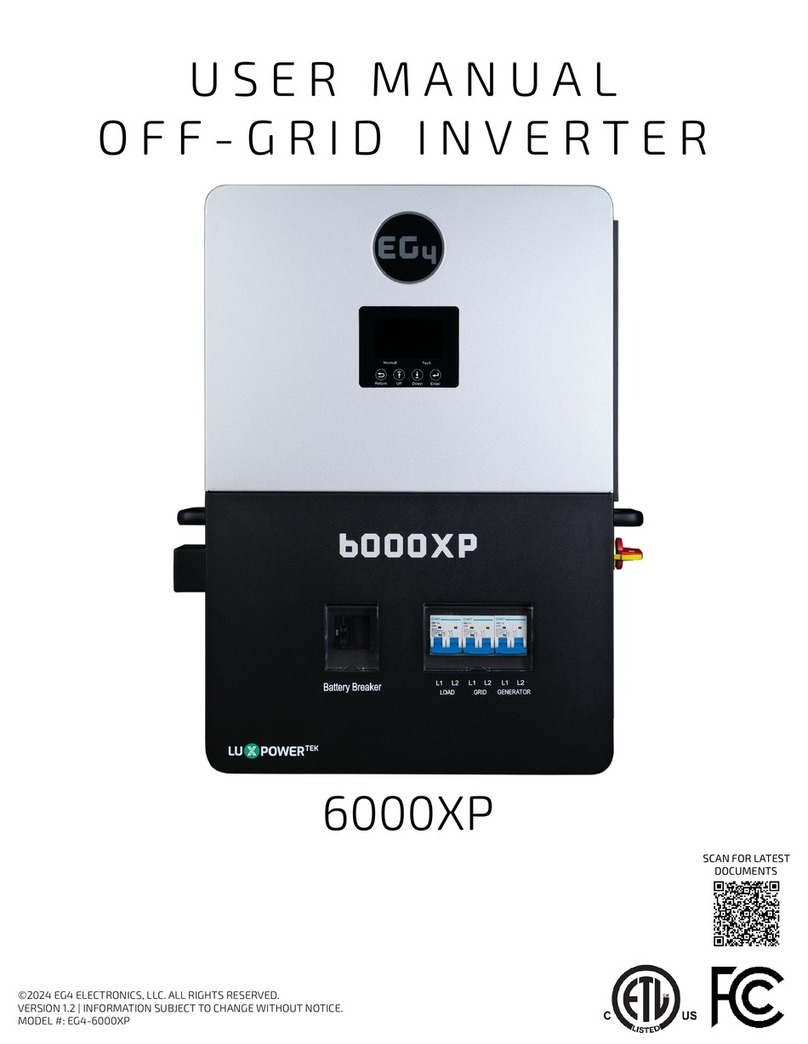

EG4 6000XP User manual

© 2023 EG4 ELECTRONICS, LLC. ALL RIGHTS RESERVED.

VERSION 1.1.7 | INFORMATION SUBJECT TO CHANGE WITHOUT NOTICE.

MODEL #: EG4-6000XP

USER MANUAL

OFF-GRID INVERTER

6000XP

SCAN FOR UPDATED

DOCUMENTS

TABLE OF CONTENTS

1. ABBREVIATIONS............................................................................................................................................................. 1

2. SAFETY ............................................................................................................................................................................ 2

2.1 SAFETY INSTRUCTIONS ..................................................................................................................................... 2

2.2 IMPORTANT SAFETY NOTIFICATIONS............................................................................................................ 2

3. BRIEF INTRODUCTION................................................................................................................................................. 4

3.1 INVERTER FEATURES ......................................................................................................................................... 4

3.2 INVERTER INTERFACE........................................................................................................................................ 5

3.3 STORAGE INFORMATION................................................................................................................................... 6

4. INSTALLATION................................................................................................................................................................7

4.1 PACKING LIST.........................................................................................................................................................7

4.2 LOCATION SELECTION AND INSTALLATION..................................................................................................7

4.2.1 REQUIREMENTS FOR INSTALLATION LOCATION .................................................................................7

4.2.2 INSTALLING THE INVERTER ...................................................................................................................... 8

4.2.3 MOUNTING STEPS ....................................................................................................................................... 8

