Shimax MP1 Series User manual

1

Notice

Please ensure that this manual is given to the final user of the instrument.

Preface

This instruction manual is meant for those who will be involved in wiring, installation,

operation and routine maintenance of the MP1 Series.

This manual describes the care, installation, wiring, function, and proper procedures

regarding the operation of MP1 Series.

Keep this manual on hand while using this device. Follow the guidance provided herein.

Matters Regarding Safety

For matters regarding safety, potential damage to equipment and/or facilities and

additional instructions are indicated as follows:

◎This heading indicates hazardous conditions that could cause injury or death of

personnel. Exercise extreme caution as indicated.

「

WARNING」

◎This heading indicates hazardous conditions that could cause damage to

equipment and/or facilities. Exercise extreme caution as indicated.

「

CAUTION」

◎This heading indicates additional instructions and/or notes.

「NOTE」

「

WARNING」

MP1 Series is designed for controlling power such as heater power in general industrial

facilities. It must not be used in any way that may adversely affect safety, health, or

working conditions.

「

WARNING」

● Mount this device on an indoor control panel. Do not touch the charger when using.

● To avoid electrical shock, turn off electricity during wiring operation.

● Do not touch the radiant-heat fin because its temperature becomes high when electric

current is turned on or even right after it is turned off.

● To prevent electric shock, earth the ground terminal without fail.

● Do not touch the terminals or chargers when electric current is turned on.

Take care not to put metal or other foreign matter inside this device.

When an alien substance is put inside by mistake, cut the power immediately,

make sure of safety, and remove the substance.

「

CAUTION」

To avoid damage to the connected equipment, facilities or the product itself

due to a fault of this instrument, safety countermeasures must be taken

before usage, such as proper installation of the immediately-cut fuse (option),

breaker and overheating protection device.

「

CAUTION」

● Power supply voltage, load current, and power supply frequency should be within the

rated ranges. Wrong usage reduces the life of the product and/or result in problems

with the product.

● Voltage different from that of the input specification should not be

connected to the control input terminal. It reduces the life of the product

and/or result in problems with the product.

● Fasten the screws tightly after wiring has been done. Otherwise, overheat due to contact

resistance may result in damage by a fire.

● Put the cover of the terminals on after wiring has been done.

● No modification or irregular usage is allowed.

Symbol Marks used for this product

Alert symbol mark This mark is to arouse a user’s attention regarding electric

shock and high temperature.

High temperature This indicates the place ( a radiant-heat fin) where the

temperature becomes high and may cause a burn.

Electric shock This mark is to arouse a user’s attention not to touch the chargers

when electric current is turned on.

Ground terminal Earth the terminals without fail to avoid electric shock.

Guarantee and repair

● The term of a guarantee is restricted to the main part of a product for one

year after purchase.

● Within the term of a guarantee, the products will be repaired free if it has broken

down after being used properly based on this instruction manual and attached labels.

● Even within the term of a guarantee, the repair is charged in the following cases.

(1)Failure or damage due to wrong connections, incorrect usage, or modification.

(2)Failure or damage due to transportation, movement, or fall after purchase.

(3)Failure or damage due to natural disasters like a fire, earthquake, lightening,

or storm/flood disaster, due to environmental conditions such as gas or salt,

or due to an abnormal voltage.

● Our company cannot take responsibility about the accident or damage which are caused

directly or indirectly due to neglecting warnings or notes of this handling description.

● when repair is needed, please contact the office or agency of our company.

Contents

1.Confirmation of model code and accessories ・・・1

2.Notes on usage ・・・2

3.Installation ・・・2

4.Name of each part ・・・3

5.Wiring ・・・3

6.Explanation of screen, function, and operation ・・・4

7.Automatic return function ・・・6

8.Abnormal detective function ・・・6

9.Accessorie ・・・6

10.Specification ・・・7

11.Table of display characters, figures, and alphabet ・・・8

12.Main causes of trouble and check points ・・・8

1.Confirmation of model code and accessories

A label of model code is put on the left of the cover of the body.

TYPE :MP1–M 0300 ← Model code

№ :0110000001–001 ← Manufacture number

INPUT :MULTI ← Input type

100 TO 240 V AC ~ ← Power supply voltage

30A 50/60Hz ← Current-carrying capacity

SHIMAX CO., LTD. MADE IN JAPAN Power supply frequency

NOTE: Accessory codes are not printed on the label of model code.

◎Model Code

MP1- :Series

M :Input Signal

M:Multi Input I1:4~20mA DC

I2:0~20mA DC

V1: 1~5V DC

V2: 0~5V DC

C1: No-voltage Contact (or Open Collector 5V DC 3mA)

S1: Voltage Pulse (SSR Drive Voltage 12V DC 3mA)

V:Voltage V3: 0~10V DC

030 :Current-carrying Capacity 020:20A,030:30A,050:50A,070:70A,100:100A

0 :Remarks 0:without, 9: with

◎Accessory:Instruction Manual 1 set

※Regarding accessories, refer to Item 9 Accessory (option), page 6.

SHIMAX CO., LTD. MP1F-1HE December, 2020

MP1 SERIES

Thyristor Single-Phase Power Regulator

Instruction Manual

Thank you for purchasing SHIMAX products. Please check that the delivered

product is the item you ordered. Please do not begin operating this product until

you have read this instruction manual thoroughly and understand its contents.

