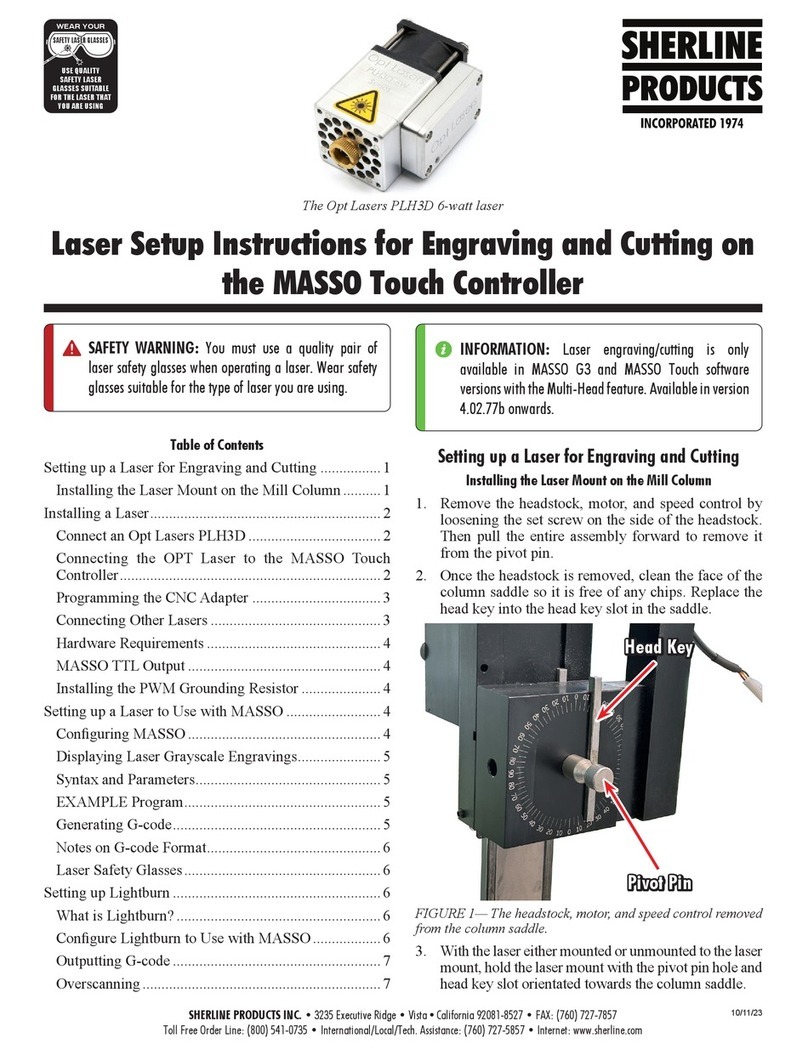

Sherline Products MASSO 8781 Installation and maintenance instructions

SHERLINE PRODUCTS INC. •3235 Executive Ridge •Vista •California 92081-8527 •FAX: (760) 727-7857

Toll Free Order Line: (800) 541-0735 •International/Local/Tech. Assistance: (760) 727-5857 •Internet: www.sherline.com

