Shelbourne SB 150 User manual

Shelbourne Reynolds Engineering Ltd

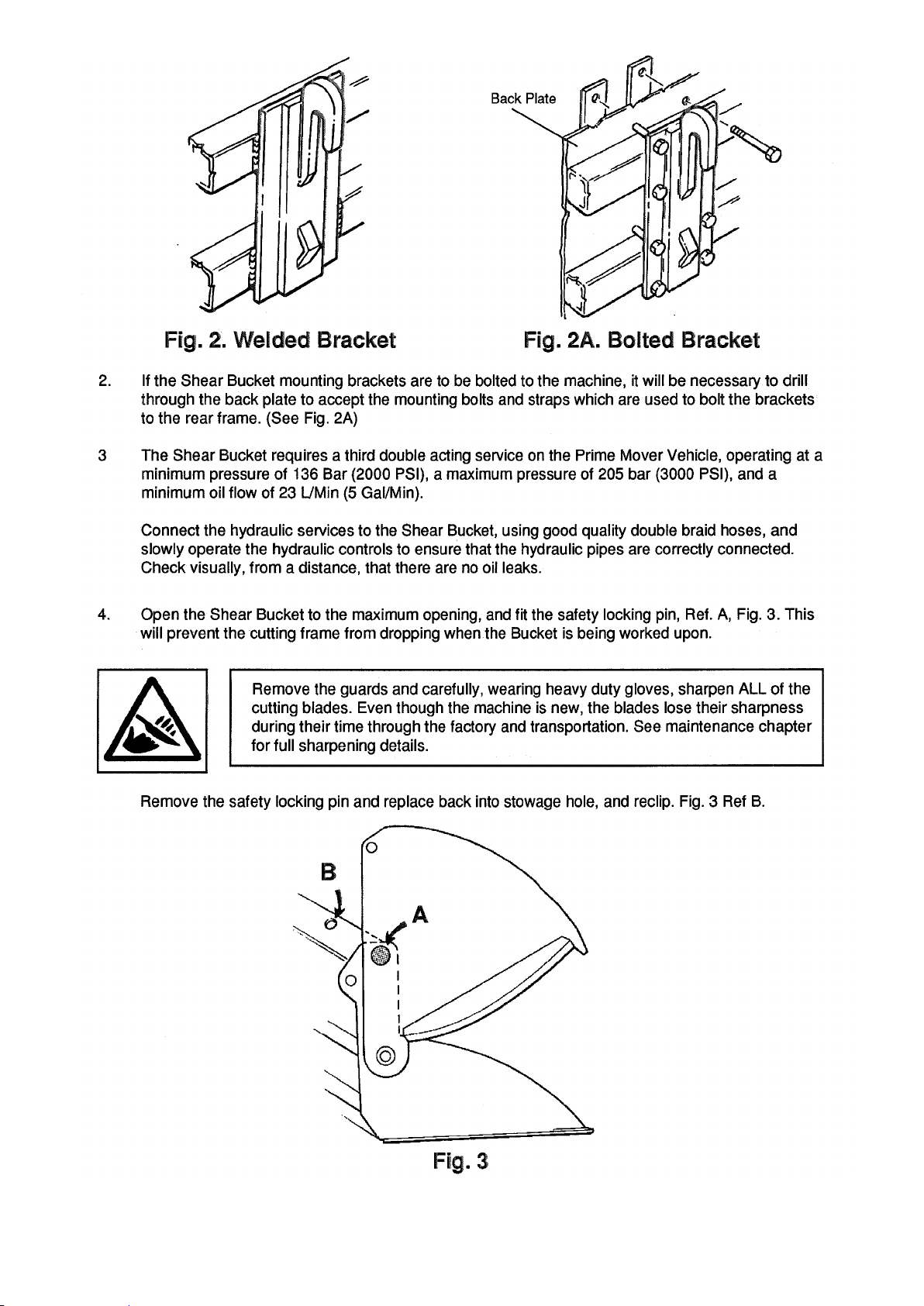

Stanton

Bury St Edmunds

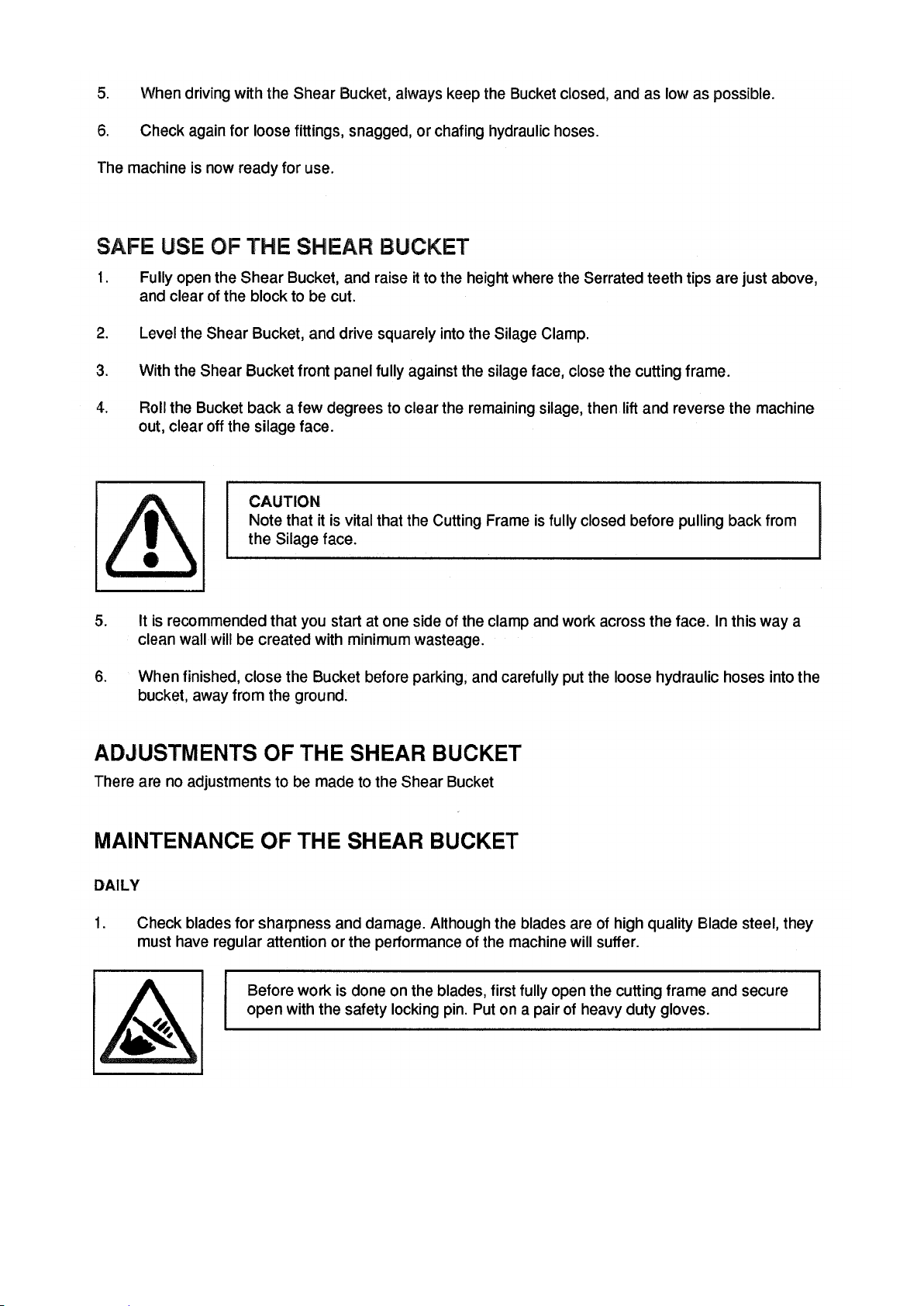

Suffolk

IP31 2AR

England

Telephone: 01359 250415 Stores Direct : 01359 251231

Fax: 01359 250464 Stores Direct: 01359 252031

Issue 12 26/11/2018

SHEAR BUCKET

www.shelbourne.com

2163 0108

All MODELS

PARTS & OPERATORS MANUAL

SHEAR BUCKET

ORDERING SPARE PARTS

IMPORTANT

Your Shear Bucket is a made up of a Machine assembly number

(common parts), specific sub assemblies and also customer optional build

kits. The machine, sub assemblies and optional kit numbers are listed in

the front pages of your Operators manual, part no. 2163 0108.

