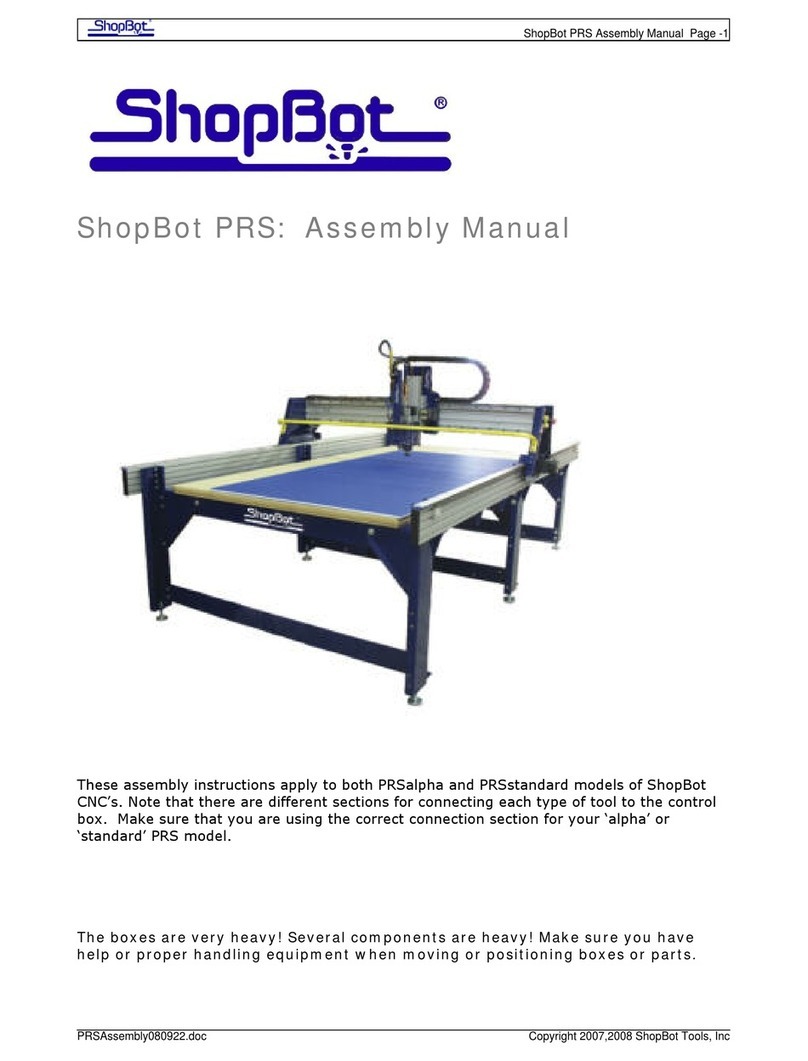

ShopBot PRSalpha User manual

© Copyright 2016 ShopBot Tools, Inc. page 1

ShopBotTools.com888-680-4466 •

Assembly Guide

For PRSalpha and PRSstandard Tools

Assembly Guide for PRS Alpha and Standard Tools • May 2, 2016

© Copyright 2016 ShopBot Tools, Inc. page 2

Assembly Guide for PRS Alpha and Standard Tools • May 2, 2016

© Copyright 2016 ShopBot Tools, Inc. page 3

Table of Contents

General Safety and Precautions..............................................................................................................7

PRS Quick-Start Process Flow ...............................................................................................................8

Main Parts of PRSalpha ..........................................................................................................................9

Section 1. Setup and Assembly Overview .......................................................................................... 1-1

Electrical Precautions ................................................................................................................. 1-1

Safety.......................................................................................................................................... 1-1

Unpacking the Crate................................................................................................................... 1-2

Terms to Know............................................................................................................................ 1-3

Major Components..................................................................................................................... 1-3

Section 2. Table Assembly .................................................................................................................. 2-1

Introduction ................................................................................................................................ 2-1

Hardware .................................................................................................................................... 2-2

Marking the Rails........................................................................................................................ 2-3

Mount Table Levelers to Legs..................................................................................................... 2-4

Install Table Legs ........................................................................................................................ 2-4

Table Sides for 12” and 24” Z-Axis Congurations.................................................................... 2-6

Stabilize with Lower Table Supports .......................................................................................... 2-7

Connect Side Assemblies .......................................................................................................... 2-7

Install Middle Lower Cross Support ........................................................................................... 2-8