Sherline/MASSO Controller

Initial Start

11/20/19

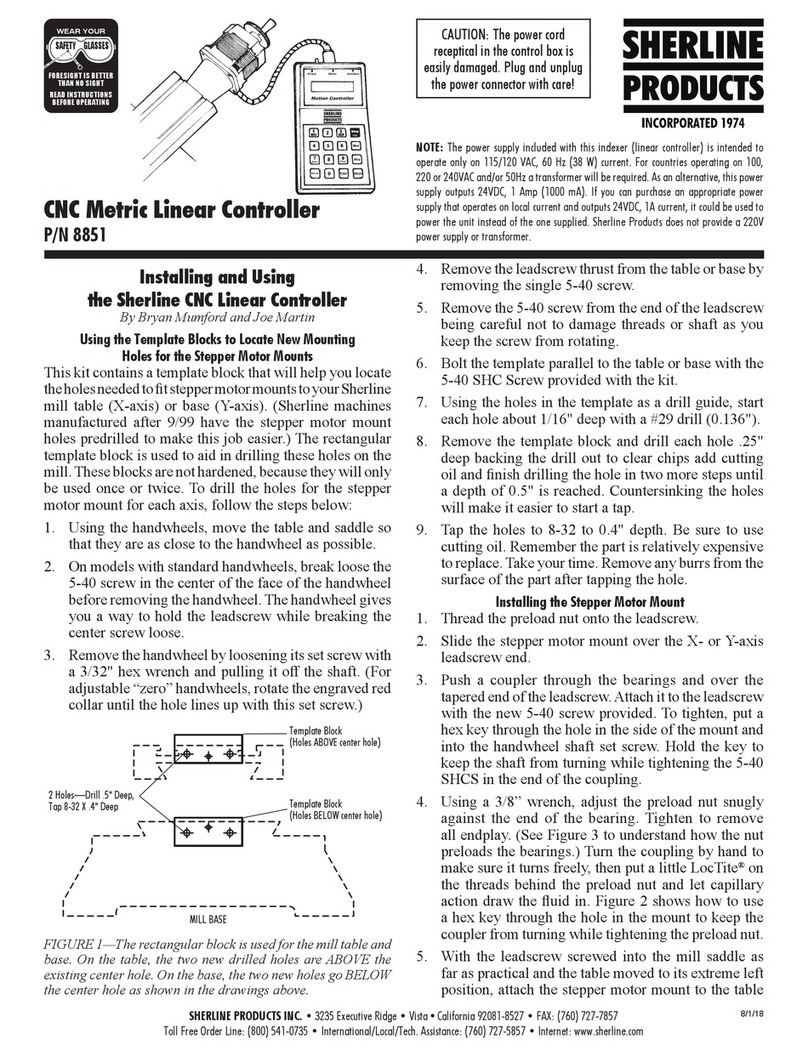

WHAT’S INCLUDED

Shown here is what comes with the Sherline/MASSO Controller for our mill package.

A lathe package will be similar except that it will have two limit switches instead

of three, and different mounting hardware.

Assembling Your System

Mill orLathe: Unpackand assemble your machine according

to the instructions included in the Sherline Assembly and

Instruction Guide packed with the your new machine.

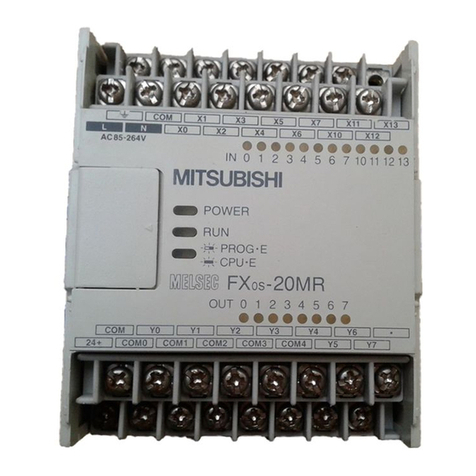

UnpacktheP/N8760driverboxandtheP/N8781Sherline/

MASSO controller box.

Set the driver box on your table rst, then set the controller

box on top of the driver box.

FIGURE 2—Front view of the controller box and the driver box.

Connect the white X, Y, and Z stepper motor cables leading

from the back of the driver box to each of the stepper motor

connectors. The axis that the cables will control are laser

engraved on the driver box (see Figure 3).Afourth cable is

unused unless you have purchased an optional CNC rotary

table, which can be connected here as a 4th (A) axis.

Sherline/MASSO CNC Controller Initial Start Instructions

Clockwise, from upper right

1. Controller box

2. 4-axis CNC driver box*

3. Wifi antenna

4. Parallel cable

5. Limit switch main cable bundle

6. USB 4 GB flash drive

7. Limit switches (with pigtail and connector)

8. Speed control cable

9. P/N 68047 Plastic plug for speed control housing

10. Tach/spindle control cable bundle

11. Optical encoder

12. Tach gap setter and cover

13. Tach spindle pulley RPM sticker

14. Tach bracket and headstock spacer (standard or 3C)

15. Ball screw mill headstock cable support (zip ties for leadscrew mills)

* NOTE: P/N 8780 includes the driver box. P/N 8781 does not include the driver box.

CAUTION—Protect your motors, cables, and driver board!

• Never connect or disconnect the optical encoder grounding cable or

the stepper motor cables with the Controller/Drive box power on.

•Do not unplug stepper motors using the rectangular white plug that

goes into the motor. Disconnect only at the cable plug.

•Do not pull on cable wires to disconnect plug—grip at connector.

• Turn handwheels slowly (1 rev/sec) with driver power OFF when

manually positioning. For longer travels use Jog Mode.

FIGURE 1—Back view of the controller box and the driver box

CUSTOMER FEEDBACK REQUEST

Afteryouhaveread alltheinstructionsand watchedallthehow-to videos,pleasefeel

freetosendusanyfeedbackso wecanimproveourMASSOcontrollerdocumentation.

1

2

3

6

7

4

8

12

11

10

13

5

14

15

9

Sherline/MASSO Controller

Initial Start

Page 2 OF 22

FIGURE 3—Each axis is laser engraved above the cable ports.