If you do not have these numbers please contact Shelbourne Reynolds Parts

Department direct on (telephone) 01359 251231.

To ensure that you order the correct part from your SRE dealer please use

the following procedure.

ALWAYS QUOTE THE MACHINE AND SERIAL NUMBERS WHEN ORDERING.

Refer to the Parts Manuals front page/s, listing the machine assemblies.

Select the correct machine assembly number which is printed in the top left

corner of the page (starting with 2599_ _ 01), This machine number can

also be taken off the Shear Bucket identification plate located on the front

of the main chassis beam.

On this page you will find the parts listing for the common parts for every

configuration of that machine assembly number.

You will find the corresponding drawing by either looking at the facing

page or progressing through the manual to the next drawing.

The drawings indicate the components by item numbers, which you will

find, are repeated in the left-hand side of your parts listing, and therefore

referring to the correct part.

Note all parts will not be found listed below the machine number. Other

parts will be from specific sub assemblies and optional kits. These sub

assemblies and kits will be found in numerical order further through the

manual.Sub assemblies start with 2590_ _ 01 and kits start with

KIT- 25 _ _ _.

PLEASE TICK APPROPRIATE COLUMN FOR EACH ITEM UNDERTAKEN

Dealer Pre Customer Delivery / Installation / Commissioning Checks OK Adjusted

Ensure the shear grab / bucket is correctly mounted to the prime mover vehicle.

Check & tighten if necessary all tine nuts (Shear Grab only).

Check & tighten if necessary both main pivot securing nuts (Shear Bucket only).

Ensure that the combined weight of the Shear Grab/Bucket and the heaviest silage

load does not exceed the safe working load of the prime mover vehicles front axle,

wheels & tyres.

Ensure Prime mover vehicle has a load holding facilty on the hydraulic system.

(Load holding valve kit available –Order Part No: KIT-25020)

Ensure the hydraulic pressure of the prime mover vehicle does not exceed 210 bar

(Relief valve kit available –Order Part No: KIT-25021)

Remove blade guards and SHARPEN ALL THE CUTTING BLADES.

Ensure the hoses are not taught when the Shear Grab / Bucket is connected to the

prime mover vehicle.

Check operation of hydraulic service.

Check hydraulic system for leaks.

Grease pivot points and hydraulic ram pivot bushes.

Ensure cutting frame locking pin is supplied. (Shear Bucket only)

Check paintwork & finish.

Ensure that all safety decals are fitted.

Ensure that an operator’s manual is supplied with the machine.

Additional Comments:

Dealer Representative’s Name:

Date:

Customer Instruction Actioned

Explain the correct operation of the machine to the customer.

Ensure the maintenance schedule is explained to the customer.

Ensure the lubrication & grease points are indicated to the customer.

Ensure all safety precautions & safety signs are explained to the customer.

Ensure the warranty policy is explained to the customer.

Ensure that the operator’s manual is handed to the customer.

Additional Comments:

Dealer Representative’s Name:

Date:

For specific details please refer to the operator’s manual.

Dealer’s pre-delivery/installation check

IMPORTANT

All items listed on the left must be checked, and adjusted if necessary. The person conducting the

inspection should tick each item in the space provided, indicating whether or not adjustments were

required. In the event of additional work being needed, details should be given in the additional work

/ discrepancy box, located at the bottom of this sheet, or on a separate sheet if required.