2

2. Caution for use

(1) Avoid operating the front panel keys with hard or sharp objects.

Touch the keys lightly with fingertips.

(2) To clean, wipe gently with a dry cloth. Avoid using solvents such as thinner.

3. Installation

3-1. Installation site (environmental conditions)

「

CAUTION」

Do not use this instrument under the following conditions. Otherwise, the

likelihood of fire and/or other dangerous situations is considerable

(1) Where flammable gas, corrosive gas, oil mist or dust that can deteriorate

electrical insulation is generated or is abundant.

(2) Where the humidity is over 90%RH or where condensation occurs.

(3) Where highly intense vibration or impact is generated or can affect the operation

of the product.

(4) Where inductive interference, static electricity, magnetism, and noise are likely

to be generated.

(5) Where there are water drops or direct sun light.

(6) The rated current is 100% in case of the ambient temperature -10〜40℃.

In case the temperature is over 40℃, reduce load current according to the

following chart.

The operation temperature is 55℃ max. In case of the ambient temperature 55℃,

load current should be within 80% of the rated current.

Ambient Temperature – Allowable Current Characteristic

Ambient Temperature(℃)

0 10 20 30 40 5550

0

20

40

60

80

100

Rated Current(%)

-10

(7) Where the altitude is above 2,000m.

NOTE: The environmental conditions here comply with the installation

category Ⅱ and the pollution degree 2 set by IEC664.

3-2. Mounting

「

CAUTION」

MP1 Series has a structure to use after it is fixed on an indoor panel.

Do not use this product on the table/desk or in a non-fixed condition.

Improper usage may result in damage to the product due to fall, electric

Shock, and injure. Fix this device on a panel without fail. Make sure to

keep people from touching the charger.

・Screw the regulator on the panel by referring to the Set-up Dimension Drawing.

・Prepare screws (Size M5) to fix the regulator on a panel.

・Set the regulator up vertically to enhance a cooling effect with the display section

up and the main circuit terminal down.

3-3. Set-up Dimension Drawing

181

7 5

2 4 2 8

2-M5 2-M5 4-M5

20A・ 30 A 50 A 70A・ 10 0A

unit:mm

3-4. Set-up Space Drawing

・When two or more MP1s are mounted or when MP1 is mounted next to other devices,

or when MP1 is mounted adjacent to the wall, mount them according to the Set-up Space

Drawing below to allow a cooling effect.

MP1 MP1 MP1

100mm min

5mm m in

5mm m in

100mm min

Internal heating value of MP1 is approximately as follows.

Follow the set-up space and use environment.

Keep in mind that the set-up site needs to be ventilated and the radiated

heat needs to be relieved.

