Shindengen MD1320N Instructions for use

CAT.No.U085

3.3V/5V Stepdown

DC to DC Converter Power IC

MD1320N

Application Manual

SHINDENGEN ELECTRIC MFG. CO., LTD.

1

Using the MD1320N DC to DC Converter Power IC

Thank you for purchasing the MD1320N DC to DC Converter Power IC. This manual contains important

information on the safe use of the MD1320N. Your safety is most important to our company. Please read these

instructions carefully before using this device.

CAUTION

The improper use of this device can result in serious injury or death.

Expensive damage to this and other equipment can result. Failure to observe the cautions in this

Manual can also result in minor injuries and annoying equipment damage.

The MD1320N is intended for use with general electronic equipment (office automation, communication,

measurement, household, etc.) It is not intended for use with equipment whose failure might result in the death or

injury of those depending upon it (medical treatment, air navigation, railroad, cargo handling, nuclear power, etc.)

If you intend to use the MD1620F with other than the general equipment listed above, please consult with our

company.

Under no conditions attempt to repair or modify this device by yourself. Doing so can result in electric shock,

equipment breakage, fire, and unreliable (and dangerous) equipment operation.

Abnormal operating conditions may result in excessive voltage at the output terminal or excessive voltage drops

elsewhere in the device. Take steps to prevent load mishandling and breakage (overvoltage and overcurrent

prevention) at the final point in the equipment chain.

Overvoltage protection

The MD1320N is not equipped with an overvoltage protection function. In the event excessive voltage appears

within a module, the high input voltage may remain together with a high output voltage even when the equipment

is turned off. Smoke and flame may appear. To prevent this, be sure to install some sort of overvoltage protection

circuitry before using the equipment.

Before providing electrical power to the device, check that the polarity of the input and output terminals is correct

(check for misconnections). If circuit protection circuitry is cut off from the rest of the equipment, smoke and

flames may appear.

Be sure that input voltage level is maintained at the specified level. This may require the installation of a voltage

regulator to the input line. Voltage fluctuations may result in the appearance of smoke and flames.

If a breakdown or other abnormal condition occurs during equipment use, immediately stop power to the

equipment. Contact our company at your earliest possible convenience.

CAUTION

The information appearing in this Manual is the latest available at the time of publication. We reserve the right to make changes to the device without prior

notice. Therefore, your device may differ slightly from that described in this Manual.

Every effort has been made to make the information in this Manual accurate and reliable. However, our company takes no responsibility for injuries or

damage incurred when using the device as described in this Manual. Neither do we take responsibility for damages incurred as a result of patent or other

defined rights.

We do not give consent for a third person to use our patent or other rights based on this material. We do not guarantee these rights.

No part of this material may be reproduced or copied without the specific written consent of our company.

This device fully meets the reliability and quality control standards described in our company's catalog. If this device is to be used in a situation where its

misuse or failure might cause serious injury or death, consult with our company.

Reliability and quality control standards for this device are considered adequate when it is used with the following types of end equipment.

Computer - Office automation - Communication terminal - Measurement .Machine tools - Audio-visual - Games and other amusements - Household

appliance - Personal items - Industrial robot.

Special applications where the device may or may not be suitable include the following.

Transportation and conveyance (cargo loading) equipment- Primary communications equipment- Traffic signal control equipment - Fire and burglary alarms -

Various safety devices - Medical equipment

Other special applications where the device reliability is not considered high enough include the following.

Atomic energy control systems - Aviation equipment- Aeronautics and space equipment - Ocean depth sounding equipment - Life supportequipment

Our company makes a constant effort to improve the quality and reliability of our products. However, it is the customer,s responsibility to provide safety.

Take the appropriate steps to prevent personal injury, fire, and damage by providing redundancy equipment, fire containment equipment, and devices to

protect personnel and equipment from operational mistakes.

