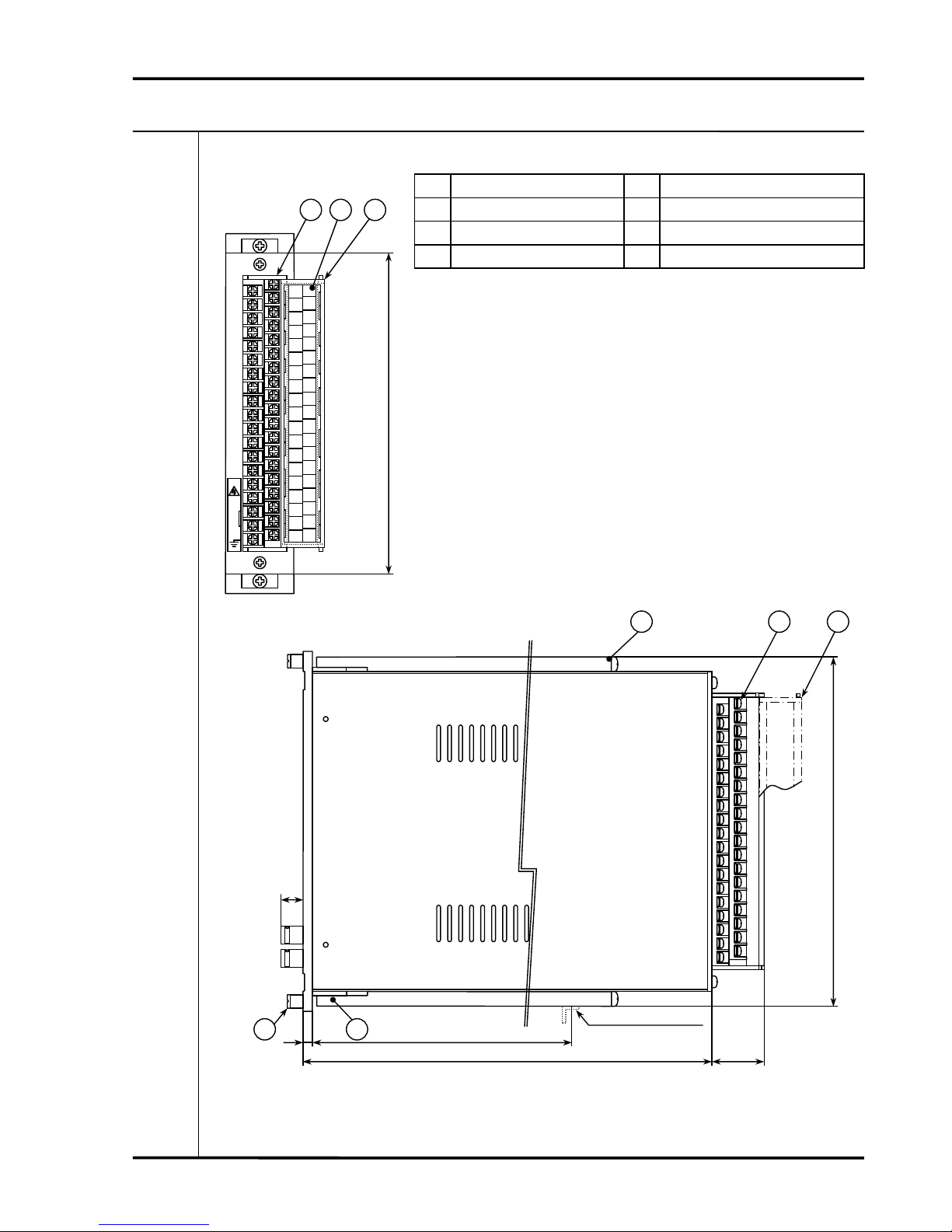

2. SPECIFICATIONS VM-5G

-2-

Power supply voltage Input Tropical

spec. CE marking *3

0 85 to 264VAC 1 CA Series,CV-86 *1

1 24VDC

2 110VDC

2 CV-85,CV-87 *2

VK,RD,FK,MS

VC,VM-11P,VM-21P

3 Input for VM-51

1CH:VK,FK

2CH:VK,FK

φ

I:VK,RD,FK

4 Input for VM-55

1CH:VK-202A,FK-202F

2CH:CV-86,CV-88

BEZEL

(OPTION)

Required(couple)

Not required

POWER OUTPUT FOR

TRANSDUCER

+24VDC, 4mA (input code:1)

-24VDC,20mA (input code:2)

1CH : -24VDC, 40mA 2CH : -24VDC, 20mA (input code:3)

1CH : -24VDC, 20mA 2CH : +24VDC, 4mA (input code:4)

EXTERNAL CONTACT

INPUT

(FROM REAR PANEL)

Contact for alarm reset (normally open)

Contact for sequence (normally open)