Current-carrying capacity

20A

30A

50A 70A

100A

Heating value 24W

40W

56W 79W

109W

3-5. External Dimension Chart

unit:mm

Current

W H D P1 P2 P3

20A 50 192.5 128

24 181 4

30A 50 192.5 128

24 181 4

50A 60 192.5 154

28 181 4

70A 110 192.5 154

75 181 4

100A 155 192.5 154

75 181 4

W ±0 .5

P 1 ±0 . 5 P 1 ±0. 3

W ±0.5

P 2 ±1

H ±1

H ±1

P 2 ± 1

D ±1

D ±1

20~50A 70~100A

2- 5.5 ±0.2 4- 5.5 ±0.2

P 3 ±0.2

P 3 ±0 . 2

3

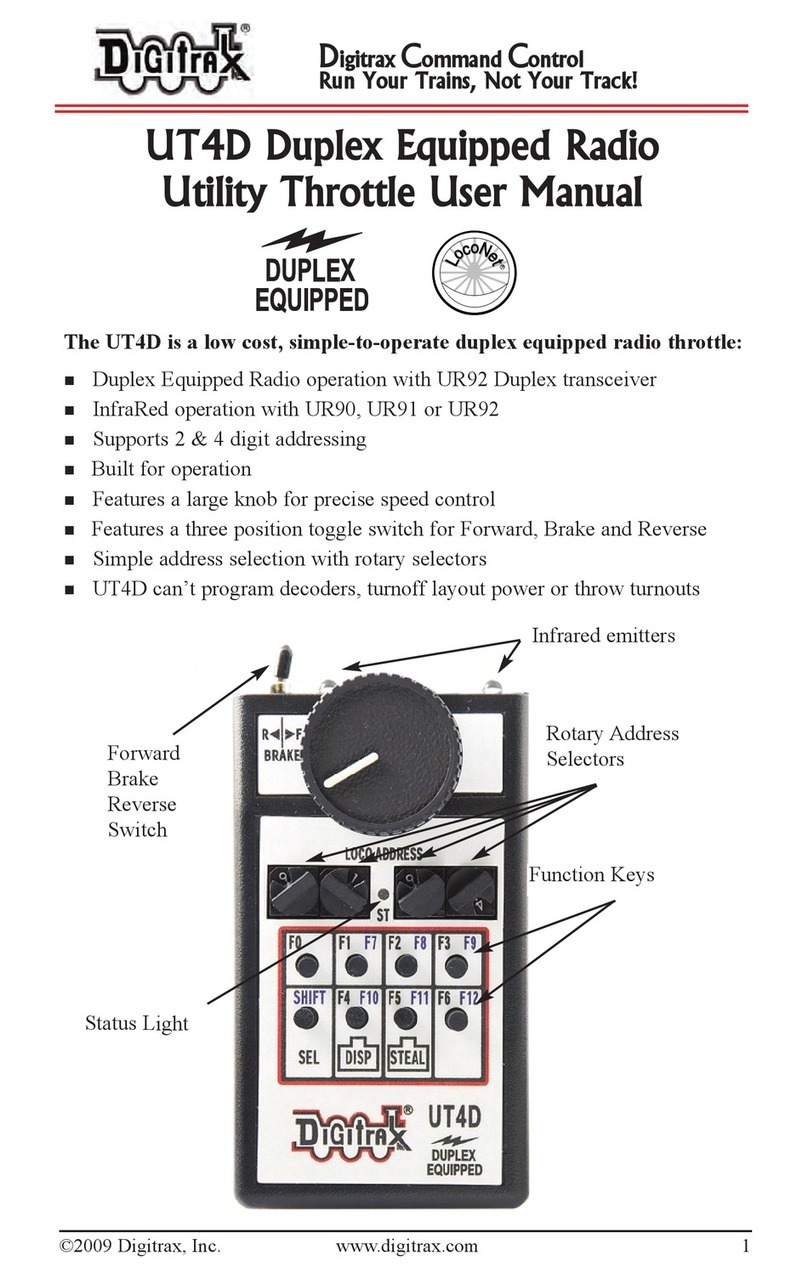

4. Name of Each Part

%

OUTPUT

INPUT

HIGH-SET

LOW-SET

SOFT-START

SLOW-UP

SLOW-DOWN

1

2

3

4

5

6

7

8

9

mA

V

INPUT

VR-HIGH

VR-LOW

POWER

L

N

MP1

MADE IN JAPAN

100-240VAC 50/60Hz

②Menu Display Section ①Data Display s

e

③Menu Key ④Up Key

⑤Down KeY

⑥Description of

Characters used

for Menu Display

⑦Control Terminals

⑧Main Circuit Terminals

⑨Ground Terminals

NAME CONTENT

①Data Display Section This section displays input values, output values,

and setting data

②Menu Display Section This section displays a character to show what

data is displayed

③

Menu Key This key is used to shift data display screens and

to register settings

④

Up Key This key is used to increase or move forward set values

and settings

⑤

Down Key This key is used to reduce or move backward set values

and settings.

⑥Description of Character This section shows what the character on the Menu

used for Menu Display Display means

⑦Control Terminals These are the terminals to connect control circuit’s

input/power supply to an external variable

resister (accessory).

⑧Main Circuit Terminals These are the terminals to connect Thyristor element

(built-in) to power supply/load

⑨Ground Terminals For the safety, earth the terminals at the ground

impedance 100Ωor below

5. Wiring

「

WARNING」

・To prevent electrical shock, turn off electricity during wiring operation.

・Earth the ground terminals without fail.

Otherwise, there is a possibility of electric shock.

・Avoid touching the wired terminals and chargers while supplying power.

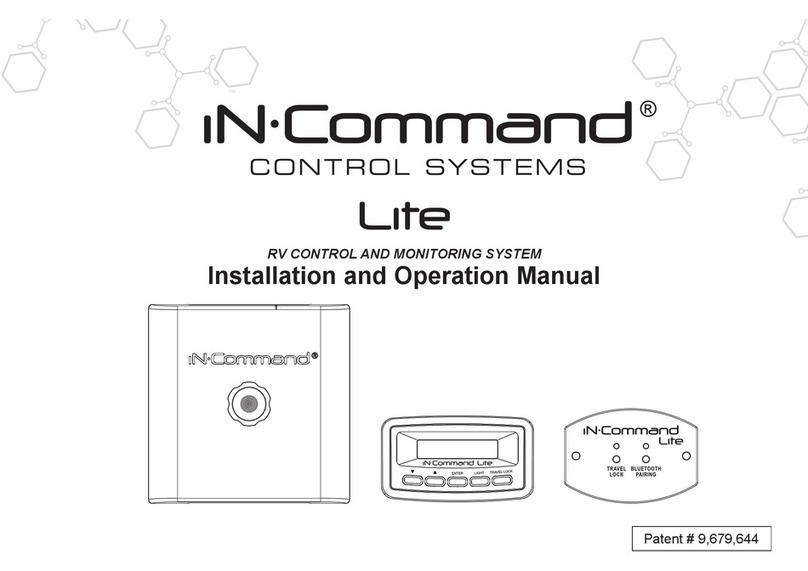

5.1 Wiring of the main circuit terminals and power terminals for control

◎ Use wires with enough capacity to the load current for the main circuit

terminal wiring.

◎Terminal screws for the main circuit should be M5 for 20〜50A,and M6 for 70A

and 100A,M10 for 200A. Screw tightly by using a proper sticking-by-presser terminal.

(Tightening torque: Size M5 2.0〜2.4N-m Size M6 2.5〜3.0N-m Size M10 10.0~12.0N-m)

◎The phase of the main circuit (L1, L2) and control power supply (8, 9)

must be the same.

Load

L2

Ground

Terminals

1234 5 6 7 8 9

LN

Fast acting fuse

Power

supply

100-240V AC

50/60Hz

Contorol Terminals

L1

Drawing of connection of the main circuit terminals and

power supply terminals for control

MP1

5-2. Wiring of control terminal

◎Size M3 screws are used for the control terminal. Please use a sticking-by-pressure

terminal with its inside diameter over 3mm and its outside diameter over 6mm.