1

2

CONTENTS

DC to DC Converter Power IC

MD1320N Application Manual Table of Contents

1. Using the MD1320N DC to DC Converter Power IC................................................1

2. General description of the DC to DC Converter Power IC MD1320N .....................3

2

-

1 Features

2

-

2 Applications

2

-

3 Nomenclature

2

-

4 Peripheral functions

2

-

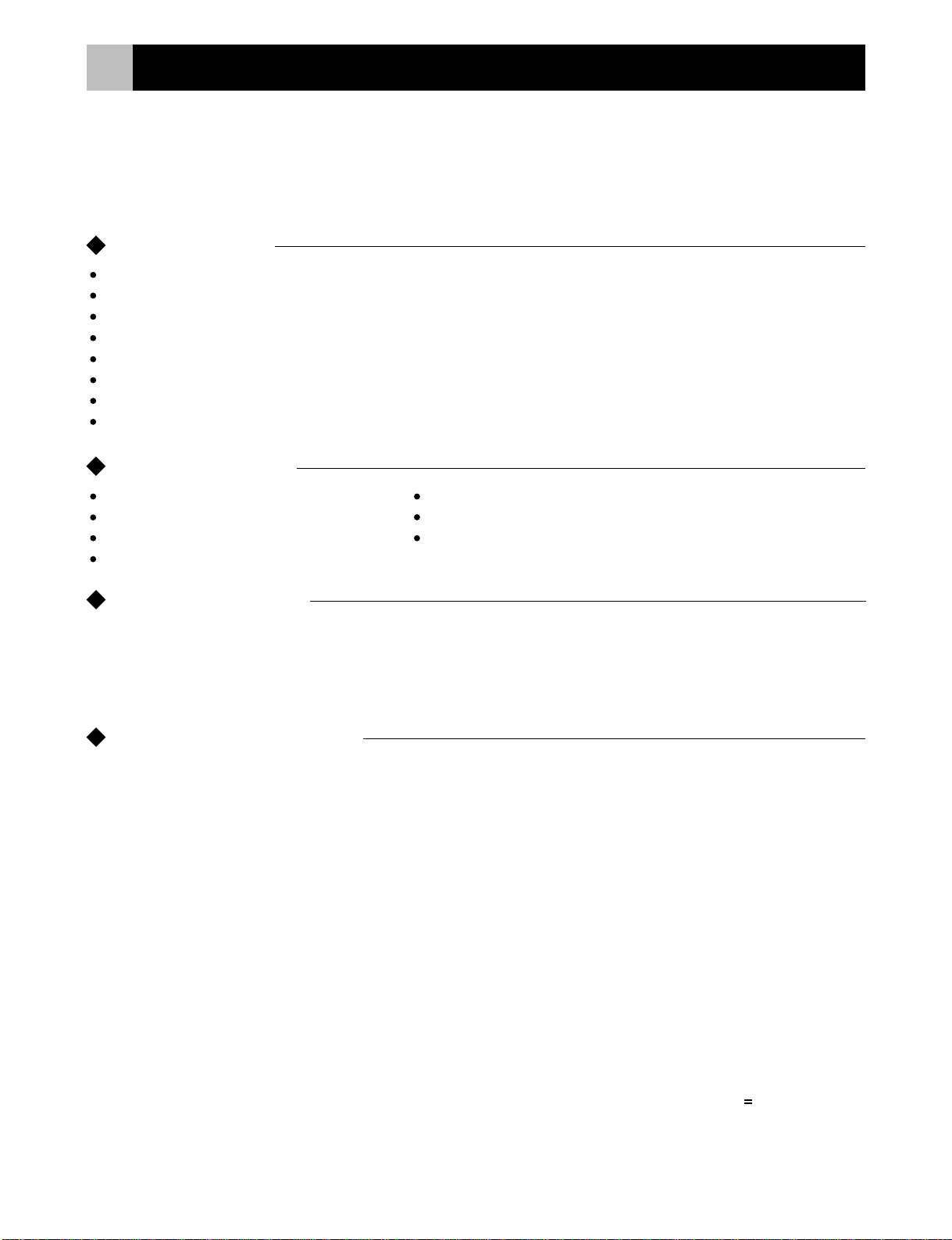

5 Terminal functions.......................................................................................4

2

-

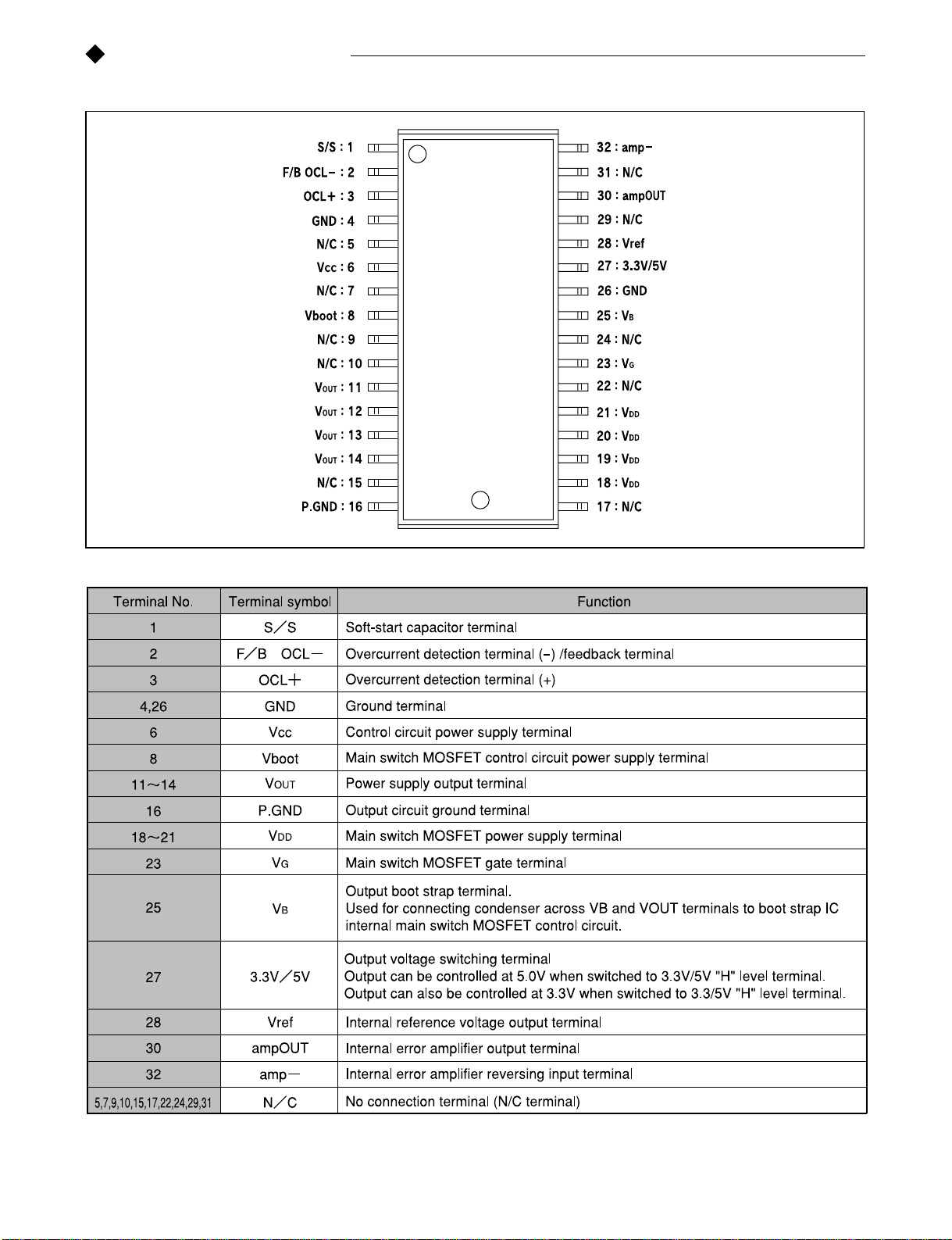

6 Block diagrams...........................................................................................5

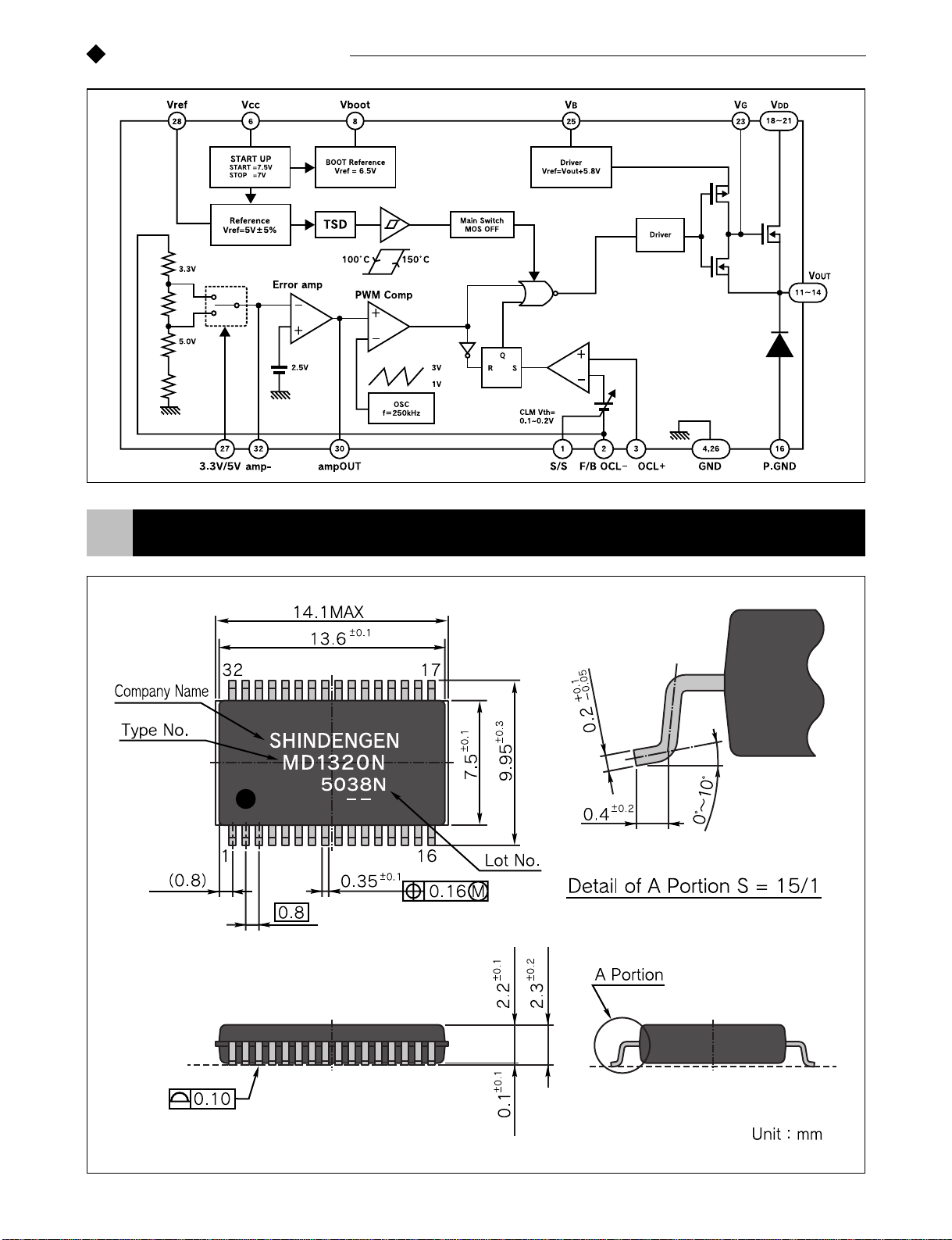

3. External dimensions (Diagram) ...............................................................................6

4. Characteristics .........................................................................................................7

5. Mounting .................................................................................................................8

5

-

1 Soldering pattern reference (Reflow-type)

5

-

2 Mounting cautions

5

-

3

Printed circuit board patterns and design considerations (Reference)

.............9

6. Operating instructions ..........................................................................................10

6

-

1 Basic input and output connections

6

-

2 Input protection element connection .......................................................11

6

-

3 Overvoltage protection

6

-

4 Remote ON/OFF Control Function...........................................................12

6

-

5 Reference parts .......................................................................................13

6

-

6 Electrical characteristics

7. Basic design procedure .........................................................................................14

7

-

1 Overcurrent detecting resistor (R1) selection

7

-

2 Inductance (L1) selection

7

-

3 Output capacitor selection ......................................................................15

7

-

4 Input capacitor selection

7

-

5 Thermal management

8. Electrical measurement data...........................................................................16

~

19

8

-

1 Output voltage - 3.3V

8

-

2 Output voltage - 5V

9. Packing conditions ...............................................................................................20

9

-

1 Taping type

9

-

2 Package configuration

9

-

3 Order quantity and dimensions

3

2

General description of the DC to DC Converter Power IC MD1320N

