Shimax MAC5 Series User manual

1

11

1

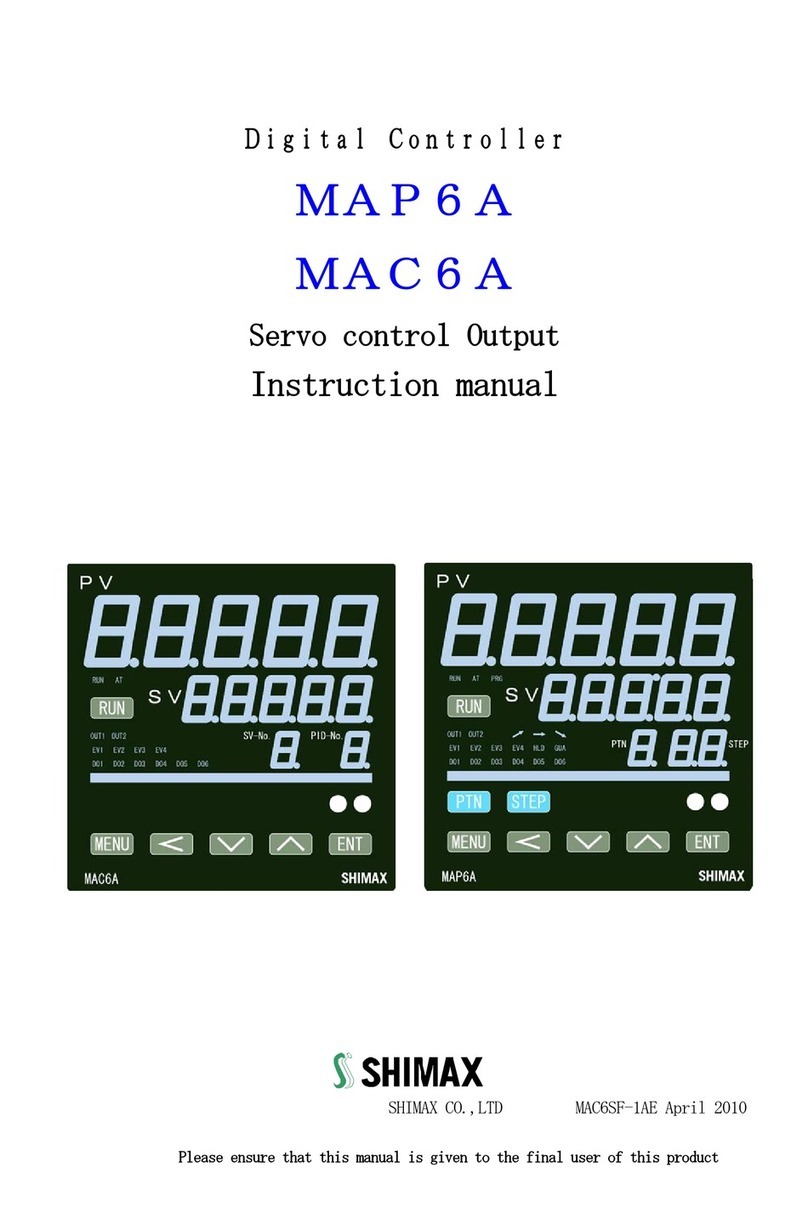

MAC5 Series

MAC5 Series MAC5 Series

MAC5 Series

Digital Controller Instruction Manual

Digital Controller Instruction Manual Digital Controller Instruction Manual

Digital Controller Instruction Manual

Thank you for purchasing SHIMAX product.

Thank you for purchasing SHIMAX product. Thank you for purchasing SHIMAX product.

Thank you for purchasing SHIMAX product.

Please check that the product is the one you ordered.

Please check that the product is the one you ordered.Please check that the product is the one you ordered.

Please check that the product is the one you ordered.

Please operate after you read the instruction manual and fully understand it

Please operate after you read the instruction manual and fully understand itPlease operate after you read the instruction manual and fully understand it

Please operate after you read the instruction manual and fully understand it

「

「「

「Notice

NoticeNotice

Notice」

」」

」

Please ensure that this manual is given to the final user of the instrument

Please ensure that this manual is given to the final user of the instrumentPlease ensure that this manual is given to the final user of the instrument

Please ensure that this manual is given to the final user of the instrument.

Contents

ContentsContents

Contents

Preface

PrefacePreface

Preface

1.Matters regarding safety

1.Matters regarding safety1.Matters regarding safety

1.Matters regarding safety

2.Introduction

2.Introduction2.Introduction

2.Introduction

2

22

2-

--

-1.Check before use

1.Check before use1.Check before use

1.Check before use

2

22

2-

--

-2.Caution for use

2.Caution for use2.Caution for use

2.Caution for use

.Installation and wiring

.Installation and wiring.Installation and wiring

.Installation and wiring

3

33

3-

--

-1. Installation site (environmental conditions)

1. Installation site (environmental conditions)1. Installation site (environmental conditions)

1. Installation site (environmental conditions)

3

33

3-

--

-2. Mounting

2. Mounting2. Mounting

2. Mounting

3

33

3-

--

-3. E ternal dimension and panel cutout

3. E ternal dimension and panel cutout3. E ternal dimension and panel cutout

3. E ternal dimension and panel cutout

3

33

3-

--

-4. Wiring

4. Wiring4. Wiring

4. Wiring

3

33

3-

--

-5. Terminal arrangement diagram

5. Terminal arrangement diagram5. Terminal arrangement diagram

5. Terminal arrangement diagram

4. Description of front panel

4. Description of front panel4. Description of front panel

4. Description of front panel

4

44

4-

--

-1. Names of front panel.

1. Names of front panel.1. Names of front panel.

1. Names of front panel.

4

44

4-

--

-2. E planation of front panel section

2. E planation of front panel section2. E planation of front panel section

2. E planation of front panel section

5. Description of screens

5. Description of screens5. Description of screens

5. Description of screens

5

55

5-

--

-1. How to move to another screen

1. How to move to another screen1. How to move to another screen

1. How to move to another screen

5

55

5-

--

-2. Setting Method

2. Setting Method2. Setting Method

2. Setting Method

5

55

5-

--

-3. Power

3. Power3. Power

3. Power-

--

-on and initial screen display

on and initial screen displayon and initial screen display

on and initial screen display

5

55

5-

--

-4. Monitoring screen

4. Monitoring screen 4. Monitoring screen

4. Monitoring screen

6. Operating setting

6. Operating setting 6. Operating setting

6. Operating setting

7. MODE setting

7. MODE setting7. MODE setting

7. MODE setting

7

7 7

7-

--

-1 . MODE1 :Key lock and SV Limit setting

1 . MODE1 :Key lock and SV Limit setting1 . MODE1 :Key lock and SV Limit setting

1 . MODE1 :Key lock and SV Limit setting

7

77

7-

--

-2. MODE2: Scale and PV setting

2. MODE2: Scale and PV setting2. MODE2: Scale and PV setting

2. MODE2: Scale and PV setting

7

77

7-

--

-3. MODE3

3. MODE33. MODE3

3. MODE3-

--

-4:Out 1

4:Out 14:Out 1

4:Out 1-

--

-2 setting

2 setting2 setting

2 setting

7

77

7-

--

-4. MODE 5:Event setting

4. MODE 5:Event setting4. MODE 5:Event setting

4. MODE 5:Event setting

7

77

7-

--

-5 . MODE6:DI setting

5 . MODE6:DI setting5 . MODE6:DI setting

5 . MODE6:DI setting

7

77

7-

--

-6 .DI operation character table

6 .DI operation character table6 .DI operation character table

6 .DI operation character table

7

77

7-

--

-7 .Measuring range code table

7 .Measuring range code table7 .Measuring range code table

7 .Measuring range code table

8. Supplementary Explanation of Function

8. Supplementary Explanation of Function8. Supplementary Explanation of Function

8. Supplementary Explanation of Function

8

88

8-

--

-1 . Auto return function

1 . Auto return function1 . Auto return function

1 . Auto return function

8

88

8-

--

-2. Output Soft Start Function

2. Output Soft Start Function2. Output Soft Start Function

2. Output Soft Start Function

8

88

8-

--

-3. Event Selection Alarm Operation Figure

3. Event Selection Alarm Operation Figure3. Event Selection Alarm Operation Figure

3. Event Selection Alarm Operation Figure

8

88

8-

--

-4. AT (Auto Tuning)