(Tightening torque 0.5〜0.6 N-m)

◎In wiring control terminals, be careful with polarity (±) and noises from

a strong electric circuit.

(1) Wiring of control input signal

●In case of current signal (4-20mA‧0-20mA: receiving impedance approx. 100Ω),

connect control terminal No.1 (+) with No.3 (-).

①

②

③

④

⑤

⑥

⑦

⑧

⑨

Controller

+

-

Current output

●In case of voltage pulse (1-5V‧0-5V: input impedance approx. 500kΩ) or in case

of voltage pulse (SSR drive voltage) signal (12V DC 3mA), connect control terminal

No. 2 (+) with No.3 (-).

①

②

③

④

⑤

⑥

⑦

⑧

⑨

Controller

+

-

Voltage or Voltage pulse

output

●In case of contact signal (non-voltage) or in case of open collector signal

(sink load 5V DC 3mA), connect control terminal No. 2 (+) with No.3 (-).

There is no polarity in contact signal.

①

②

③

④

⑤

⑥

⑦

⑧

⑨

Controller

C o n t a c t o u t p u t o r

Open Collecter output

(2) Wiring when an external setting device (accessory) is connected to set

grade and lower limit value

●In case of grade setting, connect terminal 4‧5‧7 with terminal 4‧5‧7

with terminal No.3‧2‧1 of the variable resistor and in case of lower limit setting,

connect terminal 4‧6‧7 with terminal No.3‧2‧1 of the variable resistor.

①

②

③

④

⑤

⑥

⑦

⑧

⑨

①

②

③

④

⑤

⑥

⑦

⑧

⑨

Grade

setting

device

VR-HIGH

Lower limit

settingdevice

VR-LOW

1

2

3

1

2

3

B 10kΩ

B 10kΩ

4

6. Description of screens, functions, and operation

6-1. Power-on and initial screen display

At power-on, each initial screen is successively displayed as below and moves

on to the lead screen (monitor of operation volume) of a group of basic screens.

Power-on

Lighting of all the display sections

Display of control method

:Phase-Voltage square

:Phase-Angle

:Zero-cross Switching

:Phase & Zero-cross Switching

Display of voltage frequency

Display of software version

Lead screen of a group of basic screens

(monitor of operation volume)

6-2. Description of basic screens

Monitor of operation volume This screen displays the

operation volume to Thyristor in the range of 0〜100%.

Press

key, and the screen will move to the input

value screen.

Monitor of input value This screen displays the

control input value in the range of 0〜100%.

Press

key, and the screen will move to the input

value screen

Grade setting Initial Value: 100%

Setting Range:

, 0〜100%

Output can be set at the time of control input 100%.

Press of

or

key can change settings. During setting,

a dot beside the least decimal place is blinking.

(All setting is the same as this setting.)

When

is chosen, setting can be changed via an external

variable resistor (accessory).

(Refer to input/output characteristic chart)

Blinking of a dot beside the least decimal place

Press of

key can register the setting changed by

or

key.

A dot beside the least decimal place stops blinking.

(All setting is the same as this setting.)

Lights-out of a dot beside the least decimal place

(Setting registered)

Another press of

key shifts the screen to the next

screen. (All setting is the same as this setting.)

Lower limit setting Initial Value: 0%

Setting Range:

, 0〜100%

Output (base output) can be set at the time of control output 0%.

When

is chosen, setting can be changed via an external

variable resistor (accessory). (Refer to input/output

characteristic chart)

Time setting of soft-start

Initial Value: Control Method

,

,

2 sec.

Control Method

20 sec.

Setting Range: Control Method

,

,

0.0〜25.0 sec.

Control Method

0〜250 sec.

This is a function to delay output in response to changes of the

control input signal at the time of power-on. It is effective to

check in-coming current to the heater. The time needed from output

0 to 100% can be set. Soft-start function is valid only once

at the time of power-on.

Time setting of slow-up Initial Value: 0 sec.

Setting Range: 0.0〜25.0 sec.

This is a function to control an output flow to rise gradually

at the time of a sudden change of control input signal due to a

change of setting. of control input or setting happening and,

makes the output flow gradually. The time needed from output 0

to 100% can be set. At the time of power-on, the time setting

of soft-start takes precedence.

Time setting of slow-down Initial Value: 0 sec.

Setting Range: 0.0〜25.0 sec.

This is a function to control an output flow to drop gradually

at the time of a sudden change of control input signal due to

a change of setting. of control input or setting happening,

and makes the output flow gradually. The time needed from output

0 to 100% can be set.

