SHINCHANG SVF-40E User manual

「 Operation Manual 」

Frequency variable controller

SVF - 40E (AC 100/200V)

1. Caution before use

2. Caution at the time of use

「 a. Dangerour b. Warning c. Caution 」

3. Function and characteristics

4. Outer Case and Name of Each Part

5. Method of Attachment

6. How to Connect and Output

7. How to Operate and Control

8. Change of Set Value

9. Indication of Setting Items

10. Trouble-shooting

11. Specification of the Product

12. Check Bowl Feeder

SHINCHANG F.A

◆Content ◆

Make sure to read this operation manual before use

and to have accurat work.

1. Caution before Use

In order to use this controller safely and to use ite function to the maximun

be sure to refer to the following.

a. If any damagte is discovered in the course of transportation, please contact the company.

b. This controller for exclusive use of Shinchang F/A. If it is used to object other than

the applicabe main body for its use, then it may surpass its scope of use and

may cause trouble.

c. Use this operation manual (Part's feeder)

It means <Bowl Feeder , Linear Feeder, Hopper Feeder etc.>

2. Caution at the time of use

First of all, read this manual carefully and then use it.

Be sure to observe required caution for safety as follows:

a. Dangerous

1) Do not start any work such as linear arrangement etc. until LED sign

on cotrol panel is off.

Please start the work after lapse of more than 2minutes after Off condition.

Otherwise, there is risk of electric shock.

2) Do not operate it under the condition the cover of terminal is taken off.

(Emergency case is exceptional)

And when cover of the terminal is taken off, be sure to turn off the power.

There is dange of fire due to electric shock or short-circuiting.

3) Never do any wiring works without turning off the electric power.

This controller is exclusive controller for Part's Feeder.

It can not be used for piezo electric Part's Feeder or single phase motor etc.

There is dange of fire due to electric shock or short-circuiting.

b. Warning

1) Be sure to ground the earth line of the main body of controller. Unless

『Earth』 is done, there is danger of electric shock.

2) Never use it at places where explosive or inflammable gas is present. It may

cause fire.

3) No one else except repair technician should disassemble , repair or modify it.

There is dange of fire or injury due to abnormal function.

4) Avoid its use near water, outdoors or at places where the temperature is high or

highly humid. There is danger of fire and electric shock.

5) Avoid damage to wirting or forcible bending by pressing it down.

If heavy materials are placed or inserted, then wiring is damaged, which can

cause damage to wiring, fire and electric shock.

6) Even during use of controller or while it is stopped, avoid contact with output

terminal of controller. There is output of 200V in the output terminal.

Therefore, there is danger of electric shock.

7) Do not put any foreign materials shch as papers, wood or oil etc.

There is danger of fire.

8) Do not control switch with wet hands.

There is danger of electric shock.

9) Avoid use of any other voltage except specified voltage.

It may cause fire and trouble.

10) At the time of replacing fuse, make sure to turn off primary side power source or

main switch. There is danger of electric shock.

c. Caution

1) Radiation panel may become high in temperature(50~70℃)

There is danger of burn.

Make sure to design space around it in consideration of heat radiation.

2) Do not turn on/off power hastily.

It may cause trouble to controller.

3) Do not turn on/off power within short time. Because of flow of big lead-in

current, it cause trouble to controller.

4) Avoid its installation at the place with vibration or shock.

Controller may get in trouble.

5) There is distinction between earth and non-earth type.

Make sure to check the earth side of power source and connect the specified

terminal of controller to the earth side.

When wiring is wrong, then there is danger of fire.

6) Be sure to connect earth grip to welding machine at the time of welding to bowl.

If earth for welding is uncertain, then earth line which is connecting the main body

and controller may burn or there is danger of electric shock, leak or damage to controller.

7) Choose cabel suitable to voltage, electric current and environment concerned.

If cable is below capacity, then there is danger of fire.

8) Controller may produce noise through wire, equipment or

equipment connected to it.

Make sure to prevent any erroneous operation of instruments, equipment

or sensor arount it. There is danger of accident.

3. Function and Characteristics

a. Precise digital control by means of micro-processor

Various setting and operation are done by digital control through installing

micro-processor. In particular, output frequency is based on crystal transmitter,

thus unprecedented high precision and stability are realized. Also, by virtue of

display of set value, resetting can be done very simply.

b. Input

Scope of input voltage is AC95-110V (+/-10%)A, AC200~220C(+/- 10%) and

both 50Ha and 60Hz is possible.

c. Protective function

At the time of overheating, excess load or excess current, this function stops operation

and protect controller or circuit device arount it.

At the time of overheating, excess voltage, error is indicated and operation stops.