Plug in the limit switch connector, the encoder/spindle

connector, and the 24VDC power supply cable into the

backside of the controller box.

FIGURE 4—Encoder/Spindle drive cable P/N 87820

FIGURE 5—Limit Switch Cable P/N 87825

FIGURE 6—Backside of control box.

The controller and the drive box only need one power

supply. When you look at the front of the controller box

you will see the 24VDC power out connector. Plug it into

the power in connector on the drive box.

FIGURE7—Powerconnectorcablepluggedintothedriverbox.

Now take the parallel port cable P/N 87605 and plug the

female end into the driver box.

FIGURE 8— Female end of the parallel cable.

Sherline/MASSO Controller

Initial Start

Page 3 OF 22

Now plug the male end of the parallel cable into the

controller box.

FIGURE 9—Male end of the parallel cable.

FIGURE 10—The parallel cable shown plugged into both the

driver box and the controller box.

Plug your monitor cable into the monitor port (see Figure

11). The monitor port is set up for a VGA connector. If you

have an HDMI connection on your monitor, you will need

to buy a VGA-to-HDMI converter* (see Figure 12 for an

example). You can pick these up on eBay, Amazon, or at

your local electronics supplier, and most are inexpensive.

*NOTE: Make sure you purchase a VGA-to-HDMI

converter. There are many HDMI-to-VGA connectors out

there and they will not display the VGA video output signal

to your HDMI monitor.

FIGURE11—Monitorconnection.TheVGAconnectorisplugged

into the monitor port on the controller box.

FIGURE 12—Shows an example of a VGA-to-HDMI converter.

Please note that some VGA-to-HDMI converters require a USB

powered connection.

Now plug your USB dongle for your wireless mouse and

keyboard into the AUX USB connection*. You cannot use

a multi-port USB hub connector in either of the USB ports

to operate your old, USB-wired mouse and keyboard. The

software is designed to take single-source information only

from each of the USB ports. A multi-port connector will

not work. You must use a wireless USB dongle for your

peripherals.

*NOTE: We do not supply the wireless mouse, keyboard,

or dongle. There is only one USB port for your mouse

and keyboard. Make sure you buy a wireless mouse and

keyboard set.

FIGURE13—Left:close-upoftheUSBdongle;Right:thedongle

plugged into the AUX USB port.

Sherline/MASSO Controller

Initial Start

Page 4 OF 22

Now plug in your ash drive with your machine settings,

tool settings, and programs into the Program USB

connection.

FIGURE 14—Left: close-up of the Sherline 4 GB USB ash

drive; Right: the ash drive plugged into the Program USB port.

Connecting the Cables to Your Machine

Now that all ofyour cables are hooked up tothe control and

driver boxes, it’s time to connect them to your machine.

NOTE: Make sure that all power is o on the controller

and drive box before proceeding.

First we will install the headstock cable support P/N 87840.

This cable support is easy to install. It has two slots that

go onto the two 10-32 screws that hold the motor mount

to the headstock.

NOTE: This bracket is not included for “leadscrew

machines” (only ball screw machines). See instructions for

leadscrew machines at the end of this document.

FIGURE 15—P/N 87840 mill headstock cable support.

Loosen these two 10-32 screws about three turns.

FIGURE 16—The red arrows indicate the screw locations.

This should give you a large enough gap between the

motor bracket and the headstock for the cable support to

t in easily.

FIGURE 17—The photo above shows the gap between the

headstock and the mounting bracket.

Now position the cable support so the slotted side can be

positioned onto the 10-32 screws between the motor mount

and the headstock.

FIGURE 18—The red arrows show how the slots on the cable

support align to the 10-32 screws on the headstock mounting

bracket.

Sherline/MASSO Controller

Initial Start

Page 5 OF 22

Now push the cable support into place. Once the cable

support is in place, tighten the two 10-32 screws in order

to clamp the cable support between the motor mount and

the headstock.

At this point just tighten the top screw all the way, and leave

the bottom screwalone. We will beattaching the grounding

cable from the encoder cable to the bottom screw.

FIGURE 19

Below is a picture of the end of the encoder cable with the

black grounding cable.

FIGURE 20—The black grounding cable is above the encoder

cable.

Place the encoder cable on top of the column saddle

assembly with the grounding cable hanging inside of the

cable support (see Figure 21).

FIGURE21—Noticethatthegroundingcableisinsidethesupport

toward the front of the machine.

CAUTION

Any time that you connect or disconnect the grounding cable,

all power to the machine and the Controller/Drive boxes must

be off.

Failure to do so may result in a ground fault that will severely

damage the Optical Encoder.