Monitor of operation volume screens

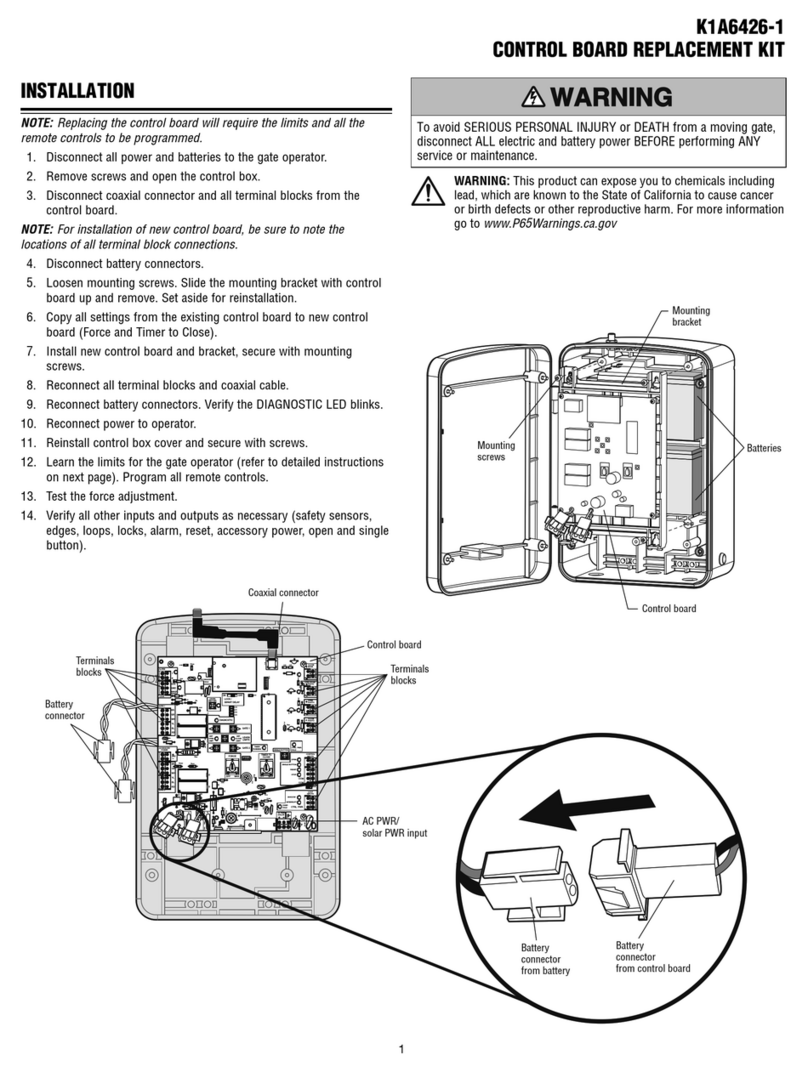

6-3. Input/output characteristic in case of grade or lower limit setting

Control input

0 50 100%

Grade setting input-Output characteristics

Grade setting

100%

Grade setting

80%

Grade setting

50%

0

50

100%

Output

Control input

0 50 100%

Lower limit setting input-Output charac

t

0

50

100%

Output

Lower

limit

setting

50%

Lower

limit

setting

20%

Lower

limit

setting

0%

Control input

0 50 100%

Characteristics of higher limit(grade)・

lower limit setting

0

50

100%

Outout

Lower

limit

setting

20%

Grade setting 100%

Grade setting 50%

(Maximum output value

100%)

(Maximum output value

60%)

◎Lower limit setting is the output value at the time of control input

value 0%, that is the base output. Therefore, the formula to calculate the

maximum output value in grade setting is as follows:

