ShopBot Desktop MAX User manual

© Copyright May, 2022 ShopBot Tools, Inc.

page 1

Desktop MAX Automatic Tool

Changer (ATC) User Manual

Desktop MAX Automatic Tool Changer (ATC) User Manual SBG00358

© Copyright May, 2022 ShopBot Tools, Inc.

page 2

Table of Contents

Introduction...............................................................................................................................................3

ATC Software Setup and Tool Calibration.................................................................................................4

Install the ATC Software........................................................................................................................4

ShopBot Setup (TS)..................................................................................................................................5

Software Inputs and Outputs Check ..........................................................................................................9

Inputs.................................................................................................................................................... 9

Outputs............................................................................................................................................... 10

Basic Function Check.......................................................................................................................... 10

Additional function checks................................................................................................................... 11

Z Zero Plate.................................................................................................................................... 11

Fixed Z Zero Plate........................................................................................................................... 11

Tool Draw Bar................................................................................................................................. 11

Calibrating the ATC................................................................................................................................. 12

Calibration Routine.............................................................................................................................. 12

Set Fixed Z-Zero Plate Location...................................................................................................... 14

Setup Tool Holders.......................................................................................................................... 15

Change Tools (C1).......................................................................................................................... 17

Zero Tools in Rack (CN72) (Daily Operation)................................................................................... 17

Get Plate Offset (CN73)................................................................................................................... 18

Zero to Various Z Heights (C2) (Daily Operation)............................................................................. 19

Regularly Used ATC Files....................................................................................................................... 19

Create a Tool Change File ...................................................................................................................... 20

Spindle Warmup Routine (C5)................................................................................................................. 21

Run the File ............................................................................................................................................ 21

Troubleshooting...................................................................................................................................... 22

Desktop MAX Automatic Tool Changer (ATC) User Manual SBG00358

© Copyright May, 2022 ShopBot Tools, Inc.

page 3

Introduction

The ShopBot Automatic Tool Changer (ATC) automates the bit changing process during projects that require

multiple tool changes. The ATC reduces the time a project must remain on the machine by automatically

changing bits between cuts, thus eliminating the need to change and calibrate tools by hand.

The ATC system includes:

A 1HP Teknomotor spindle

Filter/regulator with low pressure switch

Six-position tool bar

Magnetically removable dust skirt

ATC interface board

The 1HP Teknomotor spindle assembly is fan-cooled. The ATC requires 4 scfm at 90 psi of clean, dry, un-

oiled compressed air. PORTABLE AIR COMPRESSORS ARE NOT RECOMMENDED, as they can have

trouble maintaining this pressure reliably and have a reduced service life.

It is not recommended to leave a tool holder in the ATC spindle when not using the machine. When you are

done using the machine all tool holders should be removed and stored in the tool rack at the rear of the tool.

Using the software to change to tool #0 (explained on page 17) will accomplish this.

Connecting the Pneumatics

Locate the filter/regulator included with your tool. Inside the bag will be a mounting bracket and two

M5x12mm Button Head Screws. First, attach the mounting bracket to the rear of the tool on the corner

opposite the red power switch. Remove the plastic nut from the regulator and drop the regulator into the

bracket and thread the nut onto the regulator to lock it in place. Pull the blue main pneumatics hose from

under the tool and insert it into the orange quick-connect fitting. Plug your shop’s air-line into the fitting on the

left side of the filter.

Desktop MAX Automatic Tool Changer (ATC) User Manual SBG00358

© Copyright May, 2022 ShopBot Tools, Inc.

page 4

ATC Software Setup and Tool Calibration

This portion of the installation covers the software setup and tool calibration.

Install the ATC Software

Download the latest ShopBot control software from the ShopBot website:

http://www.shopbottools.com/mSupport/controlsoftware.htm

If an earlier version of the ShopBot control software is present, uninstall the software and install the most

recent version. Refer to “Uninstall/Reinstall ShopBot and VCarve Software”