Now push the spade connector on the end of the grounding

cable onto the 10-32 screw and between the washer and

the motor bracket.

FIGURE 22—Make sure the spade connector is located behind

the washer. The inset photos shows an alternate location for the

grounding wire on the opposite side of the headstock.

Sherline/MASSO Controller

Initial Start

Page 6 OF 22

Make sure that the spade connector is straight up and down

so it sits in the middleof the motorbracket.Also be sure that

the washer is not clamping on the insulation of the spade

connector, but directly on the metal area of the connector.

Then tighten the bottom 10-32 screw (see Figure 23).

FIGURE 23—The orientation of the grounding wire is straight

up and down.

Now that the grounding cable is mounted, we can power

up the controller. You will need access to the Setup page

on the controller in order to adjust your limit switches.

Flip the power toggle switch on the controller up, and you

should see the green power light come on.

FIGURE 24—The white arrow shows the on/o controller switch.

Now ip the power toggle switch on the driver box up, and

you should see the red power light come on.

FIGURE 25—The black arrow shows the on/o driver box switch.

When your monitor comes on, you will see the control page

below. The yellow Home icon will be ashing. The red

E-Stop icon will be ashing, and the password box will be on.

FIGURE 26—The white arrows point to the “HOME,” and

“E-STOP,” buttons.

First turn the E-stop button clockwise on the top of the

controller box to deactivate it. If you didn’t use the E-Stop

button to turn the machine o when you last used it, you

will need to push the button down to activate it rst, and

the turn it to deactivate it.

FIGURE 27—Note the clockwise direction of the arrows on the

red button.

When you deactivate the E-Stop button, the red ashing

E-Stop icon will stop blinking.

FIGURE 28—The E-stop button stops ashing red.

Sherline/MASSO Controller

Initial Start

Page 7 OF 22

Now enter the password [ SP] into the password box. The

[SP] must be ALL CAPS.

FIGURE 29

At this point you would normally home out your machine.

Instead of homing the machine, we are going to go to the

Setup page so you can see the input signals from your

encoder and your limit switches.

FIGURE 30—At the bottom left-hand corner, you will see the

“F1 Setup,” button. Click on it and the setup page will come up.

Mounting Instructions for the Encoder

Tach Decal for the Optical Encoder

First, place the Tach/Encoder sticker on the headstock

pulley.

Remove any dirt, oil, or grease from the mounting surface

of the pulley. You can use rubbing alcohol on a clean cloth

or paper towel.

FIGURE 31—Clean the spindle pulley surface before placing

the tach/encoder decal.

FIGURE 32—Tach/Encoder sticker P/N 68060.

The center hole on the sticker is made to t our standard

headstock pulley. If you are placing the sticker on one of

our 3C headstocks, you will need to cut out the center on

the line shown below.

FIGURE 33—The red arrow indicates the 3C spindle diameter.

Peel o the paper backing on the sticker. Then align the

sticker on the end of the spindle and lower it down onto the

pulley. If you bow the sticker slightly so the center is lower

than the outer edge, you can use the spindle to locate the

sticker. Then lower it down until the center makes contact

with the pulley area near the spindle. The location doesn’t

need to be perfect and you should be able to get it close

enough by centering it around the spindle. Once the center

has made contact with the pulley, check your centering

before there is too much surface contact and make minor

adjustments. Nowlower therestof thesticker ontothe pulley.

The outer edge should be centered with the outer edge of

the pulley as well. Now press down on the sticker with your

ngers at the center and then rub from the inside outward to

remove any bubbles or imperfections. The sticker has to be

at or it will interfere with the encoder readings.

Optical Encoder

Next we will mount, adjust, and connect the optical encoder

to the headstock.

We are mounting this encoder on one of our standard

Sherline/MASSO Controller

Initial Start

Page 8 OF 22

headstocks. The parts and the procedures are the same

for our 3C headstock with the exception of the encoder

spacer block. For thestandard headstock we use spacerP/N

87816 and mounting screws P/N 40720 (10-32 x 1-1/2"

SHCS). For the 3C headstock we use spacer P/N 87817

and mounting screws P/N 40340 (10-32 x 1" SHCS).

1

23

4

5

6

7

8

FIGURE 34—Encoder parts, clockwise from top right:

(1) P/N 87812 optical encoder cover

(2) P/N 87811 5-40 x 3/8" Phillips, button-head machine screw

(3) P/N 87810 optical encoder

(4) P/N 40530 5-40 X 3/8" SHC Screws (2 ea.)