The maximum output value (%) =(100 – lower limit set value) x grade set value

+ lower limit set value

Example: In case of lower set value 20% and grade set value 80%

The maximum output value = (100 – 20) x 80% + 20 = 84%

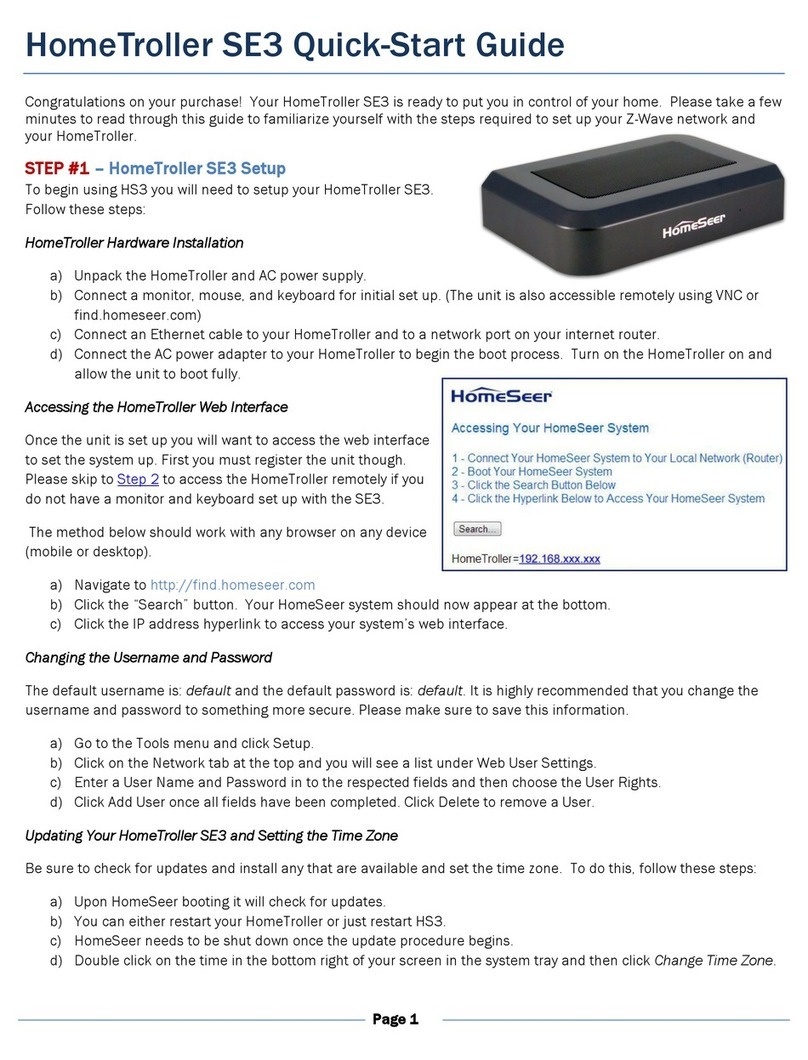

6-4. Time of soft-start, slow up and slow-down

(1) The set time of soft-start, slow-up and slow-down is the time needed from

0% to 100% output. Each grade is fixed and the actual time needed is

proportional to a deviation.

Time

100%

Power

ON

Soft-start time Slow-up time Slow-down time slow-up time

Output

(2) Soft-start function is valid only once at the time of power-on. However, the deviation

of input and output at the time of power-on is 0, soft-start operation is not activated.

When the deviation of input and output becomes 0(for example, input drops) while

soft-start operation is on, soft-start function is over at that time.

NOTE:Slow-up and slow-down operation restrains a sudden change of load voltage

and load current at the time of a sudden change of input or setting.

However, in some control systems, this operation may affect the control system.

5

6-5. Description of setting screens

Press

key for three seconds on the basic screens and the screen jumps to

the control method choice screen, one of the setting screens.

Press

key for three seconds on the setting screens and the screen jumps

to the monitor of operation volume, one of the basic screens.

「

CAUTION」:When control method and input code are changed, turn

off the power supply of the main circuit.

Basic screens

Press

key for three seconds.

Control method choice Initial Value:

Choice

:(Phase-Voltage square)

:(Phase-Angle)

:(Zero-cross Switching)

:(Phase & Zero-cross Switching)

Input sampling frequency setting Initial Value: 0

Setting Range: 0〜120 sec.

This screen is displayed when contact or voltage pulse (SSR drive

voltage) is chosen for input. Two-position operation responds to

0 sec. setting and proportional operation responds to 1〜120 sec.

setting. Keep in mind to set the value as an integral multiple

of the proportional frequency time of the regulator.

NOTE:When a regulator with proportional frequency time changes

is used, the best control effect may not be obtained.

Linear input compensation(lower limit compensation)

Initial Value: -2.0 Setting Range: -5.0〜5.0%

This screen is displayed when current or voltage is chosen for

input. This function is to compensate errors between input monitor

value (lower limit) and the value converted into 0〜100% unit from

the value of current or voltage input by actual measurement.

In response to input signal, this function delay or precipitate

output boosting within ±5%.

Example: Input signal 4〜20mA Converted value of input value

by actual measurement 0%

Input monitor value 5%

Input compensation value is set as -5.0%

Control Input

050 100%

50

100%

Input moniter value

Display value with -0.5% compensation

Display value before input compensation

Linearinput compensation

(Lower limit compensation)Drawing

Code choice of input type Initial Value: 0

Setting Range: 0〜 5

:4~20mA

:0~20mA

:1~5V

:0~5V

:contact or open collector

:voltage pulse (SSR drive voltage)

This screen is not displayed when input is 0〜10V at the time of

order. In case of multi a type appropriate to the output

specification of the regulator.

External grade set value monitor

This screen monitors the set value when an external grade setting

device is connected. When it is not connected, this screen

displays an indefinite number.

External lower limit set value monitor

This screen monitors the set value when an external lower limit

setting device is connected. When it is not connected, this screen

displays an indefinite number.

Control method choice screens

6-6. Description of control method

(1) Phase control

This method is to control power to the load successively by changing the

phase angle of AC voltage applied to the load.

50%

Output

(2) Zero-cross switching control

This method is to control output by turning Thyristor on or off when the

voltage becomes 0. As the output is turned on or off at 0V, there is less

noise compared to phase control.

50%

Output

(3) Phase Control & Zero-cross Switching Control

Soft-start Time

Boosted by phase control

during soft-start time.

Shifted into zero-switching control

at the end of soft-start time.

Load created by initial current at the time of power-on (platinum, molybdenum,

tungsten, inflated lamp, etc) can be controlled by zero-cross switching.

(4) Input/output characteristic of angle control in case of phase control and voltage square control

Angle Control(PA) Voltage square Control(PP)

Input Signal Input Signal

0

0

0

050 50

5050

100%

100% 100%

100%

Electric Power

Electric Power

●In case of angle control, in response to input signal, output voltage draws S-shaped curve.

●In case of voltage control, in response to input signal, output draws a mostly straight line,

which is voltage proportional. (In case of fixed impedance load)

6-7. Input

(1) When contact input is chosen, open collector signals also run this regulator.

In case of open collector, sink load is 5V DC, 3mA.

(2) When voltage pulse (SSR drive voltage) is chosen, keep leak current less than 0.1mA or at the

time of OFF of this regulator. If it is not possible, connect a bleeder resistor to the output terminal

of a controller or to terminal 2-3 of MP1 so that the residual electric charge of MP1 control

input is less than 0.5V at the time of OFF of this regulator.