at http://www.shopbottools.com/ShopBotDocs/software.htm

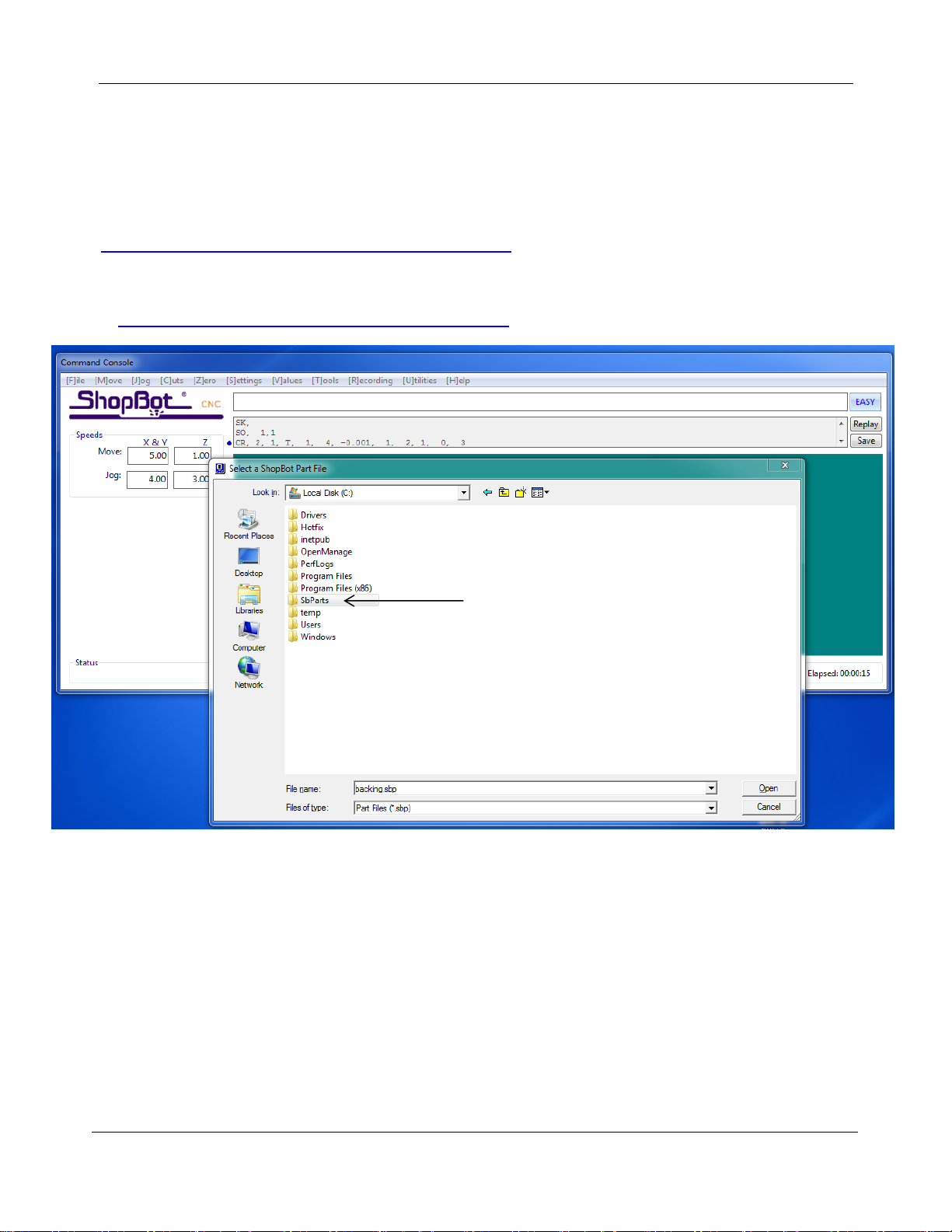

Note: If there are personal files within the “SbParts” folder, be sure to rename or move this folder so the files

are not lost.

Desktop MAX Automatic Tool Changer (ATC) User Manual SBG00358

© Copyright May, 2022 ShopBot Tools, Inc.

page 5

ShopBot Setup (TS)

Type in “UR” or go to “Utilities” pull-down menu and select “Reset default Settings”. Select the file name that

correctly describes the machine (under the “PRS ShopBots” folder, then

ShopBot_PRSDesktopMAX3624.sbd)

Move the cutter to the location that is to be “0, 0” (the reference point for programming) on the

table. Open the ShopBot control software and open the “ShopBot Setup” file in the “Tools” drop-

down (TS). Read through the window and click “Next”. The second window is the “Tool Settings”.

(0,0)

Desktop MAX Automatic Tool Changer (ATC) User Manual SBG00358

© Copyright May, 2022 ShopBot Tools, Inc.