When the inspection is complete, THIS FORM MUST BE COPIED & RETURNED TO:- Shelbourne

Reynolds within 30 days of delivery to customer, otherwise the invoice date to the dealer will be

deemed to be the start date for the warranty period.

Dealer Pre-delivery / Installation check and warranty registration –Shear Grab / Bucket

This page must be faxed or e-mailed to Shelbourne Reynolds Engineering ltd.

Fax No: - +44 (0)1359 250464. E-mail: - warranty@shelbourne.com

Dealer signature:_________________________________________________________________

Print Name:_____________________________________________Date:_____________________

Customer’s signature:_____________________________________________________________

Print name:_____________________________________________Date:_____________________

The customer’s signature certifies that the machine was delivered in a satisfactory condition

and that adequate instruction was received as to its correct operation, safety requirements,

and maintenance as stated in the operator’s manual, and that the customer has read,

understood, and agrees to the Terms and Conditions of Sale and Warranty (including the

disclaimers and limitations) contained in Section 1.5 of the operator’s manual.

Additional work / discrepancies:

SERIAL NUMBER: ______________________ MACHINE NUMBER: ________________________

MODEL: _______________________________

Dealer Name: ___________________________________________________________________

Address:

_______________________________________________________________________

_____________________________________________Post / Zip code:

_____________________

Dealer Salesman Name:

___________________________________________________________

Customer Name: _________________________________________________________________

Business Name (if different from above):_______________________________________________

Address: ________________________________________________________________________

_______________________________________________________________________________

_____________________________________________Post / Zip code: _____________________

Email Address:___________________________________________________________________

Tel No. Home / Office:__________________________ Cell / Mobile:_________________________

Issue 1 21/03/2016

3

EC Declaration of conformity for machinery

(Machinery Directive 2006/42/EC, Annex II., sub. A)

Manufacturer : Shelbourne Reynolds Engineering Ltd.

Address : Shepherds Grove Industrial estate,

Stanton,

Bury St Edmunds,

Suffolk.

England.

IP31 2AR

Name and address of the person (established in the European Community/EEA)

authorised to compile the technical file (to the authorities on request):

Name : Mr. Neil Smith

Address : As stated above.

Herewith we declare that : DESIGNATION: SILAGE SHEAR BUCKET

MODEL:

TYPE:

MACHINE No.:

SERIAL No.:

is in conformity with the relevant provisions of the Machinery Directive (2006/42/EC)

Neil Smith

Director

Place : Stanton, England. Date :

Dear Customer,

Thank you for purchasing a Shelbourne Parmiter Shear Bucket.

Shelbourne Parmiter have produced this Product Manual in line with the relevant essential

Health and Safety regulations to help you achieve the very best from your machine, without

harm to yourself. You should be aware that any other person operating your machine with your

permission must be given adequate guidance and information to allow him, or her, to use the

machine safely.

Where as every effort has been made to ensure that the Shear Bucket conforms to Shelbourne

Parmiters policy of quality, the machine cannot be expected to withstand abuse caused by

misuse and negligence by the operator.

INTRODUCTION

The Shear Bucket is designed to both cut and hold blocks of Silage or other forms of animal

feed, and then used to unload into suitable feeding arrangements. The bottom base has wear

strips on it which help protect the blade and act as scrapers to ensure a clean floor at the dump

area.

PATENTS

Produced under licence granted by William Taylor under

International Patent Application No PCT/EP94/01179

European Patent No 0693868

Australian Patent Application No 66787/94(Serial No 678245)

Canadian Patent Application No 2160454

Finnish Patent Application No 954870

New Zealand Patent No 265629

Norwegian Patent Application No 954082

South African Patent No 94/7945

UK Patent No 2292553

US Patent Application No 08/532762

CONTENTS

Page 2 Standard warranty policy

Page 4 Product specification

Page 4 Safety rules and warning label identification

Page 5 Identification of the machine

Page 5 Handling of the Shear Bucket

Page 5 Preparation for work of the Shear Bucket

Page 7 Safe use of the Shear Bucket

Page 7 Adjustment of the Shear Bucket

Page 7 Maintenance of the Shear Bucket

Page 9 Possible dangerous misuses of the Shear Bucket

1

2

STANDARD WARRANTY POLICY

NEW MACHINE WARRANTY

All new machines supplied by Shelbourne Reynolds Engineering Ltd.