4.3 CONNECTION OVERVIEW .................................................................................................................................. 9

4.3.1 SYSTEM CONNECTIONS ............................................................................................................................. 9

4.4 PV CONNECTION .................................................................................................................................................. 9

4.4.1 CONNECTING PV TO THE INVERTER....................................................................................................... 9

4.4.2 STRING SIZING ............................................................................................................................................ 10

4.4.3 PV WIRING INSTRUCTIONS ...................................................................................................................... 11

4.5 BATTERY CONNECTION.....................................................................................................................................12

4.5.1 BATTERY CABLE CONNECTION ...............................................................................................................12

4.5.2 LITHIUM BATTERY COMMUNICATIONS ................................................................................................13

4.6 AC WIRING INFORMATION ...............................................................................................................................13

4.6.1 STEPS FOR AC CONNECTION .................................................................................................................. 14

4.7 WORKING WITH A GENERATOR..................................................................................................................... 14

4.7.1 GENERATOR SYSTEM CONNECTION..................................................................................................... 14

4.7.2 INTEGRATED DRY CONTACTS ..................................................................................................................15

4.7.3 GENERATOR AC CONNECTIONS ..............................................................................................................15

4.8 GENERATOR START AND STOP SETTINGS ..................................................................................................16

4.9 OFF-GRID...............................................................................................................................................................16

4.9.1 OFF-GRID WIRING.......................................................................................................................................16

4.10 PARALLELING INFORMATION .........................................................................................................................17

4.10.1 PARALLEL COMMUNICATION CONNECTIONS.....................................................................................17

4.10.2 PARALLEL CONFIGURATION.....................................................................................................................17

5. END USER SETTINGS..................................................................................................................................................18

5.1 APPLICATION SETTING..................................................................................................................................... 18

5.2 CHARGE SETTING................................................................................................................................................19

5.2.1 GENERATOR CHARGE.................................................................................................................................19

5.3 DISCHARGE SETTING........................................................................................................................................20

5.4 RESET....................................................................................................................................................................20

6. INSTALLER SETTINGS ............................................................................................................................................... 20

6.1 COMMON SETTING............................................................................................................................................20

6.2 APPLICATION SETTING......................................................................................................................................21

6.3 CHARGE SETTING...............................................................................................................................................22

6.4 DISCHARGE SETTING........................................................................................................................................ 23

6.5 OTHER SETTING .................................................................................................................................................24

6.6 RESET....................................................................................................................................................................24

7. MONITOR SYSTEM SETUP....................................................................................................................................... 25

7.1 WI-FI/4G/LAN DONGLE CONNECTION ....................................................................................................... 25

7.2 THIRD-PARTY RS485 COMMUNICATION.................................................................................................... 25

7.3 ONLINE MONITORING SYSTEM USER INTERFACE...................................................................................26

7.3.1 DASHBOARD (MONITOR TAB) ................................................................................................................26

7.3.2 DASHBOARD (DATA TAB) .........................................................................................................................29

7.3.3 DASHBOARD (CONFIGURATION TAB) ...................................................................................................32

7.3.4 DASHBOARD (OVERVIEW TAB)............................................................................................................... 33

7.3.5 DASHBOARD (MAINTENANCE TAB)......................................................................................................34

8. FIRMWARE UPDATES................................................................................................................................................ 35

8.1 FIRMWARE UPDATE VIA EG4 ELECTRONICS APP..................................................................................... 35

8.2 FIRMWARE UPDATE VIA MONITOR CENTER (WEBSITE) .......................................................................36

9. SMARTPHONE APP SETUP ...................................................................................................................................... 37

10. OPERATION GUIDE .....................................................................................................................................................38

10.1 AC CHARGE MODE .............................................................................................................................................38

10.2 RAPID SHUTDOWN (RSD)............................................................................................................................... 40

10.2.1 EXTERNAL RSD WIRING INSTRUCTIONS............................................................................................ 40

10.3 LCD DISPLAY AND SETTINGS.......................................................................................................................... 41

10.3.1 LCD DISPLAY ................................................................................................................................................42

11. LCD SETTINGS .............................................................................................................................................................44

12. INVERTER START-UP AND SHUT-DOWN PROCEDURE ................................................................................... 53

12.1 START-UP............................................................................................................................................................. 53