page 6

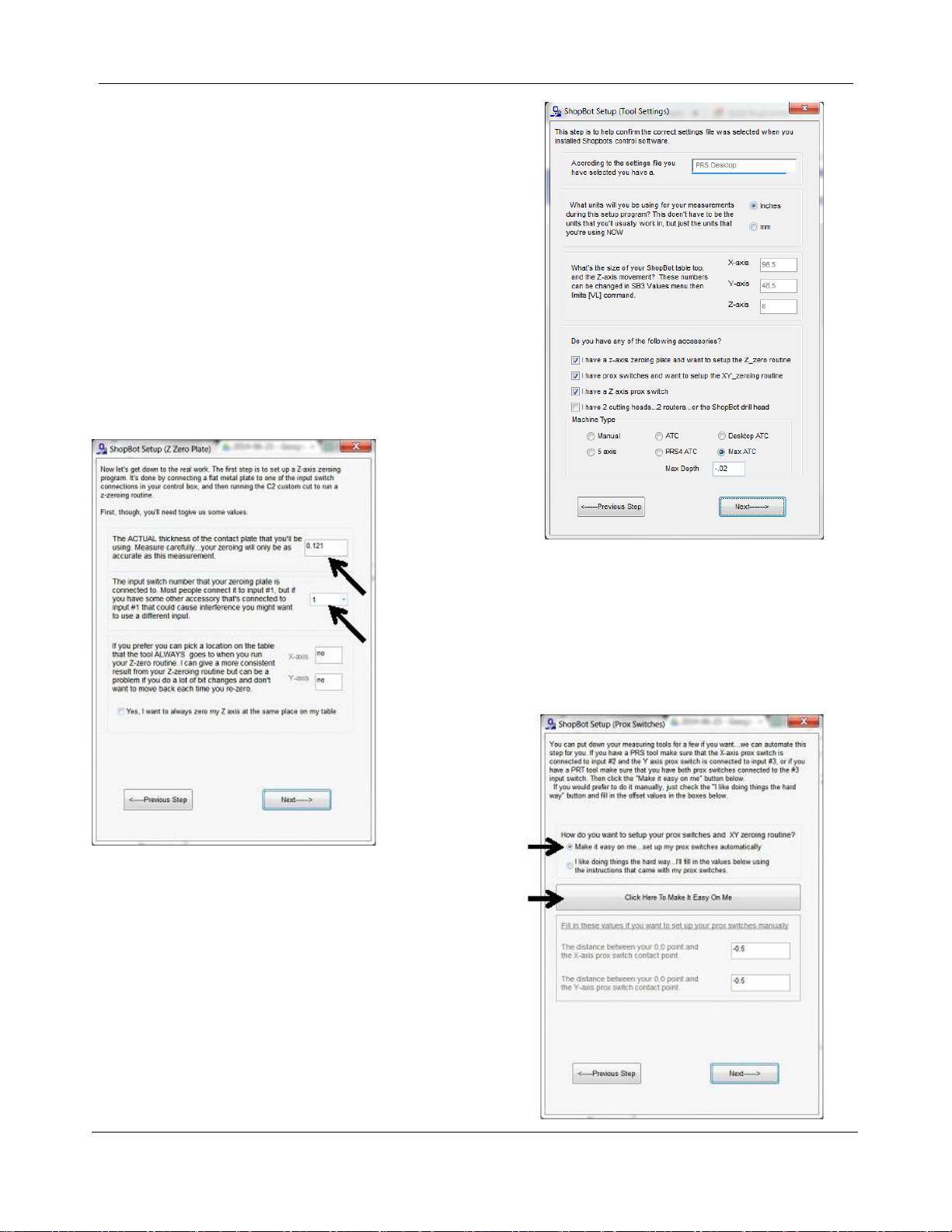

Go step-by-step through this window while verifying

information about the machine. Make sure that the check

boxes for the Z zero plate and proximity switches are checked at

the bottom of the window. Select the radio button marked

“MAX ATC”. Click “Next”.

In the “ShopBot Setup (Z Zero Plate)” screen, measure the

thickness of the plate and enter that value. Make sure the input

switch is set to “1”. DO NOT check the “Yes, I want to always zero

my Z axis at the same place on my table”. Click “Next”

.

At the “ShopBot Setup (Prox Switches)” screen, select

“Make it easy on me…” and click the “Click Here To Make It

Easy On Me” button to start the zeroing routine.

Desktop MAX Automatic Tool Changer (ATC) User Manual SBG00358

© Copyright May, 2022 ShopBot Tools, Inc.

page 7

The next screen is “X and Y axis zeroing setup”. Read this screen and click

“Run the prox switch setup routine”.

Follow the prompts from the pop-up screens. Select “Yes” to

open the keypad for any adjustment to the “0, 0” home

position, then click “OK”. The default home position is the

corner of the spoilboard near the machine’s natural “0,0”, but

you can set it wherever you want if you are using a specific

jig or fixture.

Move the machine to the zero point, and hit “ESC” to exit the keypad

mode.

Click “Yes” to zero out the X and Y axes and click “OK”.

Desktop MAX Automatic Tool Changer (ATC) User Manual SBG00358

© Copyright May, 2022 ShopBot Tools, Inc.

page 8

Read through the “ShopBot Setup (Finished)” window and click “I’m

done.”

Desktop MAX Automatic Tool Changer (ATC) User Manual SBG00358

© Copyright May, 2022 ShopBot Tools, Inc.

page 9

Software Inputs and Outputs Check

Ensure that all of the inputs and outputs are being recognized by the automatic tool changer (ATC) by

checking for each of the cases outlined in this section.

