1.PREFACE............................................................................................................................................

2.INSTALLATION....................................................................................................................................

3.ELECTRICAL WIRINGS......................................................................................................................

5.DEFINITION OF FRONT PANEL AND ACCESSING TO THE PARAMETERS..................................

6.PARAMETERS.....................................................................................................................................

7.FAILURE MESSAGES IN ESM-4930 PROCESS CONTROLLERS...................................................

8.SPECIFICATIONS................................................................................................................................

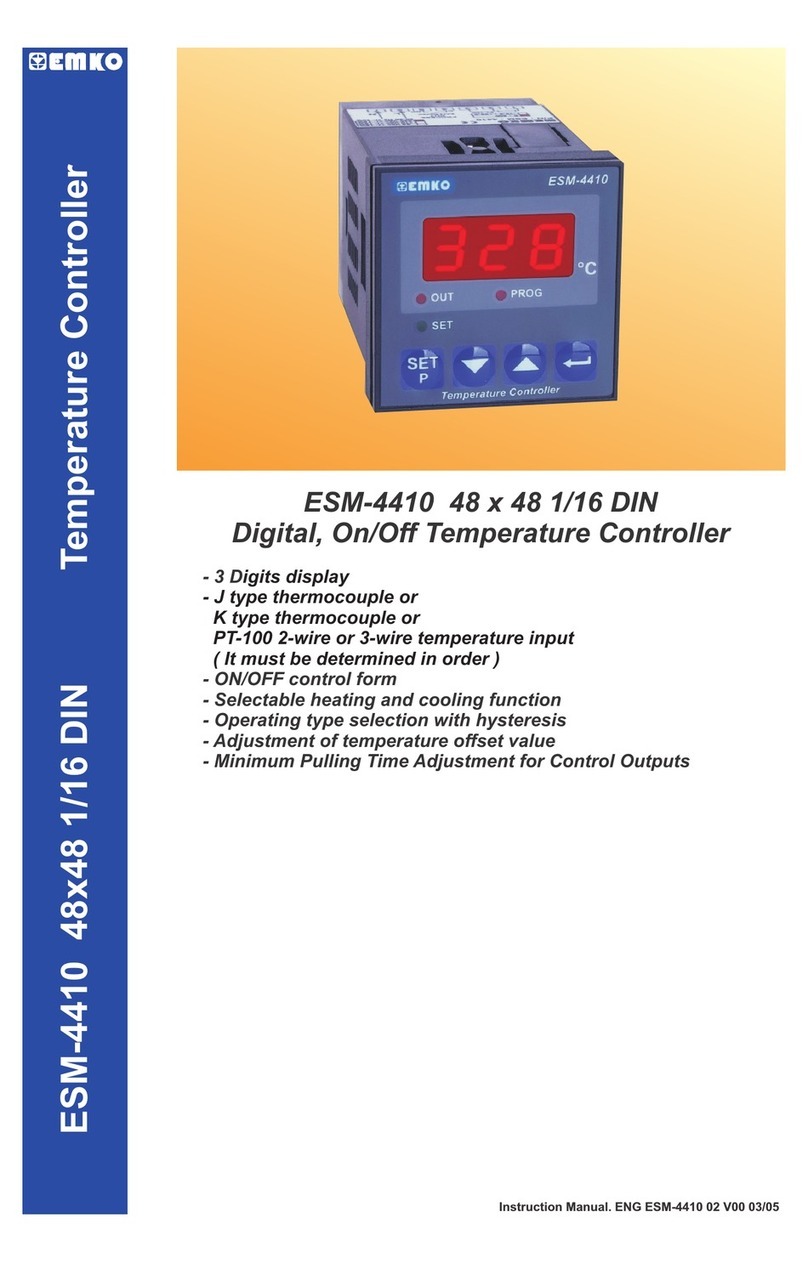

1.1 GENERAL SPECIFICATIONS

1.2 ORDERING INFORMATION

1.3 WARRANTY

1.4 MAINTENANCE

2.1 GENERAL DESCRIPTION

2.2 DIMENSIONS

2.3 PANEL CUT-OUT

2.4 ENVIRONMENTAL RATINGS

2.5 PANEL MOUNTING

2.6 INSTALLATION MOUNTING CLAMP

2.7 REMOVING FROM THE PANEL

3.1 TERMINAL LAYOUT AND CONNECTION INSTRUCTION

3.2 ELECTRICAL WIRING DIAGRAM

3.3 VIEW OF THE LABELS

3.4 CONNECTION OF DEVICE SUPPLY VOLTAGE INPUT

3.5 PROCESS INPUT CONNECTION

3.5.1 TC (THERMOCOUPLE) CONNECTION

3.5.2 RTD CONNECTION

3.5.3 PROCESS INPUT CONNECTION OF SERIAL TRANSMITTERS WITH CURRENT

OUTPUT (LOOP POWERED)

3.5.4 PROCESS INPUT CONNECTION OF 3-WIRE TRANSMITTERS WITH CURRENT

OUTPUT

3.5.5 CONNECTION OF TRANSMITTERS WITH VOLTAGE OUTPUT TO PROCESS

INPUT

3.6 GALVANIC ISOLATION TEST VALUES OF ESM-4930 PROCESS CONTROLLER

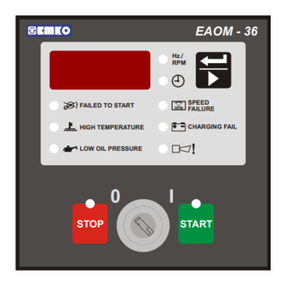

5.1 DEFINITION OF FRONT PANEL

5.2 OBSERVATION OF SOFTWARE REVISION ON THE BOTTOM DISPLAY WHEN POWER

IS ON

5.3 ADJUSTMENT OF PROCESS AND ALARM SET VALUES

5.4 EASY ACCESS DIAGRAM FOR PROGRAM PARAMETERS

5.5 ACCESSING TO THE TECHNICIAN MENU

5.6 CHANGING AND SAVING PARAMETERS

6.1 PROCESS / ALARM SET PARAMETERS

6.2 TECHNICIAN PARAMETERS

6.2.1 SELECTION OF PID TUNE AND OPERATION FORM

6.2.2 FUNCTION SELECTION FOR TOP AND BOTTOM DISPLAY

6.2.3 PROCESS INPUT TYPE AND RELEVANT PARAMETERS WITH PROCESS INPUT

6.2.4 PID CONFIGURATION PARAMETERS

6.2.5 PROCESS OUTPUT CONFIGURATION PARAMETERS

6.2.6 ALARM OUTPUT - 1 CONFIGURATION PARAMETERS

6.2.7 ALARM OUTPUT - 2 CONFIGURATION PARAMETERS

6.2.8 GENERAL PARAMETERS

6.2.9 TECHNICIAN PASSWORD

4.CONNECTION WIRINGS FOR OUTPUTS IN ESM-4930 PROCESS CONTROLLER......................

4.1 PROCESS OUTPUT (SSR DRIVER OUTPUT) CONNECTION

4.2 ALARM OUTPUT -1 RELAY CONNECTION

4.3 PROCESS OUTPUT OR ALARM OUTPUT -2 RELAY CONNECTION

CONTENTS

3

Page 5

Page 42

Page 20

Page 13

Page 8

Page 22

Page 65

Page 67