12.2 SHUT-DOWN ....................................................................................................................................................... 53

13. ERROR/WARNING TABLES......................................................................................................................................54

13.1 ERROR DEFINITIONS AND TROUBLESHOOTING.......................................................................................54

13.2 WARNING DEFINITIONS AND TROUBLESHOOTING................................................................................. 55

14. INVERTER MAINTENANCE....................................................................................................................................... 56

15. TECHNICAL SPECIFICATIONS................................................................................................................................... 56

1

1. ABBREVIATIONS

• AWG – American Wire Gauge

• A – Amp(s)

• Ah – Amp hour(s)

• AC – Alternating Current

• AHJ – Authority Having Jurisdiction

• ANSI – American National Standards Institute

• BMS – Battery Management System

• DC – Direct Current

• DIP – Dual In-line Package

• DOD – Depth of Discharge

• EG – Equipment Ground

• EGS – Equipment Grounding System

• EPS – Emergency Power System

• ESS – Energy Storage System

• E-Stop NO – Emergency Stop Normally Open

• GE – Grounding Electrode

• GEC – Grounding Electrode Conductor

• GES – Grounding Electrode System

• Imp – Maximum Power Point Current

• Isc – Short-Circuit Current

• In. lbs. – Inch Pounds

• kW – Kilowatt

• kWh – Kilowatt-hour

• LFP – Lithium Iron Phosphate or LiFePO4

• mm – Millimeter(s)

• mV – Millivolt(s)

• NEC – National Electrical Code

• NFPA – National Fire Prevention Association

• Nm – Newton Meters

• PC – Personal Computer

• PCB – Printed Circuit Board

• PE – Protective Earth (G or Ground)

• PPE – Personal Protective Equipment

• PV – Photovoltaic

• RSD – Rapid Shut Down

• SOC – State of Charge

• STC – Standard Testing Conditions

• V – Volt(s)

• VOC – Open-Circuit Voltage

• VMP – Voltage Maximum Power

2

2. SAFETY

2.1 SAFETY INSTRUCTIONS

International safety regulations have been strictly observed in the design and

testing of the inverter. Before beginning any work, carefully read all safety

instructions, and always observe them when working on or with the inverter. The

installation must follow all applicable national or local standards and regulations.

Incorrect installation may cause:

•injury or death to the installer, operator or third party

•damage to the inverter or other attached equipment

2.2 IMPORTANT SAFETY NOTIFICATIONS

DANGER: Hazardous Voltage Circuits!

AVERTISSEMENT: Circuits à tension élevée!

There are various safety concerns that must be carefully observed before, during,

and after the installation, as well as during future operation and maintenance. The

following are important safety notifications for the installer and any end users of this

product under normal operating conditions.

1. Beware of high PV voltage. Please install an external DC disconnect switch or

breaker and ensure it is in the “off” or “open” position before installing or working

on the inverter. Use a voltmeter to confirm there is no DC voltage present to

avoid electric shock.

2. Beware of high grid voltage. Please ensure the AC switch and/or AC breaker are

in the “off” or “open” position before installing or working on the inverter. Use a

voltmeter to confirm there is no voltage present to avoid electric shock.

3. Beware of high battery current. Please ensure that the battery module breakers

and/or on/off switches are in the “open” or “off” position before installing or working

on the inverter. Use a voltmeter to confirm there is no DC voltage present to avoid

electric shock.

4. Do not open the inverter while it is operating to avoid electric shock and

damage from live voltage and current within the system.

5. Do not make any connections or disconnections (PV, battery, grid, communication, etc.)

while the inverter is operating.

6. An installer should make sure to be well protected by reasonable and

professional insulative equipment [e.g., personal protective equipment (PPE)].

7. Before installing, operating, or maintaining the system, it is important to inspect

all existing wiring to ensure that it meets the appropriate specifications and

conditions for use.

8. Ensure that the PV, battery, and grid connections to the inverter are secure

and proper to prevent damage or injuries caused by improper installation.

3

Warning: To reduce the risk of injury, read all instructions

1. All work on this product (system design, installation, operation, setting, configuration,

and maintenance) must be carried out by qualified personnel. To reduce the risk of

electric shock, do not perform any servicing other than those specified in the

operating instructions unless you are qualified to do so.