The MD1320N is a non-isolated step-down DC to DC converter power IC with built-in main switch MOSFET and SBD

flywheel. The maximum output is 7.5W (5V, 3.5A). The highly efficient power IC can be used over a wide range of

applications. Furthermore, the output switching function permits optional selection of 3.3 and 5V.

The use of a surface mounted type SSOP-32 package permits controls with minimal externally mounted parts. As a

result, the overall size of DC-DC converter power IC as a power supply unit is reduced and made as thin as possible.

Input voltage range: 8

~

30V

Output voltage: 3.3V/5V (Output switching function permits optional selection of output voltages)

Maximum output current: 1.5A

Main switch MOSFET and built-in SBD flywheel

Oscillation frequency: 250 kHz (Built-in oscillator does not require external capacitors or resistors)

Overcurrent protection function

Heat protection function

Built-in low-voltage protection (UVLO) function

Information distribution equipment Telecommunications equipment

Office automation equipment Factory automation equipment (Process control)

Electronic measuring instruments Audio-video devices

Home appliances

Device name and packaging specification codes are provided. Shipping conditions are determined according to these

specifications.

Entry example: MD1320N 4072

Specification code: Shows package configuration and product name

1 )Internal reference voltage (Vref)

IC internal circuitry reference voltage is provided by the temperature compensation reference voltage (5.0V). This reference

voltage (Vref) provides a maximum external output current measured at the terminal of 1 mA.

2 )Oscillation circuit (OSC)

The oscillation circuit is built into the device. No external oscillation capacitor nor resistor is required. The oscillation

frequency (250 kHz) is set internally and has a sawtooth wave pattern. The sawtooth wave pattern cannot be outputted

externally.

3 )Error amplifier (Error Amp.)

The error amplifier senses the DC to DC converter voltage and provides a PWM control signal output. Loop gain

between the error amplifier ampOUT terminal and the negative amp terminal is determined by the connections between

the feedback resistor and the capacitor. This provides stable loop compensation throughout the system.

4 )Overcurrent sensor (OCL)

The OCL is a pulse-by-pulse overcurrent sensor. The voltage drop across the external current sensing resistor is

measured between the negative and positive terminals of the OCL. If the voltage drop exceeds 0.19V, the main

switch (MOSFET) opens.

2

-

1 Features

2

-

2 Applications

2

-

3 Nomenclature

2

-

4 Peripheral functions

..