(5) P/N 87813 .129 optical encoder gauge

(6) P/N 87816 optical encoder spacer for standard headstock*

P/N 87817 optical encoder spacer for 3C headstock**

(7) P/N 87814 optical encoder bracket

(8) P/N 40720* 10-32 x 1-1/2" SHC Screws and P/N 40660

#10 washers (2 ea.) for standard headstock spacer

P/N 40340** 10-32 x 1" SHC Screws and P/N 40660 #10

washers (2 ea.) for 3C headstock spacer

Optical encoder mount, spacer, and mounting screw

assembly (see Figure 35).

FIGURE 35—Left: side view; Right: end view.

Mounting the Optical Encoder

The power switch on the speed control must be in the

off position when the spindle is not in use.

Notice the tapered sides of the mounting bracket and the

two lines on the mating surface of the encoder.Any contact

with the encoder must be between the two white lines (see

Figure 36).

FIGURE 36—The arrows point to the two white lines on the

encoder surface.

FIGURE 37—Full assembly side view: The screws are just in

place for show. Nothing is tightened at this point.

Sherline/MASSO Controller

Initial Start

Page 9 OF 22

You may need to drill and tap the 10-32 holes on your

headstock to mount the optical encoder. If this is the case,

please go to the page 20 of this document for the Optical

Encoder Mounting Template Instructions.

FIGURE 38—Mounting hole locations on the headstock. Use

the template at the end of this document to drill and tap the

mounting holes.

The encoder assembly is mounted to the headstock (see

Figure 39), with the 10-32 screws just snug, so we can

adjust the encoder bracket to get the encoder gap set (see

Figure 40).

FIGURE 39

FIGURE 40—Encoder Gap Gauge P/N 87813.

FIGURE 41—Gap gauge placement.

With the two 10-32 bracket mounting screws loose, lower

the optical encoder down until it makes contact with the

gap gauge. Make sure that the screws are loose enough so

the optical encoder body is not exing when you lower it

into position.

Once the encoder is touching the gap gauge, put pressure

on the top of it with your nger (see Figure 42).

While pressing on the encoder, tighten the two 10-32

bracket mounting screws.

Sherline/MASSO Controller

Initial Start

Page 10 OF 22

FIGURE 42—With the gap gauge in place, apply pressure on

top of the encoder.

There will generally be some space between the encoder

and the gap gauge after you tighten the screws. This is

ne. The gap gauge is set to the middle of the LED focal

point length (.129" or 3.27 mm). Therefore, if the encoder

is slightly higher or lower than the gap gauge, it will still

be in tolerance.

Once the screws are tight, remove the gap gauge.

FIGURE 43—The red arrow shows the gap between the pulley

and the LED sensors.

FIGURE44—ShowstheLEDlightsontheencoderwiththepower

connection plugged in (Just for show). Remover the connection

until the cover is in place.

Now we are going to mount the encoder cover.

First a special note: The primary reason for the cover is

to help avoid any damage to the encoder and also to keep

oil and machine debris o of it. The second reason (which

we found out the hard way) is to avoid exterior LED light

interference with the LEDs that are on the encoder. If your

machine is in an area that has uorescent lighting, then

exterior light interference will not be a problem. However,

if you are using LED lights around your machine, such as

overhead energy saving LED lights. The exterior LED light

will bounce o of the tach/encoder sticker and cause the

encoder to receive bad light readings and send inaccurate

signals to the controller. This will cause erratic RPM and

cross threading on the lathe threading cycle.

If the encoder is positioned correctly, you will see the

signals coming into the setup page.

Click on the F1 Setup button on the lower left corner of

the screen. If you double click on the password box and

then click on the setup page, the password box will close.

A

Zero

B

FIGURE 45—On the tach sticker, the black and white sections

on the outer ring are for the A and B signals. The solitary black

section in the center area is for the Index signal.

CAUTION

Do not connect or disconnect the optical encoder connector or

the ground wire with the power on or you will do irreparable

damage to the optical encoder!

Sherline/MASSO Controller

Initial Start

Page 11 OF 22

If you turn the spindle pulley by hand starting with the

index point under the encoder, the signals will come into

the setup page. See the signal sequence below.

FIGURE 46—Starting between the index point and position 1,

the status for A, B, and Index will be Low.

FIGURE47—Turningthepulleyslowly,Signal-AwillturntoHigh.

FIGURE 48—Continue to turn and Signal-B will turn to High.

FIGURE49—Continueto turnandSignal-Awillchange to Low.

FIGURE 50—Then Signal-B will change to Low.

The inputs will follow this sequence from position 1

through position 4.

FIGURE 51—When you get to position 5 for the index point,

rst Signal-A will change to High, then Index Position 5 will

change to High.

FIGURE 52—Then Signal-B will change to High so all three

Inputs are showing High.