2. Read all instructions before installing. For electrical work, follow all local and national wiring

standards, regulations, and these installation instructions.

3. Make sure the inverter is properly grounded. All wiring should be in accordance with the

National Electrical Code (NEC), ANSI/NFPA 70.

4. The inverter and system can inter-connect with the utility grid only if the utility provider

permits. Consult with your local AHJ (Authority Having Jurisdiction) before installing this

product for any additional regulations and requirements for your area.

5. All warning labels and nameplates on this inverter should be clearly visible and must not be

removed or covered.

6. The installer should consider the safety of future users when choosing the inverter’s correct

position and location as specified in this manual.

7. Please keep children away from touching or misusing the inverter and relevant systems.

8. Beware! The inverter and some parts of the system can be hot when in use, please do not

touch the inverter’s surface or most of the parts when they are operating. During operation,

only the LCD and buttons should be touched.

DISCLAIMER

EG4 reserves the right to make changes to the material herein at any time without notice.

Please refer to www.eg4electronics.com for the most updated version of our manuals/spec sheets.

4

3. BRIEF INTRODUCTION

3.1 INVERTER FEATURES

•Applicable for purely off-grid inverter/backup power situations.

•Integrated with 2 MPPT solar charge controllers with maximum PV input of 480V with an

optimal range of 120VDC-385VDC.

•Additional safety features such as PV Arc Fault Protection and PV Ground Fault Protection.

•Rated for 6kW output, with a power factor of 1.

•Able to run without battery in off-grid mode.

•Able to utilize generators with dedicated generator terminals.

•Supports paralleling for up to 16 inverters.

•Supports CAN/RS485 for Lithium battery communications.

•Features remote monitoring and firmware updates via mobile phone app or monitoring

system website.

5

3.2 INVERTER INTERFACE

6

3.3 STORAGE INFORMATION

If placing the inverter into storage before installation, please keep the following factors in mind when

selecting a storage location.

1. The inverter and its components must be stored in its original packaging.

2. The storage temperature should remain within -13 – 140°F (-25 – 60°C), and humidity within 0-

85%.

3. The packing should remain upright.

4. Do not store the inverter or its packaging in direct sunlight or where there is potential for water

to accumulate.

5. See diagram below for an example.

7

4. INSTALLATION

4.1 PACKING LIST

When the product is unpacked, the contents should match those listed below:

Pictures are for reference only, subject to our available products.

4.2 LOCATION SELECTION AND INSTALLATION

4.2.1 REQUIREMENTS FOR INSTALLATION LOCATION

1. The mounting wall should be strong enough to bear the weight of the inverter.

2. Please maintain the minimum clearances presented below for adequate heat dissipation.

3. The inverter should be installed upright on a vertical surface.

8

4.2.2 INSTALLING THE INVERTER

The inverter is designed to be wall-mounted and should be installed on a vertical, solid,

mounting surface, such as brick, concrete, or other non-combustible material. Two or

more people may be needed to install the inverter due to its weight (≈53 lbs).

4.2.3 MOUNTING STEPS

Note: Ensure the surface you are mounting the inverter to can support the weight of the unit,

and has proper spacing as per the diagram on the previous page.

1. Identify where the inverter’s final placement will be.

2. Use the included cardboard template to mark where the mounting screws will be

installed.

3. Using a ruler, ensure the top left to top right marks are ≈10.63in. apart, along with the

bottom left to bottom right marks.

4. Using a ruler, ensure the top left to bottom left marks are ≈26.4in., along with the top

right to bottom right marks.

5. Place the inverter over the holes to ensure they line up with the bracket plate. Upon

confirmation, proceed to next step.

6. Drill 5/16 in. (8 mm) diameter holes on the marks, making sure the holes are deeper

than 2 in. (50 mm).

7. Insert the expansion bolts into the drilled holes.

8. Use the corresponding nuts and washers (packaged together with the

expansion bolts) to install and affix the inverter onto the wall. Use the

team-lift technique to ensure the user’s safety.

Mounting Bracket Holes

Mounting Template

9

4.3 CONNECTION OVERVIEW

4.3.1 SYSTEM CONNECTIONS

Before connecting any wiring, please remove the bottom cover by removing the 7 screws as shown

below.