4. AT (Auto Tuning)4. AT (Auto Tuning)

4. AT (Auto Tuning)

8

88

8-

--

-5 .Output

5 .Output5 .Output

5 .Output-

--

-characteristics figure

characteristics figurecharacteristics figure

characteristics figure

9. Trou le Shooting

9. Trou le Shooting9. Trou le Shooting

9. Trou le Shooting

9

99

9-

--

-1. Cause and Treatment of Main Defects

1. Cause and Treatment of Main Defects 1. Cause and Treatment of Main Defects

1. Cause and Treatment of Main Defects

9

99

9-

--

-2. Cause and Treatment of Error Display

2. Cause and Treatment of Error Display2. Cause and Treatment of Error Display

2. Cause and Treatment of Error Display

10. Specification

10. Specification10. Specification

10. Specification

11. General Specification

11. General Specification11. General Specification

11. General Specification

2

22

2

Preface

PrefacePreface

Preface

This instruction manual is intended for those who will be involved in wiring,

installation, operation and routine maintenance of the MAC5.

This manual describes the care, installation, wiring, function, and proper

procedures regarding the operation of MAC5.

Keep this manual on hand while using this device. Please follow the provided

guidance.

1.Matters regarding safety

For matters regarding safet , potential damage to equipment and/or facilities

and additional instructions are indicated as follows:

◎This mark indicates hazardous conditions that could cause injur or death

of personnel. Exercise extreme caution as indicated.

「

「「

「

WARNING」

」」

」

◎This mark indicates hazardous conditions that could cause damage to

equipment and/or facilities. Exercise extreme caution as indicated.

「

「 「

「

CAUTION」

」」

」

◎This mark indicates additional instructions and/or notes.

「NOTE」

「

「 「

「

WARNING」

」」

」

MAC5 is designed for controlling temperature, humidit , and other ph sical

subjects in general industrial facilities. It must not be used in an wa that

ma adversel affect safet , health, or working conditions.

「

「 「

「

CAUTION」

」」

」

To avoid damage to the connected equipment, facilities or the product itself

due to a fault of this instrument, safet countermeasures must be taken

before usage, such as proper installation of the fuse and the overheating

protection device. No warrant , expressed or implied, is valid in the case of

usage without having implemented proper safet countermeasures.

The mark on the plate affixed to the instrument:

On the terminal nameplate affixed to the case of our instrument, the

mark is printed. This is to warn ou of the risk of electrical shock which ma

result if the charger is touched while it is energized.

The external power circuit connected to the power terminal of this instrument

must have a means of turning off the power, such as a switch or breaker.

Install the switch or breaker adjacent to the instrument in a position which

allows it to be operated with ease, and with an indication that it is a means of

turning off the power. Use a switch or breaker, which meets the

requirements of IEC127.

Fuse:Since the instrument does not have a built-in fuse, do not forget to

install a fuse in the power circuit to be connected to the power terminal. The

fuse should be positioned between the switch or breaker and the instrument

and should be attached to the L side of the power terminal.

Fuse Rating: 250V AC 0.5A/medium lagged or lagged t pe.

Use a fuse which meets the requirements of IEC127

Load voltage/current to be connected to the output terminal and the alarm

terminal should be within the rated range. Otherwise, the temperature will rise

and shorten the life of the product and/or result in problems with the product.

lVoltage/current that differs from input specification should not be connected

to the input terminal. It ma shorten the life of the product and/or result in

problems with the product.

Input, output of voltage pulse, and output of electric current are not insulated.

Therefore, do not ground an adjusted power terminal when a ground sensor is

emplo ed.

A signal wire's common mode voltage to ground (signal wires other than

contact output including power suppl and event) should be less than 30V

rms, 42.4V peak, and 60 VDC .

「

「 「

「

CAUTION」

」」

」

All the wires for the interior distribution, except for communication and

contact output (including power suppl and event), should be less than 30m in

length. When the wire's length is 30m or more, or in the case of outdoor

wiring,

the suitable measure against a lightning surge is required.

EMC standard (IEC61326) classifies MAC5 into Class A apparatus.

Electromagnetic interference ma occur when MAC5 is used at a business

district or in the home. Please use after taking sufficient measures.

2.Introduction

2.Introduction2.Introduction

2.Introduction

2

22

2-

--

-1. Check before use

1. Check before use1. Check before use

1. Check before use

Before using MAC5, please check the model code, the exterior appearance and

accessories. Also, make sure that there are no errors, impairs and shortages.

Confirmation of model code: Check that the product ou ordered is being

delivered properl . Check the model code of the main bod case against the

following code table.

Example of model code

1. Series MAC5A-:96×96mm size digital controller

MAC5B-:48×96mm size digital controller

MAC5C-:72×72mm size digital controller

MAC5D-:48×48mm size digital controller

2. Input M:multi,

3. Control Output 1 C:contact, S:voltage pulse, I:current(4~20mA)

4. Power Suppl F-:90 - 264V AC,

5. Event Output E:Event Output1・2 (two points)

6. Control Output 2・Event Output・Optional Selection

N-:none, C-:contact, S-:voltage pulse, E-:Event out

D-Digital input one point

2

22

2-

--

-2. Caution for use

2. Caution for use2. Caution for use

2. Caution for use

(1) Do not operate the front panel ke s with hard or sharp objects.

Do not fail to touch ke s lightl with a fingertip.

(2) Wipe gentl with a dr rag and avoid using solvents such as

thinner.

3. Installation and wiring

3. Installation and wiring3. Installation and wiring

3. Installation and wiring

3

33

3-

--

-1. Installation site (environmental conditions)

1. Installation site (environmental conditions)1. Installation site (environmental conditions)

1. Installation site (environmental conditions)

「CAUTION」

Do not use this product under the following conditions.

Otherwise, failure, damage and fire ma occur.

(1) Where flammable gas, corrosive gas, oil mist or dust generate or grow rife.

(2) Where the temperature is below -10℃ or above 55℃.

(3) Where the humidit is over 90%RH or where condensation occurs.

(4) Where high vibration or impact occurs

(5) Where inductive interference ma easil affect the operation.

Or, in the region of strong electric circuit area.

(6) Where water drops or direct sunlight exists.

(7) Where the altitude is above 2,000m.

「

NOTE」: The environmental conditions compl with the IEC664.

Installation categor isⅡ and the pollution degree is 2.

3

33

3-

--

-2. Mounting

2. Mounting2. Mounting

2. Mounting

(1) Machine the mounting hole b referring to the panel-cut illustration in

Section 3-3.