Inputs

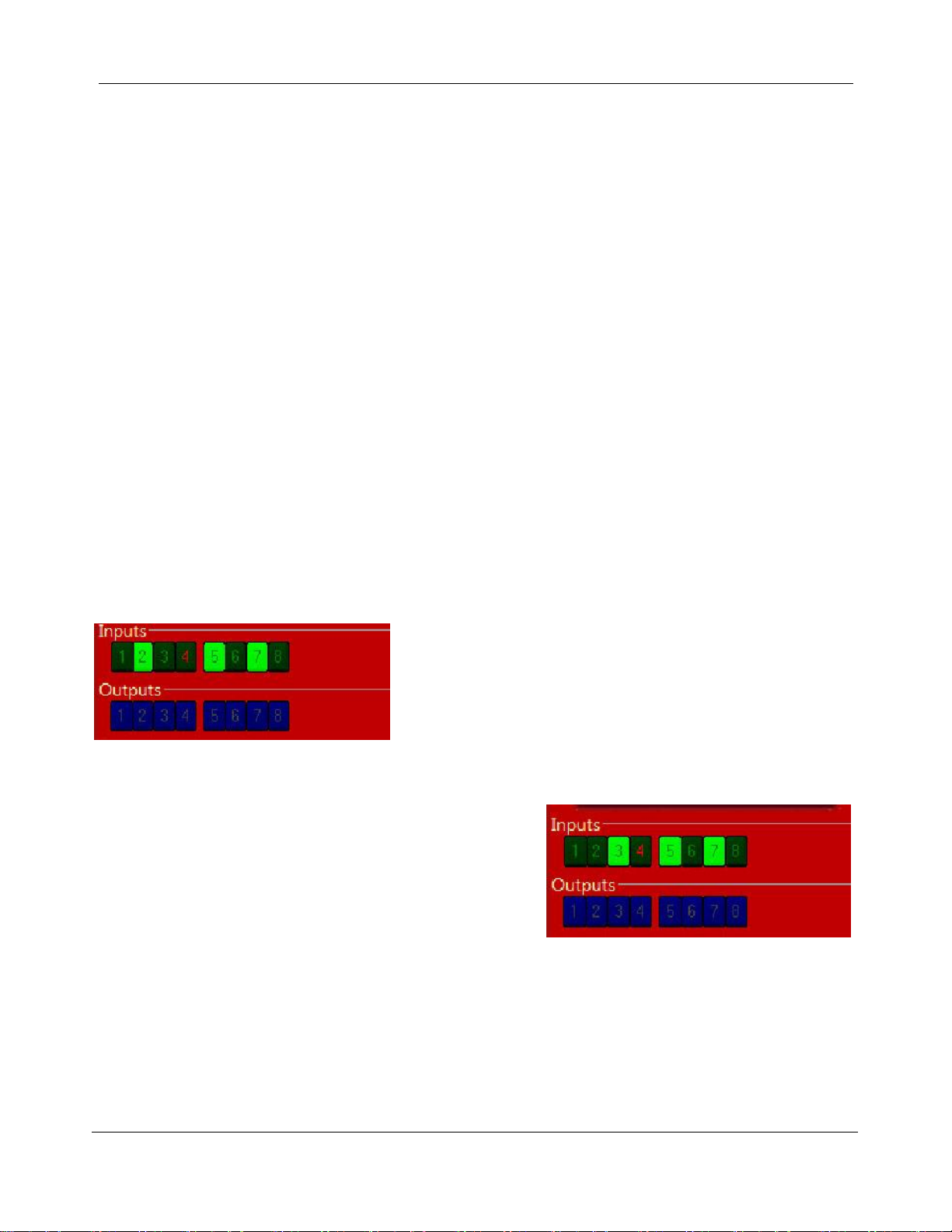

Inputs are signals that the software receives from devices that cause the tool to have a specific reaction.

Input 1 –The Z zero plate and the fixed Z zero are connected to this input. When either of these

plates are connected to a ground, the circuit is closed and input “1” on the ShopBot position screen

lights up. The tool’s fixed z-zero plate does not require a grounding clip, however use of the

standard z-zero plate does.

Input 2 –NA

Input 3 –The X, Y, and Z-axis proximity switches are connected to this input. During normal

operation, the input “3” light will be off in the ShopBot position screen. If one of the proximity

switches passes the proximity targets, the light will turn on. Among other things, this feature will be

used for homing the X, Y, and Z positions and for limiting the safe table cutting boundaries.

Input 4 –This input is connected to the stop switch. When inactive, the switch allows for use of the

tool and when active, the connection is severed and the tool comes to a stop.

Input 5 –NA

Input 6 –Tool bar in extended position, ready to make tool change. Lights when tool bar is fully

extended.

Input 7 –Tool in spindle. Lights when tool holder is properly inserted into spindle and clamped.

Input 8 –Drawbar open. Lights during tool change when draw bar is open and tool holder can be

inserted or removed.

Desktop MAX Automatic Tool Changer (ATC) User Manual SBG00358

© Copyright May, 2022 ShopBot Tools, Inc.

page 10

Outputs

Outputs are signals that ShopBot software is sending to cause a desired action. Unused outputs can be

programed to activate other peripherals using an optional relay board.

Output 1 –Runs the spindle.

Output 2 –NA

Output 3 –NA

Output 4 –Turns on during machine operation (safety flashing screen). Required for spindle “on” signal.

Output 5 –NA

Output 6 - NA

Output 7 –Toggles the toolbar forward and backward. When output 7 is triggered, the toolbar should be

extended and ready for a tool change.

Output 8 - Toggles the spindle drawbar open /close (releases tool holders from spindle).

Caution: When the spindle is not spinning it is possible to drop the tools from the spindle if Output 8

is activated.

Basic Function Check

Check that all systems involved are working properly, starting with the proximity switches.

In keypad mode (K) move the X-axis into the proximity target

using the left arrow on the keypad. The proximity switch will

have a red LED lit until it comes across the proximity target,

when it will turn off. Moving off the top of the target should cause

the LED to come back on. This should also be evident in the

ShopBot position screen when looking at input “2”, the light will

turn from black (normally closed) to green (open).

In keypad mode (K), move the Y-axis into the proximity target

using the down arrow on the keypad. The proximity switch will

have a red LED lit until it comes across the proximity target,

when it will turn off. Moving off of the target should cause the

LED to come back on. This should also be evident in the

ShopBot position screen when looking at input “3”.

In keypad mode (K), move the Z-axis into the proximity target using “Page Up” on the keypad. The proximity

switch will have a red LED lit until it comes across the proximity target, when it will turn off. Moving off the top

of the target should cause the LED to come back on. This should also be evident in the ShopBot position

screen when looking at input “3”.

Desktop MAX Automatic Tool Changer (ATC) User Manual SBG00358

© Copyright May, 2022 ShopBot Tools, Inc.

page 11

Additional function checks

Z Zero Plate

To check the Z zero plate, insert the plug end of the Z zero plate cable into the socket located on

the gantry.

Touch the Z zero plate grounding clip to the Z zero plate and make sure that input “1” lights up

green on the position screen.

Fixed Z Zero Plate

To check the fixed Z zero plate, simply press down firmly on the

plate. Input “1” should light up green on the position screen while the

plate is pressed. The light should go off again when the plate is

released.

Tool Draw Bar

Make sure your compressed air supply is on for the

following checks.

Press the green button on the back of the gantry. While the

button is depressed the internal draw bar will open, allowing

the spindle to accept tools. While the draw bar is open, a

rush of air will be heard, and input “8” will be lit.