4

2

-

5 Terminal functions

5

3External dimensions(Diagram)(SSOP-32)

2

-

6 Block diagrams

6

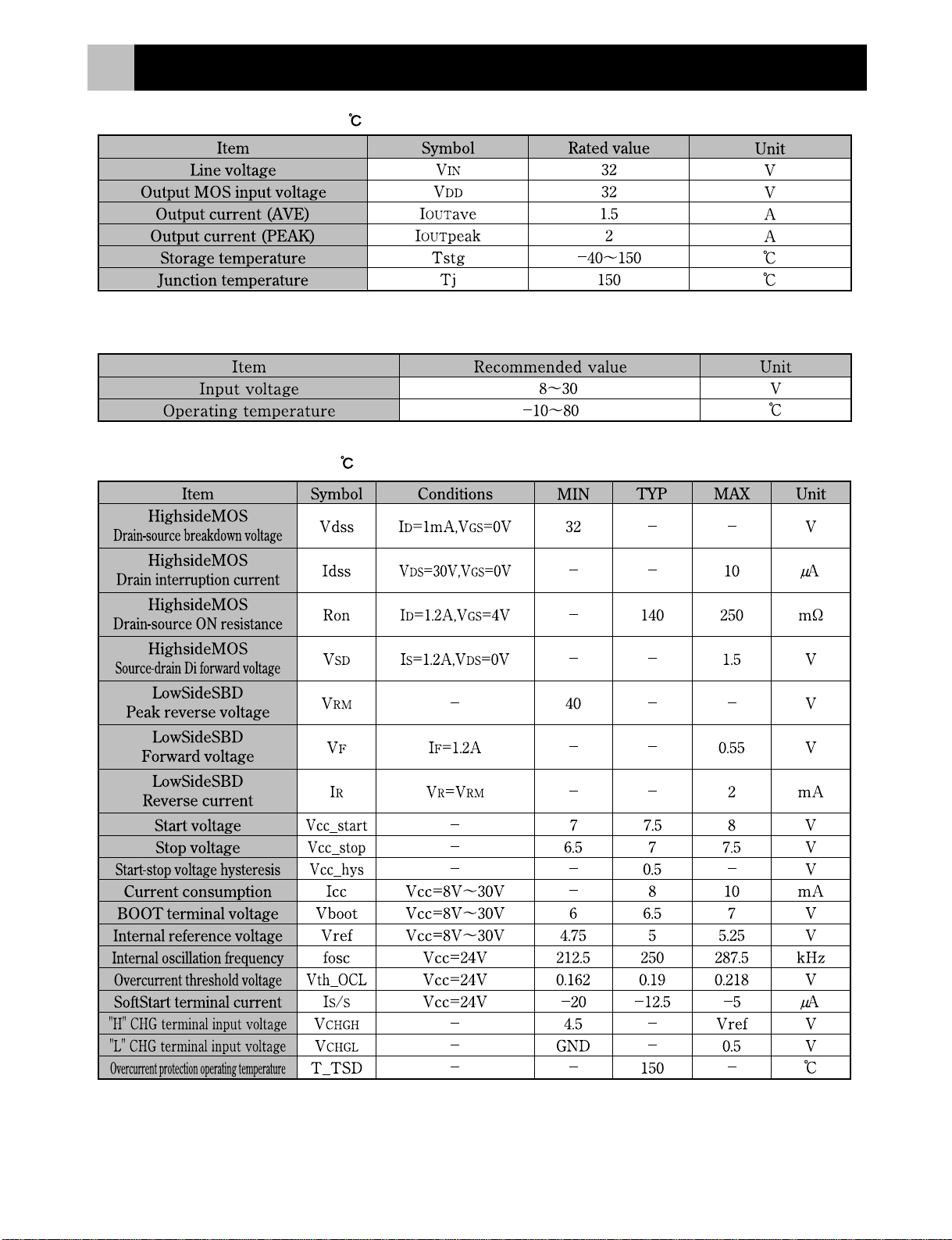

2 )Recommended operating conditions

3 )Electrical characteristics (Ta=25 )

4Characteristics

1 )Absolute maximum rating (Ta=25 )

7

1 )Mounting

Vibration and other mechanical disturbances

can exert stress on the internal parts of the

device. Carefully examine your equipment and

place the device where vibration and other

shock is minimal.

2 )Soldering cautions

Infrared reflow method

This method provides very high temperature

soldering. The chart at the right shows the

recommended temperature profiles for the

Infrared reflow soldering method.

Soldering iron

When using a soldering iron, observe the

following.

Soldering iron temperature: Not to exceed

300

Soldering iron contact time: Not to exceed 5

seconds

3 )Cleaning cautions

Carefully remove all flux. Allow time for the soldered areas to completely dry before using the device.

4 )Secondary mold cautions

After installation of the device to a board, remolding using plastic may be required. During this process, stress on the

device will depend on the type of plastic used. The best plastic (that which causes the least stress on the device) has a

minimum contraction ratio and high flexibility. Hardening temperatures should not exceed the storage temperature.

Carefully check the plastic characteristics before use.

Static electricity can damage the device. The person and clothing of personnel working with the device

should be grounded to prevent the build-up of static electricity. It is recommended that personnel stand

on rubber mats (electrical safety mats) having a resistance greater than 1M when working with the

device. This will prevent damage to the device from static electricity discharge and protect the personnel

form electrical shock.