(2) Applicable thickness of the mounting panel is 1.2 ~ 2.8mm.

(3) As this product provides mounting fixture, insert the product into the panel.

「NOTE」:

MAC 3 is a panel set-up t pe.

Please use the product after setting up to the panel.

3

33

3-

--

-3. E ternal dimension and panel cutout

3. E ternal dimension and panel cutout 3. E ternal dimension and panel cutout

3. E ternal dimension and panel cutout

(unit: mm)

MAC

MACMAC

MAC5

55

5A-

A-A-

A- M

MM

M C

CC

C F-

F-F-

F- E

EE

E C

CC

C

1 2 3 4 5 6

MAC5C 72mm*72mm

MAC5C 72mm*72mmMAC5C 72mm*72mm

MAC5C 72mm*72mm

MAC5D 48mm*48mm

MAC5D 48mm*48mmMAC5D 48mm*48mm

MAC5D 48mm*48mm

96

96

4

68.4

48

96

4

65.4

48

48

4

65.5

MAC5B 48mm*96mm

MAC5B 48mm*96mmMAC5B 48mm*96mm

MAC5B 48mm*96mm

4

68.4 72

72

MAC5A 96mm*96mm

MAC5A 96mm*96mmMAC5A 96mm*96mm

MAC5A 96mm*96mm

3

33

3

MAC5 panel cutout (unit: mm) Applicable thickness is 1.2 to 2.8mm

Note: Proximit attachment b a single hole is possible onl in the case of

horizontal direction. When an apparatus that was attached in vertical direction

is removed, a dedicated detachment tool is required.

3

33

3-

--

-4. Wiring

4. Wiring4. Wiring

4. Wiring

「

「「

「

WARNING」

」」

」

◎Do not turn on electricit while wiring to avoid an electric shock.

◎Do not touch a terminal or live part while turning on electricit .

(1) Make sure that wiring operation is properl done in line with a terminal wire

diagram of section 3-5.

(2) Choose a suitable compensation lead wire in the case of

thermocouple input.

(3) In the case of resistance bulb input, resistance value of each

lead wire must be less than 5Ω and that of three lead wires must

be equal.

(4) Do not wires an input signal line inside of an electric wire pipe

or a duct same with the high voltage line.

(5) Shield wiring (single point grounding) is effective against static

induction noise.

(6) Wiring twisted at equal short intervals is effective against

electromagnetic induction noise.

A

AA

A

B

BB

B

C

CC

C

D

DD

D

E

EE

E

A B C D E

MAC5A 92 92 96min 96min (96*N-4)

MAC5B 92 45 48min 96min (48*N-3)

MAC5C 68 68 72min 72min (72*N-4)

MAC5D 45 45 48min 48min (48*N-3)

+

++

+0.8

—

——

—0

+

++

+0.8

-0

+

++

+0.6

-0

+

++

+0.6

-0

+

++

+0.8

-0

+

++

+0.6

-0

+

++

+0.7

-0

+

++

+0.7

-0

+

++

+0.7

-0

+

++

+0.6

-0

+

++

+0.6

-0

+

++

+0.6

-0

OUT2/EV3/DI4

7

8

9

10

11

12

13

14

15

16

17

18

EV2

EV1

INPUT

L

N

POWER

OUT1

90-264V AC

50/60Hz 9VA

+

-

A

B

B

+

-

+

-

CONTACT:240V AC 2A

SSR DRIVE:12V DC 20mA

CURRENT:4-20mA DC

CONTACT:240V AC 2A

SSR DRIVE:12V DC 20mA

EV3

:240V AC 2A

240V AC 2A

240V AC 2A

COM

4

5

6

10

11

12

13

14

15

EV2

EV1

L

N

POWER

OUT1

90-264V AC

50/60Hz 9VA

OUT2/EV3/DI4

INPUT

+

-

A

B

B

CONTACT:240V AC 2A

SSR DRIVE:12V DC 20mA

CURRENT:4-20mA DC

+

-

+

-

CONTACT:240V AC 2A

SSR DRIVE:12V DC 20mA

EV3

:240V AC 2A

240V AC 2A

240V AC 2A

COM

7

8

9

1

2

3

4

5

6

7

8

9

10

11

12

EV2

EV1

L

N

POWER

OUT1

90-264V AC

50/60Hz 9VA

OUT2/EV3/DI4

INPUT

+

-

A

B

B

CONTACT:240V AC 2A

SSR DRIVE:12V DC 20m

A

CURRENT:4-20mA DC

+

-

+

-

CONTACT:240V AC 2A

SSR DRIVE:12V DC 20m

A

EV3

:240V AC 2A

240V AC 2A

240V AC 2A

COM

Terminal arrangement MAC5D

Terminal arrangement MAC5C

Terminal arrangement MAC5A,B

4. Description of front panel

4. Description of front panel4. Description of front panel

4. Description of front panel

4

44

4-

--

-1. Names of front panel.

1. Names of front panel.1. Names of front panel.

1. Names of front panel.

4

44

4-

--

-2. Explanation of

2. Explanation of 2. Explanation of

2. Explanation of

front panel section

front panel sectionfront panel section

front panel section

① : Display of measured value (PV) (red) Measured value (PV) and type of

setting is displayed on ea h setting s reen.

② : Display of target value (SV) (green)

Target value and set value are displayed on ea h setting s reen.

③:Monitor LED

(1) RUN monitor LED RUN (green)

If RUN is performed with RUN key, operation mode1 s reen, external

ontrol input (DI), and ommuni ation, it lights up, and put out

by standby (reset). It blinks, if a manual output is hosen in

output monitoring s reen or external ontrol input (DI).

(3) Auto tuning operation monitor LED AT (green)

If AT is hosen in ON or external ontrol input (DI), blinks during

AT exe ution. Lights up when AT is on standby, and puts out

with AT automati termination or release.

(4) ontrol out put 1 monitor LED OUT (green)

At the time of a onta t or a voltage pulse output, the it lights up

with ON and lights off with

OFF. Lights off with 0% power output, and lights up with 100%

power.

And blinks in intermediate ratio.

(5) Event output monitors LED EV1 and EV2 (yellow)

Lights up when the allotted event output turns to ON.

(6) Control out put 2/event output 3 monitors LED OUT2/EV3 (yellow)

When ontrol output 2 is hosen, it operates like ontrol output 1

monitor LED does.

When event output 3 is hosen, it operates like event output

monitor LED does.

④: Key-swit h se tion

(1) (MENU)key

Press this key to move onto the next s reen among the s reens.

Press (MENU) key for three se onds on the basi

s reen, then it jumps to the lead s reen of Mode 1. Press key

for three se onds on the lead s reen of ea h Mode s reens, then

it jumps to the basi s reen.

Press key for three se onds on the lead s reen of (2) (DOWN) key

Press (DOWN) key one time, and the shown value de reases

by one numeri al value.

One time press of key de reases by one numeri al value. By

pressing the key ontinuously, the value as well onse utively

de reases. A de imal point of the smallest digit blinks at this

time. This shows that a setting hange is in progress.

「Note」: If input type is

thermo ouple or voltage, errors

may o ur when terminal 5 and

terminal 6 terminal are short-

ir uited

3

33

3-

--

-5. Terminal arrangement diagram

5. Terminal arrangement diagram5. Terminal arrangement diagram

5. Terminal arrangement diagram

When the thi kness of the

panel is different from the

1.2 to 2.8mm,

Atta hment available

4

44

4

(3 ) (UP) key

Press (UP) key one time, and the shown value in reases by

one numeri al value.