When power source, voltage and temperature are restored, then restoring controller

is also possible. When such restoration is not possible, contact the company.

※ Protection of this controller against earth line, short-circuiting and leakage is

impossible. Be careful.

d. Lock

Controlling funciton by control panel can be stopped when necessary.

It eliminates unintended setting or change ect. by error of the operator or by

mistake in controlling.

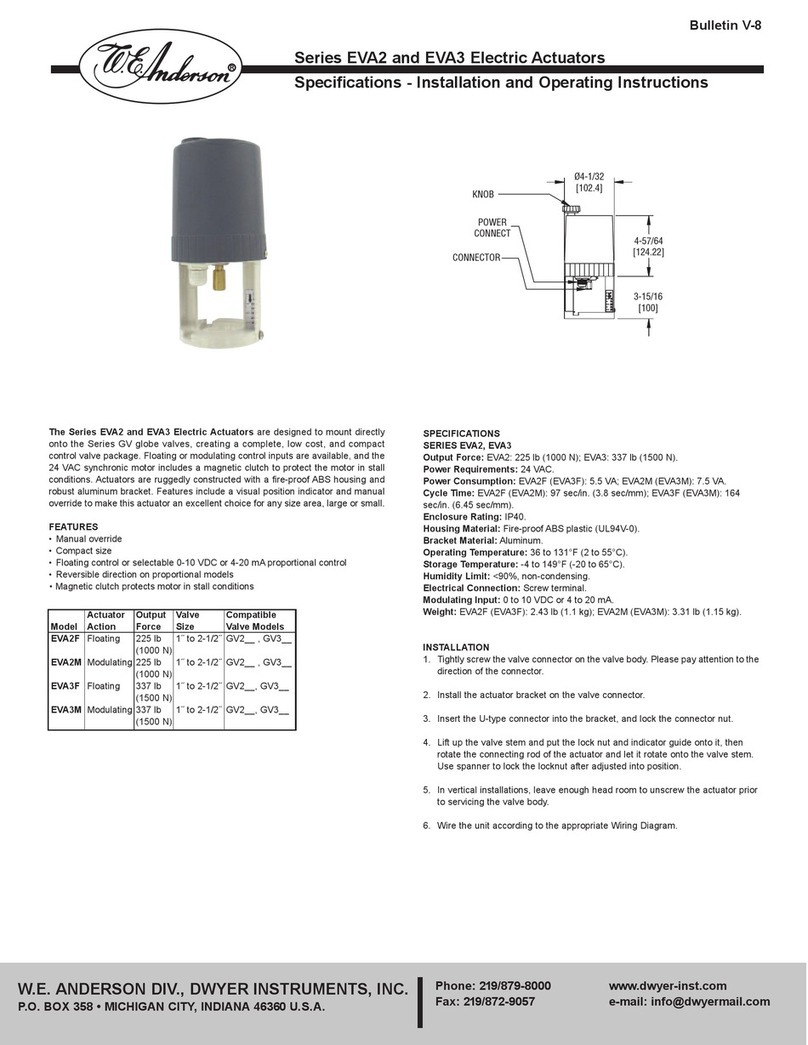

4. Outer case and name of each part

a. Name of outer case

b. Terminal stand structure

5. Method for attachment (external diagram)

6. How to connect input and output

a. Input of power source

220 Volt input is set initially.

Make sure to ground green earth line.

There is danger of elecric shock.

When using 110V, please contact the company.

b. Connection to feeder

Feeder output is possible to bowl, linear and hopper etc.

Make sure to ground the green earth line.

There is danger of electric shock.

c. Input of external control

1) DC input

When DC24V is input, then feeder operates.

Using sensor concurrently is impossible.

Controller mode can be used when it is set to USE at SEN1.

2) Input of contact point

When SS1 and GND are connected, then feeder is operated.

Controller mode can be used when it is set to NOT at SEN1.

d. How to input to sensor

No Contents

1 +24

2 SS1

3 GND

When the products are fully loaded on chute, it controls

bowl feeder. Controller mode can be used when is set to USE

at SEN1.

e. How to enter speed transfer

At regular speed of SS1 and at the time of contact connection

and speed shift of GND, connect SS2 additionally.

At the time of stop, everything is short-circuited.

At the mode of USE, S-VT when mode key is pressed once more,

then S-OP appears at window and strength for voltage

is set by left arrow key. After completion,

either run key is pressed or if there is no key control for about

5 seconds, then automatically seting mode is ended.

Wiring color

Red or brown

White or blue

Black

7. How to operate and control

When power source is put to controllr and controller switch is set to On position,

then press Run switch and press lower key among left upper and lower key

at the position of 100~120V, then frequency descends downward from 400.