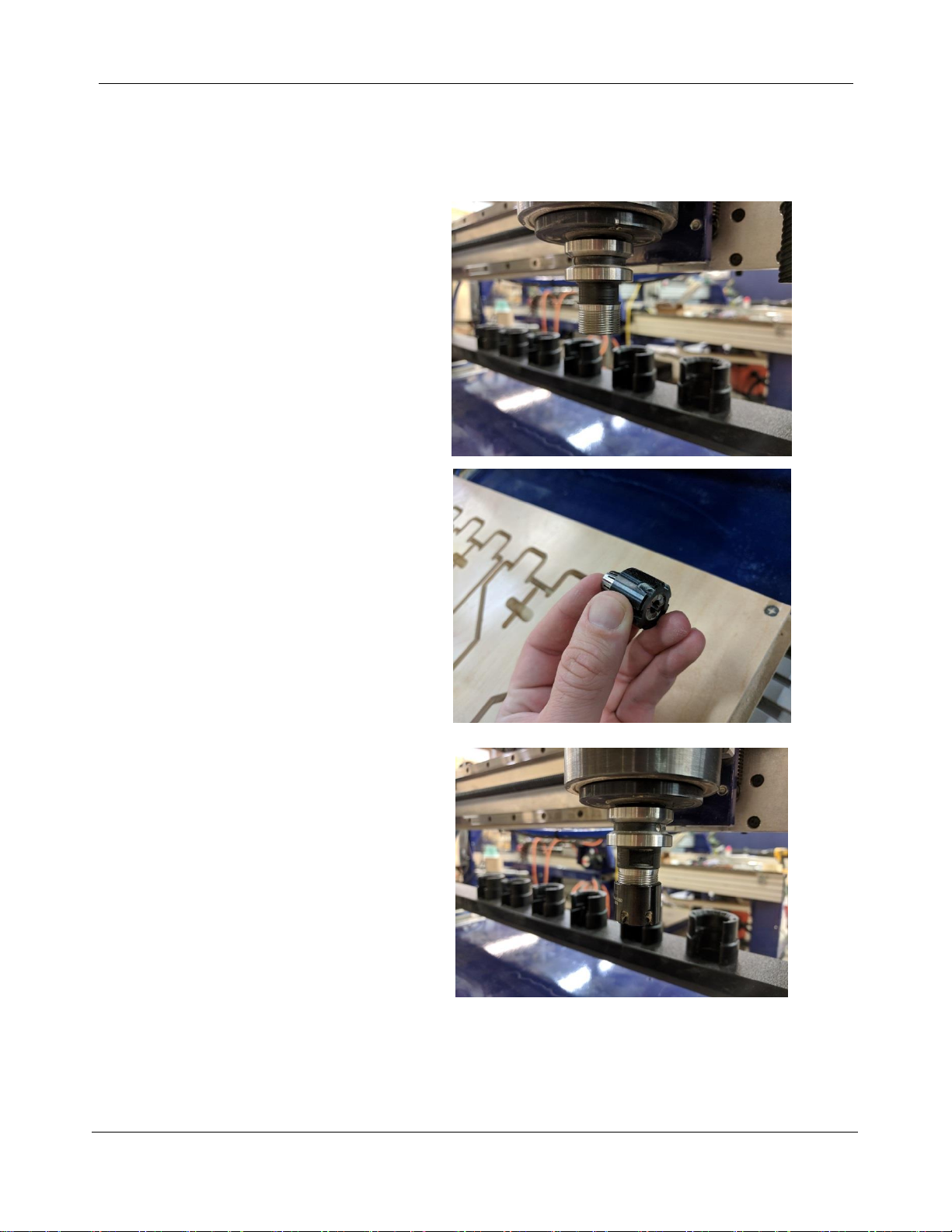

With the green button still

depressed, insert a tool holder into

the spindle and hold it there.

Release the green button. The

drawbar will close, capturing the

tool holder. Input “7” should light

up, and input “8” should turn off.

Desktop MAX Automatic Tool Changer (ATC) User Manual SBG00358

© Copyright May, 2022 ShopBot Tools, Inc.