(“Shelbourne”), are warranted to the original purchaser (who is not the Shelbourne

dealer), under normal use and service, to be free from defects in material and

workmanship for a period of 12 months from the date of delivery to the original

purchaser (“Warranty Period”). This limited warranty gives you specific legal rights

and is in addition to any statutory rights to which you may be entitled. Your statutory

rights are not affected by this warranty.

To qualify for the full benefit of this warranty, the dealer must ensure that the

warranty registration details have been returned to Shelbourne within 30 days

from the date of delivery. Using the machine implies the knowledge and

acceptance of these instructions and the limitations contained here in this

Manual. Shelbourne reserves the right to suspend the operation of these

warranty conditions unless and until the purchaser has paid in full for the goods

or parts in question.

WARRANTY CLAIMS

If the original purchaser:

1) gives notice in writing to Shelbourne during the Warranty Period, and within a

reasonable time of discovery, that the machine supplied does not comply with

the warranty given above;

2) gives Shelbourne a reasonable opportunity of examining the machine or the

damaged or defective parts; and

3) if requested by Shelbourne, returns damaged or defective parts (via the

original authorised Shelbourne dealer) within 30 days of notification of a defect,

then Shelbourne shall, at is option, repair or replace the defective machine or parts, or

refund the price of the defective machine in full.

If Shelbourne authorises the original purchaser to arrange a repair of the machine, all

claims for repair costs must be submitted to Shelbourne by an authorised Shelbourne

dealer within 15 days of the date of the repair on a Shelbourne Warranty Claim Form.

The submission of a claim is not a guarantee of payment. Any decision reached by

Shelbourne is final.

This Warranty Policy does not give the original purchaser any additional rights other

than those specified above. In particular, Shelbourne shall not be liable for any loss of

profit, loss of or damage to goodwill, loss of contract business or business opportunity,

or indirect or consequential loss, arising from any failure by a machine to comply with

the terms of this warranty.

LIMITATIONS AND EXCLUSIONS

Shelbourne will not be liable for the machine’s failure to comply with this warranty in

any of the following circumstances:

3

1) any repairs or modifications are carried out without Shelbourne’s prior consent

to the work being done;

2) where damage or depreciation caused by normal wear and tear;

3) where any non-genuine Shelbourne parts have been fitted or used within the

machine,

4) wilful or accidental damage, damage caused by foreign objects (e.g. stones,

metals and any materials other than those suitable for the machines intended

use).

5) where damage or depreciation is caused by neglect or failure to carry out

proper maintenance as recommended in the Shelbourne Operators Manual.

6) where damage or depreciation caused by abnormal or in-proper use in

accordance with Shelbourne recommendations and/or as per the Operating

Instructions.

7) where the original purchaser or any third party continues to use the machine

after notifying a defect to Shelbourne, or after becoming aware of such a

defect.

This warranty shall not apply in respect of:

1) chains, bearings or any other items which are considered to be a normal

wearing or consumable item; and

2) items not manufactured by Shelbourne such as trade accessories e.g. tyres,

belts, hydraulic motors, hydraulic valves, PTO shafts etc. are warranted by

their respective manufacturer.

TRANSFER OF WARRANTY

Shelbourne may at its sole discretion allow this warranty to be transferred to a

subsequent owner of the machinery for the balance of the warranty period, subject to

all of the warranty conditions being met and only with Shelbourne giving prior written

consent.

WARRANTY ON PARTS

Shelbourne warrants that any part or components supplied by Shelbourne in

accordance with this limited warranty are free from defects in material or workmanship

from the date of sale to the original purchaser for 6 months. Shelbourne will at its

option, either repair or replace the defective part free of charge. Original Purchaser

shall be responsible for labour and all freight charges to and from the place where the

warranty work is performed.

