Shimadzu OMRON CJ Series Instruction Manual

Programmable Controller CJ-series

General-purpose Serial

Connection Guide

(RS-232C)

SHIMADZU CORPORATION

Shimadzu Analytical Balance /

Electronic Balance

(ATX-R/ATY-R/UPX/UPY/UW/UX Series)

P732-E1-01

About Intellectual Property Rights and Trademarks

Microsoft product screen shots reprinted with permission from Microsoft Corporation.

Windows is a registered trademark of Microsoft Corporation in the USA and other countries.

Company names and product names in this guide are the trademarks or registered trademarks of

their respective companies.

Contents

1. Related Manuals........................................................................................ 1

2. Terms and Definitions............................................................................... 2

3. Precautions................................................................................................ 3

4. Overview .................................................................................................... 4

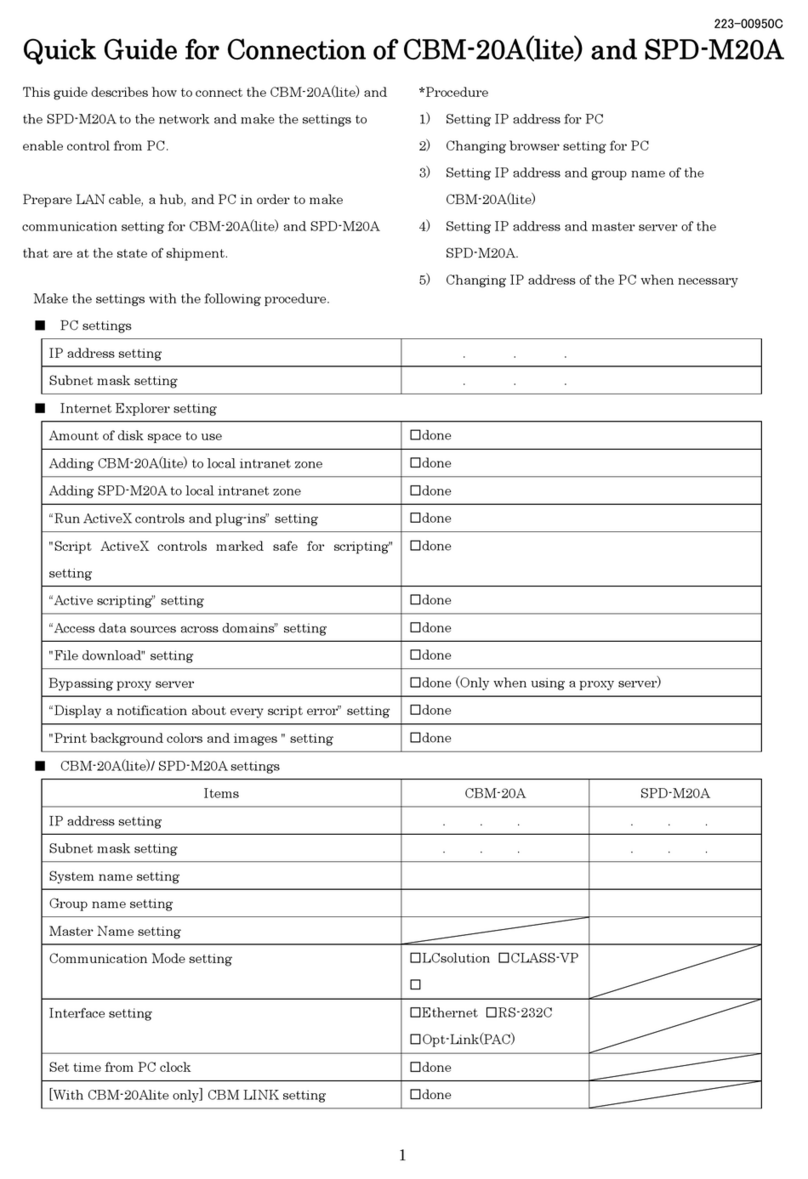

5. Applicable Devices and Device Configuration ....................................... 5

5.1. Applicable Devices............................................................................. 5

5.2. Device Configuration.......................................................................... 6

6. Serial Communications Settings ............................................................. 8

6.1. Parameters ........................................................................................ 8

6.2. Cable Wiring ...................................................................................... 9

7. Serial Communications Connection Procedure ....................................11

7.1. Work Flow.........................................................................................11

7.2. SHIMADZU Balance Setup.............................................................. 13

7.3. PLC Setup........................................................................................ 21

7.4. Serial Communication Status Check................................................ 40

8. Initialization Method................................................................................ 48

8.1. Initializing a PLC .............................................................................. 48

8.2. Initializing a SHIMADZU Balance..................................................... 49

9. Program.................................................................................................... 50

9.1. Overview.......................................................................................... 50

9.2. Communications Sequence............................................................. 55

9.3. Error Detection Processing .............................................................. 57

9.4. Memory Maps .................................................................................. 58

9.5. Ladder Program............................................................................... 61

9.6. Protocol Data ................................................................................... 67

9.7. Timing Chart .................................................................................... 75