Insert T-Nuts in Bottom Slot ....................................................................................................... 2-8

Mount Table Supports and Gussets to Table Legs .................................................................... 2-9

Mount Table Supports and Cross Supports to Rails................................................................ 2-11

Install Cross Supports .............................................................................................................. 2-11

Level and Square the Table ...................................................................................................... 2-12

Level the Front Table Side ........................................................................................................ 2-12

Level the Rear Table Side ......................................................................................................... 2-13

Square the Rear Table Side ...................................................................................................... 2-14

Install the Rails ......................................................................................................................... 2-15

Adjust the Front Rails ............................................................................................................... 2-16

Section 3. Gantry Installation .............................................................................................................. 3-1

Introduction ................................................................................................................................ 3-1

Hardware .................................................................................................................................... 3-2

Install Gantry............................................................................................................................... 3-3

Adjust the Rails........................................................................................................................... 3-3

Fine Tune the Rail Level.............................................................................................................. 3-4

Install the YZ Car ........................................................................................................................ 3-4

Test and Adjust Wheel Tension................................................................................................... 3-5

Mount the X-Axis Stop Blocks and Proximity Targets................................................................ 3-6

Adjust the Y-Axis Stop Blocks and Sensor Targets.................................................................... 3-7

Section 4. Cable Carrier Installation.................................................................................................... 4-1

Introduction ................................................................................................................................ 4-1

Hardware .................................................................................................................................... 4-2

Prepare the Cable Carriers ......................................................................................................... 4-3

Reversing the End Links............................................................................................................. 4-3

Assembly Guide for PRS Alpha and Standard Tools • May 2, 2016

© Copyright 2016 ShopBot Tools, Inc. page 4

Table of Contents (cont’d)

Y-Axis Cable Carrier ................................................................................................................... 4-4

Mount the Lower Y Bracket........................................................................................................ 4-4

Install Upper Y-Chain Bracket .................................................................................................... 4-5

Mount Cable Carrier to Lower Y Bracket ................................................................................... 4-5

Mount Cable Carrier to Upper Y Bracket ................................................................................... 4-5

X-Axis Cable Carrier ................................................................................................................... 4-6

Install Trough Brackets for ShopBots with 6” Z’s....................................................................... 4-6

Install the X-Axis Trough: 6” Z-Axis ............................................................................................ 4-7

Machines with 12” and 24” Z-Axis ............................................................................................. 4-7

Install the Upper X Cable Carrier Bracket .................................................................................. 4-8

Cable Carrier to Upper X Bracket............................................................................................... 4-8

Cable Carrier to Lower X Bracket............................................................................................... 4-9

Test Cable Carrier Mobility on Both Axes................................................................................... 4-9

X-Axis Cable Carrier Congurations......................................................................................... 4-10

Section 5. Control Box Installation...................................................................................................... 5-1

Introduction ................................................................................................................................ 5-1

Hardware .................................................................................................................................... 5-2

Installation .................................................................................................................................. 5-4

Alternate Mounting for 12” and 24” Z-Axis Models ................................................................... 5-5

Section 6. VFD Installation and Spindle .............................................................................................. 6-1

Introduction ................................................................................................................................ 6-1

VFD Installation........................................................................................................................... 6-1

Hardware .................................................................................................................................... 6-2

Determining the VFD Model ....................................................................................................... 6-2

Voltage Amperage ...................................................................................................................... 6-3

Mounting the 10” VFD ................................................................................................................ 6-3

Mounting the 16” VFD ................................................................................................................ 6-4

Spindle Installation ..................................................................................................................... 6-5

Hardware .................................................................................................................................... 6-5

Lower the Z-Axis Extrusion ........................................................................................................ 6-6

Spindle Mounting Plate .............................................................................................................. 6-6

Attach Spindle ............................................................................................................................ 6-7

Replace Stop Screw................................................................................................................... 6-7

Section 6 Appendix: Table Leg Drawings................................................................................... 6-8

6” Table Leg....................................................................................................................... 6-8

12” Table Leg..................................................................................................................... 6-9

Section 7. Mounting X- and Y-Axis Motors ......................................................................................... 7-1

Introduction ................................................................................................................................ 7-1

Hardware .................................................................................................................................... 7-2

Motors ........................................................................................................................................ 7-2

Mount Pinions to Motors ............................................................................................................ 7-2

Identify Motors............................................................................................................................ 7-3

Check Alignment of Pinions with Rack ...................................................................................... 7-3