By pressing ontinuously, the value By pressing the key

ontinuously, the value onse utively in reases. A de imal point

of the smallest digit blinks at this time. This shows that a setting

hange is in progress.

Also used as a shift key between lead s reen in ea h mode

s reens.

(4) (ENTRY/REGISTER)key

The setting data hanged on ea h s reen is determined (the

de imal point of the minimum digit is also lighted off).

Press key for 3 se onds on the output monitoring s reen,

then the shift between manual output and automati output is

arried out.

5. Description of screens

5. Description of screens5. Description of screens

5. Description of screens

5

55

5-

--

-1. How to move to another screen

1. How to move to another screen1. How to move to another screen

1. How to move to another screen

Operation Setting screens

Operation Setting screens Operation Setting screens

Operation Setting screens

Mode setting screen

Mode setting screenMode setting screen

Mode setting screen

Press the key for 3 se onds on a basi s reen, then it shifts to the lead s reen

of setting s reens.

Press the key for 3 se onds on

, then it shifts to the basi s reen

Basic Screen

Basic ScreenBasic Screen

Basic Screen

5

55

5

5

55

5-

--

-2. Setting Method

2. Setting Method2. Setting Method

2. Setting Method

To hange settings, display an appropriate s reen and hange the setting (value or fun tion) by pressing or key.

On the output monitor s reen of basi s reens, you an hange the ontrol output from "Automati " to "manual" ,and save its hange of setting. Display the

output monitor s reen, and then press key for three se onds to shift from Automati to Manual. Then by pressing or key, you an adjust to the

desirable output value. In this ase, no need to press key in order to determine the hange of setting.

Press key for three se onds as well to shift ba k to Automati . Ex luding when a key lo k is OFF, Automati ⇔ Manual swit hover does not work while

STBY<RST> and AT are in operation.

In the ase of two-output type, the swit hover between automati and manual is operatable through output 1 and output 2. The setting is altered

simultaneously.

5

55

5-

--

-3. Power

3. Power3. Power

3. Power-

--

-on and initial screen display

on and initial screen displayon and initial screen display

on and initial screen display

At power-on, the display se tion shows ea h s reen of initial s reens for one se ond , then moves on to the basi s reen.

Output monitor Output monitor Output monitor

Automati s reen Run LED right up Manual s reen RUN LED blinks Manual s reen RUN LED blinks

three se onds

or

All LED light up Input type Upper limit & lower

limit

Out 1 type Out 2 type

Displays only optional addition

5

55

5-

--

-4. Monitoring screen

4. Monitoring screen 4. Monitoring screen

4. Monitoring screen

Basi s reen

Exe uted SV initial value:Sensor input 0

Linear input Lower limit of s aring range

Setting range:Sensor input Within measuring range

Linear input With in s aring range

Within SV limiter besides

Targeted value (PV) is displayed on the upper row as

four-digit ,and targeted value (SV) is displayed on the

lower row also as four-digit. (Notes:hereinafter

measured value and targeted value are referred to

as"PV" and "SV")

At the time of FIX, exe ution SV is displayed and

hange of setting is possible.

Initial value::(stanby)(Initial value at the time

of onstant value ontrol)

Setting range:: Control stop [Output OFF

(0%)] operation ondu t of ontrol

operation Choose (RUN) by key. De ide by

key, then Monitor LED's RUN lights up to start ontrol

operation.

Choose by key、De ide by key, Then

Monitor LED's RUN lights off and be omes ontrol stop

[Output OFF (0%)] ondu ting.

When measuring range, a unit, s aling, and output

hara teristi s are hanged it is initialized and

is displayed.

Priority is given to DI when RUN is allotted to external

ontrol input.

DI. Key operation annot be performed unless allotment

is an eled.

A tion Mode1 s reen

Manual output setting range: :0.0-100.0% (within

output limiter) At the time of automati

output,monitor display only. Refer to Item 5-2 about

automati ⇔ manual swit h over, and setting

method at the time of manual operation. A manual

output is an eled when an operation mode is made

into When a power sour e is inter epted

and re-swit hed on, it returns to the ondition just

before inter epting.

Out put 1 monitoring s reen

Out put 2 monitoring s reen

Contents are the same with that of an Output1.

Output 2 monitoring s reen displayed only when

Output 2 option is added.

PID No, monitoring s reen

Chosen PID № is displayed when FIX is in

operation.

PID № of output 1 is displayed in the first digital,

and PID № of output 2 is displayed in the third

digital. The third digital is shown as when there is

no output 2 option. This s reen is not displayed in

the state of STBY .

SV No, monitoring s reen

Chosen SV № is displayed when FIX is in operation.

6

66

6

AT (Auto tuning) execution screen

AT (Auto tuning) execution screenAT (Auto tuning) execution screen

AT (Auto tuning) execution screen

Initial value::

Setting range:: 、

AT is performed by ON sele tion ,and an eled by

OFF sele tion. Not displayed at the time of STBY, a

manual output, and P (proportional band) =OFF.

Ex ept in the setting of key lo k OFF, AT is unable to

perform in s ale over.

(At the time of DI allotment, exe ution of AT by DI

an be performed .)Even in su h a ase, halfway

release is performed on this s reen.

Release of AT, STBY, EV operating point, setting of

key lo k, and mode 5 ~ 6 s reen are operate able

with key. Ex ept in the setting of AT normal end,

exe ution of AT is an eled ompulsorily at the time

of STBY(RST) sele tion and AT release setup.

EV1(Enent 1)operationg point setting screen

EV1(Enent 1)operationg point setting screenEV1(Enent 1)operationg point setting screen

EV1(Enent 1)operationg point setting screen

Initial value: upper limit absolute value measuring

range S aling upper limit lower limit absolute value

measuring range S aling lower limit

Upper limit deviation

Lower limit deviation

Within deviation

Outside deviation

guarantee

Setting range: upper limit absolute value within

measuring range within s aling limit lower limit

absolute value within measuring range within

s aling limit

Upper limit deviation ~ unit

Lower limit deviation ~ unit

Within upper-lower limit deviation ~

unit

Outside upper-lower limit deviation ~

unit

The operating point of the alarm type allotted to

EV1 is set up. No option, No display when ,

, are allotted to EV1. The operation mode of

ea h deviation alarm is .

Effe tive at the time of automati output.

Ea h deviation alarm serves as PV’s deviation to

Exe ution SV.

Event operation other than ea h deviation alarm is

EV2(Enent 2)operating point setting screen

EV2(Enent 2)operating point setting screenEV2(Enent 2)operating point setting screen

EV2(Enent 2)operating point setting screen

Initial value ,setting range, ontents are the same

with EV1

EV3(EVnent 3)operating point setting screen

EV3(EVnent 3)operating point setting screenEV3(EVnent 3)operating point setting screen

EV3(EVnent 3)operating point setting screen

Initial value, setting range, ontents are the same

with EV1

When EV3 option is added, event 3 is displayed as

the same ontents with EV 1 and 2, irrespe tive of

EV 1 and 2.

Initial value::

Setting range:: release EV1

release EV2

release EV3

release all EV at a time

On the lat hing setting s reen of ea h EV mode,

№ and whi h hose are

displayed. If lat hing is ,on e EV is outputted,

EV output state is maintained even if EV is in the

state of OFF. When EV is in a lat hing state,

de imal point of the minimum digit blinks, and it

shows that release of EV is possible. If key is

pressed, EV is released and a de imal point lights

off. However, release is impossible when a state is

in EV power range.