9.8. Error processing............................................................................... 76

10. Revision History...................................................................................... 78

1.Related Manuals

1

1. Related Manuals

To ensure system safety, make sure to always read and follow the information provided in all

Safety Precautions and Precautions for Safe Use in the manuals for each device which is

used in the system.

The table below lists the manuals provided by SHIMADZU CORPORATION (hereinafter

referred to as "SHIMADZU") and OMRON Corporation (hereinafter referred to as "OMRON"),

which pertain to this guide.

Manufacturer

Cat. No.

Model

Manual name

OMRON W472 CJ2M-CPU□□

CJ2H-CPU6□

CJ2H-CPU6□-EIP

CJ Series

CJ2 CPU Unit

Hardware USER'S MANUAL

OMRON W473 CJ2M-CPU□□

CJ2H-CPU6□

CJ2H-CPU6□-EIP

CJ Series

CJ2 CPU Unit

Software USER'S MANUAL

OMRON W336 CJ1W-SCU□1-V1

CJ1W-SCU□2 CJ Series

Serial Communications Units

OPERATION MANUAL

OMRON W474 CJ2□-CPU□□ CJ Series Programmable Controllers

INSTRUCTIONS REFERENCE

MANUAL

OMRON W446 CXONE-AL□□C-V4

/ AL□□D-V4 CX-Programmer

OPERATION MANUAL

OMRON W344 CXONE-AL□□C-V4

/ AL□□D-V4 CX-Protocol

OPERATION MANUAL

SHIMADZU 321-78327 ATX-R series

ATY-R series Analytical Balance Instruction Manual

SHIMADZU 321-78282 UPX series

UPY series

Top-loading Balance Instruction Manual

SHIMADZU 321-78048 UW series

UX series Electronic Balance Instruction Manual

2.Terms and Definitions

2

2. Terms and Definitions

The terms and definitions used in this guide are given below.

Term

Explanation and Definition

protocol macro Data transfer procedures (protocols) with general-purpose external

devices are created and stored in Serial Communications Boards or Serial

Communications Units. These protocols enable data to be exchanged with

general-purpose external devices by executing the protocol macro

instruction (hereinafter referred to as "the PMCR instruction") in a CPU

Unit.

protocol A set of rules governing the data transmission procedure that unifies

independent communication processes for a specific general-purpose

device. A protocol consists of more than one sequence.

sequence

An independent process that can be performed by executing the PMCR

instruction in a program. The sequence started by the instruction executes

its steps in a given order.

step A unit to execute any one of the followings: message send processing,

message receive processing, message send/receive processing, receive

buffer clear or step wait. Up to 15 steps can be created per sequence.

send message A communication frame (command) sent to a general-purpose external

device. The send message is invoked by steps in the sequence and is sent

to general-purpose external devices.

receive message A communication frame (response) sent from a general-purpose external

device. The receive message is invoked by steps in the sequence and is

compared with data received from general-purpose external devices.

receive matrix A function to register and use some communication frames (responses)

when more than one communication frame is expected to be received from

a general-purpose external device. The receive processing can be

executed according to registered communication frames by using this

function.

