs to fully-closed position, LD1

comes on , then supplies input signal (1V or 2V or 4mA).

o Press “MODE” once. The CLOSE setting is completed.

After completing the above settings, press “SET” once

Adjust Output Signal

o VR2:

MECHANICAL STOPS

Mechanical stops should only be reached during manual operation. They are

factory set, though in some cases adjustment may be required once a valve is fitted.

For Electric Operation:

o Please refer to Travel Cam & Limit Switches Adjustment section of this

document.

It is the responsibility of the customer to determine the suitability of Sharpe®Valves products in their particular application.

Disclaimer: Supplier shall not be liable or responsible for omissions or errors in its bulletin.

IM-SEA-1

10-12-17 / Rev. 1

Page 13 of 16

MECHANICAL STOPS (cont.)

For Manual Operation:

o Set the open stop.

Remove power from actuator.

Loosen locknut on the open stop stud (left side) and unscrew it a few

turns.

Unscrew the stop stud.

Manually turn the actuator to the desire limit position.

Screw in the stop stud until it contacts the internal cam, then reverse one

rotation.

Tighten the locknut.

Check that the electrical limit switches can still be reached.

o Set the close stop.

Remove power from actuator.

Loosen locknut on the close stop stud (right side) and unscrew it a few

turns.

Unscrew the stop stud.

Manually turn the actuator to the desire limit position.

Screw in the stop stud until it contacts the internal cam, then reverse one

rotation.

Tighten the locknut.

Check that the electrical limit switches can still be reached.

Failures to ensure the electrical limit switches are reached before the mechanical stops are

hit, when operating in electric mode, can cause personal injury or damage to the actuator.

It is the responsibility of the customer to determine the suitability of Sharpe®Valves products in their particular application.

Disclaimer: Supplier shall not be liable or responsible for omissions or errors in its bulletin.

IM-SEA-1

10-12-17 / Rev. 1

Page 14 of 16

LAMP SIGNALS

It is the responsibility of the customer to determine the suitability of Sharpe®Valves products in their particular application.

Disclaimer: Supplier shall not be liable or responsible for omissions or errors in its bulletin.

IM-SEA-1

10-12-17 / Rev. 1

Page 15 of 16

TROUBLE SHOOTING

On-Off controller:

.

.

.

.

It is the responsibility of the customer to determine the suitability of Sharpe®Valves products in their particular application.

Disclaimer: Supplier shall not be liable or responsible for omissions or errors in its bulletin.

IM-SEA-1

10-12-17 / Rev. 1

Page 16 of 16

TROUBLE SHOOTING (cont.)

Modulating controller:

This manual suits for next models

12

Table of contents

Popular Controllers manuals by other brands

Malmbergs

Malmbergs 99 170 21-23 instruction manual

Panasonic

Panasonic FP-XH Series user manual

Ingersoll-Rand

Ingersoll-Rand 150BMPC Series Installation and maintenance information

Wisy

Wisy ZETA 02 operating instructions

Kramer

Kramer SL-12 user manual

Motor Company Warehouse

Motor Company Warehouse SDS075OC400V10 user guide

Curtiss-Wright

Curtiss-Wright EL30 Installation and service manual

Johnson Controls

Johnson Controls SNC Series installation guide

Ultraflex

Ultraflex B47 installation instructions

BEA

BEA Hunter LO-LINX Wiring diagram

DEEP SEA ELECTRONICS

DEEP SEA ELECTRONICS DSE8620 operating manual

Fuji Electric

Fuji Electric ALPHA7 user manual