Return to basi s reen

Latching release screen

Latching release screenLatching release screen

Latching release screen

6. Operating setting

6. Operating setting 6. Operating setting

6. Operating setting

Operating setting screens

Operating setting screens Operating setting screens

Operating setting screens

Basic screen

Basic screenBasic screen

Basic screen

Initial value : At the time of sensor input 0

linear input time s aling lower limit

Setting range: sensor input time within

measuring range

linear input time within s aling range

Moreover, within limit of SV limiter

.

When SV1 is Exe ution SV,being refle ted in

basi s reen.

Being initialized when easuring range, unit,

Being initialized when easuring range, unit, Being initialized when easuring range, unit,

Being initialized when easuring range, unit,

and scaling are changed.

and scaling are changed.and scaling are changed.

and scaling are changed.

SV1 output1 PID No. setting screen

SV1 output1 PID No. setting screenSV1 output1 PID No. setting screen

SV1 output1 PID No. setting screen

Initial value : 1

Setting range:1, 2, 3

When SV1 is Exe ution SV,PID№ that will be

used for ontrol of output 1is hosen from

1~3.

SV1 output2 PID No. setting screen

SV1 output2 PID No. setting screenSV1 output2 PID No. setting screen

SV1 output2 PID No. setting screen

Initial value : 1

Setting range:1, 2, 3

When SV1 is Exe ution SV,PID№ that will be

used for ontrol of output 1is hosen from

1~3.

Displayed when output 2 option is added.

SV1 setting screen

Basic screen

Basic screenBasic screen

Basic screen

7

77

7

SV2

SV2SV2

SV2-

--

-4 setting screen

4 setting screen4 setting screen

4 setting screen

Initial value: same with SV1

Setting range: same with SV1

Displayed when SV2-4 is allotted to DI.When

terminal of allotted DI short- ir uits, it be omes

Exe ution SV.

When SV2-4 is Exe ution SV, it is refle ted in

basi s reen.

Being initialized when measuring range, unit, and

s aling are hanged.

SV2 output1 PID No. setting screen

SV2 output1 PID No. setting screenSV2 output1 PID No. setting screen

SV2 output1 PID No. setting screen

SV2 output2 PID No. setting screen

SV2 output2 PID No. setting screenSV2 output2 PID No. setting screen

SV2 output2 PID No. setting screen

SV3 setting screen

SV3 setting screenSV3 setting screen

SV3 setting screen

SV4 setting screen

SV4 setting screenSV4 setting screen

SV4 setting screen

SV4 output2 PID No. setting screen

SV4 output2 PID No. setting screenSV4 output2 PID No. setting screen

SV4 output2 PID No. setting screen

Operating setting screens

Operating setting screens Operating setting screens

Operating setting screens

MODE 1 : Key lock and SV li it setting

MODE 1 : Key lock and SV li it settingMODE 1 : Key lock and SV li it setting

MODE 1 : Key lock and SV li it setting

MODE 2 : PV and scale setting

MODE 2 : PV and scale settingMODE 2 : PV and scale setting

MODE 2 : PV and scale setting

MODE 3 : OUT 1 setting

MODE 3 : OUT 1 settingMODE 3 : OUT 1 setting

MODE 3 : OUT 1 setting

MODE 4 : OUT2 setting

MODE 4 : OUT2 settingMODE 4 : OUT2 setting

MODE 4 : OUT2 setting

MODE 5 : EV setting

MODE 5 : EV settingMODE 5 : EV setting

MODE 5 : EV setting

7

77

7-

--

-1 .MODE1 :Key lock and SV Limit setting

1 .MODE1 :Key lock and SV Limit setting1 .MODE1 :Key lock and SV Limit setting

1 .MODE1 :Key lock and SV Limit setting

7.MODE setting

7.MODE setting7.MODE setting

7.MODE setting

MODE 6: DI setting

MODE 6: DI settingMODE 6: DI setting

MODE 6: DI setting

7

77

7-

--

-2. MODE2:Scale and PV setting

2. MODE2:Scale and PV setting2. MODE2:Scale and PV setting

2. MODE2:Scale and PV setting

MODE 2

MODE 2 MODE 2

MODE 2

Scale and PV setting

Scale and PV settingScale and PV setting

Scale and PV setting

Display

Display Display

Display

Description

Description Description

Description

PV offset correction (PV bias) setting screen

PV offset correction (PV bias) setting screenPV offset correction (PV bias) setting screen

PV offset correction (PV bias) setting screen

PV gain correction setting screen

PV gain correction setting screenPV gain correction setting screen

PV gain correction setting screen

PV filter setting screen

PV filter setting screenPV filter setting screen

PV filter setting screen

Measuring range setting screen

Measuring range setting screenMeasuring range setting screen

Measuring range setting screen

Temperature unit setting screen

Temperature unit setting screenTemperature unit setting screen

Temperature unit setting screen

Input scaling lo er limit value setting screen

Input scaling lo er limit value setting screenInput scaling lo er limit value setting screen

Input scaling lo er limit value setting screen

Input scaling upper limit value setting screen

Input scaling upper limit value setting screenInput scaling upper limit value setting screen

Input scaling upper limit value setting screen

Note:

Note:Note:

Note:

Suppose that the difference bet een a lo er limit value and upper limit value is 10

Suppose that the difference bet een a lo er limit value and upper limit value is 10Suppose that the difference bet een a lo er limit value and upper limit value is 10

Suppose that the difference bet een a lo er limit value and upper limit value is 10

Input scaling Decimal point position Setting screen

Input scaling Decimal point position Setting screenInput scaling Decimal point position Setting screen

Input scaling Decimal point position Setting screen

Note:

Note:Note:

Note:

The screen of input scaling serves as a monitor at the time of a sensor input

The screen of input scaling serves as a monitor at the time of a sensor inputThe screen of input scaling serves as a monitor at the time of a sensor input

The screen of input scaling serves as a monitor at the time of a sensor input

MODE 1 Key Lock and SV limit setting

MODE 1 Key Lock and SV limit settingMODE 1 Key Lock and SV limit setting

MODE 1 Key Lock and SV limit setting

Display

Display Display

Display

Description

Description Description

Description

Key lock

Key lockKey lock

Key lock

1:

2:

3:

4:

,

8

88

8

7

77

7-

--

-3.MODE3

3.MODE33.MODE3

3.MODE3-

--

- :Out 1

:Out 1:Out 1

:Out 1-

--

-2 setting

2 setting2 setting

2 setting

7

77

7-

--

- . MODE 5:Event setting

. MODE 5:Event setting. MODE 5:Event setting

. MODE 5:Event setting

MODE 3

MODE 3MODE 3

MODE 3-

--

-4 Out 1

4 Out 14 Out 1

4 Out 1-

--

-2 setting

2 setting2 setting

2 setting

Display

Display Display

Display

Description

Description Description

Description

Output 1 PID1 proportional

Output 1 PID1 proportionalOutput 1 PID1 proportional

Output 1 PID1 proportional-

--

-band (P) setting screen

band (P) setting screenband (P) setting screen

band (P) setting screen

Output 1 PID1 Integral time (I) setting screen

Output 1 PID1 Integral time (I) setting screenOutput 1 PID1 Integral time (I) setting screen