Controller

+

-

2

3

MP1

Less than 0.5V at the

time of OFF

Bleeder

resister

(3) When more than one MP1 are connected to one controller, input terminals of MP1 are connected in series

in case of current signal, and in parallel in case of voltage signal.

①

②

③

④

⑤

⑥

⑦

⑧

⑨

C o n t r o l l e r

+

-

In case of

current output

①

②

③

④

⑤

⑥

⑦

⑧

⑨

①

②

③

④

⑤

⑥

⑦

⑧

⑨

M P 1 M P 1 M P 1

①

②

③

④

⑤

⑥

⑦

⑧

⑨

C o n t r o l l e r

+

-

I n c a s e o f

v o l t a g e o u t p u t

①

②

③

④

⑤

⑥

⑦

⑧

⑨

①

②

③

④

⑤

⑥

⑦

⑧

⑨

M P 1 M P 1 M P 1

6

6-8. Operation at the time of power brake down

Operation of MP1 at the time of power brake down is as follows:

(1)If a power brake down is less than 3 msec., operation is continued.

(2)When control voltage is 100V, output becomes 0% at 3〜60msec.power brake

down. When control voltage is 200V,output becomes 0% at 3〜120msec.

power brake down. In both cases, according to soft-start set time,

it goes back to operation status.

(3)When control voltage is 100V, the system goes to reset status at more

than 60msec. power brake down. When control voltage is 200V, the system

goes to reset status at more than 120msec. power brake down. In both cases,

the operation is resumed just like at a normal power-on.

7. Auto-return function

When there is no key operation for three seconds on the screens other than the output

monitor screen, the screen automatically shifts to the output monitor screen. However,

if the status is “during setting” (a dot beside the least decimal place is blinking),

even when there is no key operation for three seconds, the setting status is continued.

8. Abnormal detective function

8-1. Frequency automatic distinction function

Frequency automatic distinction is made only at the time of power-on.

When the frequency is either less than 45Hz or more than 65Hz, the function stops with

the value displayed. In this case, there is a possibility of abnormality in power supply

or disorder in the unit. Confirm the power supply frequency.

8-2.Abnormal of Cooling Fan(Current capacity 200A only.)

When the system detects the trouble of the fan stopping

during an operation, the output is shut down to 0% and

is shown on the display section.

Once the detection function fan on, the system cannot start again even

if the fan recovers. In order to get the system started,

fan off the power supply and then turn it on again.

「NOTE:A possible cause of why the fan stops is the accumulation of dust or soot.

If the fan itself is broken, contact our agency or us.」

「

CAUTION:When you inspect or clean the fan, shut off the power supply

so that there can be no accident such as fingers caught

between the fan blades or any other kind of injury. 」

9. Accessory

9-1. External setting device (variable resistor, knob, and scale)

Accessory code 021: 1 set (for grade setting or lower limit setting)

Accessory code 022: 2 sets (for grade setting or lower limit setting)

φ2 4.6

13 . 5 10 10

2

φ6

M9 P0.75

10

①②③

φ2.8

External Variable Resistor(Resistance:10kΩ Characteristic:B)

φ9 . 5

φ3

10

Panel Cut Drawing

Unit:mm

10

0100

20

30

40 50 60

70

80

90

φ55

φ9

Dial

25.5

16

Knob

Unit:mm

9-2. Fast acting Fuse (with a fuse holder)

Accessory code 01A: for 20A (250GH-32)

Accessory code 01B: for 30A (250GH-40)

Accessory code 01C: for 50A (250GH-63)

Accessory code 01D: for 70A (250GH-100)

Accessory code 01E: for 100A (350GH-125UL)

※Fuse holder: For 20A ~ 70A HT4017

For 100A HT5723

For 20A~70A Fuse holder dimension drawing

For 100A fuse holder dimension drawing

Products of K.K.Hinode Denki.

7

10. Specification

●Display

(1)Display Type :Digital display 7-segment red LED 1+3 digits(character height 10mm)

Operation volume display value 0~100%

Control input display value 0~100%

Grade variable resistor setting level 0~100%

Lower limit variable resistor setting level 0~100%

Parameters (Refer to Setting)

●Setting

(1)How to Set :Using the three keys on the front(

)or an external setting device(accessory, separately sold)

(2)Setting Parameter

:Option of setting method{Phase control angle/Phase control voltage square/Zero-cross switching control}

:Higher limit(grade)setting 0~100%

:Lower setting 0~100%

:Soft-start timer setting Control Method

,

,

0.0~25.0s

Control Method

0~250s This function is being operated only at the time of power-on.

:Slow-up timer setting 0.0~25.0s

:Slow-down timer setting 0.0~25.0s

:Option of input method{voltage/Current/Contact/Voltage pulse(SSR drive voltage)} 6types

:Input sampling cycle setting(0~120s)In the case of contact or voltage pulse input

Proportional operation responds to 1〜120 sec (Set the value as an integral multiple of the proportional frequency of

the regulator) Two-position operation responds to 0 sec. setting

:Linear input compensation(lower limit compensation) –5.0~5.0% Being able to set at the time of power-on

●Power Supply

(1)Rated Voltage :90~264V AC(free voltage)

(2)Rated Frequency :45~65Hz

●Control Input

(1)Types of Input(multi-input) (Choose by key operation from the following 6 types)

:I1-current1 4~20mA DC Receiving impedance approx.100Ω

:l2-current2 0~20mA DC Receiving impedance approx.100Ω

:V1-voltage 1~5V DC input impedance approx.500kΩ

:V2-voltage2 0~5V DC input impedance approx.500kΩ

:C1-contact(Contact No-voltage contact or open collector sink load 5V DC 3mA

:S1-Voltage pulse(SSR drive) 12V DC 3mA

※In the case of C1 or S1 input ,the regulator responds to both two-position and proportional control.