3.Precautions

3

3. Precautions

(1) Understand the specifications of devices which are used in the system. Allow some

margin for ratings and performance. Provide safety measures, such as installing a safety

circuit, in order to ensure safety and minimize the risk of abnormal occurrence.

(2) To ensure system safety, make sure to always read and follow the information provided in

all Safety Precautions and Precautions for Safe Use in the manuals for each device

which is used in the system.

(3) The user is encouraged to confirm the standards and regulations that the system must

conform to.

(4) It is prohibited to copy, to reproduce, and to distribute a part or the whole of this guide

without the permission of OMRON Corporation.

(5) The information contained in this guide is current as of November 2019. It is subject to

change for improvement without notice.

The following notations are used in this guide.

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury or property damage.

Precautions for Safe Use

Precautions on what to do and what not to do to ensure safe usage of the product.

Precautions for Correct Use

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional Information

Additional information to read as required.

This information is provided to increase understanding or make operation easier.

Symbol

The triangle symbol indicates precautions (including warnings).

The specific operation is shown in the triangle and explained in the text.

This example indicates a general precaution.

The filled circle symbol indicates operations that you must do.

The specific operation is shown in the circle and explained in the text.

This example shows a general precaution for something that you must do.

4.Overview

4

4. Overview

This guide describes procedures for connecting a SHIMADZU Analytical Balance

ATX-R/ATY-R series or Electronic Balance UPX/UPY/UW/UX series (hereinafter collectively

referred to as the "Balance") to an OMRON CJ-series Programmable Controller + Serial

Communications Unit (hereinafter referred to as the "PLC") via serial communications and for

checking their serial communication connection.

Refer to Section 6. Serial Communications Settings and Section 7. Serial Communications

Connection Procedure to understand setting methods and key points to send and receive a

message via serial communications.

This guide uses the pre-configured program (ladder program in the CX-Programmer project

file and the protocol data in the CX-Protocol project file) in order to check the serial

communication connection by sending a message of "single output with stability information"

to and receiving a response from the Balance.

Sending "single output with stability information" and receiving a response

PLC

Serial communications

(RS-232C)

Balance

Sends command data Executes the command

Receives response data

and stores in memory Returns response data

Contact OMRON to obtain latest versions of the CX-Programmer and CX-Protocol project files

before proceeding.

Name File name Version

CX-Programmer project file

(extension: cxp) P732_CJ_PMCR232C_SHIMADZU_E-Balance

_V100.cxp Ver.1.00

CX-Protocol project file

(extension: psw)

P732_CJ_PMCR_SHIMADZU_E-Balance_V10

0.psw

Ver.1.00

This guide aims to explain wiring methods, communications settings and setting

procedures necessary to connect the devices used in this guide. The program

used in this guide is not designed to be constantly used at a site but is designed

to check if the connection is established normally. Both functionality and

performance are therefore not fully considered for the program.

When you build a system, please use the wiring methods, communications

settings and setting procedures described in this guide as references, and

design a program according to your application needs.

Command data

Response data

5.Applicable Devices and Device Configuration

5

5. Applicable Devices and Device Configuration

5.1. Applicable Devices

The applicable devices are as follows:

Manufacturer Name Model

OMRON

CJ2 CPU Unit

CJ2□-CPU□□

OMRON

Serial Communications Unit

CJ1W-SCU□1-V1

CJ1W-SCU□2

SHIMADZU

Analytical Balance

ATX-R series

ATY-R series

SHIMADZU

Electronic Balance

UPX series

UPY series

UW series

UX series

Precautions for Correct Use

In this guide, the devices with models and versions listed in 5.2. Device Configuration are

used as examples of applicable devices to describe the procedures for connecting the

devices and checking their connection. You cannot use devices with versions lower than

those listed in 5.2. To use the above devices with models not listed in 5.2. or versions higher

than those listed in 5.2., check the differences in the specifications by referring to the

manuals before operating the devices.