Check Pinion/Rack Alignment.................................................................................................... 7-3

Adjust Pinions (If Required) ........................................................................................................ 7-3

Mounting Locations.................................................................................................................... 7-4

Assembly Guide for PRS Alpha and Standard Tools • May 2, 2016

© Copyright 2016 ShopBot Tools, Inc. page 5

Table of Contents (cont’d)

Position Motors on Tool.............................................................................................................. 7-4

Section 8. Wire and Cable Routing ..................................................................................................... 8-1

Hardware .................................................................................................................................... 8-1

Cable Routing Strategy .............................................................................................................. 8-1

Spindle Power Cable ............................................................................................................ 8-1

Motors and Signal Cables .................................................................................................... 8-1

Spindle Fan Cable Installation.................................................................................................... 8-2

Proximity Switch Installation ...................................................................................................... 8-2

Y Proximity Switch ..................................................................................................................... 8-2

Z Zero Plate Assembly ............................................................................................................... 8-3

Route Wiring............................................................................................................................... 8-4

Mount Auxiliary Emergency Stop Switch ................................................................................... 8-4

Route Wiring (cont’d).................................................................................................................. 8-5

X Proximity Switch...................................................................................................................... 8-5

Route Wiring (cont’d).................................................................................................................. 8-6

Pneumatic Air Hoses .................................................................................................................. 8-6

Route Spindle Cable................................................................................................................... 8-7

Cable Checklist .......................................................................................................................... 8-7

Y Cable Carrier ..................................................................................................................... 8-7

Through Center of Gantry Beam .......................................................................................... 8-7

X Cable Carrier ..................................................................................................................... 8-7

Section 9. Control Box Installation...................................................................................................... 9-1

Introduction ................................................................................................................................ 9-1

Section 10. Software Installation....................................................................................................... 10-1

Introduction .............................................................................................................................. 10-1

Hardware .................................................................................................................................. 10-1

Computer Recommendations .................................................................................................. 10-2

Computer Conguration........................................................................................................... 10-2

Install ShopBot 3 Control Software and VCarve Pro Software ................................................ 10-2

Software Overview ................................................................................................................... 10-2

Engage Pinions with Rack........................................................................................................ 10-3

Connect ShopBot to Computer................................................................................................ 10-3

USB Communication Cable................................................................................................ 10-3

Load the Settings File............................................................................................................... 10-4

Install Control Box Firmware .................................................................................................... 10-4

ShopBot Control Software Familiarization ............................................................................... 10-6

Easy and Full Modes .......................................................................................................... 10-6

Full Display Overview ......................................................................................................... 10-6

ShopBot Command Format ............................................................................................... 10-7

Movement Testing .................................................................................................................... 10-7

X Proximity Switch.................................................................................................................... 10-7

Set Stop Block Positions.......................................................................................................... 10-8

Check Y-Axis Proximity Switches............................................................................................. 10-8

Mount Z Zero Plate Assembly .................................................................................................. 10-8

Assembly Guide for PRS Alpha and Standard Tools • May 2, 2016

© Copyright 2016 ShopBot Tools, Inc. page 6

Table of Contents (cont’d)

Secure Cables .......................................................................................................................... 10-9

Section 11. Secure Table and Spoil Board........................................................................................ 11-1

Introduction .............................................................................................................................. 11-1

Hardware .................................................................................................................................. 11-1

Base Layer................................................................................................................................ 11-1

Spoilboard ................................................................................................................................ 11-2

Section 12. Setup and Fine Tuning ................................................................................................... 12-1

Check Inputs and Outputs ....................................................................................................... 12-1

Machine Orientation ................................................................................................................. 12-2

Optional Axes ........................................................................................................................... 12-2

Setting Up RPM Control........................................................................................................... 12-3

System Check .......................................................................................................................... 12-4

Check Movement ............................................................................................................... 12-4

Check Stops and Targets ................................................................................................... 12-4

Check Limit Switches ......................................................................................................... 12-4

Check Movement Distance ................................................................................................ 12-5

Test X-Axis Distance........................................................................................................... 12-5

Test Y-Axis Distance ........................................................................................................... 12-5

Test Z Zero Function........................................................................................................... 12-5

Proximity Switch Targets .................................................................................................... 12-5

ShopBot Setup ......................................................................................................................... 12-6

Z Zero Plate ........................................................................................................................ 12-6

XY Zeroing Point................................................................................................................. 12-6