The other input (The following inputs should be specified when ordered. Otherwise, the input is multi type.)

:V3-Voltage3 0~10V DC input impedance approx.370kΩ

(2)Input accuracy :±(1%FS+1digit)

(3)Sampling cycle Contact or voltage pulse input: Two-position control 2ms Proportional control 1~120s

Current or voltage input: 2/control power supply frequency

●Output

(1)Current-carrying Capacity 5types:20A,30A,50A,70A,100A

(2)Output Range :0~98% or more of an input voltage

(3)Control Method 3types:Phase control angle/phase control voltage square/Zero-cross switching control/Phase & Zero-cross switching control

(4)Lowest Load Current :Current-carrying Capacity 20~100A 0.5A (in the case of output 98%)

(5)Output response :One cycle delay of the power supply frequency

(6)Applicable Load Phase Control:Resistive load, Transformer primary control (Magnetic flux density:1.25T Max.) (excepting carbonization silicon load)

Zero-cross switching control:Fixed resistive load

Phase Control & Zero-cross switching control:Resistive load (excepting carbonization silicon load)

(7)Cooling system 20~100A:Natural air cooling

●Accessory(Separately sold)

(1) External Variable Resistor

Higher Limit(grade):Variable Resistor(B 10kΩ),Knob, Scale

Lower limit :Variable Resistor(B 10kΩ),Knob, Scale

(2)Fast acting fuse :To be attached externally, with fuse holder

●General Specification

(1)Data Storage :Non-volatile memory(EEPROM)

(2)Use Environment Temperature:0~55℃(Guaranteed range for operation),0~40℃(Guaranteed range for efficiency)

Humidity:Below 90%RH(No condensation)

Altitude:2000m above see level max.

category:Ⅱ

Pollution degree:2

(3)Input Noise Ratio of rejection :Normal 50dB min.

: Common 100dB min.

(4)Insulation Resistance :Between input and power supply 20MΩ min.500V DC per minute

:Between input and chassis 20MΩ min.500V DC per minute

(5)Dielectric Strength :Between input and output 2300V AC per minute

:Between input and chassis 1500V AC per minute

(6)External Dimension/Weight 20A:W 50×H192.5×D128mm/approx. 0.6Kg

30A:W 50×H192.5×D128mm/approx. 0.7kg

50A:W 60×H192.5×D154mm/approx. 1.2kg

70A:W 110×H192.5×D154mm/approx. 1.8kg

100A:W 155×H192.5×D154mm/approx. 2.3kg

8

11. Table of display characters, figures, and alphabet

12. Main causes of trouble and check points

If there seems to be something wrong with this product, check the following. (Especially at the time of first operation and after setting is changed)

①Whether power supply is applied.

②Whether wiring is done properly

③Whether the type and capacity of the load is appropriate to MP1

④Whether each setting is correctly done

⑤Whether they type and level of the control input signal is appropriate

Trouble Likely cause Check points

There is no output ・No voltage is applied to the control power

supply terminal (No.8 and 9)

・Grade setting is around 0% or a variable

resistor is not connected when

is

chosen.

・Control input signal is not correct.

・Check voltage between terminal No.8 and 9 with a tester.

・Check whether LED is blinking.

・Check the set value on the grade setting screen

・Check whether a variable resistor is connected when

is chosen and the wiring is

done as shown on page 3, 5-2 (2). The scale of the variable resistor is not supposed to

be around 0%

・Check whether the wiring (page 3, 5-2 (1)),type, level, and polarity of the control

input signal is appropriate

Output does not become 0 ・The lower limit setting is not 0%

・Control input signal is big.

・Check the set value on the lower limit setting screen

・Check the type, level of the signal and check the controller (Signal source)

There is load voltage though

the current is OA.

・Load is open. ・Check the heater and the wiring of the main circuit terminal.

Output is not proportion for input

and unstable output.

・Un in-phase main circuit (L1-L2) and control

power supply terminals (№8 and №9).

・Check the main circuit (L1-L2) and control power supply terminals (№8 and №9).

・Refer to page3 Drawing of connection of the main circuit terminals and control power supply terminals.

If there is still something wrong even after inspecting and checking the items mentioned above, there might be some mechanical trouble

with the product. Please contact the office or agency of our company.

he contents of this instruction are subject to change without notice.

SHIMAX CO.,LTD.

Head Office: 190 Shimoniiyachi, aza, yotsuya, Daisen-shi, Akita 014-0102, Japan

Phone: +81-187-86-3400 Facsimile: +81-187-62-6402

E-MAIL: info@shimax.co.jp URL: http://www.shimax.co.jp

PRINTED IN JAPAN T2012

Display

characters

Figures

Alphabet Display

characters Alphabet Display

characters Alphabet

1 I

D

P

2

E

Q

3

F

r

4

G

s

5 S

H

T

6

h

t

7

i

U

8

J

u

9

K

V

0 O

L

W

A

l

X

B

M

Y

C

N

Z

c

o

Table of contents