Then Signal-A will change to Low, Index Position 5 will

change to Low and then position B will change to Low.

NOTE: If you are not getting these readings, try shading

the encoder and the tach sticker with a piece of cardboard

to eliminate any outside light source. Then turn the spindle

again.

Sherline/MASSO Controller

Initial Start

Page 12 OF 22

FIGURE 53—Placement of encoder cover P/N 87812.

There must be a gap between the front edge of the cover

and the tach/encoder sticker so it doesn’t rub on the sticker.

FIGURE 54—The red arrows indicate the gap between the

encoder cover and the tach/encoder sticker.

NOTE: The gap is approximately .020"-.050" (.50 – 1.27mm).

Tighten the mounting screw snug. Then readjust the cover

so there is still a gap between the cove and the pulley.

FIGURE 55—Encoder cover mounting screw P/N 87811 5-40 x

3/8" Phillips, button-head machine screw.

FIGURE 56—The red arrows show the gap after nal adjustment.

Sherline/MASSO Controller

Initial Start

Page 13 OF 22

Turn the Spindle on and Check the Readout

For customers who are doing a retrot, see this video,

Speed Control Retrot for CNC Controller (https://youtu.

be/1zIAV6I4MBo), for instructions on how to wire the

speed control for the MASSO controller.

1. Flip the spindlecontrolpowerswitchtotheONposition.

FIGURE 57—The white arrow indicates the direction of the

“ON,” position.

2. Click on the “F2 Program & MDI,” button.

FIGURE 58—The F2 Program & MDI button should be

highlighted yellow.

3. Click on the blank box to the right of “Spindle CW.,”

FIGURE 59— The cursor arrow is over the blank box.

4. Type in 1000. Then hit enter.

5. Now click on the “Spindle CW,” button and the spindle

will turn on.

FIGURE60—Thecursorarrowisoverthe“SpindleCW,”button.

NOTE: Do not click on the “Spindle CCW,” button. Our

motors do not turn CCW. If you click on the CCW button,

the motor will hum and it may oscillate a bit, but it will

not turn CCW or CW. Click on “Spindle STOP,” and then

use “Spindle CW,” to start it.

6. The spindle RPM will uctuate a bit at rst, and then

they will settle down and bounce between 995 and 1008

RPM. You can see the actual RPM on the control page.

FIGURE 61

7. To turn o the spindle, click on the yellow “Spindle

STOP,” button.

FIGURE 62

If your RPM are incorrect, or if they are fluctuating

excessively, make sure that the encoder cover is on and

positioned correctly. If the RPM are still o, reset your

encoder gap.

Sherline/MASSO Controller

Initial Start

Page 14 OF 22

Mounting and Adjusting the Limit Switches

Y-axis Limit Switch and Eccentric Trigger

1

2

3

4

5

6

FIGURE63—Y-axislimitswitchparts,clockwisefromtopright:

(1) P/N 68040 limit switch w/pigtail

(2) P/N 68024 Y-axis limit switch mount

(3) P/N 68046 Limit switch mounting tab

(4) P/N 68049 #2 Phillips x 5/8" at-head sheet metal screws (2 ea.)

(5) P/N 67115 5-40 x 7/8" SHC screws (2 ea.)

(6) P/N 87841: 1/8" x 1-1/2" steel transfer punch for mill Y-axis

limit switch (Retro)

(7) Zip ties

Figure 64 shows the limit switch positioning on the Y-axis

mount: Limit switch P/N 68040, Mounting screws P/N

68048, and Y-axis mounting bracket P/N 68024.

FIGURE 64—The mounting screws are used to attach the limit

switch to the Y-axis limit switch mount.

FIGURE 65—Backside view of the Y-axis limit switch assembly.

FIGURE66—Y-axislimitswitchassemblywiththebackingplate

P/N 68046 attached.

FIGURE 67—Front side view.

FIGURE68—The redoval showsthemounting holelocation for

the Y-axis limit switch assembly.*

*NOTE: If you are doing a retrot, see the Limit Switch

Hole Templates for the Y and Z-axes on page 21.

You can also watch our YouTube video, Mill Base Limit

Switch Retrot, for how to drill and tap these mounting

holes. (https://youtu.be/8-BOprooqIQ)

Sherline/MASSO Controller

Initial Start

Page 15 OF 22

FIGURE 69—The limit switch mounted the with wires going

between the mounting bracket and the mill base.

The Eccentric Trigger Assembly and Mounting

Eccentric trigger parts.

FIGURE70—Left:10-32x1"SHCSP/N40340,eccentrictrigger

P/N 68039, and nylon spacer P/N 68044; Right: Assembly

FIGURE 71a—The red oval shows the location of the eccentric

trigger mounting hole on the ball screw saddle.

