Shenchen AMC Series User manual

Shenchen Precision Pump

Manual of AMC Series Pump Head

Baoding Shenchen Precision Pump Co.,Ltd.

Note:

Please read the manual carefully before operating the product.

Warning:

Tubing may have cracks due to wear, which results in overflow of

fluid from the tubing. In that time human body and instruments may

be harmed. So, users must check frequently and change the tubing in

time.

Please stop pump head rotating when replacing the tube or changing

the tube position, otherwise it may cause fingers or clothes got caught.

There are moving parts of the pump head inner, before opening the

upper block, it must be carried out according to the following

requirements:

Ensure the pump is isolated from the main power supply.

Ensure there is no pressure in the tubing.

If the tubing has defects, ensure the liquid in the tubing is

discharged to other containers or drain tubing.

If transferring dangerous liquid, the user must wear protective

clothing and eye protection.

Catalogue

1. Product Introduction ............................................................................. - 1 -

2. Pump Head Instruction ......................................................................... - 1 -

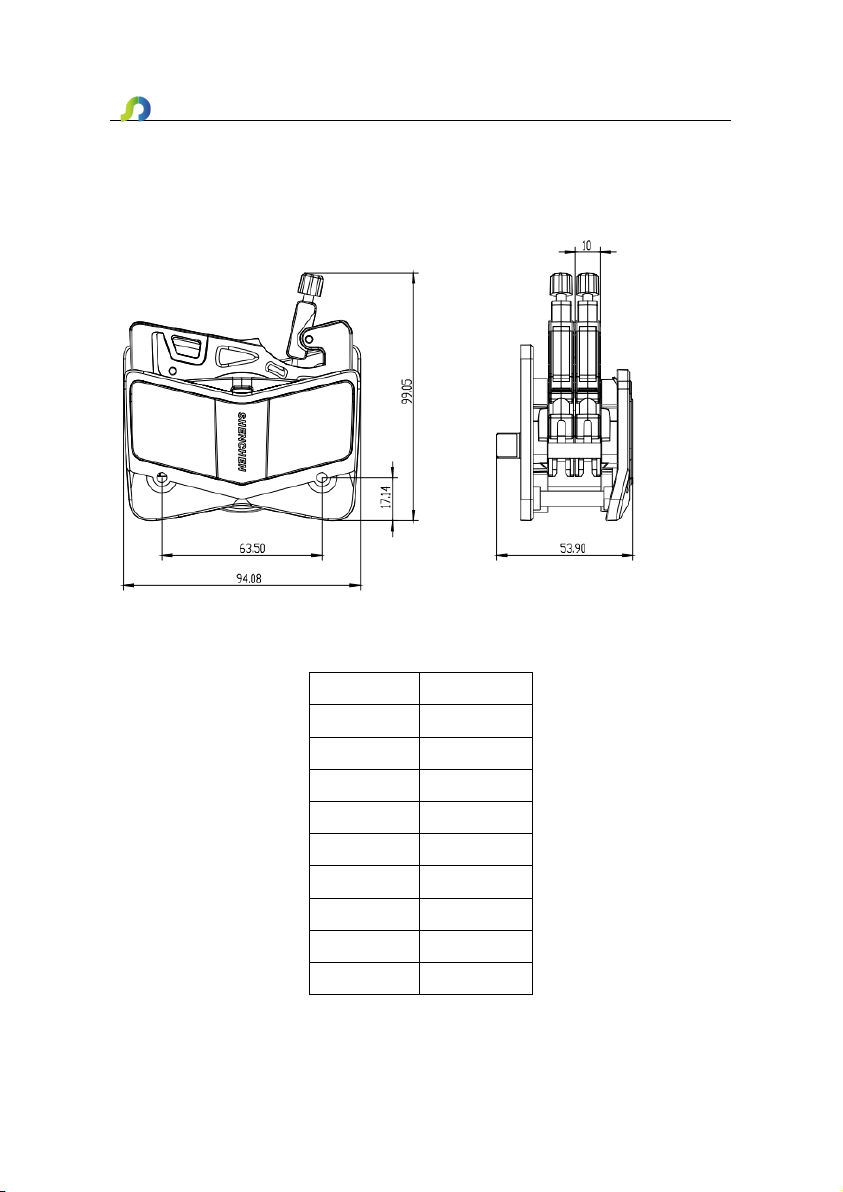

3. Dimension Drawing.............................................................................. - 3 -

4. Pump Head Technical Specification ..................................................... - 4 -

5. Function Instruction.............................................................................. - 6 -

6. Troubleshooting .................................................................................... - 7 -

7. Maintenance.......................................................................................... - 7 -

8. Warranty and After Service................................................................... - 8 -

Shenchen Pump AMC Series

- 1 -

1. Product Introduction

AMC series pump head has flexible positioning mechanism, where users can install

and remove the cartridge easily. Flexible pressure tube design to extend the service

life of the tube. Stepless adjustment of pressure tube gap to improve the transmission

accuracy between channels. 304 stainless steel roller assembly, two types of roller

structures: 6 rollers and 10 rollers. Multichannel, low flow rate transferring, compact

structure, suitable for supporting instruments.