Output 1 PID1 Integral time (I) setting screen

Output 1 PID2 Derivative time (D) setting screen

Output 1 PID2 Derivative time (D) setting screenOutput 1 PID2 Derivative time (D) setting screen

Output 1 PID2 Derivative time (D) setting screen

Output1 PID2 manual reset setting screen

Output1 PID2 manual reset setting screenOutput1 PID2 manual reset setting screen

Output1 PID2 manual reset setting screen

Output 1 PID2 differential

Output 1 PID2 differentialOutput 1 PID2 differential

Output 1 PID2 differential-

--

-gap setting screen

gap setting screengap setting screen

gap setting screen

M

MM

Minimum limiter setting screen

inimum limiter setting screeninimum limiter setting screen

inimum limiter setting screen

:

::

:

Note:At the time of STBY and scale over output

Note:At the time of STBY and scale over outputNote:At the time of STBY and scale over output

Note:At the time of STBY and scale over output

Output 1 PID2 maximum limiter setting screen

Output 1 PID2 maximum limiter setting screenOutput 1 PID2 maximum limiter setting screen

Output 1 PID2 maximum limiter setting screen

Output 1 PID

Output 1 PIDOutput 1 PID

Output 1 PID2

2 2

2 proportional band (P) setting screen

proportional band (P) setting screenproportional band (P) setting screen

proportional band (P) setting screen

Same as Output 1 PID1

Same as Output 1 PID1 Same as Output 1 PID1

Same as Output 1 PID1

Output 1 PID3 proportional band (P) setting screen

Output 1 PID3 proportional band (P) setting screenOutput 1 PID3 proportional band (P) setting screen

Output 1 PID3 proportional band (P) setting screen

Same as Output 1 PID1 & PID2

Same as Output 1 PID1 & PID2Same as Output 1 PID1 & PID2

Same as Output 1 PID1 & PID2

Output 1 soft starting ti e setting screen

Output 1 soft starting ti e setting screenOutput 1 soft starting ti e setting screen

Output 1 soft starting ti e setting screen

Initial value: OFF

Setting range:OFF, 0.5~120.0 seconds (setting resolution 0.5

second)

This is the unction that eases change o output at the time o

a power-on and startup.

Does not unction at the time o OFF setup

Output 1 proportional periodic ti e setting screen

Output 1 proportional periodic ti e setting screenOutput 1 proportional periodic ti e setting screen

Output 1 proportional periodic ti e setting screen

Initial value: Contact output 30.0 seconds

Voltage pulse output 3.0 seconds

Setting range: 0.5~120.0 seconds (setting resolution 0.5

second)

Proportional periodic time o output 1 is set.

Not displayed when output 1 is current.

Output 1 characteristics setting screen

Output 1 characteristics setting screenOutput 1 characteristics setting screen

Output 1 characteristics setting screen

Initial value:

Setting range:、

Characteristics o control output is chosen rom (heating

characteristics)

and (cooling characteristics)

MODE 5 Event setting

MODE 5 Event settingMODE 5 Event setting

MODE 5 Event setting

Display

Display Display

Display

Description

Description Description

Description

Event 1 operation

Event 1 operationEvent 1 operation

Event 1 operation-

--

-mode setting screen

mode setting screenmode setting screen

mode setting screen

Setting range: Chosen from event type character table page 12.

Setting range: Chosen from event type character table page 12.Setting range: Chosen from event type character table page 12.

Setting range: Chosen from event type character table page 12.

Event 1 differential

Event 1 differentialEvent 1 differential

Event 1 differential-

--

-gap setting screen

gap setting screengap setting screen

gap setting screen

~

Event 1 standby operation setting screen

Event 1 standby operation setting screenEvent 1 standby operation setting screen

Event 1 standby operation setting screen

Event 1 latching setting screen

Event 1 latching setting screenEvent 1 latching setting screen

Event 1 latching setting screen

Event 1 output characteristics setting screen

Event 1 output characteristics setting screenEvent 1 output characteristics setting screen

Event 1 output characteristics setting screen

Event

Event Event

Event 2

2 2

2 operation

operationoperation

operation-

--

-mode setting screen

mode setting screenmode setting screen

mode setting screen

Same as Event 1

Same as Event 1Same as Event 1

Same as Event 1

Event

EventEvent

Event

3

3 3

3 operation

operationoperation

operation-

--

-mode setting screen

mode setting screenmode setting screen

mode setting screen

Same as Event 1&2

Same as Event 1&2Same as Event 1&2

Same as Event 1&2

9

99

9

thermo couple

thermo couplethermo couple

thermo couple

B,R,S,K,E,J,T,N:JIS/IEC

B,R,S,K,E,J,T,N:JIS/IECB,R,S,K,E,J,T,N:JIS/IEC

B,R,S,K,E,J,T,N:JIS/IEC

resistance bulb

resistance bulbresistance bulb

resistance bulb

Pt100:JIS/IEC

Pt100:JIS/IECPt100:JIS/IEC

Pt100:JIS/IEC

JPt100: former JIS

JPt100: former JISJPt100: former JIS

JPt100: former JIS

*1

*1*1

*1

thermo couple

thermo couplethermo couple

thermo couple

Accuracy is not guaranteed belo B:400℃ (752

Accuracy is not guaranteed belo B:400℃ (752Accuracy is not guaranteed belo B:400℃ (752

Accuracy is not guaranteed belo B:400℃ (752 )

))

).

..

.

*2

*2*2

*2

thermo couple

thermo couplethermo couple

thermo couple

In K, T, U,accuracy is±0.5

In K, T, U,accuracy is±0.5In K, T, U,accuracy is±0.5

In K, T, U,accuracy is±0.5%

%%

%FS for 0

FS for 0FS for 0

FS for 0~-

~-~-

~-100℃ (

100℃ (100℃ (

100℃ (-

--

-148

148148

148 )

))

)

a

aa

an

nn

nd

dd

d

±

±±

±1.0%FS if it is belo

1.0%FS if it is belo1.0%FS if it is belo

1.0%FS if it is belo -

--

-100℃

100℃ 100℃

100℃

*3

*3*3

*3

thermo couple

thermo couplethermo couple

thermo couple

Wre 5

Wre 5Wre 5

Wre 5-

--

-26: Product of Hoskins Mfg. co.,

26: Product of Hoskins Mfg. co.,26: Product of Hoskins Mfg. co.,

26: Product of Hoskins Mfg. co.,

*4

*4*4

*4

thermo couple

thermo couplethermo couple

thermo couple

PLⅡ:

PLⅡ:PLⅡ:

PLⅡ: Platinel

Platinel Platinel

Platinel

*5

*5*5

*5

thermo couple

thermo couplethermo couple

thermo couple

U:DIN43710

U:DIN43710U:DIN43710

U:DIN43710

* Setup of factory shipment is Multi input: thermo couple

* Setup of factory shipment is Multi input: thermo couple * Setup of factory shipment is Multi input: thermo couple

* Setup of factory shipment is Multi input: thermo couple

0

00

0

-

--

-1200℃

1200℃ 1200℃

1200℃

7

77

7-

--

-7 .Measuring range code table

7 .Measuring range code table7 .Measuring range code table

7 .Measuring range code table

With closed DI terminal Execution SV = 2nd SV

With closed DI terminal Execution SV = 3rd SV

With closed DI terminal Execution SV = 4th SV

RUN with closed DI terminal, S BY with open one.

Manual with closed DI terminal,auto with open one.