FIGURE71b—Left:Onastandardleadscrewmachine,youwill

removetheY-axislockingscrew;Right:Theninstalltheeccentric

trigger where the Y-axis locking screw was.

FIGURE 72—Mount the assembly with the wide side of the

eccentric trigger facing down.

At this point the 10-32 screw on the eccentric trigger and

the two screws that secure the limit switch are snug on the

verge of being loose, so the trigger and the limit switch

can be adjusted.

First turn the driver box power “O,” and then disconnect

the Y-axis stepper motor cable (NOTE: Never disconnect

or connect the stepper motor cables with the power on).

Now by hand, move the Y-axis towards the stepper motor

until the Y-axis accordion cover is almost fully closed

(you want to leave some room for the inevitable chip

build-up). You also need some extra room for the slight

over-travel when the trigger sets the limit switch (about

.100" or 2.54 mm).

Now open the F1 SETUPscreen on the controller (push F1

or click on the F1 Setup button on the screen).

FIGURE 73—Setup screen with password box.

Sherline/MASSO Controller

Initial Start

Page 16 OF 22

You don’t need the password to see the input and output

status of your limit switches and your encoder signal. If

the password box is in the way, click on it a couple times

and then click on the screen once and it will close.

Make sure that your limit switch connector is plugged into

the control harness.

In the middle of the setup screen towards the bottom, you

will see the “X, Y, Z, and A-Home Sensor Input.,” When

the limit switch is plugged in, and in the open position, the

Status column will be “green – Low,” (see picture).

FIGURE 74—Home sensor screen for limit switches.

With your Y-axis in the home position, adjust the limit

switch and the eccentric trigger so the limit switch closes

at that point. You can hear the limit switch click when it

closes.

FIGURE 75—Home position for the Y-axis.

When you believe that your limit switch is set correctly,

manually move the Y-axis o of the limit switch. Then

look at the setup page. Now move the Y-axis back slowly

and when the limit switch closes, the “green – low,” on the

status will change to “red – High.,”

FIGURE 76—Red=High status.

By looking at the status on the setup screen and moving

the Y-axis back and forth, you can adjust the limit switch

and the eccentric so the limit switch closes at the desired

position. Once the position is set, tighten the two limit

switch screws and the 10-32 eccentric trigger screw.

Z-axis Limit Switch and Eccentric Trigger

The Z-axis and the X-axis are easier to mount and adjust.

For these instructions weare mounting these limit switches

on a ball screw machine. The mounting brackets will be

dierent on a leadscrew machine.

Z-axis switch, mount, and screws.

1

2

6

54

3

FIGURE 77—Z-axis limit switch parts, clockwise from top:

(1) P/N 68020 Z-axis limit switch mount

(2) P/N 68042 Eccentric trigger

(3) P/N 12050 8-32 x 3/8" SHCS

(4) P/N 68040 Limit switch

(5) P/N 68048 #2 Phillips x 1/2" at-head sheet metal screws (2 ea.)

(6) P/N 68046 Limit switch mounting tab

(7) Zip ties

Sherline/MASSO Controller

Initial Start

Page 17 OF 22

FIGURE 78—Limit switch mounted to the Z-axis limit switch

mount.

FIGURE 79—#1: The red ovals indicate the mounting screws

from the stepper motors for the limit switch mounting bracket.

#2:This red oval shows the location of the screw hole on the mill

column saddle for the eccentric trigger.*

* NOTE: You may need to drill and tap the 8-32 hole on your

column saddle to mount the Z-axis eccentric trigger. If this is the

case, please go to page 21 of this document for the Limit Switch

Hole Templates for the Y and Z-axes.

FIGURE 80—Mount the eccentric trigger on the column saddle

and leave it loose.

FIGURE 81—Install the Z-axis limit switch mounting bracket

using the two 8-32 screws from the stepper motor.

Sherline/MASSO Controller

Initial Start

Page 18 OF 22

Once the limit switch is mounted, turn o the driver box

and then disconnect the power cord to the stepper motor.

Now raise thecolumn saddle all the wayto the top of travel.

Then lower the column saddle one full revolution of the

handwheel. This is where you want to set your limit switch

“closed position.”Adjust the eccentric and the limit switch

for the Z-axis the same way that you did for the Y-axis.

Once the position is set, tighten all of your screws.

FIGURE 82—Final Z-axis limit switch position.

X-axis Limit Switch Setting and Eccentric Trigger

X-axis limit switch parts.