4.4 PV CONNECTION

4.4.1 CONNECTING PV TO THE INVERTER

Install a separate DC circuit breaker/isolator between the inverter and PV module(s). The

recommended DC breaker is a 4-pole 600V/20A. The minimum isolator to house both positives and

both negatives if using two independent strings. If only using 1 string, a 2 pole 600V/20A

isolator/breaker is recommended. The recommended cable size for the PV connection(s) is 10 AWG

(4mm2) torqued to 1.2 Nm.

Consult with your installer to ensure that appropriate cable sizing is used due to various factors such as

voltage drop and Voc.

PV Cable Size Min. PV Disconnect/Isolator Spec

Torque Specs - PV to

Inverter

10 AWG – 6 AWG (Max)

(6mm² - 16mm²) 600V/20A 1.2Nm

10

Reminder!

Verify the lowest ambient temperature of the installation location. The rated Voc on the solar module

nameplate is obtained at STC (77°F/25°C). As the ambient temperature drops, the solar module Voc

increases. Please ensure the maximum solar string voltage, corrected at the lowest temperature, does

not exceed the inverter’s maximum input voltage of 480VDC.

PV Input Data Description

Parameter

DC Input Voltage Range Range required for the unit to operate up to max input 100–480 VDC

Load Output Minimum Voltage Minimum voltage needed to output power on Load side >140 VDC

MPP Operating Voltage Range Range where the MPPT can track 120–385 VDC

Nominal MPPT Voltage The MPPT will operate most optimally at this voltage 320 VDC

Nominal MPPT Amperage The MPPT will operate most optimally at this amperage 17A

Maximum MPPT Amperage The MPPT can accept up to this amperage (clipping will

occur past this value)

25A

Maximum Utilized Solar Power

Watts the unit can utilize from array after considering all

power loss factors

8kW

4.4.2 STRING SIZING

When solar modules are put in a series string, the voltage multiplies times the number of

modules and the amperage stays the same as each module.

For example: Using solar modules that have a 40VDC Voc (@77ºF) with a Max Power

amperage of 10 Amps (Imp) - 10 modules wired in a series string would have a Voc of 400

VDC (@77ºF) and a string amperage of 10 Amps. When the temperature lowers, the voltage

can rise above the maximum allowed by the inverter and damage will result.

CAUTION: To determine how many modules you can have per string; first verify the lowest

possible ambient temperature of the installation location. Next, find the rated Voc, Vmp, Isc and

Imp of the solar module at 77ºF and the temperature coefficients for voltage and power. Then

calculate highest possible Voc for the entire string when the ambient temperature falls to the

lowest possible ambient temperature upon sunrise. To make this calculation, use a string

calculator or consult your solar designer or solar electrician.

DANGER!

Damage WILL Occur if the string voltage exceeds the inverter’s maximum input

voltage of 480VDC!

Finally, calculate the maximum current of the string (Isc) so as not to exceed the Inverter’s

MPPT circuit ratings of 25A (see note at end of section). Double check if the calculated Vmp

range is within the 120-385 VDC optimal MPPT circuit operating range. It is recommended to

consult a solar designer for assistance.

FOR ALL MODULES, THE CALCULATIONS NEED TO BE PERFORMED OR VERIFIED BY

USING A STRING CALCULATOR OR CONSULTING A PROFESSIONAL.

The inverter has two MPPT PV charging circuits. MPPT #1 and #2 will utilize up to 17 amps, which

means two strings can be paralleled for any modules having less than 8.5A (Imp) rating.

11

When sizing strings for each MPPT, they MUST be the same model, brand and # per string

(series and parallel).

All panels on a series/parallel string should face the same orientation and be exposed to

roughly the same shading across the string. Consideration should be placed on string location

and wiring order on the racking to minimize shading effects. One shaded module can

disproportionately reduce output for the entire string so avoiding linear strings in favor of

rectangular strings can increase output. Optimizers can also achieve this.

Note: The array may have a higher Imp than the 17A specified, but the MPPTs may not make

full use of the extra current and may lead to component deterioration over time.

4.4.3 PV WIRING INSTRUCTIONS

Please follow the steps listed below to ensure proper PV connections.