A -start with rise edge.

All latching are released by rise edg.

Super key lock with closed DI terminal.

Release with opened.

30m

30m30m

30m

7

77

7-

--

-5 .MODE6:DI setting

5 .MODE6:DI setting5 .MODE6:DI setting

5 .MODE6:DI setting

MODE 6 Digital input setting

MODE 6 Digital input settingMODE 6 Digital input setting

MODE 6 Digital input setting

DI

DI DI

DI 4

44

4

mode setting screen

mode setting screenmode setting screen

mode setting screen

7

77

7-

--

-6 .DI operation character table

6 .DI operation character table6 .DI operation character table

6 .DI operation character table

8. Supplementary Explanation of Function

8. Supplementary Explanation of Function8. Supplementary Explanation of Function

8. Supplementary Explanation of Function

This is the function to increase the control output gradually with set-up time

at the time of power-on, STBY→RUN, and normal return from scale over

This is effective for controlling the excessive current to loads, such as a

heater

1) Soft- start functions in the following conditions

・At the time of the power-on in automatic operation,

STBY(RST)→RUN, and normal return from scale over

・Setup of proportional band (P) is other than OFF

・Soft starting time is not OFF

8

88

8-

--

-1 .Auto return function

1 .Auto return function1 .Auto return function

1 .Auto return function

When there is no key operation 3 minutes or more, on the screen except

for basic screen and each monitoring screen, screen automatically shifts to

basic screen (Auto return)

8

88

8-

--

-2.Output Soft Start Function

2.Output Soft Start Function2.Output Soft Start Function

2.Output Soft Start Function

8

88

8-

--

-3.Event Selection Alarm Operation Figure

3.Event Selection Alarm Operation Figure3.Event Selection Alarm Operation Figure

3.Event Selection Alarm Operation Figure

The figure of alarm operation figure allotted to event 1~3 is shown

M

MM

M

U

UU

U

-199.9~200.0 -300~400

L

LL

L

T

TT

T

I

II

I

I

II

I

N

NN

N

P

PP

P

U

UU

U

T

TT

T

▲

ON operation

▲

ON operation

:Lower limit absolute value alarm :Upper limit absolute value alarm

:Upper limit deviation alarm :Lower limit deviation alarm

▲ ▲

:Without deviation alarm :With deviation alarm

-10% 0% 100% 110% PV

:Scale over

ON operation ON operation

ON operation

10

1010

10

8

88

8-

--

-4.AT (Auto Tuning)

4.AT (Auto Tuning)4.AT (Auto Tuning)

4.AT (Auto Tuning)

・If AT is performed by FIX (constant value control)、AT monitor LED blin s and light is put out by termination or intermediate release.

・AT at the time of 2 output specification is as follows.

At the time of heating / cooling operation and cooling / heating operation = OUT1, OUT2 common - PID value At the time of heating / heating operation

and cooling / cooling operation, only OUT1 performs AT. OUT 2 output while performing AT is 0% or output limiter lower limit v

8

88

8-

--

-5 .Output

5 .Output5 .Output

5 .Output-

--

-characteristics figure

characteristics figurecharacteristics figure

characteristics figure

2-output -characteristics is shown in the following figure.

◎ Conditions: P operation, manual reset ( ) -50.0%

1) OUT 1 RA (heating)

1) OUT 1 RA (heating) 1) OUT 1 RA (heating)

1) OUT 1 RA (heating) ・

・・

・OUT 2 DA (cooling) operation

OUT 2 DA (cooling) operationOUT 2 DA (cooling) operation

OUT 2 DA (cooling) operation

2) OUT 1RA (heating)

2) OUT 1RA (heating)2) OUT 1RA (heating)

2) OUT 1RA (heating)・

・ ・

・ OUT 2 RA (heating)

OUT 2 RA (heating)OUT 2 RA (heating)

OUT 2 RA (heating)

9. Trouble

9. Trouble 9. Trouble

9. Trouble

9

99

9-

--

-1. Cause and Treatment of Main efects

1. Cause and Treatment of Main efects 1. Cause and Treatment of Main efects

1. Cause and Treatment of Main efects

9

99

9-

--

-2. Cause and Treatment of Error isplay

2. Cause and Treatment of Error isplay2. Cause and Treatment of Error isplay

2. Cause and Treatment of Error isplay

Abnormality Display of Measurement Input

Abnormality Display of Measurement InputAbnormality Display of Measurement Input

Abnormality Display of Measurement Input

Errordisplay Contents Cause Treatment

(HHHH)

Scale over in upper limit 1.wire breaking of t ermocouple input

2.wire breaking of resistance bulb input A

3.w en input exceeds upper limit of measuring range by 10%

1.wire breaking c eck of t ermocouple input wiring, replacement of t ermocouple

2.c eck of resistance bulb A wiring, replacement of resistance bulb

3.c eck of input voltage value and current value, input transmitter and specification

(matc ing of incoming signal and meter specification)

(LLLL)

Scale over in lower limit 1.w en input exceeds lower limit of measuring range by 10%

2.wire breaking of resistance bulb input B*

1.polarity of input is everse, c eck of wiring and an input transmitter

2.c eck of resistance bulb B wiring, replacement of resistance bulb

*B: Wiring of MAC5A, 5B's terminal No.11,Wirring of MAC5C ‘s terminal No,8

Wiring of MAC 5D's terminal No.5

(B---)

Breaking of resistance bulb input 1.wire breaking of b* 1.c eck of resistance bulb wiring

*b: Wiring of MAC 5A, 5B's terminal No.12,Wirring of MAC5C ‘s terminal No,9

wiring of MAC 5D's terminal No.6

2.multiple wire breaking combinations in Abb

(A and B, A and b, B and b, all of ABB)

2.replacement of resistance bulb

(CJHH)

Cold junction (CJ) temperature of t ermocouple

input is scale over in upper limit side

W en ambient temperature of a meter exceeds 80℃ 1.make Ambient temperature of meter wit in use environment condition temperature

2. C eck t e meter w en ambient temperature is not over 80℃

(CJLL)

Cold junction (CJ) temperature of t ermocouple

input is scale over in lower limit side

W en ambient temperature of meter becomes less

t an -20℃

1.make Ambient temperature of meter wit in use environment condition temperature

2. C eck t e meter w en ambient temperature is not less t an -20℃

Output 100%

Control output1(RA C aracteristics)

Control output2(DA C aracteristics)

▲

-DB

△

DB=0

▲

+DB

▲

-DB

△

DB=0

▲

+DB

△:Setting Value(SV) ▲:DB(Dead Band)

Control output1(RA C aracteristics)

Control output2(DA C aracteristics)

Output 0%

Output 100%

Output 100%

Output 0%

△:Setting Value(SV) ▲:DB(Dead Band)

10. Specification

10. Specification10. Specification

10. Specification

11

1111

11

*

Function C aracter Note

No allotment

Upper limit absolute value Alarm

Lower limit absolute value alarm

Scale over alarm HHHH, LLLL, B---- Operates, w en displayed.

Upper limit deviation value Alarm

Lower limit deviation value alarm

Wit in deviation alarm

Wit out deviation alarm

RUN signal Operates during FIX in operation.

12

1212

12

11.General specification

11.General specification11.General specification

11.General specification

2

C aracter Kinds of operation Input detection Contents

No allotment level

2nd SV level Wit closed DI terminal, Execution SV = 2nd SV

3rd SV level Wit closed DI terminal, Execution SV = 3rd SV

4t SV level Wit closed DI terminal, Execution SV = 4t SV

Control RUN level RUN wit closed DI terminal. STBY(RST) wit opened.