1

2

3

4

5

FIGURE83—X-axislimitswitchparts,clockwisefromtopright:

(1) P/N 68040 limit switch w/pigtail

(2) P/N 81270 2-56 x 3/8" Phillips head machine screws (2 ea.)

(3) P/N 40510 10-32 x 3/8" SHC screw

(4) P/N 12050 8-32 x 3/8" SHC screws (2 ea.)

(5) P/N 68026 X-axis limit switch mount

(6) Zip ties

FIGURE 84—X-axis mounting holes:

#1: 10-32 screw for the eccentric trigger.

#2: 8-32 screws for the limit switch mounting bracket.

FIGURE85—Thread in the10-32x 3/8" SHCSintothe side hole

on the saddle. If there is a set screw in this hole, remove it rst,

then thread in the 10-32.

FIGURE 86—Attach the X-axis limit switch mounting bracket,

P/N 68026, using the two 8-32 screws.

Sherline/MASSO Controller

Initial Start

Page 19 OF 22

FIGURE87—Mountthelimitswitchwiththespringrollerfacing

own using the two 2-56 screws P/N 81270.

The alignment of the limit switch and the 10-32 screw is

ne just the way it is. No adjustments needed.

Plug in the limit switch to the main cable connector for

the X-axis.

Go to the setup page.

Move the table byhand until the limit switchmakes contact

with the 10-32 screw. Slowly continue to move the table

towards the saddle and look for the “Low Green,” status to

turn to “High Red,” when the limit switch closes.

For each axis, use a small zip tie and secure the limit switch

pigtail to the stepper motor cable (see pictures below).

FIGURE 88—Limit switch axes connections.

Left: X-axis; Middle: Y-axis; Right: Z-axis

Trim the Zip Ties.

FIGURE 89—Use wire cutters to trim o the excess zip tie ush at

the knuckle. Exposed zip tie ends will cut you, so trim them ush.

Now We Can Home out the Machine

With the control box and driver box both on, and the E-stop

triggered, and the password (SP) entered, press the Ctrl,

Alt, and Home buttons on your keyboard. All of your axes

will now home out on their respective limit switches. Each

axis will move until they make contact with their limit

switch, then the axis will stop, then it will move away from

the limit switch approximately one full revolution of the

leadscrew and stop. The setup les are set to home out the

Z-axis rst, then the Y-axis, and then the X-axis.

If you have an axis that does not home out correctly, check

to see if your limit switch connector is plugged in all the

way. If you are still having problems, call us for assistance

(760-727-5857).

Optical Encoder and Speed Control Wires

on Leadscrew Machines

For the leadscrew machine, we don’t supply a bracket for

the encoder and speed control cables. We supply zip ties.

1. Push the encoder cable up so it creates a loop that goes

above the end of the spindle pulley and allow enough

room to use the draw bolt on the end of the spindle.

Then zip tie the cable to the power cord that is coming

out of the motor (see Figure 90).

FIGURE 90

Sherline/MASSO Controller

Initial Start

Page 20 OF 22

2. Now zip tie the speed control cable and the encoder

cable to the power cord that is coming out of the speed

control (see Figures 91 and 92).

FIGURE 91—See the red arrow for the zip ite location.

FIGURE 92

3. We highly recommendusing the alternative groundwire

mounting location, so there will be one less wire going

over the spindle and pulley (see Figure 93).

FIGURE 93— The photo shows an alternate location for the

grounding wire on the opposite side of the headstock.

CAUTION

Always be sure to disconnect the power from the controller

before connecting or disconnecting the ground wire or the

optical encoder connection.

Failure to do so may result in a ground fault that will severely

damage the Optical Encoder.

Related Sherline Video Links

You can get further visual instructions on how to set up your

new Sherline/MASSO controller by going to our YouTube

channel, or by following the links below.

1. Setting up Your New Sherline CNC Controller

(This video shows you how to connect your controller

to your machine. It then goes on to show you how to

use the controller.)

https://youtu.be/obFdVI7K9bw

2. Setting up the Optical Encoder

(This video shows you how to mount your encoder, set

the gap, check the signals, and turn the spindle on for

the nal RPM check.)

https://youtu.be/ynfJ38QLMoE

Thank you,

Sherline Products Inc.

Other Sherline Products Controllers manuals

Popular Controllers manuals by other brands

Lenze

Lenze EPM-S900 Mounting instructions

Finnleo

Finnleo SaunaLogic SL2 Control manual

F.lli Scapin

F.lli Scapin GREEN POWER LINE Series quick start guide

Critical Environment Technologies

Critical Environment Technologies FCS-M Series Operation manual

DekunTech

DekunTech G2 Series instruction manual

Burkert

Burkert 3004 quick start