Step 1: Before installing PV wiring into the inverter, please ensure all breakers and disconnects are

open (off) and confirm your PV strings are not energized by using a multimeter to ensure there is no DC

voltage on the lines. Once that has been verified, please proceed to step 2.

Step 2: Strip off 1/4 - 5/16 in. (6 – 8mm) insulation from the PV strings’ positive and negative

conductors

Note: If using fine stranded wire, use ferrules to secure the connections to the inverter.

Step 3: Insert the conduit fitting into the openings for the PV connections and tighten from the inside

using the counter nut.

Step 4: Route the PV conductors through the conduit fitting and into the inverter.

Step 5: Secure the PV conductors in place into their respective terminals and torqued to 1.2Nm. Verify

the cables are secure by lightly tugging on them.

Step 6: Ensure the conduit and conduit fittings are fastened reliably, and the cable entry holes are

sealed.

Note: All exposed metal parts of the system must be grounded regardless of voltage, including solar

panel frames.

DO NOT GROUND NEGATIVE PV LINES, ONLY SOLAR PANEL FRAMES.

Please see the diagram below for PV terminal labeling.

PV1 +/-

PV2 +/-

12

4.5 BATTERY CONNECTION

The EG4 6000XP can utilize either Lithium or Lead-Acid batteries. There is a combination of settings

that need to be changed depending on the battery type.

4.5.1 BATTERY CABLE CONNECTION

Note: For Lead Acid batteries, the recommended charge current is 0.2C

Follow the steps below to properly connect your battery wires.

Step 1: Place all breakers in the open (off) position before connecting or disconnecting wires. Ensure

that there is no DC voltage present with a voltmeter.

Step 2: Assemble battery ring terminal based on recommended battery cable and terminal size (see

table below).

Step 3: Connect all batteries as the unit requires.

Note: If using a battery rack, ensure that all battery connections are installed properly before

proceeding. Please refer to battery manual for more information.

Step 4: Connect your positive battery cable (RED) to the positive battery terminal (BAT+) and your

negative battery cable (Black) to your negative battery terminal (BAT-) with a torque rating of 4≈5 Nm

(≈36 in-lbs. - 45 in-lbs.) per connection.

Step 5: Be sure not to cross polarize, as this will damage the equipment.

Note: The recommended battery capacity of one 6000XP inverter is ≥200AH

The recommended battery cable and terminal size are as follows:

*115A @ 48VDC (AC), 125A @48VDC (PV)

Maximum

Amperage

Battery

Capacity

Wire

Size

Ring Terminal Torque

Value

Terminal

Temperature

Rating

Cable

(mm

2

)

Dimensions

Depth

Length

125A*≥200AH 1 AWG 38 6.4mm(1/2in) 39.2mm(1.5in) 80 Nm -40 - +248°F

(-40° - +120°C)

Battery

(+) / (-)

13

4.5.2 LITHIUM BATTERY COMMUNICATIONS

Upon successful installation of your batteries, follow the next steps to enable closed-loop

communications (with compatible battery modules) between batteries and inverter.

1. Connect either the CAN or RS485 (depending on make/model of battery) communications cable

between inverter and battery. See diagram below.

2. For the inverter to communicate with the battery BMS, you must change setting 3 to “Li-ion”.

The inverter will then switch to a secondary setting. Here, you select your make/model of battery

and press enter to register the change. For EG4 batteries, you would select “0” after confirming

“Li-ion” as the battery type.

Note: If needing to extend your inverter to battery communication cable or create your own, please

refer to the following table for the inverter pinout descriptions.

For battery specific pinouts, please refer to the respective battery user manual.

PIN # 1 2 3 4 5 6 7 8

CAN

Pin

Description

X

X

X

BMS_CAN H

BMS_CAN L

X

X

X

RS485 BMS_485 B BMS_485 A X X X GND

4.6 AC WIRING INFORMATION

When sizing AC wires, please adhere to the following information.

AC Cable Requirements:

Terminal Connection Wire Size Torque Values

GRID 8 AWG (10mm²) 2 Nm (18 in. lbs.)

GEN

8 AWG (10mm²) 2 Nm (18 in. lbs.)

LOAD

8 AWG (10mm²) 2 Nm (18 in. lbs.)

Ground-Neutral Bonding

The information below describes the nature of the ground and neutral in the inverter and

their relationship to the system. Always consult with your installer or a licensed electrician to

ensure that the right configuration is being used:

•The neutral line is a solid connection between AC input and AC output (known as

a Common Neutral Architecture).