Fine Tune Setup........................................................................................................................ 12-7

Square the Spindle ............................................................................................................. 12-7

Secure Mounting Screws.................................................................................................... 12-7

Test Movement Distance .................................................................................................... 12-7

Install Push Bars....................................................................................................................... 12-7

Install Dust Foot........................................................................................................................ 12-7

Install End Caps........................................................................................................................ 12-7

Resources ......................................................................................................................................... 12-7

Assembly Guide for PRS Alpha and Standard Tools • May 2, 2016

© Copyright 2016 ShopBot Tools, Inc. page 7

General Safety and Precautions

This safety summary contains general safety warnings that should be understood during operation of

this machine. Failure to observe these precautions could result in injury.

Learn and understand safe use of the machine. Do not allow untrained individuals

to operate the machine without supervision. Be aware of the location of the Emer-

gency Stop switches at all times.

Eye and ear protection MUST be worn by the machine operator as well as any

bystanders or observers. Flying sawdust, material chips, and other debris can

cause serious eye injury.

Wear closed-toe shoes at all times.

Make sure that your material is properly secured before cutting, and be aware of

any small parts that may come loose after being cut. If a small part catches the

edge of a spinning bit, it can be thrown forcefully in any direction, causing injury

or damage.

Never place your hands on the rails of the ShopBot. Be aware that the machine

may move unexpectedly in any direction, which can cause serious injury if your

hands are in the path of movement.

Never wear gloves while operating the machine. As with any power tool, a glove

can get caught in moving or spinning parts and pull your hand into the machinery.

Never leave a machine running and unattended. Understand that a spinning tool

generates friction and heat, creating a risk of re. This risk is minimized by using

correct chip load, using sharp bits, and by always double-checking your les

before cutting. Be prepared to pause or stop the cut if something seems incorrect

or unsafe.

Keep a working re extinguisher within reach of the machine, for the reasons

listed above.

Assembly Guide for PRS Alpha and Standard Tools • May 2, 2016

© Copyright 2016 ShopBot Tools, Inc. page 8

PRS Tool Assembly Process Flow

Setup and Assembly

Overview (Section 1)

Table Assembly

(Section 2)

Gantry Installation

(Section 3)

Cable Carrier

Installation (Section 4)

Control Box Installation

(Section 5)

VFD and Spindle

Installation (Section 6)

Mounting X-and Y-Axis

Motors (Section 7)

Wire and Cable

Routing (Section 8)

Control Box

Installation (Section 9)

Software Installation

(Section 10)

Secure Table and Spoil

Board (Section 11)

Setup and Fine

Tuning(Section 12)

Assembly Guide for PRS Alpha and Standard Tools • May 2, 2016

© Copyright 2016 ShopBot Tools, Inc. page 9

Main Parts of PRSalpha

Assembly Guide for PRS Alpha and Standard Tools • May 2, 2016

© Copyright 2016 ShopBot Tools, Inc. page 10

Section 1: Setup and Assembly Overview • May 2, 2016

© Copyright 2016 ShopBot Tools, Inc. page 1-1

Section 1. Setup and Assembly Overview

Electrical Precautions

Schedule the services of a licensed electrician to complete the ShopBot setup. Connecting power to

the control box can be done before or after assembly of the machine, but it is easiest to wait until the

tool is set up in its nal position. If machine includes a high frequency spindle and/or a vacuum blower,

these will also need to be connected by an electrician. Wiring diagrams and specications are located

inside the door of the control box.

Other Electrical precautions:

Motor connections: DO NOT connect or disconnect motor cables while power to the control box is

on. This can damage or destroy the motors or drivers.

Induced currents: AVOID moving any axis by hand when the control box is powered off. If you must

push/pull an axis by hand, do so very slowly. Spinning the motors can generate an electric charge and

damage the drivers or other electronic components.

Static Discharges: Follow all wiring and grounding instructions - electronic circuits are very sensitive

to static and power surges. Avoid doing any vacuuming around your machine before it is properly

grounded, as vacuums can generate a large amount of static electricity that can damage the control

box.

Safety

WARNING: RISK OF ELECTRIC SHOCK

The control box needs to be connected to electrical service by a licensed electri-

cian who has experience with industrial equipment. Personal injury or damage to

the machine may occur if an unlicensed individual performs this job.

Use caution when lifting boxes and assem-

bled components out of the crate. Having an

assistant will make things much easier – partic-

ularly when unpacking the crate and lifting the

gantry onto the table rails. Do not attempt to lift

the gantry without assistance.