page 12

Calibrating the ATC

Calibration Routine

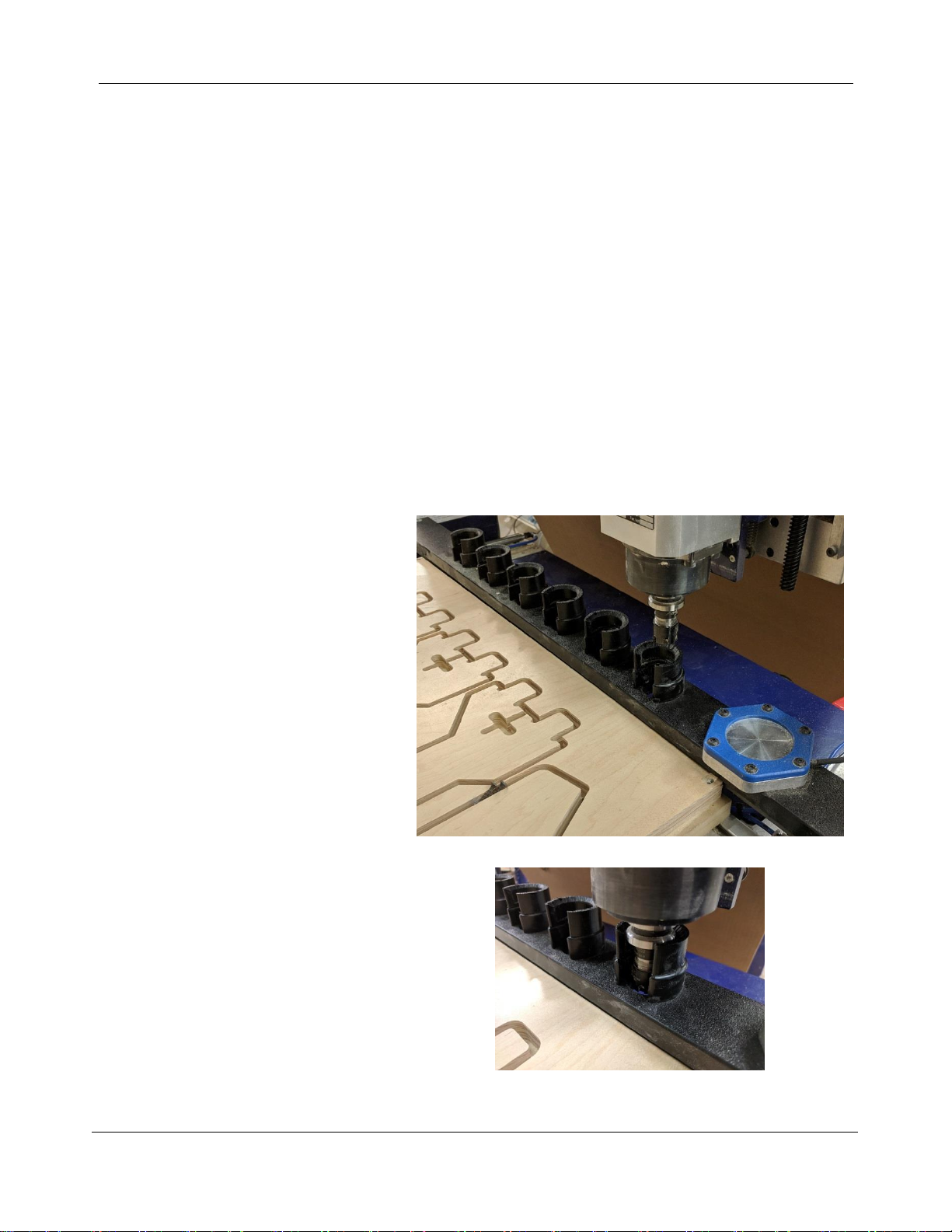

If this is your first time setting up the machine, or you are setting it up on a new computer, the ShopBot

software needs to know the location of the tool holders. To run this routine, insert an empty tool holder (no

collet or bit, but can have collet nut) into the spindle using the green button on the rear of the gantry.

In the Shopbot 3 software, click on the large “Cut Part” button. Navigate to the C:\SbParts

folder\Custom\ATC on your computer and select the file named “ATC_DT_Calibrate”.

The machine will first home the X, Y and Z axes. The tool should end up at the home location previously

set in the ShopBot Setup routine. Next you will be prompted to extend the toolbar, press OK on this

prompt and the “spindle start” prompt. Then there will be a prompt on the screen asking you to use

the keypad to move the machine to the location of tool number 1. This is the tool closest to the

fixed Z-zero plate on the tool bar. Press OK to this prompt.

Using the keypad, move the machine

towards the first tool holder location

Once you get it close to the tool clip, press

the “Fixed” button in the keypad. This will

only allow the machine to move a small

distance with each keypress. Move the

toolholder down into the toolclip very

carefully, making sure it is not touching

the sides.

Desktop MAX Automatic Tool Changer (ATC) User Manual SBG00358

© Copyright May, 2022 ShopBot Tools, Inc.

page 13

While doing this, periodically spin the tool

holder with your fingers. It should spin

freely and not drag on the sides of the

toolclip.

With the bit still centered in the holder, continue lowering it

until it is almost touching the bottom of the holder. Or,

lower it until it no longer spins easily and then raise it back

up slightly until it does. Once the tool holder is in the

proper spot, press the ESCAPE key to exit the keypad.

Then press OK to the prompt that comes up on the screen.

The tool should then move the Z up and travel over to the

general location of the last tool clip on the rack. You’ll once

again be prompted to lower the tool holder into the tool

clip. Make any necessary adjustments in X and Y position

and lower the tool holder into the clip. Once you’ve got the

tool holder in place, exit the manual control pad to save

this position.

You’ll then be prompted to set the Fixed Z-Zero Plate Location. If this is your first set-up of the tool, answer

“yes” to this prompt to initiate the location routine. The following section of this manual will provide

instructions for running the z zero plate location routine; if you’re continuing on from the calibration routine,

the z zero plate location routine will start automatically. If you do not want to set up the fixed z zero plate

location at this time or need to adjust the location later, you can follow the steps in the following section to

run the routine without first calibrating the tool bar.

Make sure to remove the tool holder when this routine is done.

Desktop MAX Automatic Tool Changer (ATC) User Manual SBG00358

© Copyright May, 2022 ShopBot Tools, Inc.

page 14

Set Fixed Z-Zero Plate Location

If you haven’t already, run the homing routine (C3) to be sure everything is zeroed.

If routine does not start automatically after calibration load the file “ATC_FixZ_Plate.sbp” located in

“C:\SbParts\Custom\ATC\ ATC_FixZ_Plate.sbp”. This file will set the location of the fixed Z zero plate to set

a base zero height of the bits. This should only need to be run once during the setup procedures.

Click “OK” when the following prompt appears.

Use the keypad to move the spindle over the center of the fixed Z zero plate, as shown in the picture below.