Additional Information

This guide describes the procedures for establishing the network connection.

It does not provide information on operation, installation, wiring method, device functionality,

or device operation, which is not related to the connection procedures.

Refer to the manuals or contact the manufacturers.

5.Applicable Devices and Device Configuration

6

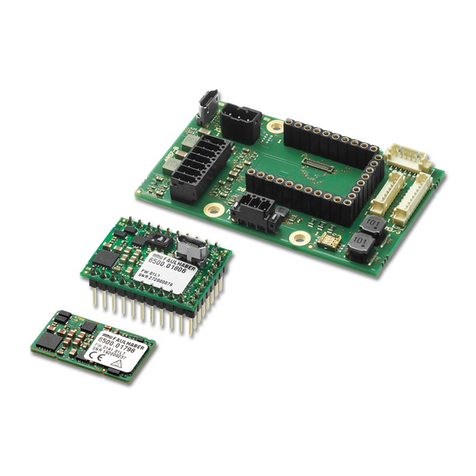

5.2. Device Configuration

The hardware components to reproduce the connection procedures in this guide are as

follows:

Manufacturer

Name

Model

Version

OMRON

Serial Communications Unit

CJ1W-SCU42

Ver.2.0

OMRON

CJ2 CPU Unit

CJ2M-CPU12

Ver.2.0

OMRON

Power Supply Unit

CJ1W-PA202

OMRON

CX-One

CXONE-AL□□C-V4

/AL□□D-V4

Ver.4.□□

OMRON

CX-Programmer

(provided in CX-One

package)

Ver.9.71

OMRON

CX-Protocol

(provided in CX-One

package)

Ver.2.01

OMRON

CX-Programmer project file

P732_CJ_PMCR232C_SHI

MADZU_E-Balance_V100.c

xp

Ver.1.00

OMRON

CX-Protocol project file

P732_CJ_PMCR_SHIMAD

ZU_E-Balance_V100.psw

Ver.1.00

―

Personal computer

(OS: Windows 10)

―

―

USB cable (USB 2.0-compliant,

USB-B connector)

―

―

Serial cable (RS-232C)

―

SHIMADZU

Balance

ATX324R

SHIMADZU

AC Adapter

(supplied with the Balance)

Precautions for Correct Use

Contact OMRON to obtain latest versions of the CX-Programmer and CX-Protocol project

files before proceeding.

Precautions for Correct Use

Update CX-Programmer and CX-Protocol to the versions specified above or to higher

versions. If you use a version higher than the one specified, the procedures and related

screenshots described in Section 7. and the subsequent sections may not be applicable.

In that case, use the equivalent procedures described in this guide by referring to the

CX-Programmer OPERATION MANUAL (Cat. No. W446) and the CX-Protocol OPERATION

MANUAL (Cat. No. W344).

AC adapter

CJ2M-CPU12

+

CJ1W-SCU42

Personal computer

(CX-One installed,

OS: Windows 10

)

USB cable

Serial cable

(RS-232C)

ATX324R

5.Applicable Devices and Device Configuration

7

Additional Information

For information on the serial cable (RS-232C) used in this guide, refer to 3-4 RS-232C and

RS-422A/485 Wiring of the CJ Series Serial Communications Units OPERATION MANUAL

(Cat. No. W336).

Additional Information

The system configuration in this guide uses USB for the connection between the personal

computer and the PLC. For information on how to install the USB driver, refer to A-5 Installing

the USB Driver of the CJ-series CJ2 CPU Unit Hardware USER'S MANUAL (Cat. No. W472).

6.Serial Communications Settings

8

6. Serial Communications Settings

This section describes the parameters and cable wiring that are used in this guide.