Shelbourne Reynolds Engineering Ltd. cannot be held responsible for any

failures or safety implications arising from the use of non-genuine parts. Use of

non-genuine parts may seriously affect the machine’s performance and safety

3

4

SPECIFICATIONS

Model

Unladen

Weight

Width

Depth

Height

Volume

Capacity

(kg)

Oil

Pressure

SB150

530 kg

1,15 m

0,80 m

0,80 m

0,74 m3

455 kg

136 bar

SB 200

570 kg

1,35 m

0,80 m

0,80m

0,86 m3

529 kg

136 bar

SB 250

670 kg

1,68 m

0,80 m

0,80m

1,08 m3

664 kg

136 bar

SB 300

760 kg

2.00 m

0,80 m

0,80 m

1,28 m3

787 kg

136 bar

SB 400

1450 kg

2.48 m

0.95 m

0.85 m

2.0 m3

1230 kg

136 bar

1. Always comply with safety rules as set out in the pictograms, and detailed in this Product

Manual.

2 Keep Shear Bucket closed at all times, except during maintenance of blades, and when

working.

3 The Shear Bucket must be used by the operator only, who will remain in the Prime Mover

Vehicle (Tractor, or Material Handler) during the complete working cycle.

4

Pictogram to indicate

“MAX HYDRAULIC

PRESSURE”

Pictogram to

indicate warning of

“HIGH PRESSURE

FLIUD”

5

5

WEIGHT

TOTAL

MC No.

SERIAL

No.

Kg

SHELBOURNE REYNOLDS ENGINEERING LTD

STANTON, SUFFOLK, IP31 2AR, ENGLAND

YEAR

FOR SPARE PARTS QUOTE BOTH

6

6

7

7

8

8

9

9

List Of Kit Numbers For Shear Bucket

Shear Bucket Assembly Parts List 12

Shear Bucket Hydraulics Parts List 14

259901 01 SB300 Shear Bucket 16

259901 02 SB250 Shear Bucket 18

259004 03 SB300 Hydraulic Sub Assembly 20

259004 04 SB250 Hydraulic Sub Assembly 22

259004 05 SB150 & SB200 Hydraulic Sub Assembly (Smaller Dia Rams) 24

259004 07 SB150 & SB200 Hydraulic Sub Assembly (Larger Dia Rams) 26

259006 01 SB300 Completing Kit 28

259006 02 SB250 Completing Kit 30

259007 01 SB300 Base Unit Sub Assembly 32

259007 02 SB250 Base Unit Sub Assembly 34

KIT-25020 Load Holding Valve Kit 36

KIT-25021 Pressure Relief Valve Kit 38

KIT-25050 JCB Q Fit Bracket Kit 40

KIT-25051 Manitou Bracket Kit 42

KIT-25052 Merlo Bracket Kit 44

KIT-25053 Matbro Bracket Kit 46

KIT-25054 Claas Bracket Kit 48

KIT-25055 Euro Bracket Kit 50

KIT-25056 Loader Bracket Plate Kit 52

KIT-25061 JCB Tool Carrier Bracket Kit 54

12

SHEAR BUCKET ASSEMBLY

PARTS LIST

(Parts listing for machines up to and including serial number SHB_ _120112

only. For serial number SHB_ _120113 & onwards see parts listing, assy number

259901 _ _ further through this manual.)