Once satisfied with the positioning of the spindle, hit “ESC”. This will set the fixed Z zero plate location in the

X and Y. You do not need a tool holder inserted in the spindle to run this routine, although it may make it

easier to align the spindle with the Z-zero plate

Once the program is finished, press “ALT”+”7” again to retract the tool bar.

Desktop MAX Automatic Tool Changer (ATC) User Manual SBG00358

© Copyright May, 2022 ShopBot Tools, Inc.

page 15

Setup Tool Holders

Locate the tool holders, collet, collet nuts (shipped on the tool holders), and desired bits. Make sure that the

collets are sized for the shank diameters of the bits that will be installed.

Remove the collet nut from a tool holder

and insert it into the spindle using the

green button on the back of the gantry.

Select the appropriate sized collet

for the bit you want to use, then

press it into the collet nut until it

snaps into place. It is VERY

IMPORTANT that the collet is

inserted into the collet nut before it

is installed in the tool holder. Failure

to install the collet into the nut may

cause damage to the tool holder.

Thread the collet nut onto the tool

holder that is in the spindle.

Desktop MAX Automatic Tool Changer (ATC) User Manual SBG00358

© Copyright May, 2022 ShopBot Tools, Inc.

page 16

Insert the desired bit into the collet.

Tighten the collet nut to 42 ft/lbs with

the ER16 spanner wrench and 17mm

shaft wrench. Do not over-tighten.

Remove tool holder from spindle

using the green button and place it

into the tool clip that you would like

that bit assigned to. Repeat this

process for the other tool holders

and place them in the tool bar as

well. Do NOT leave a tool holder in

the spindle at this time.

Desktop MAX Automatic Tool Changer (ATC) User Manual SBG00358

© Copyright May, 2022 ShopBot Tools, Inc.

page 17

Change Tools (C1)

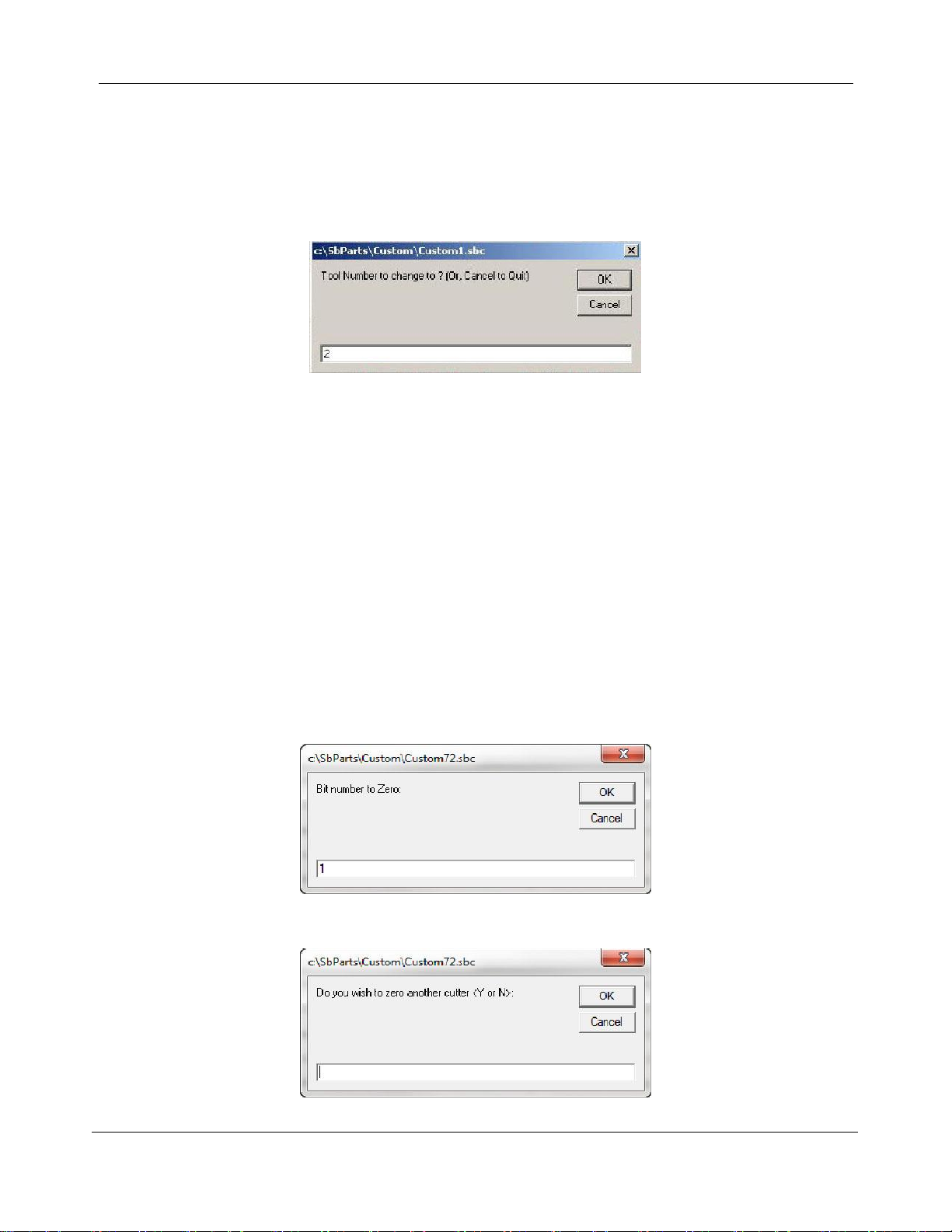

Insert bit into conical tool holder and place it in the desired tool holder location. Type C1 to run the custom

number 1 “Change Tools” routine. A screen will ask which tool should be selected. Once that tool is entered,

click “OK” and the ATC will drop off the current tool being held and select the desired tool. If there is currently

a tool in the spindle be sure that there is an empty tool clip in the correct location to receive it.