5Mounting

0.5

9.53

1.4

0.8

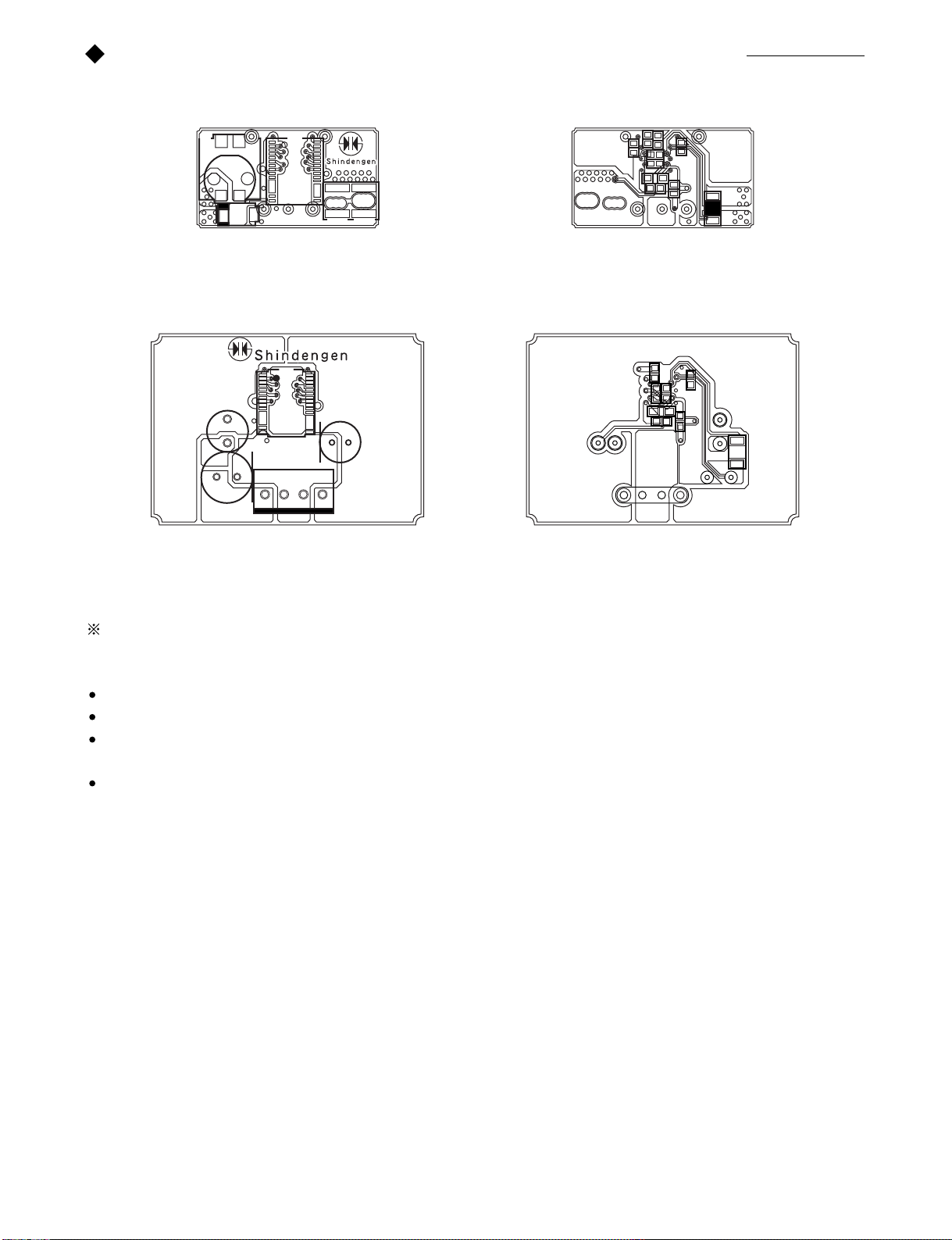

(Figure 5-A)

5

-

1 Soldering pattern reference (Reflow-type)

5

-

2 Mounting cautions

8

The device does not have a voltage surge protection circuit or an input fuse. The user should install an input fuse to protect the device and

equipment before using the device.

For optimum thermal efficiency, maintain the copper foil pattern as much as possible.

Connect the F/B OCL negative terminal (Pin 2) as close as possible to the output capacitor (C5).

Connect the input capacitor (C1), output capacitor (C5), choke (L1), and dropping resistor (R2) as close as possible to the power IC

device.

Separate the ground terminals (Pin 4 and Pin 26) and the P and ground terminals (Pins 16). Connect each of them as close as possible

to output capacitor (C5).

C6

R3 R1 C2

C3 C4 R2

D1KD1K

3.3V5V

MDMD

L1

C1-1 C1-2

+Vo +VinG

IC1 MD

L1

C1-1 C1-2

+Vo +VinG

C5

IC1

C6

R3 R1 C2

C3 C4 R2

3.3V5V

D1K

C5

R1

R2

C2C2

3.3V5V

D1K

C3C3 C4C4

L1

IC1

CN1

C1

MD

C5 +Vo +VinG

L1

IC1

CN1

C1

MD

C5 +Vo +VinG

R1

R2

C2

3.3V5V

D1K

C3 C4

Typical 1.5A lead parts model

Typical 1.5A surface mounted parts model

5

-

3

Printed circuit board patterns and design considerations(Reference)

9

6Operating instructions

The MD1320N power IC device uses chopper circuitry and can be referred to as a chopper type DC to DC

converter. The device requires an external choke and capacitor to be connected to it. The characteristics of

these external parts and the way they are packaged and connected will greatly affect the performance of the

device and its circuits. Carefully select these external parts to provide optimum device performance.

Neither the device input side nor output side is isolated.

Power IC device connection and use involves the rated output voltage and the maximum current output range.

1 ) If an output voltage of 3.3V is required, connect Pins 27 and 28. If an output voltage of 5V is required, connect Pins 26

and 27.

2 ) Pin 23 is the test terminal and must be left open.

3 ) Pins 5, 7, 9, 10, 15, 17, 22, 24, 29, and 31 are internal non-connecting pins (N/C terminals).

4 ) Figure 6-A shows the external parts and their connections. Be sure to prepare and connect these items before using the

device.

5 ) Output capacitor (C5) minimizes switching frequency ripple and provides a smooth and stable output voltage. The use of

a low-impedance capacitor is recommended (low impedance provides minimum ripple).

Standard connections (Figure 6-A)

6

-

1 Basic input and output terminal connections

10

Caution

The MD1320N device has an output current drop function. In the event of power IC device malfunction resulting in

excessive input current flow, smoke and flame may be emitted from the equipment. To prevent this, install a fuse or

protective circuitry to the power IC device input line.

Install the fuse or protective circuitry to the positive side of the input line(Figure 6-2, DC input). Be sure that the fuse or

protective circuitry is not too large to effectively protect the circuitry (the input line must be capable of carrying enough

current to blow the fuse).

The MD1320N power IC device does not have an overvoltage (voltage surge) protection function. If a malfunction occurs in

the device internal circuitry, there may be a voltage surge. Output will reflect this surge and damage to equipment may result.

Smoke and flame may be emitted from the equipment. To prevent this, be sure to install voltage surge sensing and

protection circuitry.

There are a number of ways to protect against voltage surge. Figure 6-B shows a typical voltage surge protection set-up. The

voltage surge sensing and protection circuit should be installed as close as possible to the load (away from the output

smoothing capacitor).

+

R1

Load

DC to DC converter

power supply

Circuit protection elements (fuses, etc.)

Overvoltage protection circuit

D2

C1

D1F1

DC

THY1

R2-

Reference part example (Figure 6-B)

6

-

2 Input protection element connection

6

-

3 Overvoltage protection

11

MD1320N

VOUT

GND

VDDVCC

R1 Q1

Q2

Q3

R2

R4

R3

DC input

R/C

G

+Vin +Vo

The MD1320N is not provided with remote ON/OFF control functions. When necessary, be sure to add the recommended

circuit shown below. The use of remote control (R/C) circuit turns the output ON and OFF without making or breaking the

input. The R/C circuit can also be employed in systems such as sequence control for a power supply system.

1) R/C terminal When turning ON power supply on the low side (connection to ground), be sure to add the circuit shown in

Fig. 6 - C, and turn the power supply OFF when the R/C circuit is on the high side.

2) R/C terminal When turning ON power supply on the high side (open), be sure to add the circuit shown in Fig. 6-D, and

turn power supply OFF when the R/C terminal is on the low side.