6.1. Parameters

The following parameters are required to connect the Balance and the PLC via serial

communications.

ATX-R/ATY-R series

Item

PLC (Serial Communications Unit)

ATX-R/ATY-R series

Unit number

0

―

Communications port

(communications type)

Port 2 (RS-232C)

―

Serial communications mode

Protocol macro

―

Communication specifications

―

MODE.2

(standard settings 2)

*1

Data (bit) length

8 bits

8 (fixed)

Stop bit (length)

1 bit

1 (fixed)

Parity

None

None (fixed)

Baud rate (communication speed)

1200 bps

1200 bps (fixed)

Protocol macro transmission

method (Full-duplex / Half-duplex)

Full-duplex

―

Handshake

―

Hardware

Data format

―

Shimadzu standard (fixed)

Delimiter

―

CR (fixed)

*When setting the communication specifications to "MODE.2" (standard settings 2), the following items

are all set at once: data (bit) length, stop bit (length), parity, baud rate (communication speed),

handshake and data format. For details on the communication settings, refer to 10 CONNECTION

AND COMMUNICATION of the Analytical Balance Instruction Manual (321-78327).

UPX/UPY/UW/UX series

Item

PLC (Serial Communications Unit)

UPX/UPY/UW/UX series

Unit number

0

―

Communications port

(communications type)

Port 2 (RS-232C)

―

Serial communications mode

Protocol macro

―

Data (bit) length

8 bits

8 (default)

Stop bit (length)

1 bit

1 (default)

Parity

None

None (default)

Baud rate (communication speed)

1200 bps

1200 bps (default)

Protocol macro transmission

method (Full-duplex / Half-duplex)

Full-duplex

―

Handshake

―

OFF

Data format

―

EB type (default)

Delimiter

―

CR (default)

Precautions for Correct Use

The following Serial Communications Unit, unit number and communications (connection)

port are assumed to be used in this guide.

Model: CJ1W-SCU42, Unit number: 0, Communications (connection) port: Port 2

If you connect the devices under different conditions, change the CIO area and control data

of the PMCR instruction by referring to 9. Program.

6.Serial Communications Settings

9

6.2. Cable Wiring

For details on cable wiring, refer to SECTION 3 Installation and Wiring of the CJ Series Serial

Communications Units OPERATION MANUAL (Cat. No. W336).

Check the shapes and pin layouts of the connectors before wiring.

Shape and pin layout of the connector

Serial Communications Unit (CJ1W-SCU42) applicable connector: D-SUB 9-pin female

Pin No.

Abbreviation

Signal name

I/O

1

FG

Shield

―

2

SD

Send data

Output

3

RD

Receive data

Input

4

RS

Request to send

Output

5

CS

Clear to send

Input

6

5V

Power supply

―

7

DR

Data set ready

Input

8

ER

Data terminal ready

Output

9

SG

Signal ground

―

Shell

FG

Shield

―

ATX-R/ATY-R series applicable connector: D-SUB 9-pin male

Use Pin No. Abbreviation

Signal name

RS-232C

1 ―

―

2 RXD Data input

3 TXD Data output

4 DTR Handshake (send)

5 SG Signal ground

6 DSR Handshake (receive)

7 RTS Request to send (RS-232C)

8 CTS Clear to send (RS-232C)

9 ――

Cable and pin layout

Serial Communications Unit

(CJ1W-SCU42)

ATX-R/ATY-R series

RS-232C

Interface

Signal

name

Pin No.

Pin No.

Signal

name

RS-232C

Interface

FG

1

1

NC

SD

2

2

RXD

RD

3

3

TXD

RS

4

4

DTR

CS

5

5

SG

5V

6

6

DSR

DR

7

7

RTS

ER

8

8

CTS

SG

9

9

NC

FG

Shell

D-SUB 9-pin

cable connector: female

D-SUB 9-pin

Cable connector: male

6.Serial Communications Settings

10

UPX/UPY/UW/UX series applicable connector: D-SUB 25-pin female

Use Pin No.