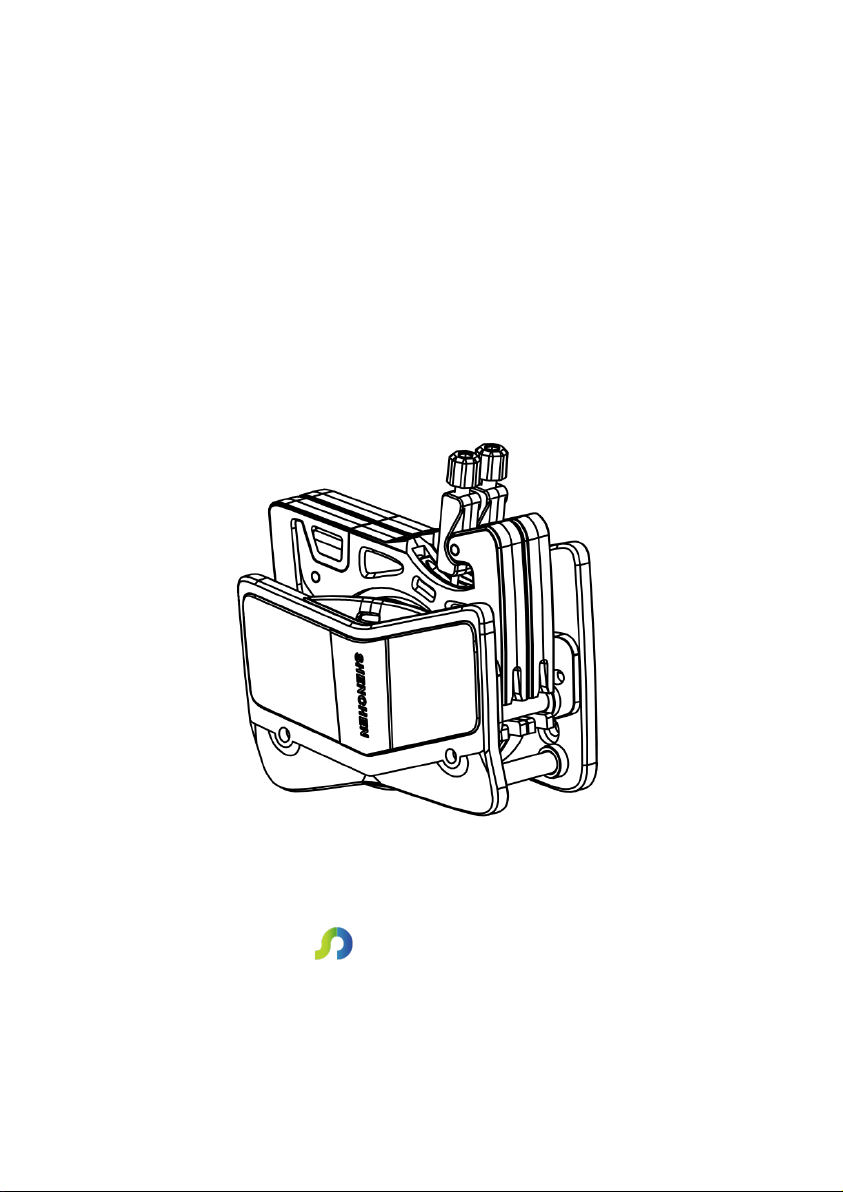

2. Pump Head Instruction

Knob

Back board

Front board

Cartridge

2.1 Pump Head Installation

Usually, the pump head is installed on the pump drive. Below is the pump head

installation instruction in case the pump head is separate from the pump drive when

you receive it. When users need to change pump head, please refer to the below

instruction:

First, remove all the cartridges from the pump head.

Connect the pump head shaft to the coupler on the pump drive. And then use 4

Shenchen Pump AMC Series

- 2 -

hexagon socket flat head screws(M4) to fix the pump head. The mounting

holes is on the back board.

Fasten the screws with a hexagon spanner.

2.2 Tubing Installation

1. Pressing elastic locking

arm mechanism to open

cartridge.

2. After the cartridge take off,

install tubing, two adjacent tube

clamps determine a working

position.

3. Install the cartridge to the

pump head, make it into the

working position.

4. Pull the lever to fix the

cartridge on the pump

head.

5. Installation finished.

Turn the knob to adjust the

pressure tubing gap

according with tubing size.

Note: It is forbidden to run the pump head without tubing.

Shenchen Pump AMC Series

- 3 -

3. Dimension Drawing

Unit: (mm)

Note: 1. Increase the thickness of one cartridge for each additional channel.

2. The number after AMC indicates the number of channels

Model type L

AMC1 43.7

AMC2 53.9

AMC3 64.1

AMC4 74.3

AMC5 84.5

AMC6 94.7

AMC8 115.1

AMC10 135.5

AMC12 155.9

Shenchen Pump AMC Series

- 4 -

4. Pump Head Technical Specification

4.1 Pump Head Technical Specification

Pump head AMC1 AMC2 AMC3 AMC4 AMC5 AMC6 AMC8 AMC10 AMC12

Channel 1 2 3 4 5 6 8 10 12

Material of

cartridge

POM/PPS

Material of

roller

304 stainless steel

Rollers 6 rollers, 8 rollers, 10 rollers

Tube size Speed

range

Pump head with 10

rollers Reference

flow rate(ml/min)

Pump head with 6

rollers Reference

flow rate(ml/min)