When speed is within the range to make operation of vibration possible, set volume

to about 140V again and then make minor setting with upper and lower key.

About 140V is most stable as for volume setting.

When volumen of 180V or above is used for a long time, then stability of voltage

becomes worst. Adjustment of Hz is required at the time of moving feeder from

the place where 60Hz area is used to the place where 50Hz is used.

If using under the condition without adjustment, it becomes cause of trouble.

8. Change of set value

a. Switch on power

b. After Motion(vibration output) Off enters setting mode by Mode key, setting

item is indicated above and set value of pertinent item is indicated at below and

then moves item with Mode key. Change value of pertinent item with↑(inc) ↓(dec)key.

c. When Mode key is pressed down again at final setting item(S-TY) then setting mode

is finished(store changed value) and then it returns to use mode.

d. If there is no key control for about 5 seconds during control of each setting,

then automatically setting mode is ended.(Store value which is changed upto now.)

e. When Run key is pressed down anywhere at setting item, then immediately setting

mode is finished and returned to standby condition. And changed value is stored.

f. As for contents of setting items, see the explaination in next page.

g. Setting/releasing locking device(setting: prohibition of change, releasing: change possible)

- If Mode key is pressed about 3seconds at motion standby condition, then 3times of

Beep are sounded, then Lock condition is indicated.

For release, carry out repetitive move.

Whenthe key is pressed down more than 10seconds, then all the keys such as volume

etc. are fixed. Release is done by repetitive move.

When Lock is set, then LOCK ON is indicated at display window

LOCK OFF is displayed when released.

9. Indication of setting items

1 ON 0.0 Delay time(sec) when Sensor 1 is On

1 OFF 0.0 Delay time(sec) when Sensor 1 is Off

2 ON 0.0 Delay time(sec) when Sensor2 is On

2 OFF 0.0 Delay time(sec) when Sensor 2 is Off

SEN 1 NOT Whether or not Sensor 1 is used

SEN 2 NOT Whether or not Sensor 2 is used

Output DC 24V

POER 200.0 Limitation of max. output voltage

STRT 15 Soft Start

VOLT 220 Display of voltage at window

S-TY NPN Change of sensor input

Possible when Sensor 1,2 not used.

50~200 50S-OP

Indication

of items Scope of choice Basic value

5~40

110/220

NPN/PNP

Contents

Characteristics of Sensor 1 interlocking

output motion

NO(Sensor 1 is On, Output is On) NC

SOUT

At the time of change to arbitrary value

from the current VR value

0.0~20.0

0.0~20.0

0.0~20.0

0.0~20.0

NOT, USE

NOT, USE

NC(Sensor 1 is Off, Output is On)

100.0~200.0

10. Trouble-shooting

When trouble occurs, check on the followin items. Also, check output voltage of (1) and (2).

When cause of touble is unclear, then contack SHIN CHANG F/A and inform condition of trouble and

in order to have quick action, read the following items and inform us in details

Poor connection of power source Check connection.

Wiring Verification method of input and output

Fuse Check condition of fuse.

Sensor recognizes the work. Verify after removing work on chute.

Controlling frequency Verify method of operation control.

Damage of panel spring Replacement

Fixing to fining device for transportation Dismantling fixing device

Panel spring is loosened Tightening volt.

Excessive weight of Bowl/Chute Consultation with the company

Power source voltage exceeds tolerance value Check voltage of excessive output

of controller. of power source. Remove cause for

Wiring See operation manual.

Erroneous polarity of wiring

Sensor checking work Remove work from chute.

Setting function Read operation manual.

Setting function Verify transfer of sensor for mode of operation.

Due to elongation of ON/OFF Check setting value of timer and

Delay Timer time. shorten the time and verify.

Check and see if lock is on at panel. Release of panel lock.

3) Vibration is

changing Due to too much work volume in bowl, there are

much changes.

Change of voltage. Adjuse volume of

work.

Trouble Actions requiredEstated cause

1) No vibration

2) Vibration is

not increasing

4) Control from

outside is not

possible.

6)Setting of

voltage frequency

is not possible

5) Sensor can

not controlled.

11. Specificatioin of the product

40.0 ~ 400.0Hz

Use of Up/Down key

0.0 ~ 220.0 V

Control variable by volume

Setting method

Setting resolving power 0.1V

0.1Hz

50/60HzChoice of AC 110/220V

Scope of setting

Setting resolving power

Setting method

Scope of setting

Protection function

Cooling mode

5A

Sensor 1, Sensor 2 move On/Off(NPN Type)

3 terminal Relay output (COM, NO, NC)

Possible to set 15~40steps.

Natural cooling type by use of radiation plate.

Mark error code is displayed in case of excess current and over-

heating and stop.