Terminal

name

Function

RS-232C

1 FG

Protective ground or

earth

2

TXD

Data output

3

RXD

Data input

4 RTS

Internal connection to

CTS

5 CTS

Internal connection to

RTS

6

DSR

Handshake (receive)

7

SG

Signal ground

8 to 19

Undefined

-

20

DTR

Handshake (send)

21 to 25

Undefined

-

Cable and pin layout

Serial Communications Unit

(CJ1W-SCU42)

UPX/UPY/UW/UX series

RS-232C

Interface

Signal

name

Pin No.

Pin No.

Signal

name

RS-232C

Interface

FG

1

1

FG

SD

2

2

TXD

RD

3

3

RXD

RS

4

4

RTS

CS

5

5

CTS

5V

6

6

DSR

DR

7

7

SG

ER

8

8 to 19

Undefined

SG

9

20

DTR

FG

Shell

21 to 25

Undefined

D-SUB 9-pin

cable connector: male

D-SUB 25-pin

cable connector: male

7.Serial Communications Connection Procedure

11

7. Serial Communications Connection Procedure

This section describes the procedures for connecting the Balance and the PLC via serial

communications. The procedures for setting up the Balance and the PLC in this guide are

based on the factory default settings.

For information on initialization, refer to Section 8. Initialization Method.

7.1. Work Flow

Take the following steps to connect the Balance and the PLC via serial communications and

send and receive a message.

7.2. SHIMADZU Balance Setup

Set up the SHIMADZU Balance.

↓

7.2.1 Parameter Settings

Set parameters for the Balance.

↓

7.3. PLC Setup

Set up the PLC.

↓

7.3.1. Hardware Settings

Set the hardware switches on the Serial

Communications Unit and connect the cables.

↓

7.3.2. Opening the Project File and

Going Online with the PLC

Start CX-Programmer, open the project file and go

online with the PLC.

↓

7.3.3. Creating an I/O Table

Create an I/O table for the PLC.

↓

7.3.4. Parameter Settings

Set parameters for the Serial Communications

Unit.

↓

7.3.5. Transferring the Project Data

Transfer the project data to the PLC.

↓

7.3.6. Starting CX-Protocol and

Opening the Project File

Start CX-Protocol and open the project file.

↓

7.3.7 Going Online and Transferring

the Protocol Data

Place CX-Protocol online and transfer the protocol

data to the Serial Communications Unit.

↓

7.Serial Communications Connection Procedure

12

7.4. Serial Communication Status

Check

Start the send/receive processing and confirm that

serial communications is performed normally.

↓

7.4.1. Starting the Trace

Start tracing with CX-Protocol.

↓

7.4.2. Executing the Communications

Sequence

Execute the communications sequence with

CX-Programmer.

↓

7.4.3. Checking the Trace Data

Check with the trace data in CX-Protocol that

correct data is sent and received.

↓

7.4.4. Checking Received Data

With CX-Programmer, check that correct data is

written to the I/O memory of the PLC.

7.Serial Communications Connection Procedure

13

7.2. SHIMADZU Balance Setup

Set up the SHIMADZU Balance.

7.2.1. Parameter Settings

Set parameters for the Balance.

The parameter settings vary depending on the model used.

Use one of the following parameter setting procedures appropriate for your Balance's model.

Model Procedure to be followed

ATX-R/ATY-R series 1) Parameter settings for ATX-R/ATY-R series

UPX/UPY/UW/UX series

2) Parameter settings for UPX/UPY/UW/UX series

1) Parameter settings for ATX-R/ATY-R series

Set parameters for ATX-R/ATY-R series.

Precautions for Correct Use

Make sure the power supply is OFF before setting up.

If it is ON, the settings described in the following steps and subsequent procedures may not

be applicable.

1

Make sure AC Adapter is

powered OFF.

2

Check the position of the

connectors on Balance.