Tubing pressure Mpa

Intermittent Continuous

1×1

0.1-15

0 rpm

0.0050-7.55 0.0062-9.36

0.1 0.1

2×1 0.0183-27.52 0.0220-33.06

2.4×0.8 0.0238-35.76 0.0319-47.81

3×1 0.0254-48.38 0.0434-65.17

0.13×0.86 0.0002-0.29 0.0002-0.31

0.19×0.86 0.0003-0.44 0.0003-0.46

0.25×0.86 0.0005-0.76 0.0005-0.80

0.51×0.86 0.0013-2.00 0.0014-2.05

1.14×0.86 0.0030-4.47 0.0031-4.65

1.42×0.86 0.0061-9.16 0.0065-9.74

1.42×0.86 0.0125-18.75 0.0142-21.28

2.06×0.86 0.0197-29.60 0.0234-35.17

2.79×0.86 0.0286-42.86 0.0372-55.77

Shenchen Pump AMC Series

- 5 -

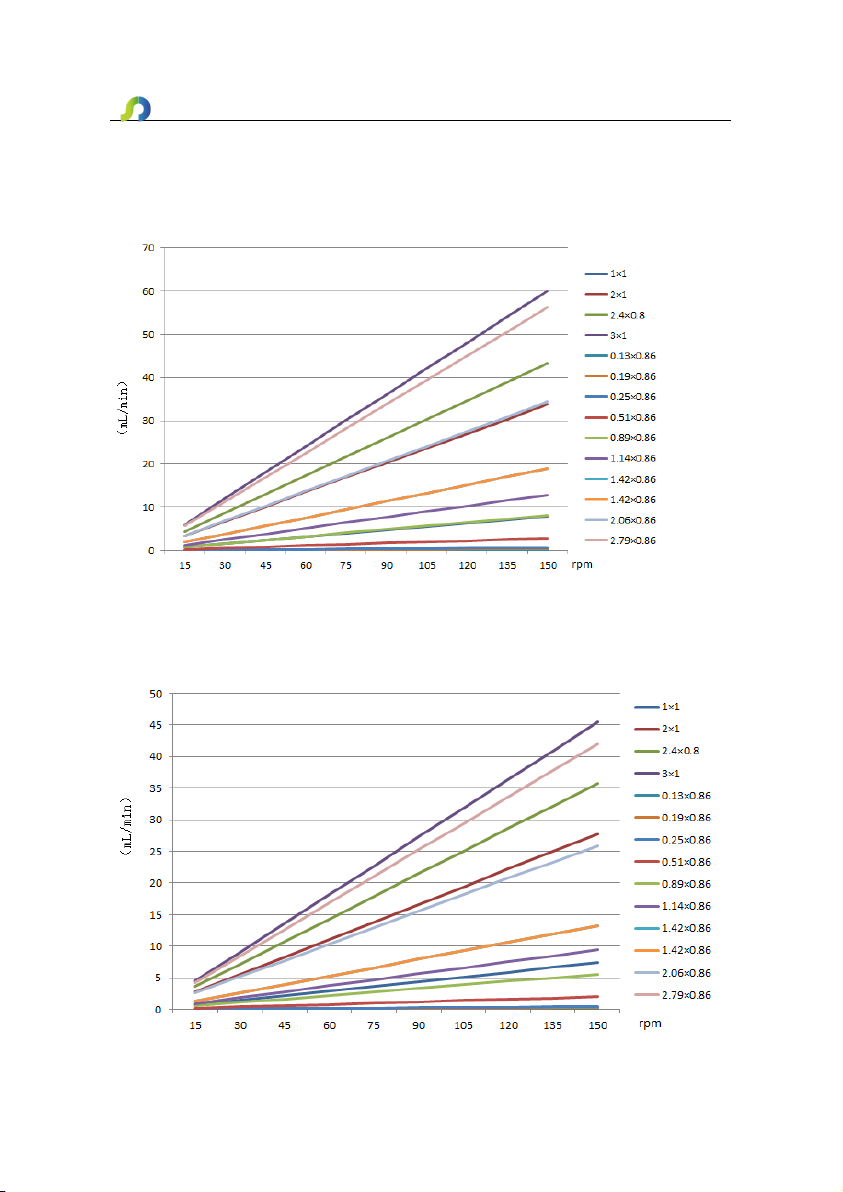

4.2 Flow Rate Chart

4.2.1 AMC1, AMC2, AMC3, AMC4, AMC5, AMC6, AMC8, AMC10, AMC12

(6 rollers) flow rate chart.

4.2.2 AMC1, AMC2, AMC3, AMC4, AMC5, AMC6, AMC8, AMC10, AMC12

(10 rollers) flow rate chart.

Shenchen Pump AMC Series

- 6 -

5. Function Instruction

Adjustment function of pressure tubing gap

Adjust the knob to adjust the pressure tubing gap, in this way you can change the

pump head and tubing outlet pressure and flow rate.

The pressure tubing gap is stepless adjustment, any position within the adjustment

range can be used normally.

Pump head pressure standard:

1) If the pump head will be used for 2*1 silicone tubing, the pressure is 0.2±

0.03Mpa.

2) If the pump head will be used for other size tubing, adjust the pressure

according with the specific tubing size.

Turn the knob clockwise, the position of the knob becomes lower, the pressure

tubing gap is reduced accordingly. And if the pump head tubing outlet pressure

increases, the flow rate becomes lower.