To check what tool the software thinks is in the spindle head, open

“C:\Sbparts\Custom\ATC_Local_Data\ATC_tool_variables.sbc”.

Look at line #3, &ToolIn= (Current tool) will show the tool last changed to.

Zero Tools in Rack (CN72) (Daily Operation)

This step will zero each tool in the rack to ensure that bits of different lengths will all cut to the same depth. It

is good practice to run this full routine (for all bits) at the beginning of each work period. If a new bit is added

to the rack (or an existing bit is replaced), use this routine to calibrate it to the other bits in the rack.

Ensure that there is no tool holder in the spindle. Run the homing routine (C3). A screen will open confirming

that tool #0 (empty spindle) is correct. Press “OK” to dismiss this prompt after confirming the spindle is

empty.

Type “CN72” (custom number 72), to run the ATC zero tools in rack file.

Enter the number of the bit to measure and then click “OK”. The tool will move to the fixed z-zero plate and

plunge until it makes contact with the plate)

If more bits need to be zeroed, answer “YES”. If not, then type “N”. Click “OK” to continue.

Desktop MAX Automatic Tool Changer (ATC) User Manual SBG00358

© Copyright May, 2022 ShopBot Tools, Inc.

page 18

Get Plate Offset (CN73)

This routine will establish where the C3 (XYZ zero) routine will set the Z zero level. Normally this is at the

table bed. This routine needs to be run whenever the location of the table bed has changed, such as after re-

surfacing the spoilboard. If a tool is not loaded in the spindle, select one before running this routine. Any tool

can be used as they have all been zeroed to the fixed plate. Type “CN73” (custom number 73) in the

ShopBot control software to run the ATC get plate offset file.

Use the keypad to move to the location where the Z level is located. If zeroing

to a specific fixture, move the tool over it. Close the keypad when the tool is at

the desired position.

Place the grounding clip on the collet or bit and place the regular Z zero plate below the bit (this routine does

not use the fixed Z zero plate). Click “OK”, and the routine will touch off the zero plate and save the offset

from the fixed Z zero plate. When the plate is removed, the tool will confirm the proximity switch locations

and new Z zero level.

Every time the C3 routine is run the tool will be zeroed at this stored level.

NOTE: Pay attention to where Z zero is set in the CAM file to avoid damaging the table surface or

cutting the wrong depth.

Desktop MAX Automatic Tool Changer (ATC) User Manual SBG00358

© Copyright May, 2022 ShopBot Tools, Inc.

page 19

Zero to Various Z Heights (C2) (Daily Operation)

ATC users will only have to zero one bit to their material or bed height each time the Z zero position is

changed. The remaining bits in the tool rack will also reference the new position.

Once all of the bits have been zeroed to the fixed Z zero plate, any bit can be used to zero to the surface

using the regular Z zero plate.

When the bit is located over the area needed to set as zero,

type “C2” (“Zero Z-Axis w/ Z zero Plate”).

Place the Z zero plate under the bit and place the grounding

clip on it. Click “OK” when both are in place. The Z-axis will

touch off the plate twice, and record this distance for use on

all the tools until this Z offset is reset.

This records a Z offset height within the ShopBot user

variables and applies this to all the other tools in the tool

rack.

Note that the Z offset is reset to the Z home position any time the C3 routine is run. To permanently change

the Z home position, refer to the Get plate offset (CN73) section of this document.

Regularly Used ATC Files

C1

Change tool

C2

Zero Z-axis using Z-zero plate

C3

Home X, Y, and Z-axes using proximity switches

C5

Spindle warmup routine

C6

Turn spindle on

C7

Turn spindle off

C9

Automatic tool change called within a part file

CN72

Zero tools in rack

CN73

Get plate offset (set Z-axis home position)

Desktop MAX Automatic Tool Changer (ATC) User Manual SBG00358

© Copyright May, 2022 ShopBot Tools, Inc.

page 20

Create a Tool Change File

The design software must first have the information to enable the ATC to do a tool change. For the software

to work correctly, the tooling must be designated to specify particular tool holders.

When setting up a tool database inside the design software, create a group named “Tool Changer” or “ATC”.

This will allow separation of tools that are setup specifically for the tool changer.

Within the group, create new tools that will be used with the ATC. The tools created need to have the same

tool number in the characteristics of the tool as the location of that tool holder on the ATC. This tool number

within the design software is what dictates what tool is selected during the tool changing process.

Create a drawing within the design software and toolpath it using the tools under the tool changer group that

you have created. When all toolpaths are created, set the order of the tool paths under the Toolpath List.

Select the save icon (disk) under “Toolpath Operations”. Make sure that the proper post processor is

selected. In VCarve Pro it will read:

ShopBot TC (Inch)(*.sbp) or ShopBot TC (MM)(*.sbp).

In Aspire it will be:

ShopBot(inch)(Toolchange)w/speed(*.sbp) or ShopBot(mm)(Toolchange)w/speed(*.sbp).

NOTE: Pay attention to where Z zero is set in the CAM file to avoid damaging the table surface or

cutting the wrong depth.

Table of contents