•The neutral line between the AC input and AC output is never disconnected.

14

•This architecture assumes there is a single neutral-ground bond in the system. Typically, the

neutral-ground bond for a system will be at the first means of disconnect for the grid. However, if

there is no neutral-ground bond in the system, the 6000XP can be configured to create the bond

internally (see setting 26).

Note:This is not a dynamic bond. It is always enabled or always disabled.

4.6.1 STEPS FOR AC CONNECTION

Please follow the steps outlined below to ensure proper AC Input/Output connections.

Note: Always be sure to connect your AC Output ground wire to the Ground terminal bus (labelled PE

in the diagram) first before installing your AC Outputs L1 and L2.

Step 1: Before installation of any wiring, please ensure all breakers are open (off) before making any

connections. Use a multimeter to confirm your AC Input lines (L1, L2 and neutral) are not energized.

Step 2: Strip off 5/16-3/8 in. (8-10

mm) insulation from the AC cables.

Note: If using fine stranded wire, use

ferrules to secure the connection.

Step 3: Fasten the AC Input wires

into their respective terminals using

the proper torque.

Reminder!

After connecting all AC wiring, put the built-in LOAD breaker back to the ON position before

providing power to the load.

4.7 WORKING WITH A GENERATOR

4.7.1 GENERATOR SYSTEM CONNECTION

The EG4 6000XP can utilize a generator for backup power in the case of Grid failure. When sizing

generators to provide both adequate power and frequency, keep in mind that the THD (Total Harmonic

Distortion) of the generator must be <3%. It is a good rule of thumb to size your generator for at least

1.5x the output of the inverter to allow for powering loads and charging batteries. The table listed below

shows the recommended generator capacity for optimal operations.

Number of Inverters in Parallel

Generator Capacity

1

>10kW

2

>15kW

3

>20kW

4

>25kW

When properly wired and configured, the generator, if compatible with remote start, will start automatically

when the battery voltage/SOC is lower than the cut-off value or there is a charge request from the BMS.

When the generator is running, it will charge the batteries and excess AC power will be diverted to the

Standard US Wiring:

L1 – Black

L2 – Red

Neutral – White

Ground – Green

AC Input

AC Output

Generator Input

15

AC output (LOAD) to power loads. The pass-through relay on the inverter Generator terminal (GEN) is

30A. When the generator is on, please ensure the total load and charge current does not exceed 30A.

4.7.2 INTEGRATED DRY CONTACTS

This inverter has two dry contact connections that can be used to remotely enable external

devices such as a generator. The Dry Port (NO2, COM2) can be used to remotely enable an

external device when the battery voltage reaches a pre-set warning level. Similarly, the GEN

Port (NO1, COM1) can be used to remotely start a generator. To do so, the generator start

signal must be connected to the inverter GEN contacts, NO1 and COM1. The following table

shows the dry contact status under various system conditions.

4.7.3 GENERATOR AC CONNECTIONS

Please follow the steps listed below to ensure your Generator connections are installed correctly.

Note: If running more than one inverter in the system, you must wire the generator to provide power to

every inverter running in parallel for the inverters to function as intended.

Step 1: Before making any wiring connections, be sure to have the inverter(s) powered off, the

generator powered off, and all circuit breakers open (off) to prevent damage to the unit.

Step 2: Properly identify the generator’s output lines. By US wiring standards, L1 wire will be black, L2

will be red, Neutral will be white, and ground will be green. Once identified, remove ≈10mm from the

insulation sleeve on the wires.

Step 3: Ground the generator’s output ground to the Ground Bus (labelled PE) of the inverter.

Inverter

Status Condition

Dry Port

Status

GEN Port

Status

Power Off Inverter is off and no output is powered Open Open

Power On

Without Grid

Battery Voltage/SOC < Generator

Charge Start Voltage/SOC Closed Closed

Battery Voltage/SOC > Generator

Charge Stop Voltage/SOC Open Open

With Grid

Battery Voltage/SOC < Generator

Charge Start Voltage/SOC Closed Open

Battery Voltage/SOC > Generator

Charge Stop Voltage/SOC Open Open

Note: NO = Normally Open, COM = Common

Dry Port and GEN relay maximum specification: 250VAC, 5A

16

Step 4: Install L1 to the GEN port’s L1 terminal, then install L2 to the GEN port’s L2 terminal. Next,

fasten the Neutral wire from your generator into the N-BUS (Neutral Bus).