Item No. Part No. Description Quantity

1 4309 0118 Cutting Frame W/A (SB 150) 1

4309 0089 Cutting Frame W/A (SB 200) 1

4309 0057 Cutting Frame W/A (SB 250) 1

4309 0075 Cutting Frame W/A (SB 300) 1

2 4309 0218 Serrated Blade W/A (SB 150) 1

4310 0162 Serrated Blade W/A (SB 200) 1

4310 0163 Serrated Blade W/A (SB 250) 1

4310 0164 Serrated Blade W/A (SB 300) 1

3 2160 2021 Centre Blade A/R

4 2160 2062 Side Blade 2

5 3309 0192 Pivot Pin 40 dia. (SB 150 & SB 200) 2

3310 0322 Pivot Pin 40 dia. (SB 250 & SB 300) 2

6 2014 6118 Hex Bolt, M12 x 90 2

7 3309 0129 Headless Pin, 30 dia. (SB 150 & SB 200 2

3309 0170 Headless Pin, 30 dia. (SB 250 & SB 300) 2

8 3309 0174 Headless Pin, 30 dia. (SB 150 & SB 200 2

3309 0128 Headless Pin, 30 dia. (SB 250 & SB 300) 2

9 2070 7061 Washer 2

10 2037 6700 Lock Nut 2

11 NIP-01000 Grease Nipple 2

12 2117 4040 Bush 4

13 3309 0062 Pin (Safety Locking) 1

14 2172 8201 Pin ‘D’ Type 1

15 2160 2050 Blade A/R

16 4309 0117 Support Frame W/A (SB 150) 1

4309 0088 Support Frame W/A (SB 200) 1

4309 0056 Support Frame W/A (SB 250) 1

4309 0076 Support Frame W/A (SB 300) 1

17 4309 0217 Wear Plates Kit (SB 150) 1

4309 0100 Wear Plates Kit (SB 200) 1

4309 0101 Wear Plates Kit (SB 250) 1

4309 0102 Wear Plates Kit (SB 300) 1

18 3309 0191 Blade Carrier (SB 150) 1

3310 0238 Blade Carrier (SB 200) 1

3310 0236 Blade Carrier (SB 250) 1

3310 0195 Blade Carrier (SB 300) 1

19 3309 0140 Carrier Support A/R

20 2160 2066 LH Support frame blade 1

21 2160 2067 RH Support frame blade 1

22 2160 2092 Front Blade (SB 150 C) 1

2160 2065 Front Blade (SB 200 C) 1

2160 2063 Front Blade (SB 250 C) 1

2160 2064 Front Blade (SB 300 C) 1

23 3309 0188 Maize Plate (SB 150) 1

3309 0168 Maize Plate (SB 200) 1

3309 0106 Maize Plate (SB 250) 1

3309 0119 Maize Plate (SB 300) 1

13

14

SHEAR BUCKET HYDRAULICS

PARTS LIST

Aluminium Manifold Type only

(For later produced machines using hydraulic Tee fittings instead of aluminium

manifold, see parts listing sub assy numbers 259004 03 –07, further through

this manual)

Item No. Part No. Description Quantity

1 2131 1038 Ram (SB 150 & SB 200) 2

2131 1066 Ram (SB 250) 2

OR CHECK RAM OUTSIDE DIAMETER 115mm (4.5”

2131 1086 Ram (SB250) 2

CHECK RAM OUTSIDE DIAMETER 127mm (5”)

2131 1086 Ram (SB 300) 2

2 2131 8127 Hose M18 1175 Long (SB150&200) 2

2131 8128 Hose M18 1325 Long (SB 250) 2

2131 8124 Hose M18 1500 Long (SB300) 2

3 2131 8115 Hose M18 750 Long (SB150&200) 2

2131 8107 Hose M18 1000 Long (SB 250) 2

2131 8110 Hose M18 1125 Long (SB300) 2

4 2130 7501 Dowty Washer 8

5 2130 4068 Adaptor M18 90o4

6 2131 7037 Manifold Block 1

7 2131 3054 Clamp Paired 2

8 2131 3055 Cover Plate 2

9 BLTA08440 Bolt 4

10 2061 3001 Grease Nipple 4

11 2170 9067 Hose Clip

12 2131 2020 Seal Kit for Ram 21311038 (SB150&200) A/R

2131 2067 Seal Kit for Ram 21311066 (SB250) A/R

21312085 Seal Kit for Ram 21311086 (SB250&300) A/R

13 2130 4060 Adaptor M18M/M 8

14 NUT-0263 Nyloc Nut M8 4

15 WSH-0012 Plain washer M8 8

This manual suits for next models

4

Table of contents