(Figure 6-C)

MD1320N

VOUT

GND

VDDVCC

R1 Q1

Q2

R2

R3

DC input

R/C

G

+Vin +Vo

(Figure 6-D)

6

-

4 Remote ON/OFF Control

12

Efficiency and ripple are measured according to external reference parts circuit configuration that is based on standard circuit

configuration.

Efficiency and ripple voltage conditions: Vin = 12V and Io = rated output current

6

-

5 Reference parts used with standard circuits

6

-

6 Electrical characteristics (Ta = 25 )

13

7Basic device set-up standards

Set-up sequence below

Areas that must be carefully considered in the set-up of the device include the overcurrent detecting resistor,

circuit inductance, output capacitor, input capacitor, and thermal characteristics.

Detects a peak voltage across the resistor of 0.19V+

-

15%

VR

R1= [ ]

IR

Switching noise and other factors may cause some variation in the calculated drop point value. Check your own

equipment and calculate the value accordingly.

VR : Average voltage level

IR: Drop point

The selected inductance sets the cut-off current at 15% of the rated output current.

L1= [H]

Vi (max) = Maximum input voltage

VO: Output voltage

VF : SBD flywheel forward voltage (0.5V)

I : Cut-off current 2 ( IO0.15 2) (Cut-off current flows through the choke coil. Current value is intermittent.)

f : Oscillation frequency (250 kHz)

IO : Output current

Calculated inductance values (L1) shown here represent those used in previously manufactured devices and may not be

applicable to your device. The use of an actual value somewhat higher than the measured value is standard procedure.

However, actual values lower than the measured value may be used where the rated current is low. Use the formula to back-

calculate the I using the selected L1 value. The recommended value is 0.2 IOI 0.4 IO(Cut-off at 10 to 20

percent).

7

-

1 Overcurrent detecting resistor (R1) selection

7

-

2 Inductance (L1) selection

( Vi (max)

-

Vo) ( Vo + VF)

I ( Vi (max) + VF) f

14

If an electrolytic capacitor is used, output ripple is determined by I and capacitor impedance. Use the formula below to

calculate the value. Select a device providing an impedance (ZC) lower than the calculated value.

Vrip

ZC[ ]

I

Vrip : Output ripple voltage (Ex: 25m VP

-

P)

I : Cut-off current 2

A large ripple current flows through the input capacitor. Use the formula below to calculate the value. Select a device

providing a higher ripple current capacity (Irip) than the calculated value.

VO +VF

D= Vi (min)+VF

Irip D (1

-

D) IO[A]

D : Duty

VO : Output voltage

Vi (min) : Minimum input voltage

VF : SBD flywheel forward voltage (0.5V)

IO : Output current

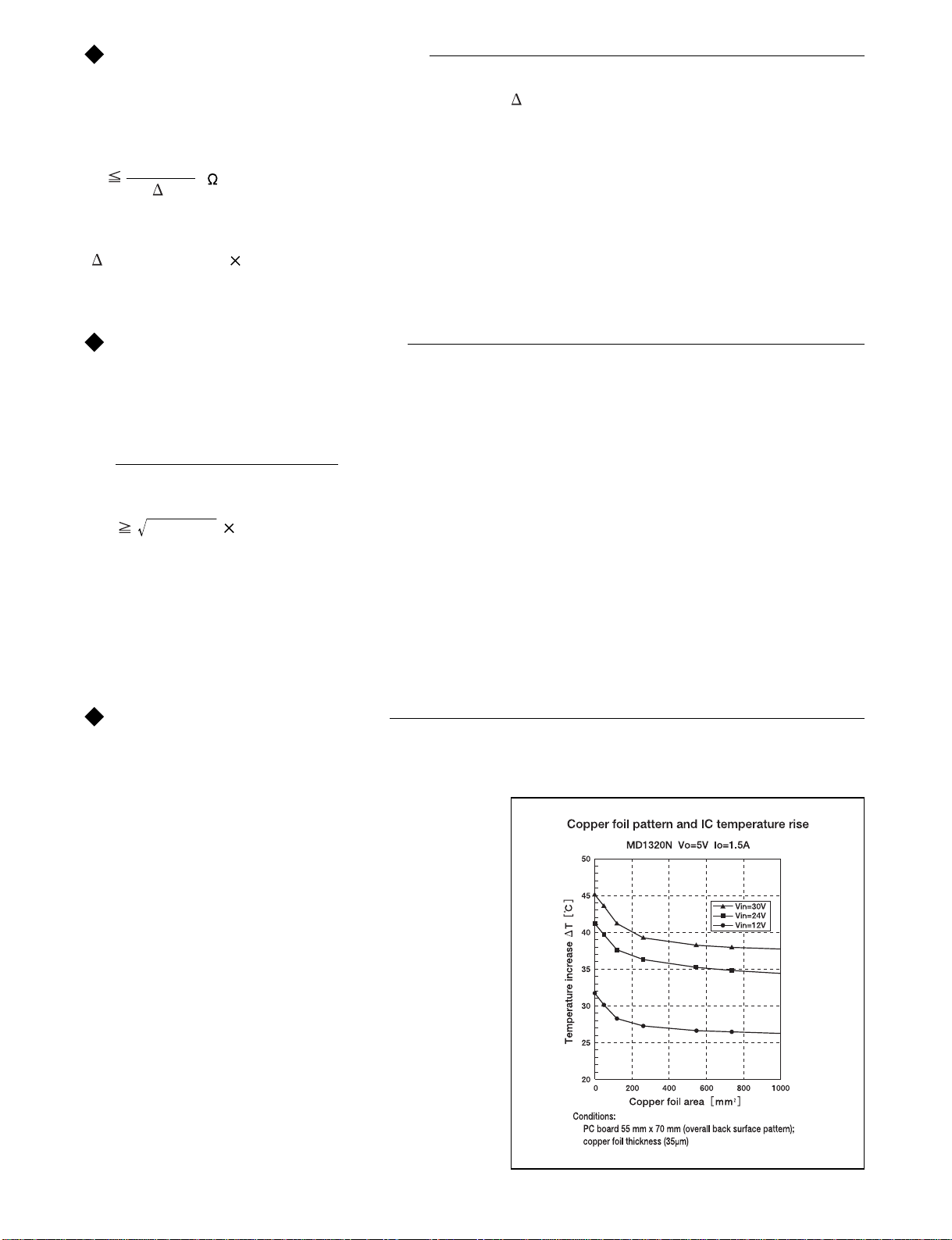

The MD1320N is so designed that heat is radiated when Pins 11, 12, 13, 14, and Pins 18, 19, 20 and 21 are connected to the

substrate pattern. The necessary area of heat radiation pattern

differs according to the material and size, but be sure to check

with an actually operating piece of equipment and referring to

the data given in Fig. 7 - A.