Contact type : Dry contact

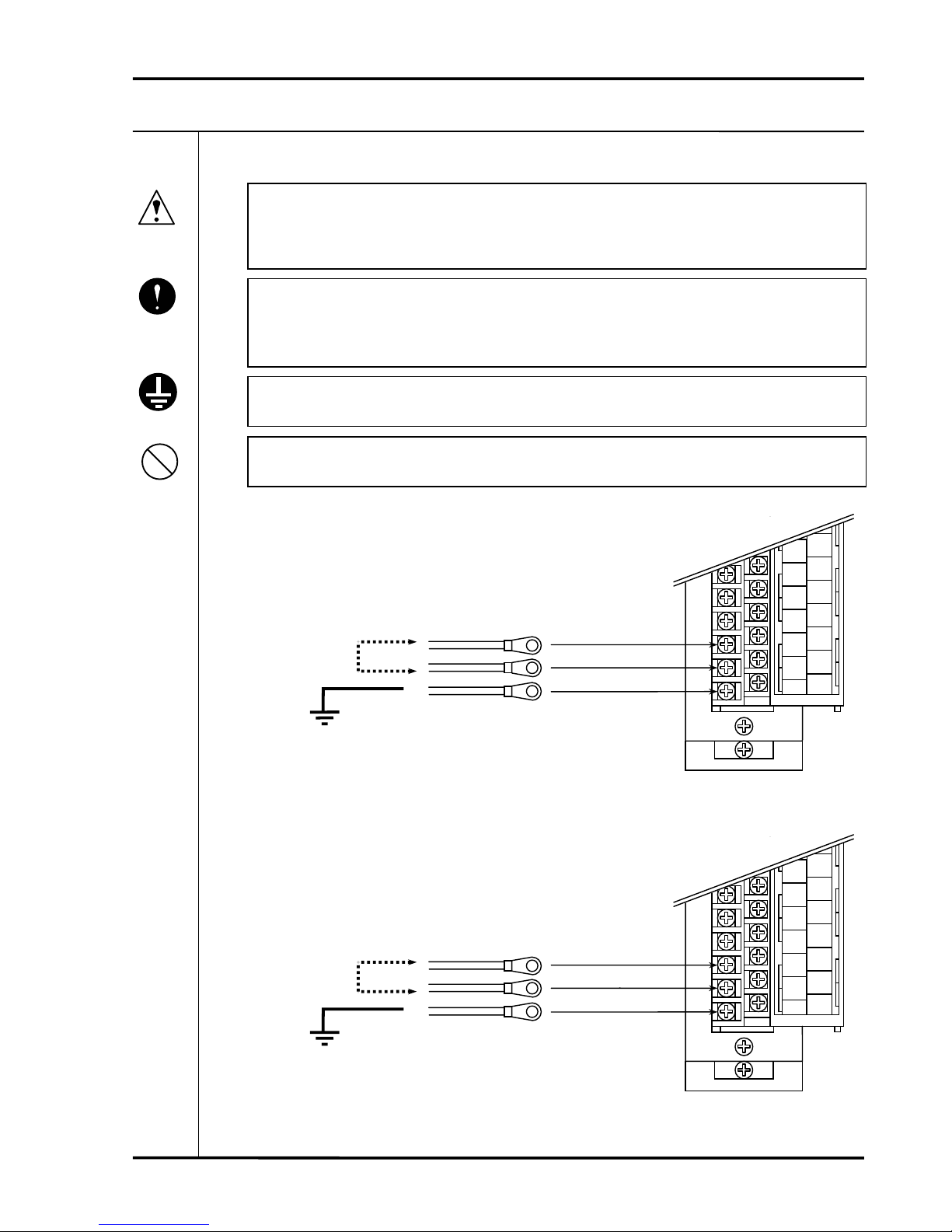

INSULATION

RESISTANCE

Between power supply and GND : 100MΩor more at 500VDC

Between GND and alarm contact : 100MΩor more at 500VDC

DIELECTRIC STRENGTH

Between power supply and GND : 1500VAC, one minute

POWER

CONSUMPTION

VM-5G0 : 40VA or less

VM-5G1 : 30W or less

VM-5G2 : 40W or less

OTHERS

RELAY POINTS 5 points(DANGER1,ALERT1,DANGER2,ALERT2,OK)

TEMPERATURE

RANGE

Operating temperature : 0 to 65°C (32 to 149°F)

Storage temperature : -30 to +85°C (-22 to +185°F)

Relative humidity : 20 to 95% (noncondensing)

CONTACT RATING

(LOAD RESISTANCE)

250VAC,0.2A 30VDC,2A

CONTACT LIFE 100,000 times or more(rated load)

CONTACT METHOD SPDT(DAN.1,DAN.2,ALE.1,ALE.2,OK)5 points relay

MATERIAL AND FINISH Rack : SPCC Unichromate plating finish (black)

Rear plate : SPCC Unichromate plating finish (black)

Bezel : Aluminum Munsell N-1.0 (equiv.)

PROTECTIVE

CONSTRUCTION

Plastic sealed

MASS Rack : max.1.8kg

Bezel : max.0.2kg

Alarm contact operation

Monitor power ON

Monitor alarm relay mode Monitor power OFF Normal state Alarm state

NO contact NORMALLY DE-ENERGIZED OPEN OPEN CLOSE

NO contact NORMALLY ENERGIZED OPEN CLOSE OPEN

NC contact NORMALLY DE-ENERGIZED CLOSE CLOSE OPEN

NC contact NORMALLY ENERGIZED CLOSE OPEN CLOSE

Note) Ventilation holes are drilled through the top, bottom and side faces of the instrument rack for natural

cooling. When mounting the instrument rack within the panel, do not close these ventilation holes. I

conditioner.

/TRP/CEM

Ordering Information Standard Specifications

VM-5G -

Note) This code is applicable only to Model VM-5G.

Model Code / Additional Spec. Code( )

No entry if additional

spec. code is not specified.

Note) *1 2-wire transducer requiring a constant current power supply

(+24VDC, 4mA).

*2 3-wire transducer requiring a -24VDC power supply,

or any other transducer that does not cause power to be

supplied from the monitor to the transducer.

*3 Power supply is 0,2 : Can not select.

Standard Specifications

39516E4.3