Manual output level Manual wit closed DI terminal. Auto wit opened.

Auto tuning edge AT starts wit rise edge.

Latc ing release edge Wit rise edge, all latc ing released

Super key lock level Super key lock wit closed DI terminal. Release wit opened.

1st SV level Wit closed DI terminal, Execution SV = 1st SV

CO., LTD

Head Office: 11-5 Fujimicho, Daisen-shi, Akita 01 -0011 Japan

Phone: +81-187-86-3 00 FAX. +81-187-62-6 02

URL;http://www.shimax.co

T e contents of t is instruction are subject to c ange wit out notice.

This manual suits for next models

4

Table of contents

Other Shimax Controllers manuals

Popular Controllers manuals by other brands

SMC Networks

SMC Networks THERMO-CON HEC001 Series Communications manual

Neptronic

Neptronic SPC Specification and installation instructions

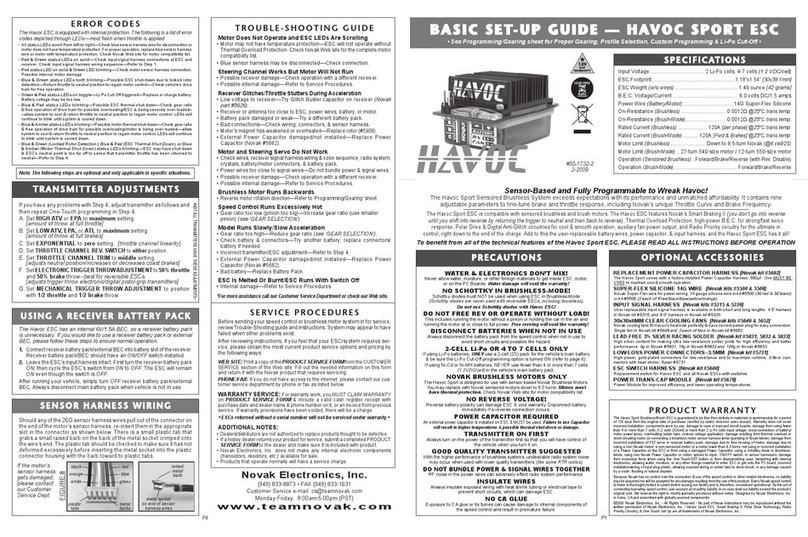

NOVAK

NOVAK HAVOC SPORT ESC - SETUP GUIDE 2-2009 Setup guide

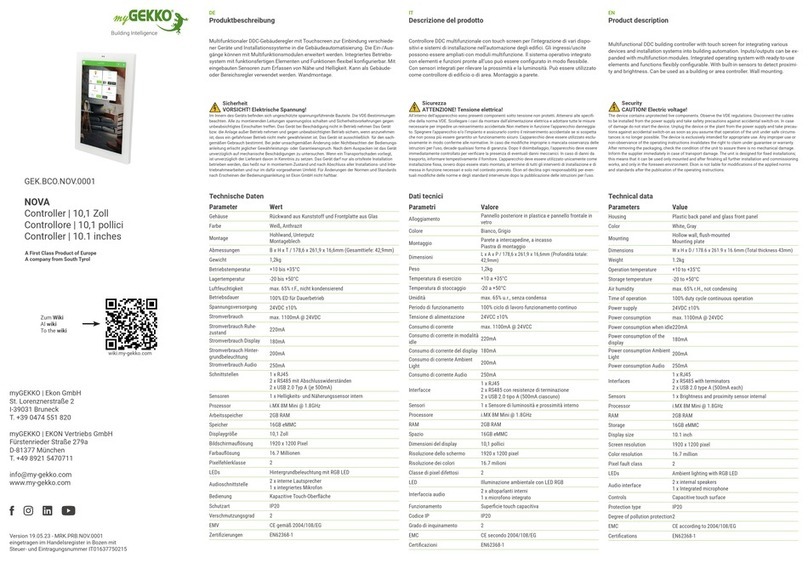

myGekko

myGekko NOVA manual

RKC INSTRUMENT

RKC INSTRUMENT CB500 Series instruction manual

Groschopp

Groschopp RBD-325-4/6-S product manual

Velleman

Velleman VM192RF user manual

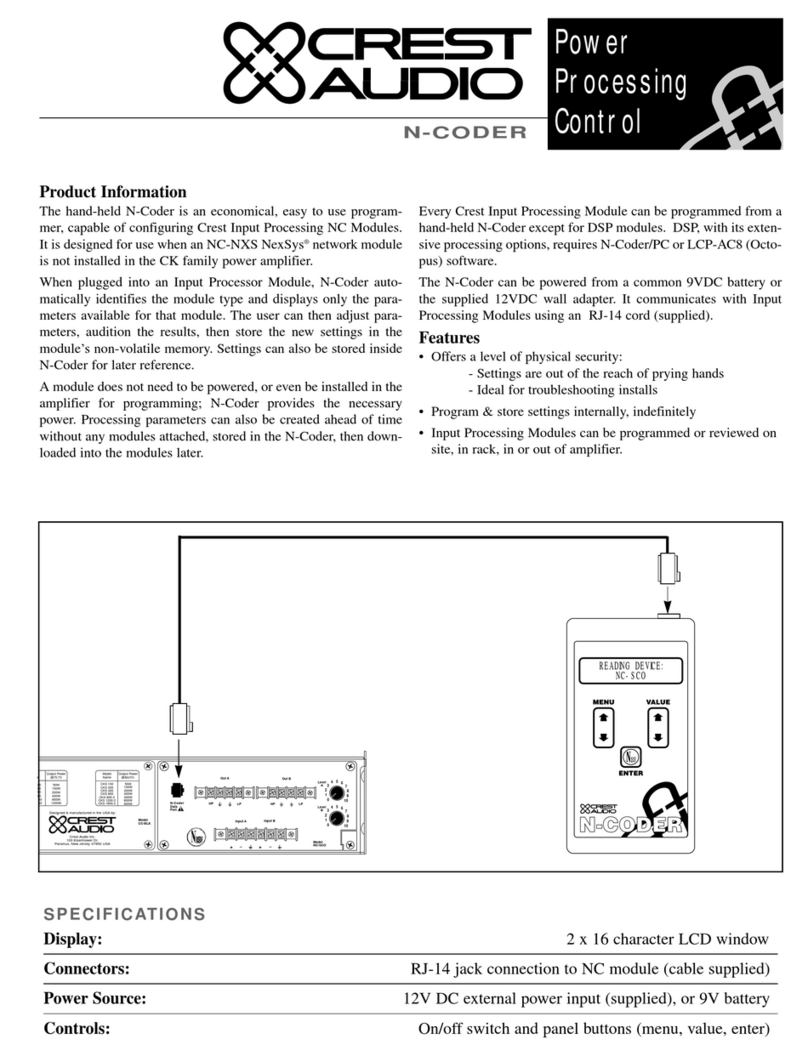

Crest Audio

Crest Audio N-CODER Specifications

Knoll

Knoll VC100SP installation guide

Automatismos Pujol

Automatismos Pujol SPIDER PRO 600 Installation and adjustment instructions

Gamma Vacuum

Gamma Vacuum DIGITEL QPC instruction manual

Aerotech

Aerotech 6020HRJ user manual