Since the temperature rise also differs according to the

conditions of I/O voltage and output current, use 105 degrees

maximum as the design target for the surface temperature of

case.

Figure 7-A

7

-

3 Output capacitor selection

7

-

4 Input capacitor selection

7

-

5 Thermal management

15

8Electrical data measurement

This data results from measurements taken using equipment connected as shown in the standard connection

diagram and using reference part and reference circuitry patterns.

8

-

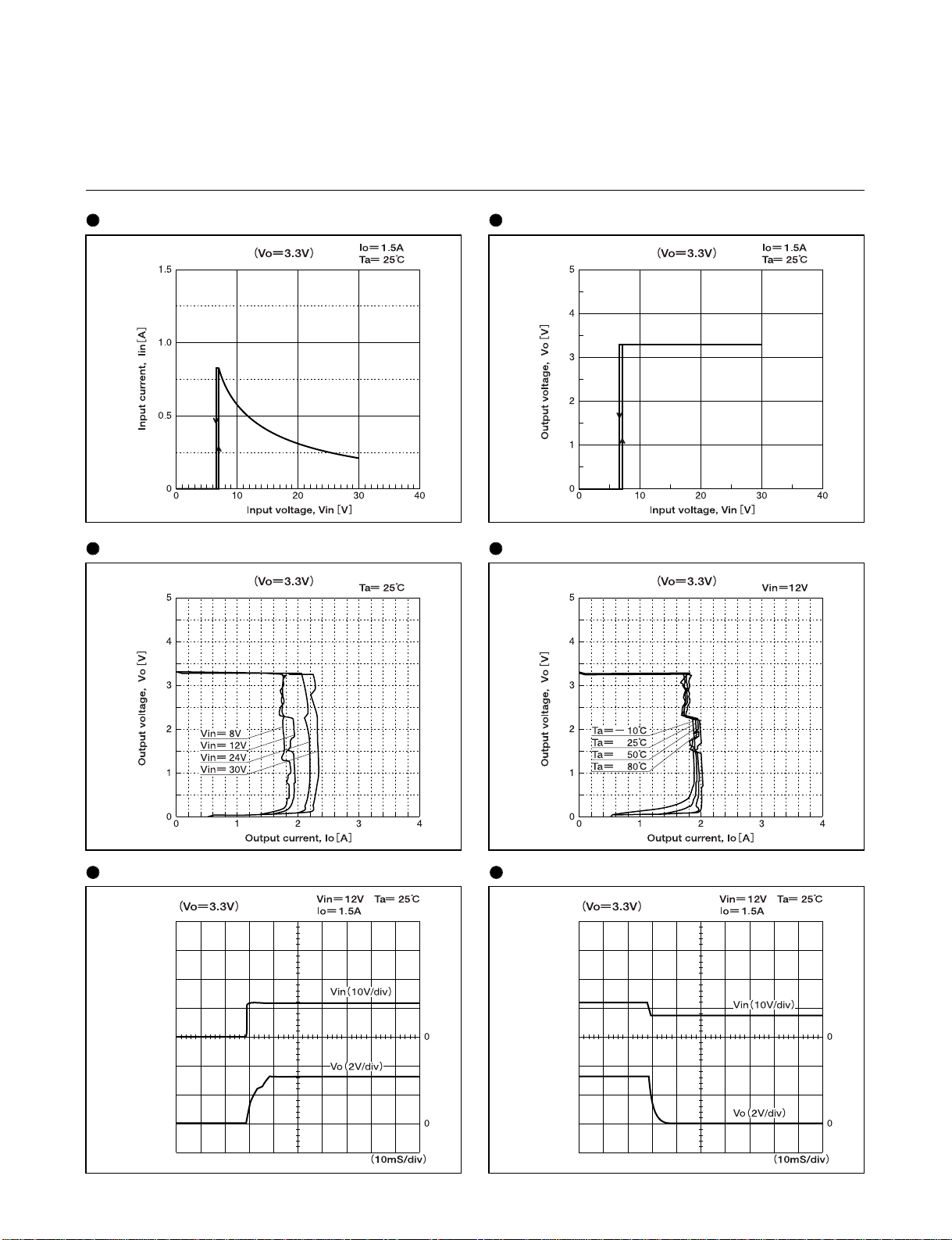

1 Output voltage - 3.3V

Line regulation Load regulation

Temperature drift Efficiency and loss characteristics

IC temperature increase Derating curve

16

Input curreent/input voltage characteristics Input voltage/output voltage characteristics

Current limit characteristic (Input fluctuation)

Current limit characteristic (Temperature fluctuation)