Modulation of intellignece type frequency which used Carrier

frequency.

On.Off Switch and external input contact and voltage(DC 24V)Operation, stop control

Sensor input

Operation synchronizing sign

Start Up

Power source, Voltage

Frequency

Output voltage

Max.output electric current

Operation mode

12. Check Bowl Feeder

If the Bowl Feeder's vibration becomes weak, refer to number 7 for resetting.

Incase the absence of the Bowl Feeder's vibrations,

1. Check connections between controller and vibrator, controller and power input line

2. Confirming the controller frequency setting

3. Check vibration coils inside the vibrator - Replace when damaged by overheating

5. Check various bolts inside the vibrator - Replace if damaged

6. Checking various bolts inside the vibrator

7. Check if the controller is out of order - Replace if faulty

4. Checking plate springs inside the vibrator - Reassembly after removal when cracks

occur - Reset frequency

SHINCHANG F.A

24, Gongdan 1-daero 259beon-gil, Siheung-city,

Gyeonggi-do, Republic of Korea

Tel : 82+31-498-4492~3

Fax : 82+31-498-4494

Table of contents

Popular Controllers manuals by other brands

Orion

Orion MBR 70 installation manual

Lunos

Lunos Smart Comfort 5/SC-FT Installation and operating manual

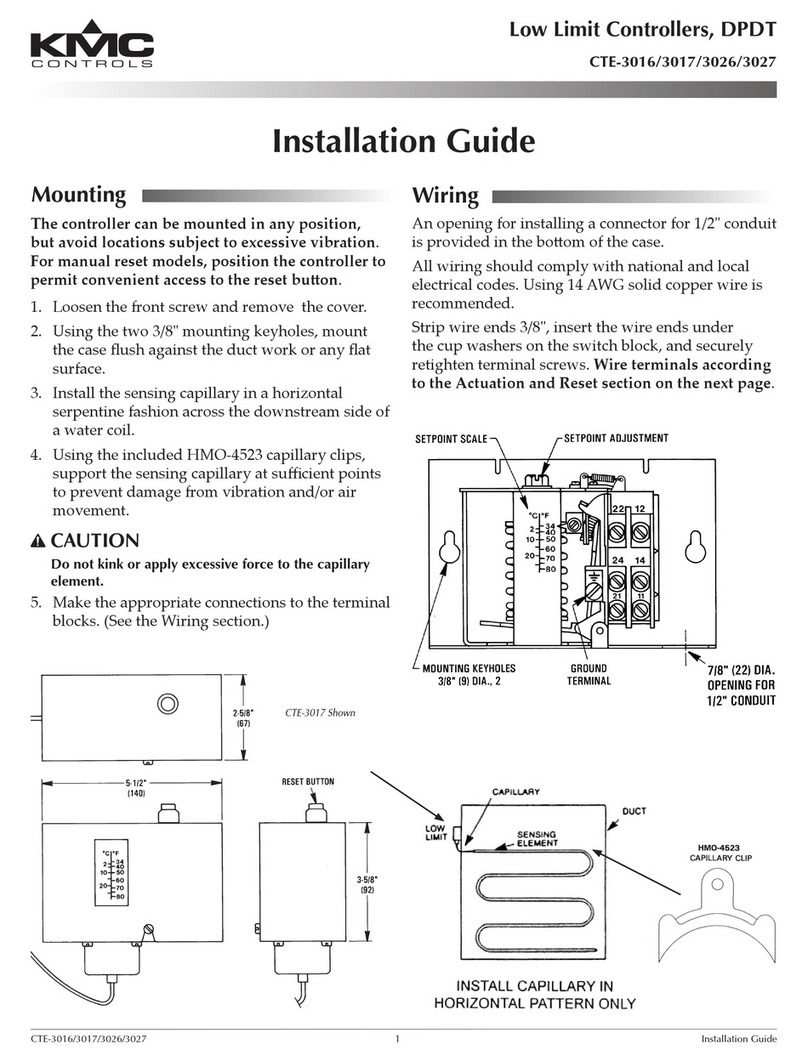

KMC Controls

KMC Controls CTE-3017 installation guide

Siemens

Siemens OCI611 Series installation instructions

Vimar

Vimar Well-contact Plus quick start guide

Honeywell

Honeywell T775U Series installation instructions

YASKAWA

YASKAWA L1000A Series Technical manual

SolarVenti

SolarVenti SControl manual

Lutron Electronics

Lutron Electronics YFSQ-F quick start guide

Neptronic

Neptronic EVCB14NIT4X/TRL24 Series Specification and installation instructions

Moog

Moog Silencer series instruction manual

Sulzer

Sulzer ABS PC 441 installation guide