Section 1: Setup and Assembly Overview • May 2, 2016

© Copyright 2016 ShopBot Tools, Inc. page 1-2

Unpacking the Crate

The ShopBot components arrive in two packages: a large wooden crate and a long box. The crate and

box leave ShopBot banded together. Contact the shipping company if a piece is missing, or if they do

not arrive together.

The components are packaged to avoid shifting during shipping. Use a large screwdriver to pry off the

clips on top on the crate, and a Phillips head screwdriver to uncrate the components. It will require two

people to lift out some of the heavier pieces.

Take a few moments to read through the assembly directions, and sort the components by their

function to help organize the assembly process. Sort hardware by size to reduce the amount of time

searching for the correct bolts, nuts and washers for a given stage of the assembly.

Many components of the machine come pre-assembled to reduce the number of assembly steps. In

many places, bolts or hardware may be loosely t in place to show their intended location. Remove

this hardware prior to tting the applicable component into place.

Section 1: Setup and Assembly Overview • May 2, 2016

© Copyright 2016 ShopBot Tools, Inc. page 1-3

Terms to Know

This is only a quick overview to get started. For each assembly section, there will be a visual guide

with all parts and hardware clearly labeled.

Major Components:

The base of the machine is referred to as the table

frame.

The two long aluminum extrusions on each side

are called table sides. Atop the sides are the rails,

which create the path of travel for the X-axis.

The table sides and rails are included in the long

cardboard package secured to the top of the crate.

The assembly that rides along the table sides is

called the gantry.

The gantry consists of an extruded aluminum

beam, which has been tted with V rails (for wheel

bearings) and gear rack. This forms the path of

travel for the Y-axis.

The blue plates on either side of the gantry are

referred to as end plates.

The YZ car moves across the gantry, and controls

the height of the cutter head (either a router or

high-speed spindle, depending on the tool).

Section 1: Setup and Assembly Overview • May 2, 2016

© Copyright 2016 ShopBot Tools, Inc. page 1-4

The control box is the “brain” of the machine and contains a control board, motor drivers, and other

electronic components that allow the tool to move with precision, accuracy, and power. It connects to

the PC through a single USB cable.

The variable frequency device (VFD) is used on machines that contain a spindle only (not a router).

It controls speed and power for the spindle. The control box provides the VFD with on/off signals, but

speed is controlled through an RPM controller unit, which connects to the PC through a separate USB

cable.

In most cases, the X-, Y-, and Z-axes will be referred to in respect to the machine. Another frequent-

ly-used term is the XY home position, as indicated here.

Section 2: Table Assembly • May 2, 2016

© Copyright 2016 ShopBot Tools, Inc. page 2-1

Section 2. Table Assembly

Introduction

The ShopBot table provides a rm foundation for all other components. This section contains instruc-

tions to assemble, square, and level the table.

The diagrams in this manual depict a 96” x 48” table, the most common ShopBot table size. The table

layout may look a little different (fewer or more legs, tool changer bar, etc.) depending on the size,

shape, and accessories, but the same basic steps will be followed. The table drawings provided will

detail the specic measurements.

Note: It is critical to follow the table drawing carefully to ensure correct assembly of the table and

accessories.

The table leveling and squaring steps should be completed with the table is in its nal location. Moving

the table after these steps may alter the level and square.

Note: This section shows a conventional table with a 6” Z-axis. Tables congured for 12” and 24” axes

have extra table side extrusions and table legs with added mounting holes.

Section 2: Table Assembly • May 2, 2016

© Copyright 2016 ShopBot Tools, Inc. page 2-2

Hardware

Part Name Quantity ShopBot P/N Notes

Table side 2 000925

Rail 2 001872

Lower table support 3 000921 Different for other lengths

Table gusset 6 000770 Different for other lengths

Upper table support 4 000915 Different for other lengths

Table leg 6 000919 Different for other lengths

Table cross support 48E 2 000926 Different for other lengths

Except for the table levelers, all of this hardware is included in the small box marked “table hard-

ware”:

Part Name Quantity ShopBot P/N Notes

1/2-13x1 1/2 Hex bolt Varies 001956 Used for components to leg

1/2" Lock washer Varies 000588 Used for components to leg

1/2" Flat washer Varies 000029 Used for components to leg

1/2-13 Hex nut Varies 000440 Used for components to leg

5/16-18x3/4 Hex bolt Varies 000529 Used for cross supports, leg

5/16” Schnorr washer Varies 004487 Used for cross supports, leg

5/16” Flat washer Varies 000848 Cross supports, leg, control box

5/16-18 T-nut Varies 002498 Used for control box

5/16-18x3/4 Button head

cap screw Varies 002033 Used for control box

5/16-18x3/8 T-nut Varies 001569 Used for cross supports, leg

Section 2: Table Assembly • May 2, 2016

© Copyright 2016 ShopBot Tools, Inc. page 2-3

Part Name Quantity ShopBot P/N Notes

5/8-11 Hex nut Varies 000160 1 per table leg

Table leveller w/Nut Varies 002926/000862 1 per table leg

3/8-16x1 1/2 Carriage bolt Varies 000953 Used to secure base board

3/8” Lock washer Varies 000092 Used to secure base board

3/8” Flat washer Varies 000444 Used to secure base board

3/8-16 Hex nut Varies 000452 Used to secure base board

* Specic quantities can be found on the packing list enclosed with the hardware.

Marking the rails

Remove table sides from packaging and lay them on

the oor side by side. Locate where the Home Posi-

tion (X =0) will be.

Locate the machine specic table drawing at the back of this assembly manual. This drawing provides

dimensions for the placement of the table legs and cross supports in relation to the end of the side

rails.

Note for international customers: The location of the table legs and cross supports along the X-rails

can be adjusted slightly to reect metric units.

Section 2: Table Assembly • May 2, 2016

© Copyright 2016 ShopBot Tools, Inc. page 2-4

Measuring from the X=0 location, use

a permanent marker to mark the inside

of the rails where each table leg and

cross support will attach to allow for

easy orientation.

Note: This image indicates the rail

marking locations for a 96” long tool.

The marks will differ for other table

congurations.

Move rails into approximate location,

orientation, and space that the tool

will occupy.

Mount Table Levelers to Legs

Screw a leg leveler into the bottom of each table leg, to its approximate half-

way point. Thread a 5/8” hex nut onto the leg leveler. Leave this nut loose

until the table is leveled.

Thread the middle leg levelers all the way up to ensure that the feet do not

interfere during the leveling procedure.

Install Table Legs

Insert eight T-nuts per table leg into the T-slots in the

pattern shown. The T-nuts slide in with the rough side

down. Note the line marked for alignment. Do not forget

to insert the T-nuts for the middle legs in the T-slots prior

to assembling the end legs.

Section 2: Table Assembly • May 2, 2016

© Copyright 2016 ShopBot Tools, Inc. page 2-5

When the T-nuts are in place, position the table legs.

Support the legs so they stay ush during installation.

Secure the legs with 5/16” hex bolts, Schnorr washers,

and at washers.

Note: The Schnorr washers are to be located with

curve towards the bolt head. They can make threading

the bolts into the T-nuts difcult. If necessary, use a

zip tie or other shim behind the T-nut to force it clos-

er to the surface of the slot so it is easier to catch the

threads with the bolt assembly.

Hold a framing square against the leg and the table side

while bolts are tightened to ensure leg is installed at a 90

degree angle. Hand-tighten the top and bottom bolts

when the leg is square. Do not tighten other bolts at this

time.

Section 2: Table Assembly • May 2, 2016

© Copyright 2016 ShopBot Tools, Inc. page 2-6

Install and square the remainder of the legs,

working from one side of the rail to the other.

Table Sides for 12” and 24” Z-Axis Configurations

Tables congured for 12” and 24” axes have

extra table side extrusions and table legs with

added mounting holes.

Assembly of these table congurations is

identical with the exception of these unique

parts and extra mounting hardware.

The table supports and gussets will go under

the bottom table side extrusion, and the rails

will mount to the top extrusion.

To turn the spindle off, click the output 1

switch again or close the keypad window.

Other manuals for PRSalpha

3

This manual suits for next models

1

Table of contents

Other ShopBot Control System manuals

Popular Control System manuals by other brands

Intermatic

Intermatic PF1112T Installation, operation & service manual

GUARDIAN GEAR

GUARDIAN GEAR ZW8198 Assembly instructions

VTS Medical Systems

VTS Medical Systems VOLCANO VR Mini manual

3DGence

3DGence MMS1 instruction manual

CHERUBINI

CHERUBINI MAGO instructions

iKarus

iKarus Easyfly Quick installation guide