4.8 GENERATOR START AND STOP SETTINGS

Using the EG4 Monitoring Software, go to the “Maintenance” page where “Remote Set” will

be selected automatically. Scroll down to the “Generator Charge”’ section and select the

“Generator Charge Type” (see screenshot below). Normally, lead-acid batteries are charged

according to voltage and Lithium batteries are charged according to SOC.

Generator Start Conditions:

The generator will start when utility fails and one of the following conditions is met:

-The battery is discharged to the cut-off setting or

-There is a force charge request from battery or

-The battery voltage or SOC is lower than the “Generator Charge Start Battery

Volt/SOC” setting

Generator Stop Conditions:

When battery voltage or SOC is higher than the “Generator Charge End Battery Volt/SOC”

settings.

4.9 OFF-GRID

The 6000XP Inverter can fully function in Off-Grid only mode. It does not need the

utility or generator to function. Purely off-grid systems that do not have access to

the utility should strongly consider having a 2-wire start backup generator for

extended cloudy periods (8-12 kW diesel recommended per 6000XP - 8kWs

minimum per inverter). Off-Grid systems should have robust battery banks sized to

ensure multiple days of power and to reduce generator run time.

4.9.1 OFF-GRID WIRING

The 6000XP can accept up to 60 Amps (14.4kWs) of generator power and will pass

through all available power to the loads. Therefore, the Loads subpanel can be

sized up to the size of the backup generator with 60 Amp minimum per inverter.

17

4.10 PARALLELING INFORMATION

4.10.1 PARALLEL COMMUNICATION CONNECTIONS

The EG4 6000XP inverter supports parallel connections to expand power and energy capacity to suit

different usage scenarios. Up to 16 units can be paralleled to reach a capacity of up to 96kW. The

parallel communication wiring diagrams are shown below. The manual bypass switch connects the

loads to LOAD panel as default. If the inverters fail, users can switch the loads to utility.

Remember!

Put the CAN communication PIN to ON status for the first and the last inverter and OFF for

inverters in between.

Note: Both switches in the “ON” position translates to address 1. Both switches in the “OFF” position

translates to address 0.

Please contact your inverter supplier for more detailed guidance on paralleling systems.

4.10.2 PARALLEL CONFIGURATION

Important notices for parallel system:

•If utilizing the Generator input (GEN), ensure that the generator is connected to all inverters in

parallel.

•If not possible to evenly divide solar strings per inverter, it is recommended to have more PV

strings on the master inverter.

•The values shown on the LCD of each inverter displays the individual inverter’s contribution to

the system, not the system’s total.

Before commissioning:

1. Verify that all inverters in the system are updated to the latest firmware. Please contact your

distributor to confirm you have the latest version.

2. Make sure the power cables and parallel communications cables have been wired correctly, and

verify the DIP-switch settings are correct.

3. Ensure your LOAD breakers are off (open). Ensure there is no AC voltage present with a

multimeter before proceeding to the next step.

4. Power on the inverters.

5. Navigate to setting 21 to configure phasing.

6. Starting with the inverter with battery to inverter communication cable connected, change setting

21 to 1PH for split-phase parallel. The LCD will then switch to a secondary setting, Parallel

Phase. Set the inverter to P1 for phase 1. Repeat this step for all paralleled inverters.

7. Enable “Battery Shared” on all inverters in parallel.

Other manuals for 6000XP

1

Table of contents

Other EG4 Inverter manuals

Popular Inverter manuals by other brands

unicraft

unicraft PG-I SE Series operating instructions

LIGHTBOX

LIGHTBOX LIGHTBOX POWERPACK user manual

Cobra

Cobra PRO Series owner's manual

Xantrex

Xantrex XPower PowerSource Mobile 100 manual

Generac Power Systems

Generac Power Systems Guardian 04758-1 owner's manual

SunSynk

SunSynk SUNSYNK-8K-SG01LP1 user manual