Turn the knob counterclockwise, the position of the knob becomes higher, the

pressure tubing gap is increased accordingly. And id the pump head tubing outlet

Shenchen Pump AMC Series

- 7 -

pressure is reduced, the flow rate become higher.

Note:

The lower the knob, the greater the outlet pressure of the pump head tubing, the

faster the tubing wears, and the shorter the tubing life. Therefore, it is not

recommended to adjust the knob too low.

Note:

1. The knob is lower, the outlet pressure on pump head tubing is greater. The faster

the tube will wear, and the shorter the tube life will be. So it is not recommended to

set the knob too low.

2. The higher the knob, the outlet pressure of the pump head tubing is lower. And the

lighter the tubing is compressed, and the easier it is to cause the problems with no

liquid or dripping from at the outlet side.

6. Troubleshooting

If the pump head is running but the flow is small or no flow, please check the

following items:

Check whether the pump is supplied with transmission liquid.

Detect whether the suction side pipeline of the pump is blocked by suction

wall.

Check if the tube is cracked.

Check for blockages or kinks in the tube.

Check whether the wall thickness of the tube used is correct.

Check whether all valves in the tube are open.

Check whether the rotation direction of the pump is correct.

7. Maintenance

When pump does not work for a long time, please loosen the cartridges from

pressing on the tubing to avoid changing the shape of tubing because of

longtime extrusion.

Keep the rollers of pump head clean and dry, otherwise it can quicken the

Shenchen Pump AMC Series

- 8 -

wearing of the tubing, reduce the useful life of tubing and lead the rollers to

damage in earlier.

Before the peristaltic pump start running, check the tubing carefully each time

to see if it is damaged.

If the pump head accidentally is exposed to water, use a soft to wipe dry to

prevent damage to the pump head.

After replacing the tube, fluid, or any connecting tube, the pump must be

re-calibrated. It is recommended to re-calibrate the pump regularly to maintain

accuracy.

8. Warranty and After Service

We support 1 year warranty for the pump head, subject to the exceptions below.

Our company shall not be liable for any loss, damage, or expense directly or

indirectly related to or arising out of the use of its products. This warranty does not

obligate our company to bear any costs of removal, installation, transportation, or

other charges which may arise in connection with a warranty claim.

If the pump fails during the warranty period, after confirmation by our technical

department, we will provide spare parts free of charge. Customers will need to

bear the shipping cost.

Exceptions:

The warranty shall not apply to repairs or service necessitated by normal wear

and tear or for lack of reasonable and proper maintenance.

All tubing and pumping accessories as consumable items are excluded.

Electrical surge as a cause of failure is excluded.

Chemical attack is excluded.

Improper operation or man-made damage as a cause of failure is excluded.

MADE IN CHINA

Baoding Shenchen Precision Pump Co., Ltd.

Address:No.103,Building

2, Zhidian Industrial Park, FuXing East Road 999, Baoding, China.

Tel: 0086- 312- 5958380

Fax: 0086-312- 6780636

Website: www.good-pump.com

Email: info@good-pump.com

Table of contents

Other Shenchen Water Pump manuals

Popular Water Pump manuals by other brands

AIRMAC

AIRMAC DB40 quick start guide

Grundfos

Grundfos LSV Series Installation and operating instructions

Simplex

Simplex G5 Air Torque Series manual

Simer

Simer 2.81E+01 owner's manual

Whale

Whale UF2025 Installation & user's instructions

Crane

Crane Barnes PS Omni Grind Plus OGP2022CO Series installation manual

Bavaria

Bavaria BDP 6535 Original operating instructions

Aquatec Equipment

Aquatec Equipment Aquapro AP550 instruction manual

Clarke

Clarke ECP20A3 Operation & maintenance instructions

BRINKMANN PUMPS

BRINKMANN PUMPS TH2 Series operating instructions

Lorentz

Lorentz PSk2 CS-F Series MANUAL FOR INSTALLATION, OPERATION, SERVICE

Predator

Predator 56718 user manual