SHENZHEN ENCOM ELECTRIC TECHNOLOGIES CO. EDS1000 series User manual

Other manuals for EDS1000 series

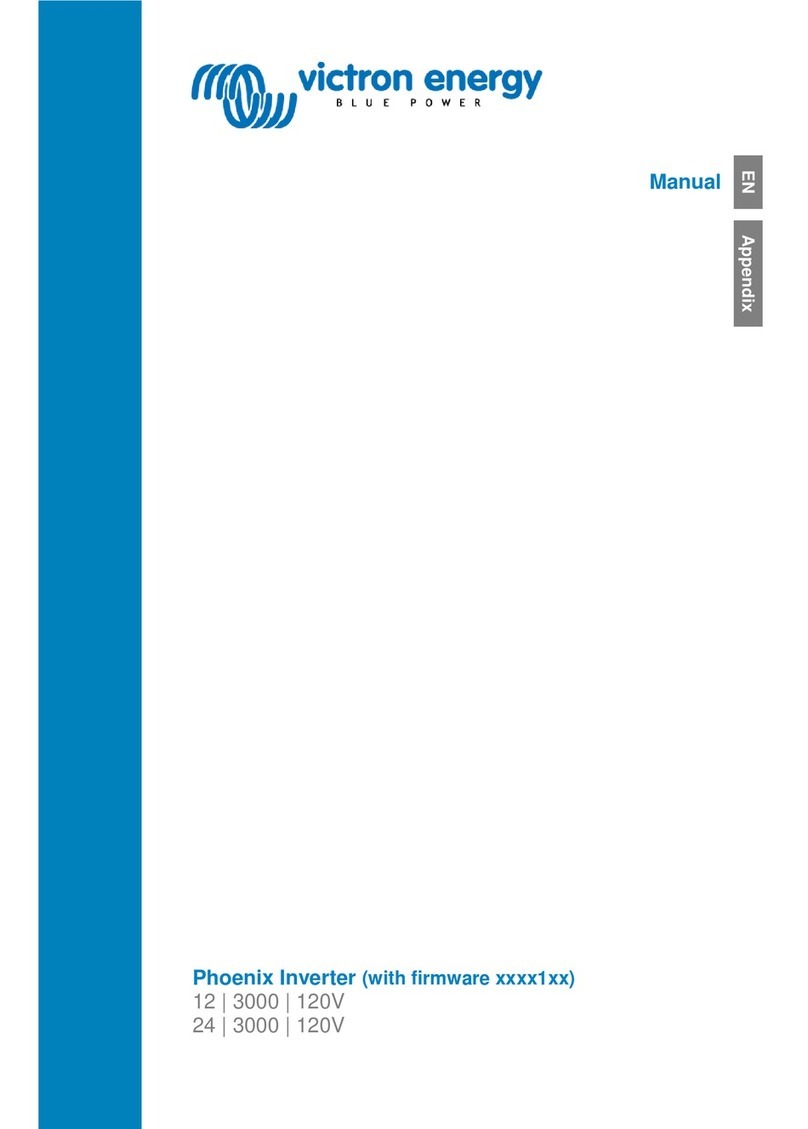

1

Table of contents

Other SHENZHEN ENCOM ELECTRIC TECHNOLOGIES CO. Inverter manuals

SHENZHEN ENCOM ELECTRIC TECHNOLOGIES CO.

SHENZHEN ENCOM ELECTRIC TECHNOLOGIES CO. EDS1000 series User manual

SHENZHEN ENCOM ELECTRIC TECHNOLOGIES CO.

SHENZHEN ENCOM ELECTRIC TECHNOLOGIES CO. enc eds800-2s0002n User manual

SHENZHEN ENCOM ELECTRIC TECHNOLOGIES CO.