Connect a Serial cable

(RS-232C) to RS-232C

connector.

Connect AC Adapter to DC IN

connector.

Back view of Balance

3

Check the position of the

operation keys by referring to

the figure on the right.

Front view of Balance

4

Turn ON AC Adapter.

Serial cable (RS-232C)

AC adapter

RS-232C connector

O/T key

USB connector

CAL key

DC IN connector

MENU key

PRINT key

UNIT key

Display

panel

BREAK key

7.Serial Communications Connection Procedure

14

5

Display panel shows "OFF".

Press BREAK key.

6

Display panel shows gram units.

Press and hold PRINT key for

about 3 seconds.

7

Display panel shows

"APL.PRN".

Press MENU key once.

Display panel shows

"COMM.SET".

Press PRINT key once.

Display panel shows "MODE.1".

Press UNIT key once.

Display panel shows "MODE.2".

Press O/T key once.

*In this guide, the communication

specifications of Balance are set

to "MODE.2" (standard settings

2), in order to send command

data from PLC to Balance and

check response data received

from Balance.

Check that Display panel shows

"SET".

Once the setting is confirmed,

Display panel shows "MODE.2".

Press and hold BREAK key for

about 3 seconds.

*For more information on the

menu operations, refer to 10

CONNECTION AND

COMMUNICATION WITH

PERIPHERAL DEVICES of the

Analytical Balance Instruction

Manual (321-78327).

7.Serial Communications Connection Procedure

15

8

Display panel shows gram units.

Press BREAK key.

9

Display panel shows "READY".

*Balance is in the standby

mode.

10

Turn OFF AC Adapter.

7.Serial Communications Connection Procedure

16

2) Parameter settings for UPX/UPY/UW/UX series

Set parameters for UPX/UPY/UW/UX series.

Precautions for Correct Use

Make sure the power supply is OFF before setting up.

If it is ON, the settings described in the following steps and subsequent procedures may not

be applicable.

1

Make sure AC Adapter is

powered OFF.

2

Check the position of the

connectors on Balance.

Connect a Serial cable

(RS-232C) to RS-232C

connector.

Connect AC Adapter to DC IN

connector.

Back view of Balance

3

Check the position of the

operation keys by referring to

the figure on the right.

Front view of UPX/UPY series

Front view of UW/UX series

4

Turn ON AC Adapter.

POWER key

PRINT key

UNIT key

Serial cable (RS-232C)

AC adapter

KEY connector

RS-232C

connector

DATA I/O

connector

AUX

connector

DC IN

connector

Display

panel

PRINT key

O/T key

CAL key UNIT key

POWER key

Display

panel

O/T key

CAL key

7.Serial Communications Connection Procedure

17

5

Display panel shows "OFF".

Press POWER key.

6

Display panel shows gram units.

Press CAL key on UPX/UPY

series twice or on UW/UX series

three times.

7

Display panel shows

"SEL:EAUS".

Check that is blinking.

Press CAL key six times.

*The blinking of indicates the

menu group 1.

*Press CAL key to move to the

next menu group.

The analog display blinks.

Check that is blinking.

Press O/T key.

Set the communication

specifications by following the

next steps.

*The blinking of indicates

the menu group 7

(communication with computer

and external devices).

*For more information on the

menu operations, refer to

Appendices of the Top-loading

Balance Instruction Manual

(321-78282) and Electronic

Balance Instruction Manual

(321-78048).

:

Table of contents

Other Shimadzu Controllers manuals

Popular Controllers manuals by other brands

Pathway connectivity solutions

Pathway connectivity solutions cognito quick guide

Rain Bird

Rain Bird CRC-8A Programming and operating instructions

Electronic Solutions

Electronic Solutions ABMHZ Advanced user's manual

Roth

Roth BW/H Komfort installation manual

HP

HP HPE VAN SDN Controller 2.7 Administrator's guide

ZIEHL-ABEGG

ZIEHL-ABEGG Econtrol EXDM Operating instruction