Start-up rising characteristics Shut-down falling characteristics

17

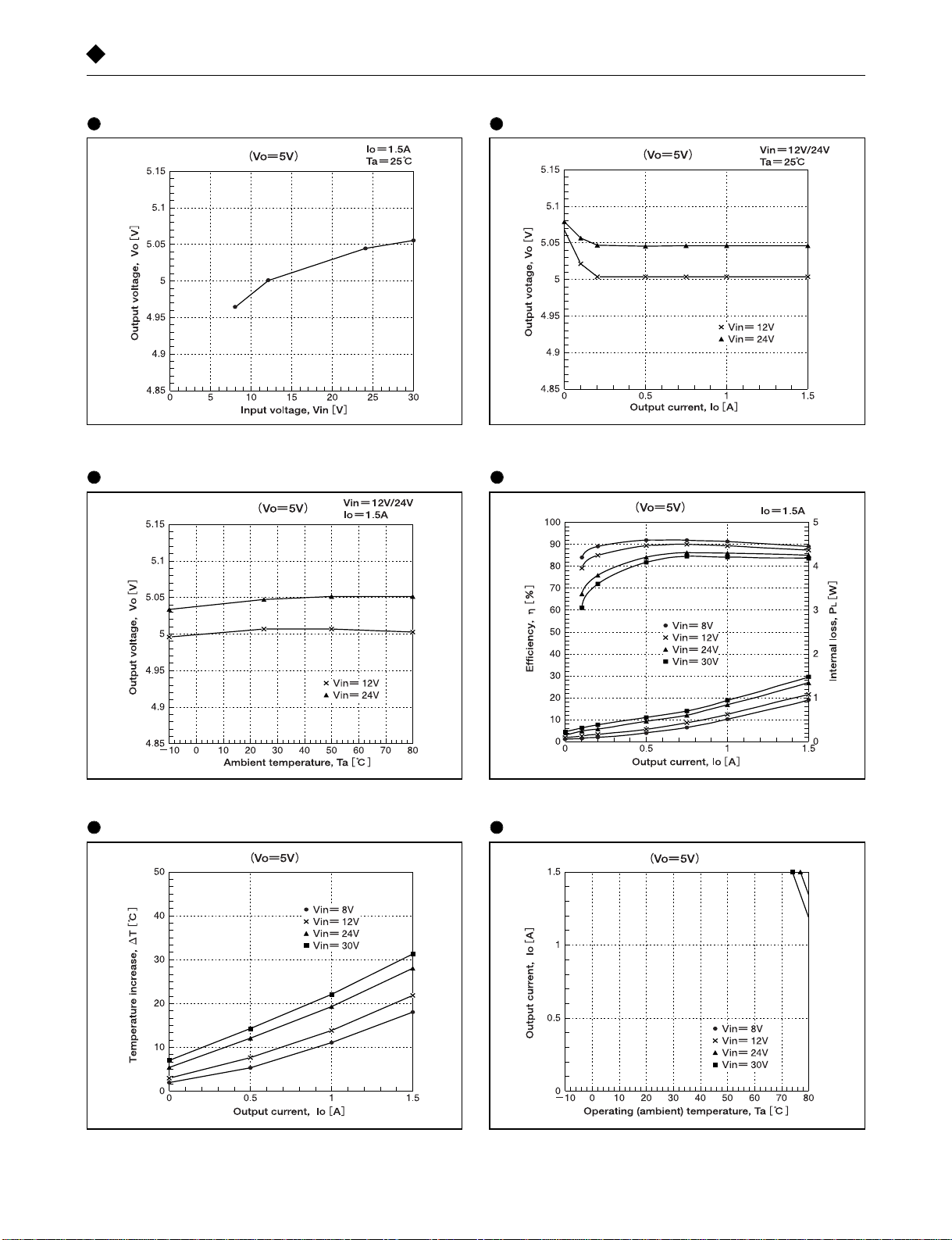

Line regulation Load regulation

Temperature drift Efficiency and loss characteristics

IC temperature increase Derating curve

8

-

1 Output voltage - 5V

18

Input curreent/input voltage characteristics Input voltage/output voltage characteristics

Current limit characteristic (Input fluctuation)

Current limit characteristic (Temperature fluctuation)

Start-up rising characteristics Shut-down falling characteristics

19

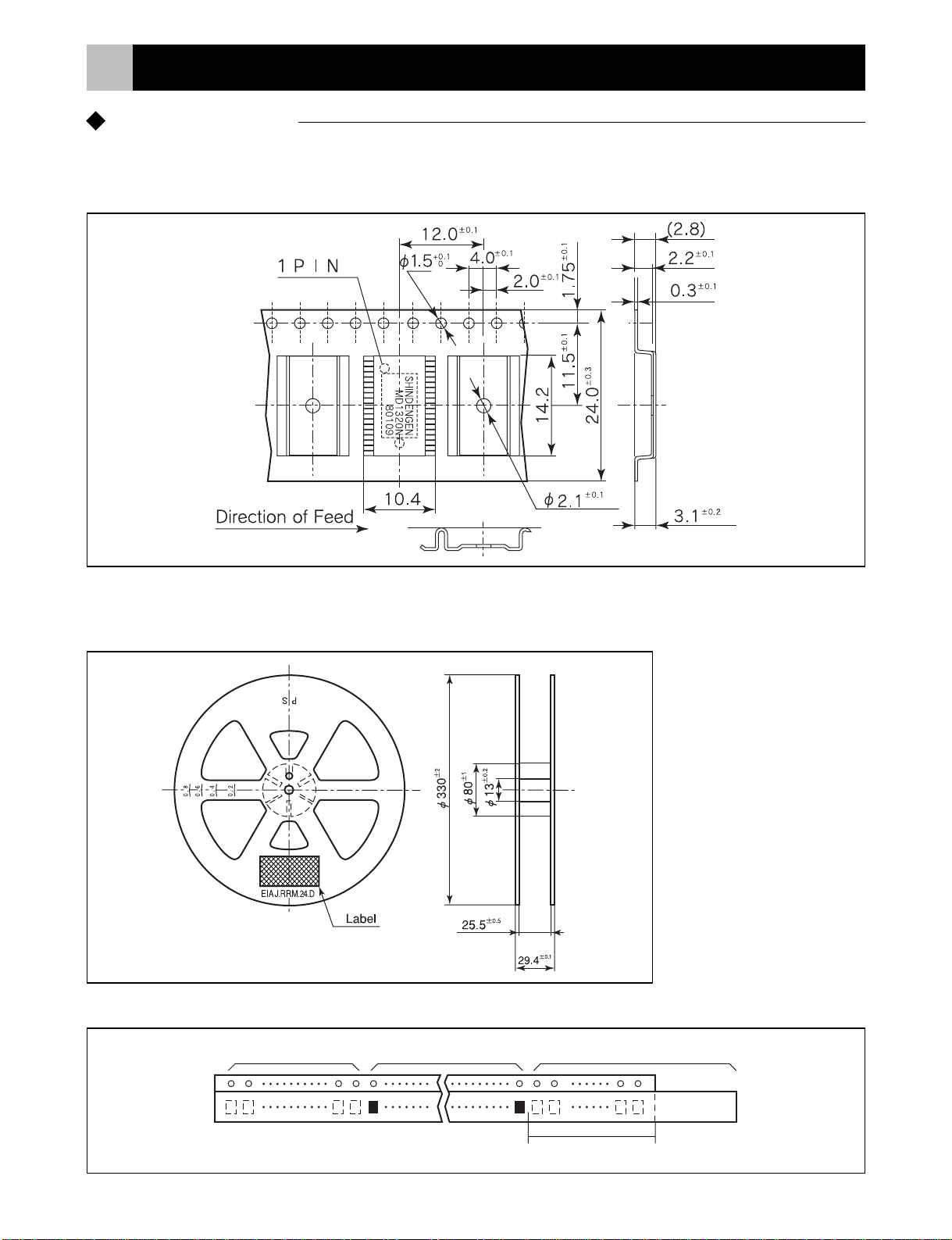

9Packing

1 )Tape

.Material : PVC

.Dimensions Comply with JIS, C-0806

2 )Reel

.Material : Polystyrene

.Demensions Comply with EIAJ, ETX-7001

.Label

Type No.

Code No.

Date Code

Quantity

Manufacturer

3 )Leader and Trailer

Trailer 120mm(min)

Leader 120mm(min)

Top cover 400mm(min)Device

9

-

1 Tape & Reel

Table of contents

Other Shindengen Media Converter manuals