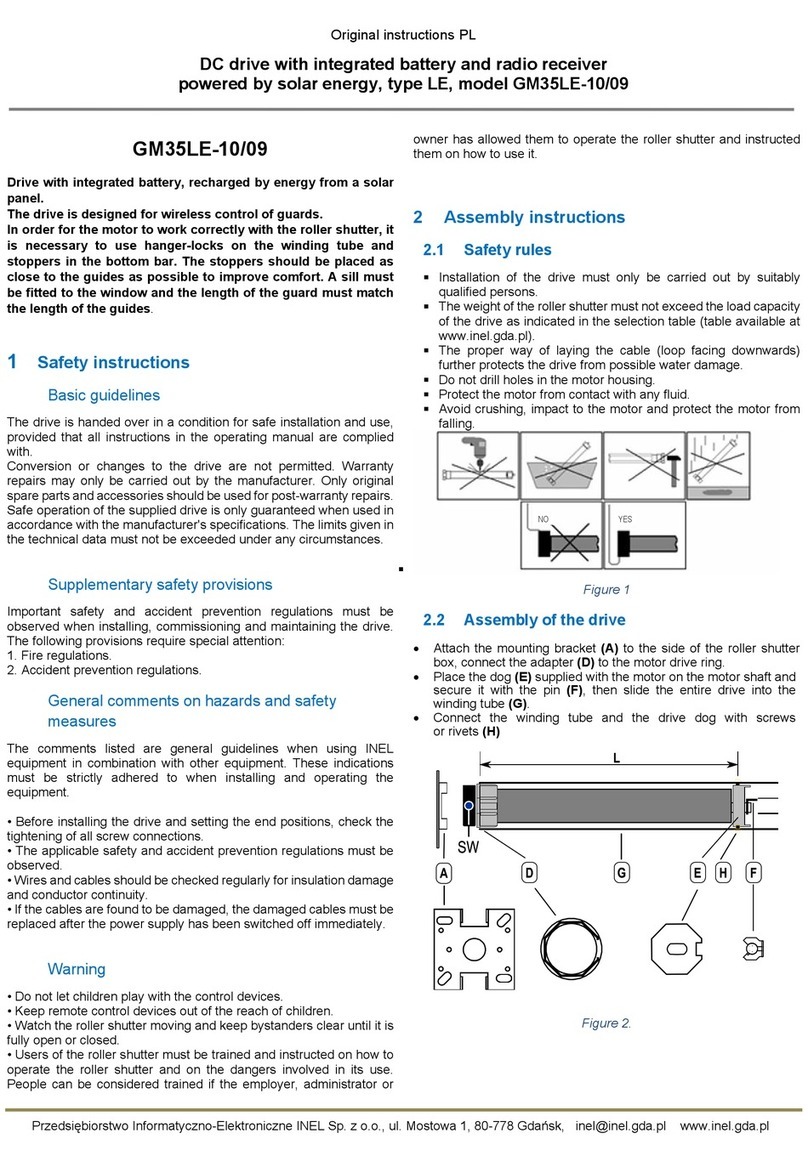

SHENZHEN ENCOM ELECTRIC TECHNOLOGIES CO. EDS780 Series User manual

SHENZHEN ENCOM ELECTRIC TECHNOLOGIES CO.

SHENZHEN ENCOM ELECTRIC TECHNOLOGIES CO. EN500 Series User manual

Popular Inverter manuals by other brands

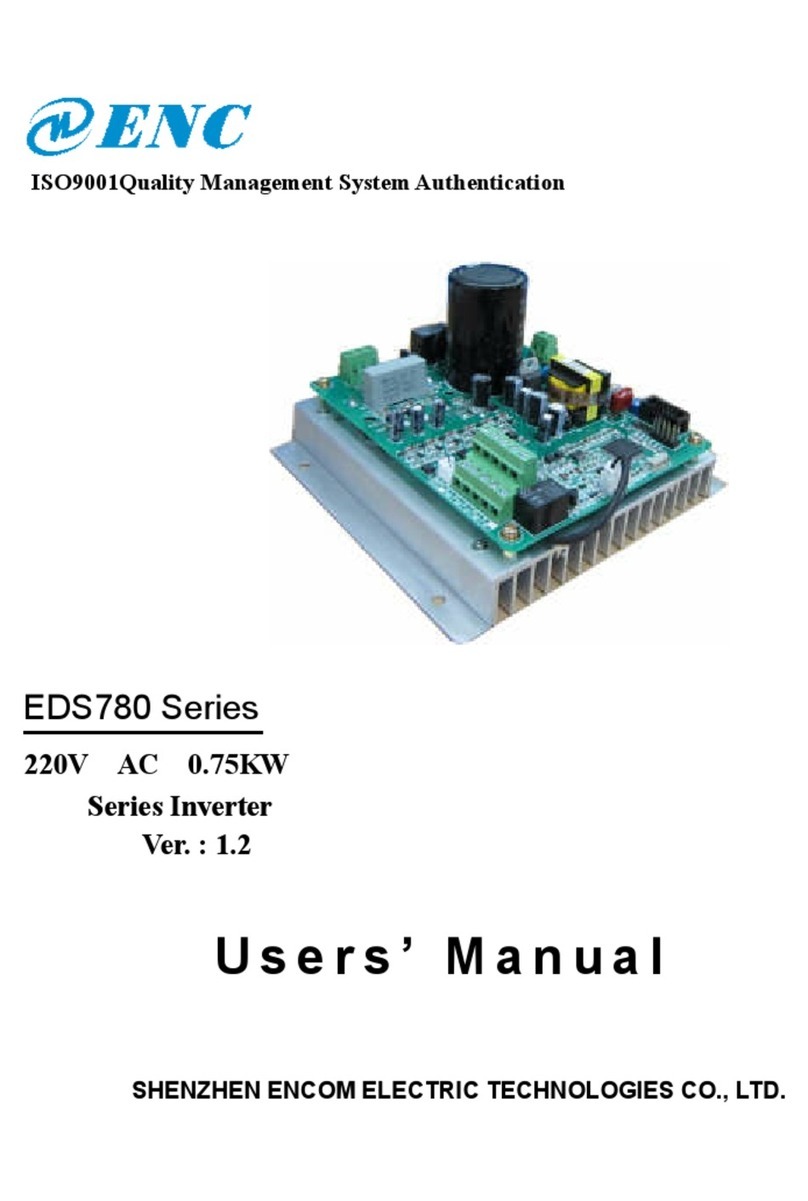

Opal Energy

Opal Energy OPAL-7.6K-1P-EU user manual

MULTIQUIP

MULTIQUIP WHISPERWELD SGW-250SS Parts and operation manual

REMKO

REMKO CMF installation manual

Victron energy

Victron energy 12 120V manual

LIFAN Power USA

LIFAN Power USA LF7250IPL-CA Operating instructions and owner's manual

Solectria Renewables

Solectria Renewables PVI 3000S Installation and operation manual

Srne

Srne HF4825U80-145 user manual

Huawei

Huawei SUN2000-28KTL user manual

DEWESOFT

DEWESOFT DS-GPS-CLOCK Technical reference manual

ECO-WORTHY

ECO-WORTHY IPT3000-21 user manual

YASKAWA

YASKAWA VS-606V7 Series instruction manual

Dometic GROUP

Dometic GROUP Waeco SinePower MSI212 Installation and operating manual